Cable coating silica gel heat setting production device

A production device and heat-setting technology, used in cable/conductor manufacturing, heat treatment equipment, and conductor/cable insulation, etc., can solve the problems of insufficient melting and mixing of constituent particles, damaged coating, and scrapped cables. Achieve the effect of speeding up heat setting, preventing sticking, and reducing cable damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

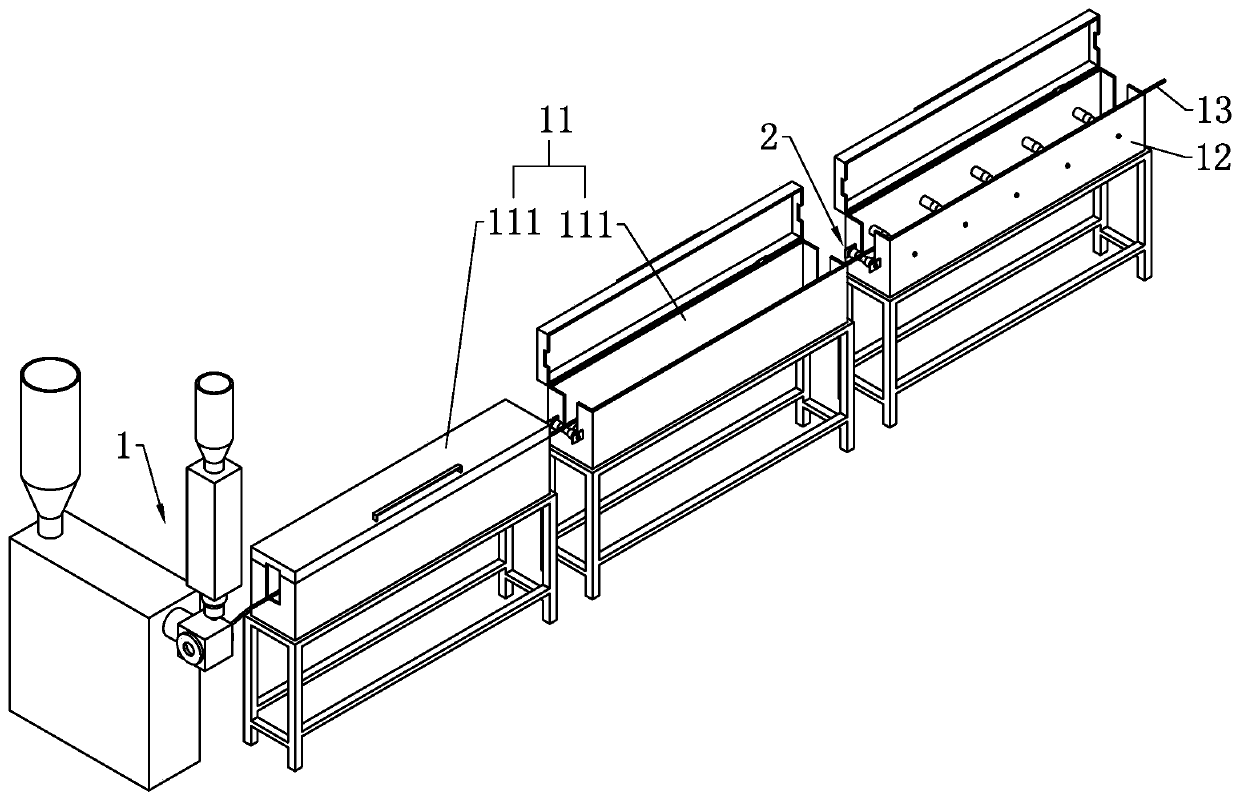

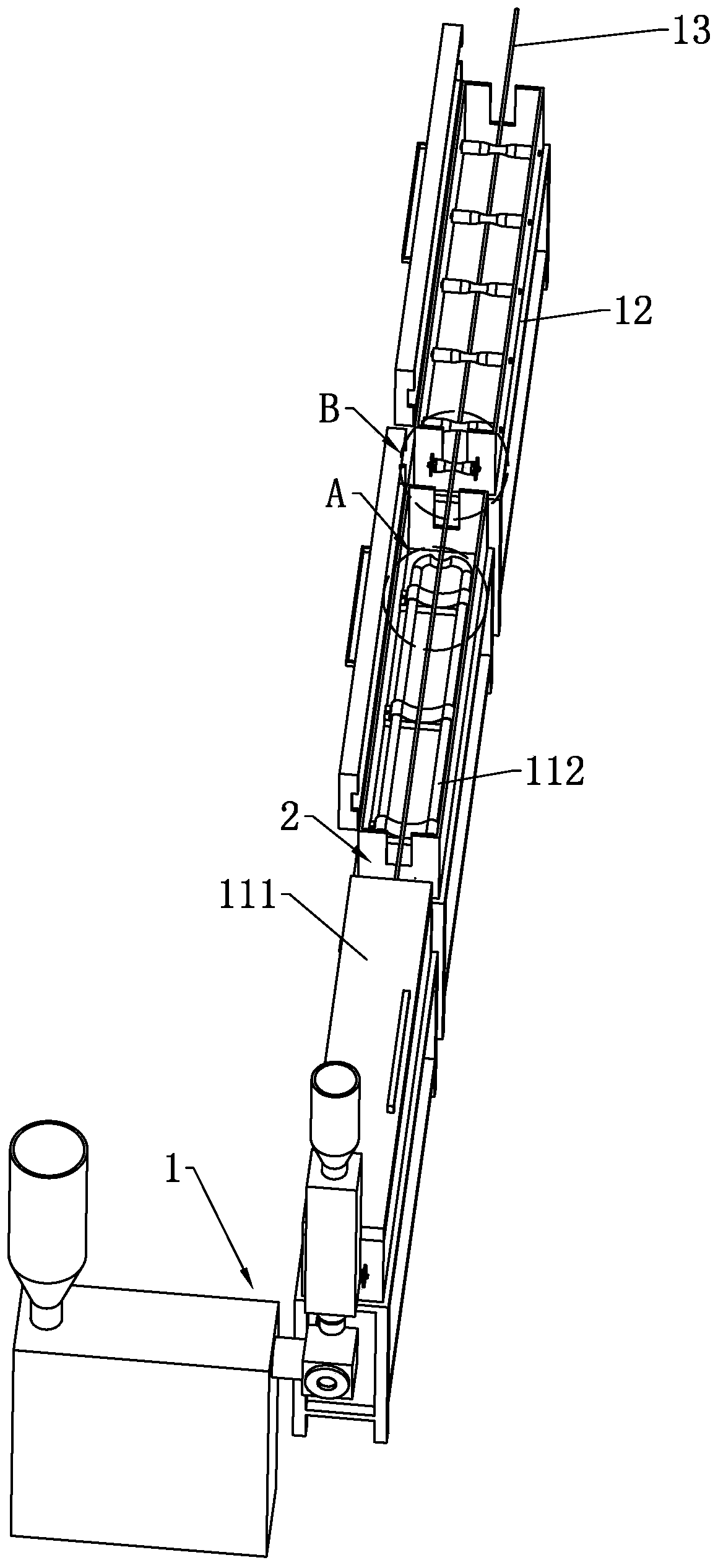

