Self-energized active suspension single-head oil cylinder equal-damping equal-inerter oil way and working method thereof

An active suspension, self-powered technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of redundancy, improvement of car ride comfort and driving safety, instability, large changes in inertia, etc. To achieve the effect of simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

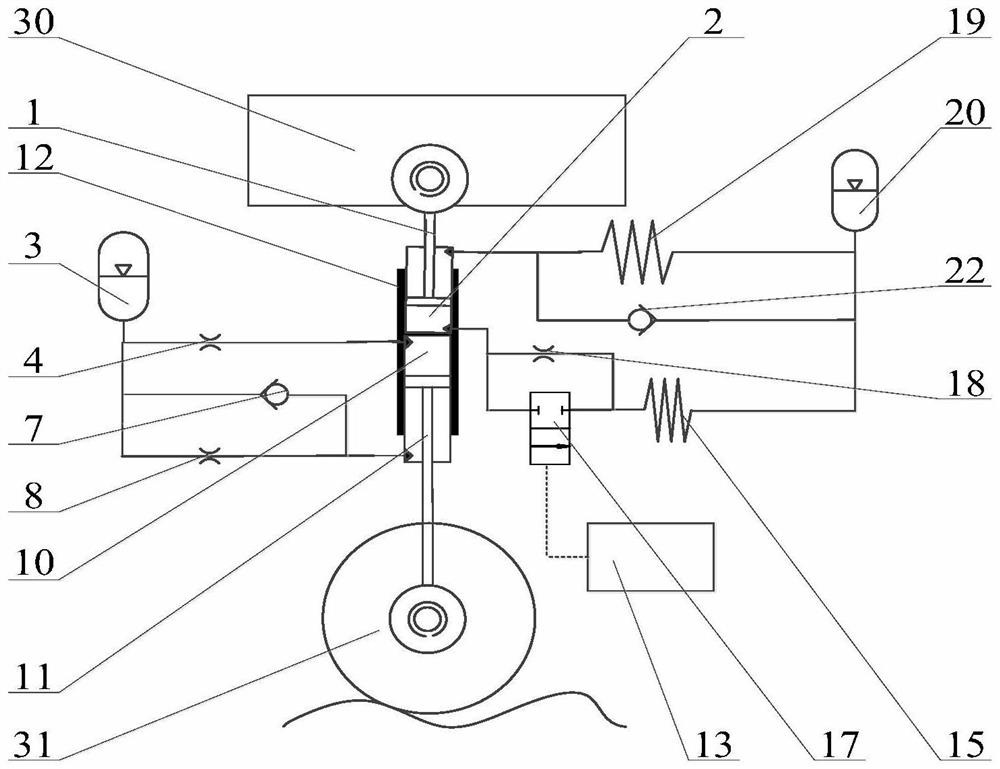

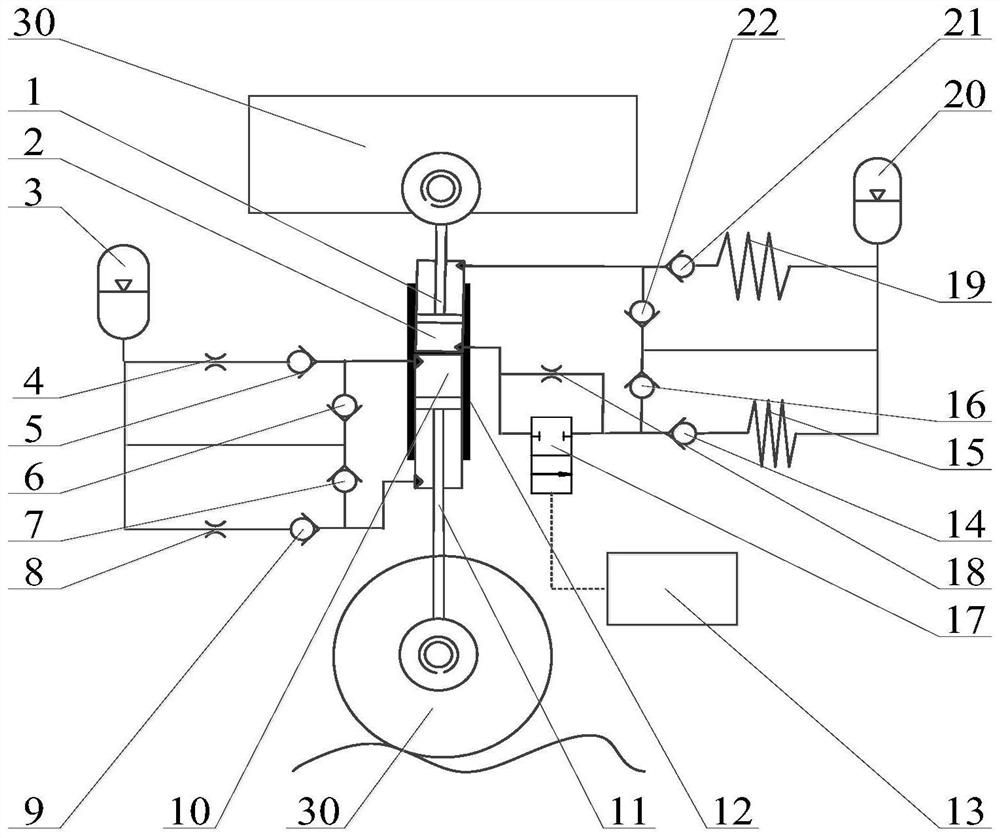

[0022] Such as figure 1 and figure 2 As shown, the self-powered active suspension includes a traditional damping structure and an anti-resonance damping structure connected in series from bottom to top, the traditional damping structure has a first oil cylinder 10 and a traditional damping oil circuit, and the anti-resonance damping structure has a second oil cylinder 2 and the anti-resonance damping oil circuit, the first oil cylinder 10 is below the second oil cylinder 2 and the bottoms of the two cylinders are fixed as one, and the first oil cylinder 10 and the second oil cylinder 2 are fixedly connected to the third mass 12 of the suspension. Both the first oil cylinder 10 and the second oil cylinder 2 are single-head oil cylinders. The first piston rod 11 divides the interior of the first oil cylinder 10 into an upper chamber and a lower chamber. The upper chamber of the first oil cylinder 10 is a rodless chamber, and the lower chamber The chamber is a piston rod chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com