Shaftless rotary coating device

A spin-coating, shaftless technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of limited effect and uneven dip coating of the workpiece, and achieve the effect of good surface quality and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

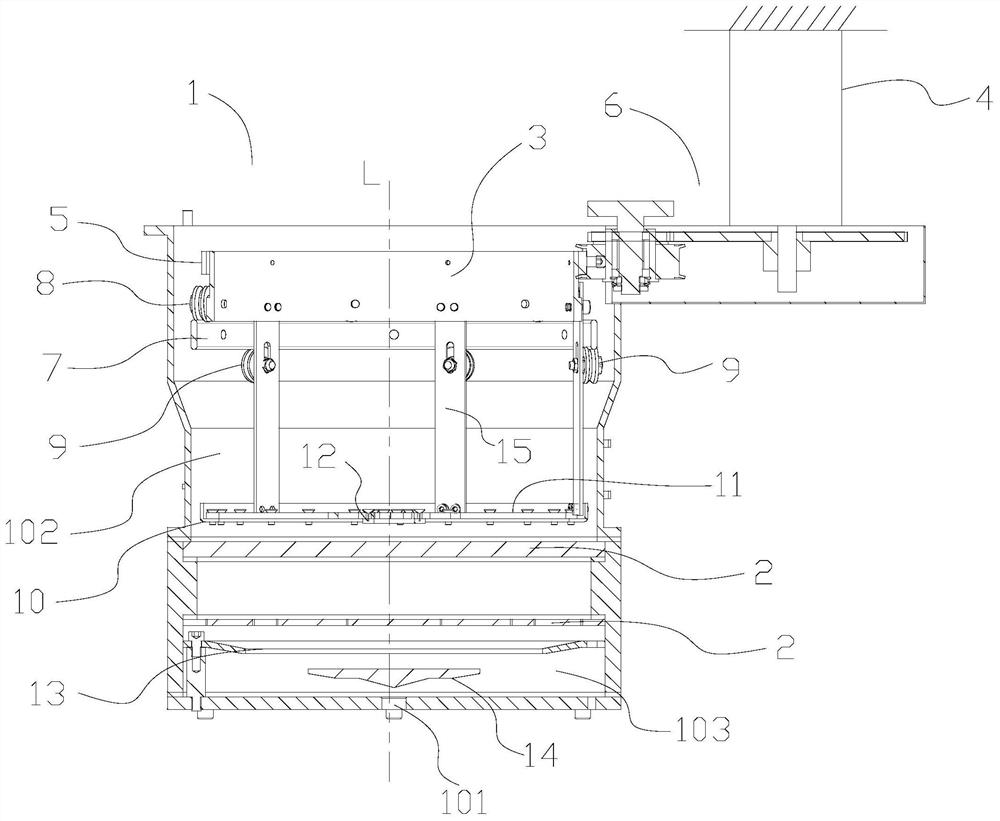

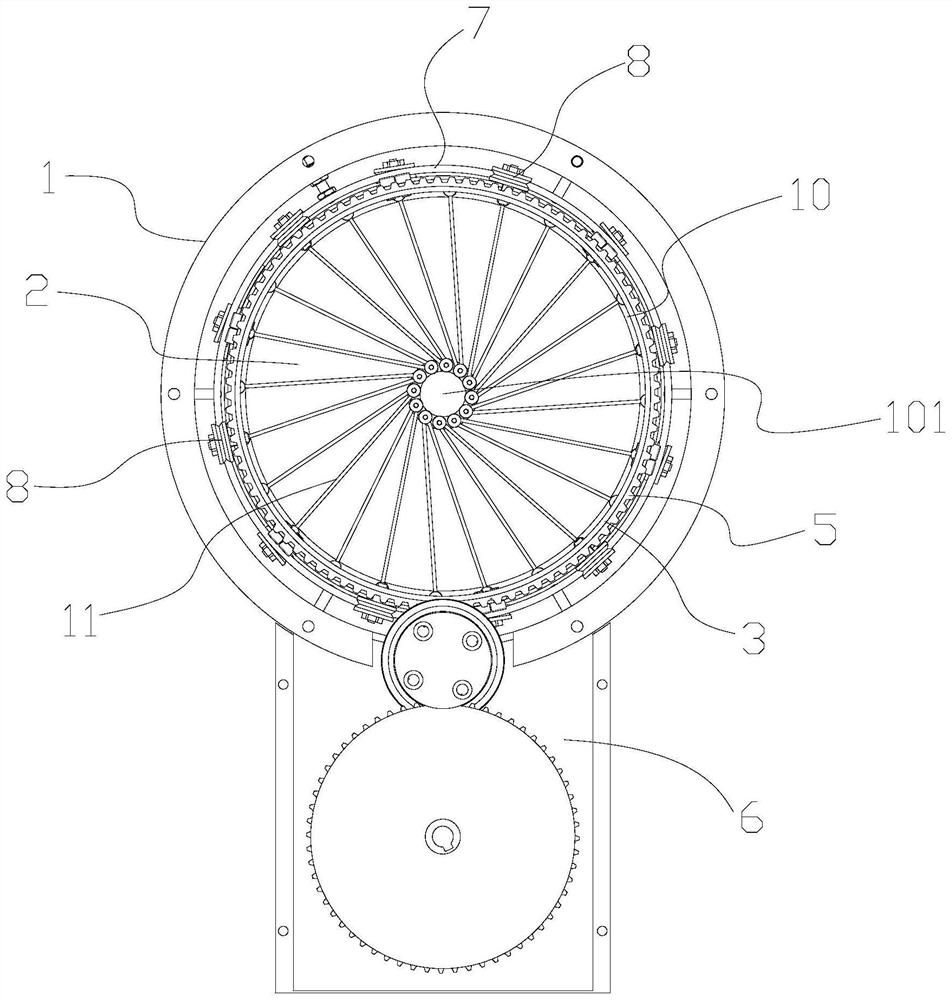

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] As shown in the accompanying drawings, the shaftless rotary coating device includes a coating bucket 1 with an open top, and the bottom wall of the coating bucket 1 is provided with an air inlet 101, and there is a horizontally arranged flow in the coating bucket 1. A fluidization plate 2, which divides the inner cavity of the coating bucket 1 into a coating chamber 102 and an air inlet chamber 103; the coating chamber 102 is located above the air inlet chamber 103; the coating chamber 102 A ring member 3 that can rotate around its own axis L is arranged inside; a stirring member is connected below the ring member 3; and a driving mechanism for driving the ring member 3 to rotate is also included.

[0024] The air inlet 101 at the bottom of the coating bucket 1 is connected to the air compressor through the air pipe, and the airflow generated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com