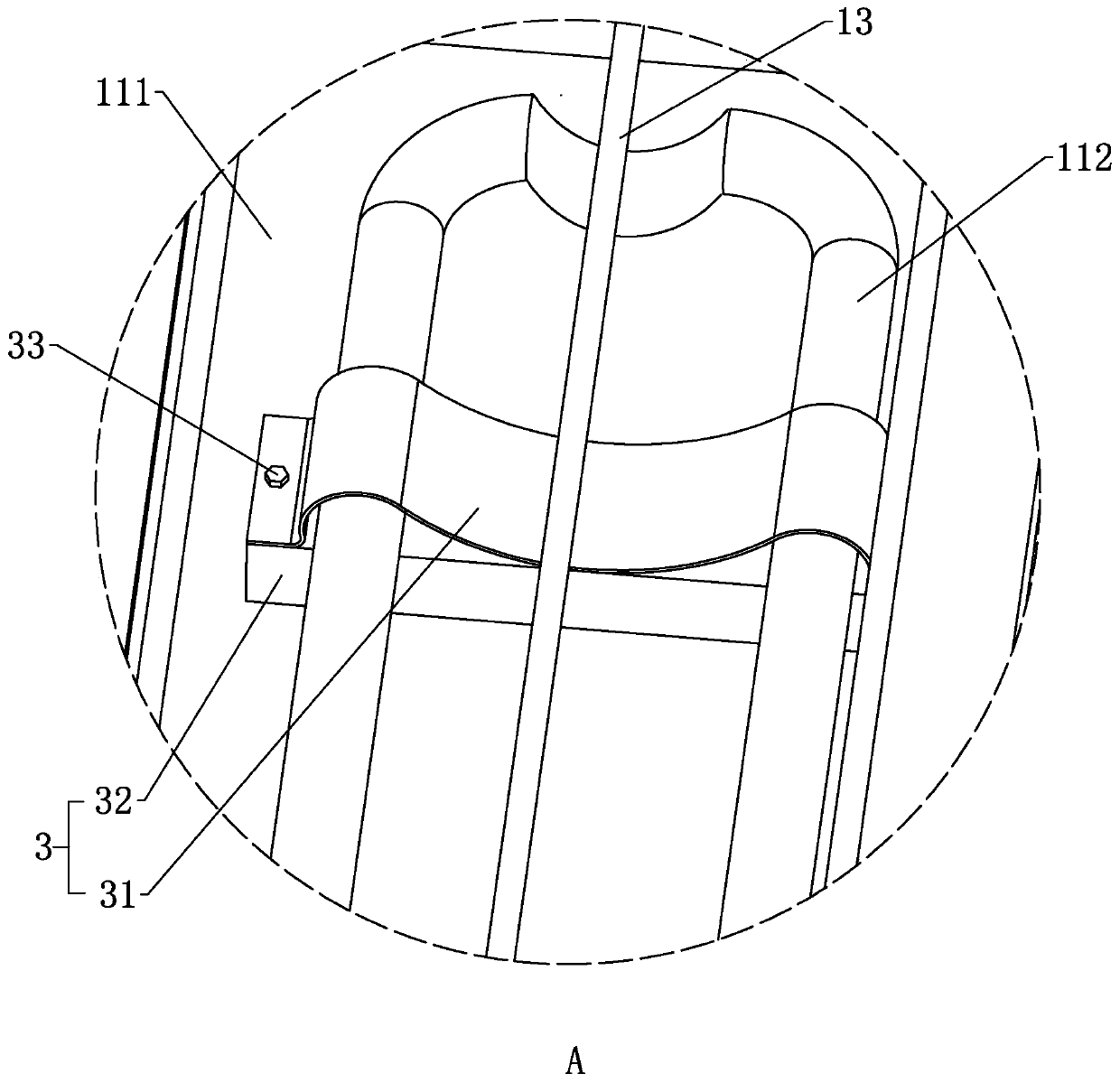

[0036] refer to figure 1 and figure 2 , a cable-coated silica gel heat-setting production device disclosed in the present invention includes an extruder 1, a forming tank 11 and a cooling tank 12 arranged in sequence. In order to reduce or prevent the adhesion between the covering layer of the cable 13 and the forming groove 11 , the forming groove 11 in this embodiment includes several split grooves 111 , and a heating element 112 is disposed in the split grooves 111 . The cable core is wrapped with a cladding layer in the extruder 1, and silicon rubber is used as the cladding layer in this embodiment. When the cable 13 just extruded from the extruder 1 passes through each split tank 111 in turn, it is heated and shaped by the heating element 112 in the split tank 111 , and finally enters the cooling tank 12 to be cooled by water.

[0037] In particular, the principle of heating and setting the divided groove 111 by the heating element 112 is: the silica gel coating layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com