Continuous thermal cracking device for smoking set material

A thermal cracking and smoking tool technology, applied in feeding device, material separation, pyrolysis reaction and other directions, can solve problems such as affecting health, unclear harmful substances in smoking tool materials, etc., to achieve continuous cycle testing, avoid mutual influence, use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment:

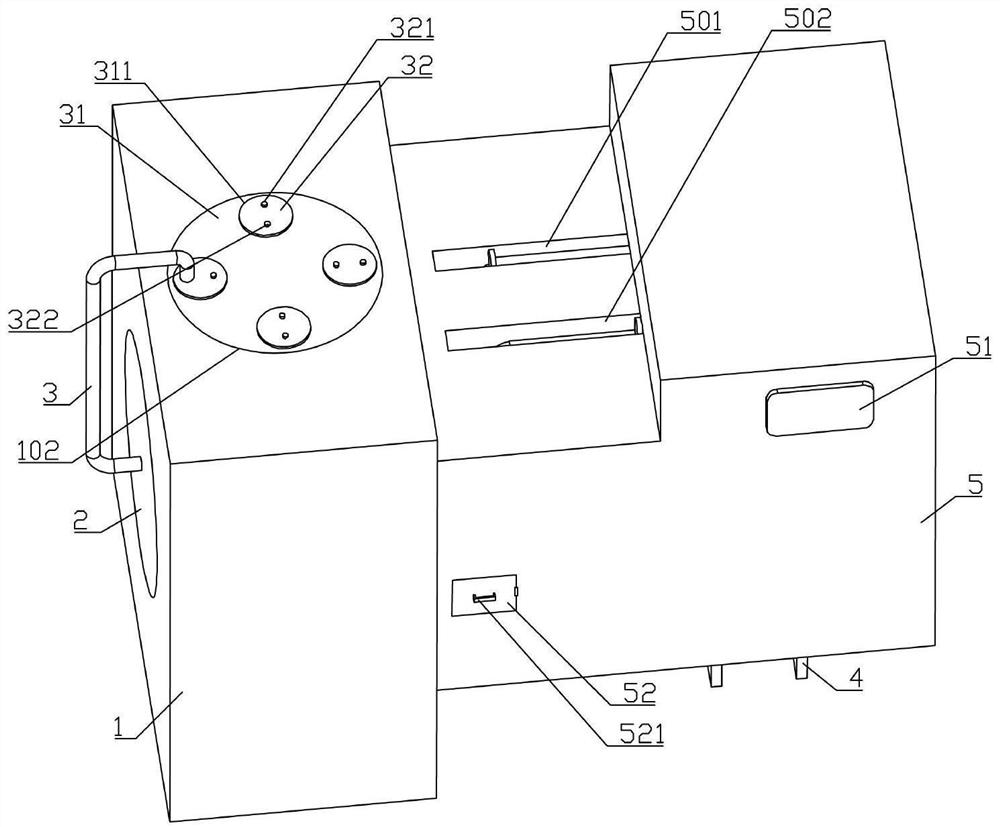

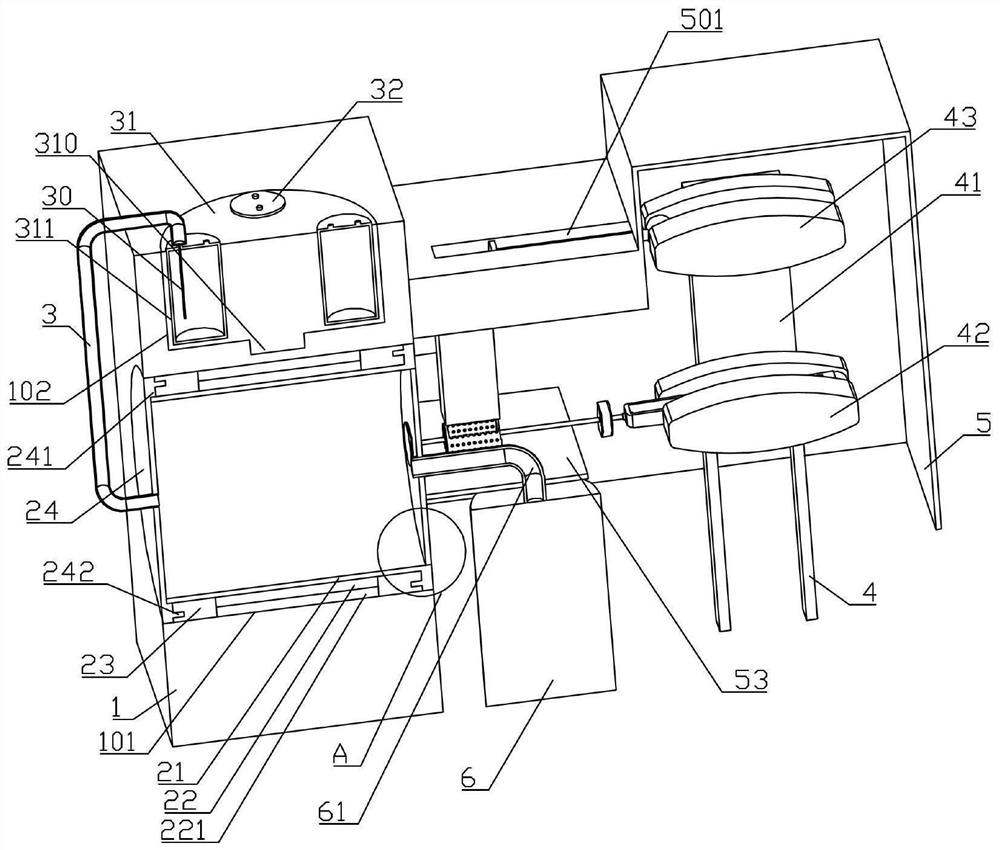

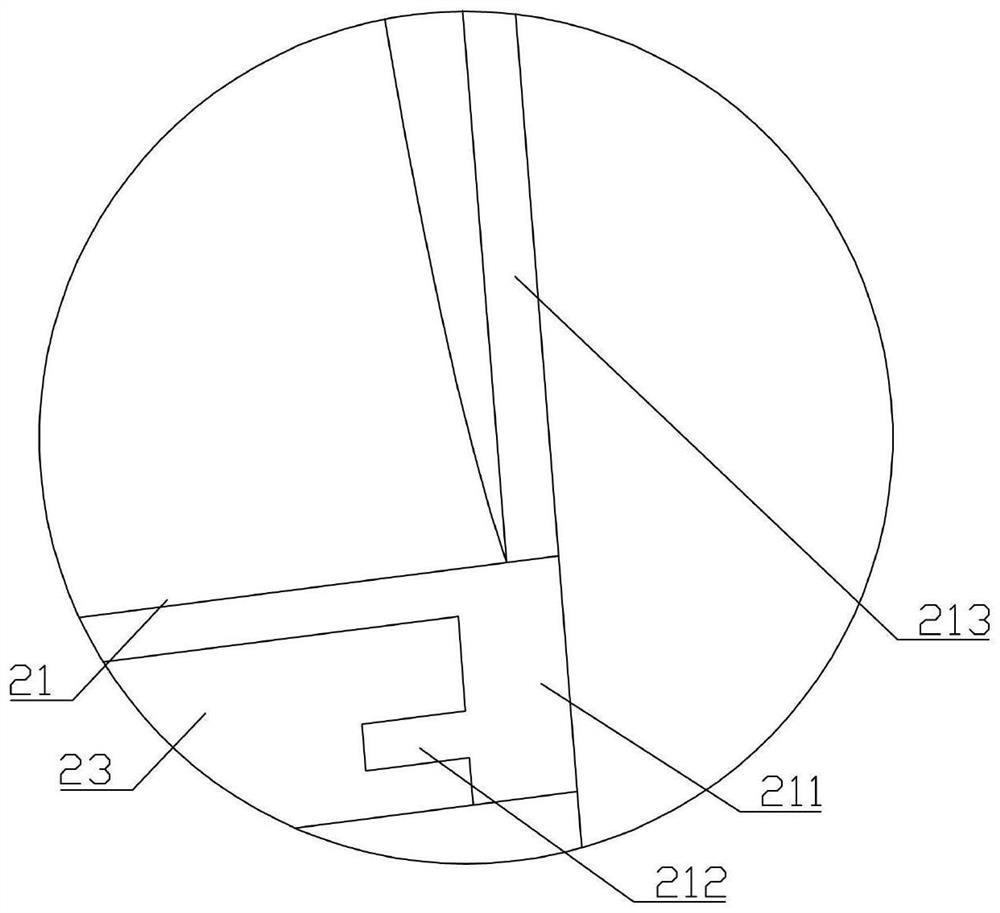

[0030] like Figure 1-7 As shown, a continuous pyrolysis device for smoking utensil materials according to the present invention includes a mounting base 1, and a heating assembly 2 is installed in the mounting base 1 to provide a heat source for pyrolyzing the polymer material of smoking utensils. A carrier gas bottle 6 is installed on one side of the mounting base 1, and the carrier gas bottle is electrically connected to the controller for controlling the amount and speed of the carrier gas output from the carrier gas bottle 6. The output end of the carrier gas cylinder 6 is connected with an output pipe 61, which communicates with the heating assembly 2 and is used to provide a carrier gas so that the gas generated by thermal cracking of the polymer material can move with the carrier gas. One end of the heating assembly 2 is connected with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com