Packaging method for high polymer material production and processing

A technology of polymer material and packaging method, which is applied in the field of packaging for polymer material production and processing, can solve the problems of low efficiency, cumbersome loading process, low degree of automation, etc., and achieves the effect of high efficiency and guaranteed clamping degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

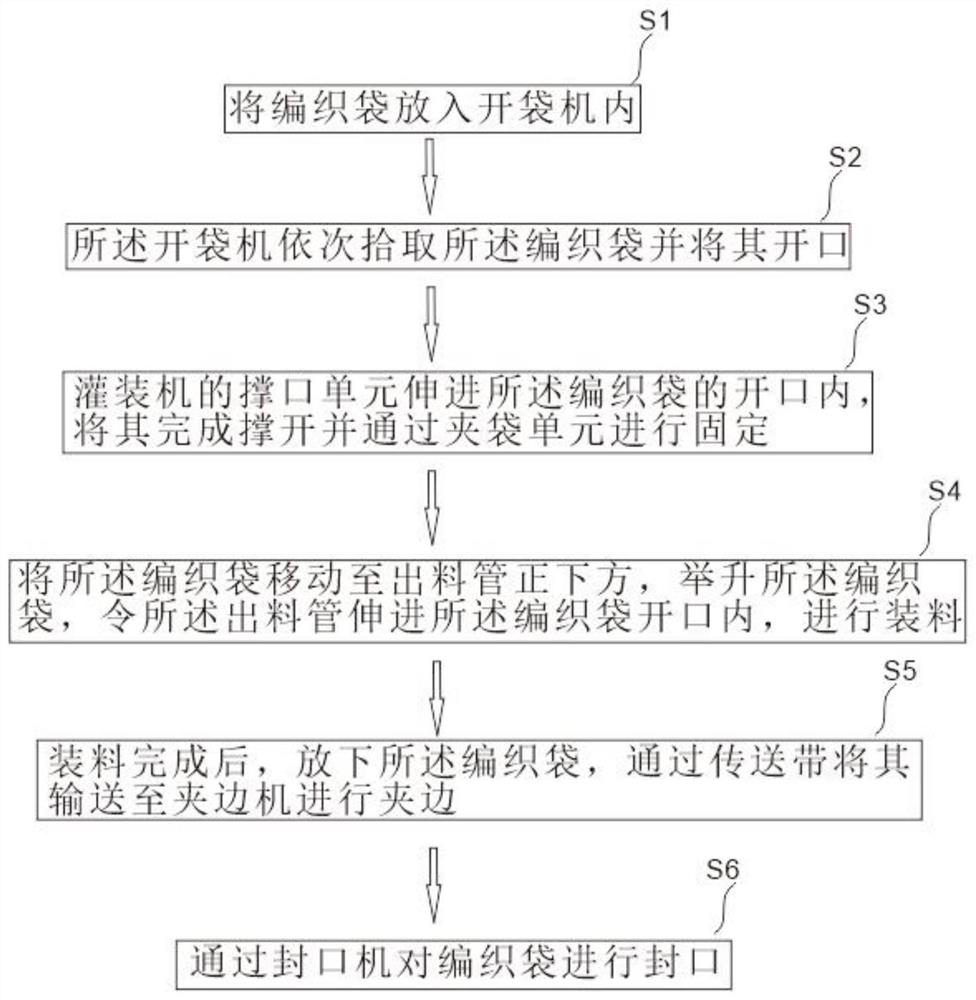

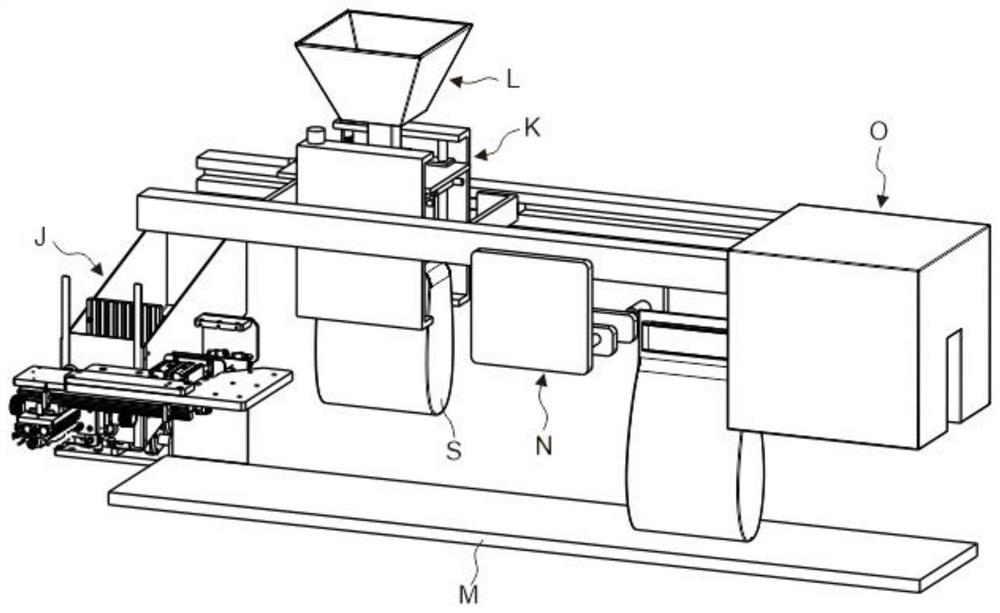

[0039] refer to Figure 1 to Figure 10 , which is the first embodiment of the present invention, this embodiment provides a packaging method for the production and processing of polymer materials, the packaging method for production and processing of polymer materials includes the following steps:

[0040] S1: Put the woven bag S into the bag opening machine J.

[0041] S2: The bag opening machine J sequentially picks up the woven bags S and opens them.

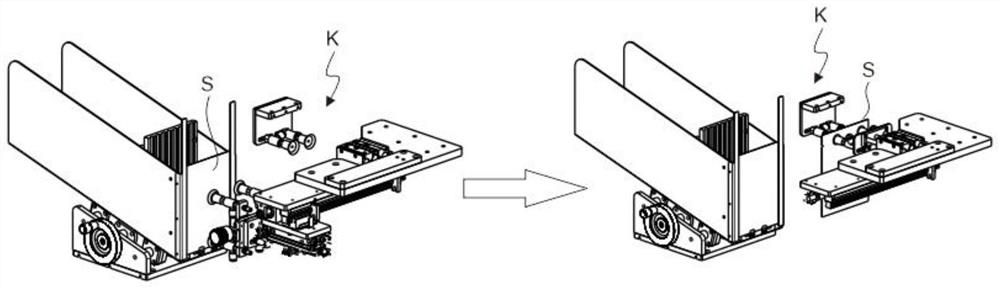

[0042] S3: The stretching unit 100 of the filling machine K extends into the opening of the woven bag S, stretches it completely and fixes it by the bag clamping unit 200 .

[0043] S4: Move the woven bag S directly under the discharge pipe L, lift the woven bag S, make the discharge pipe L extend into the opening of the woven bag S, and carry out loading.

[0044] S5: After the loading is completed, put down the woven bag S, and transport it to the edge clamping machine N through the conveyor belt M for edge clamping.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com