High-safety double-beam bridge crane

A high-safety, crane-based technology, applied to cranes, trolley cranes, mechanical equipment, etc., can solve the problem of increasing the frictional resistance between the crane and the double-girder bridge arm, the sliding resistance of the crane and the double-girder bridge arm, and the internal problems of the crane Problems such as damage to the driving mechanism, to achieve the effect of guaranteeing life, convenient and centralized collection and cleaning, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

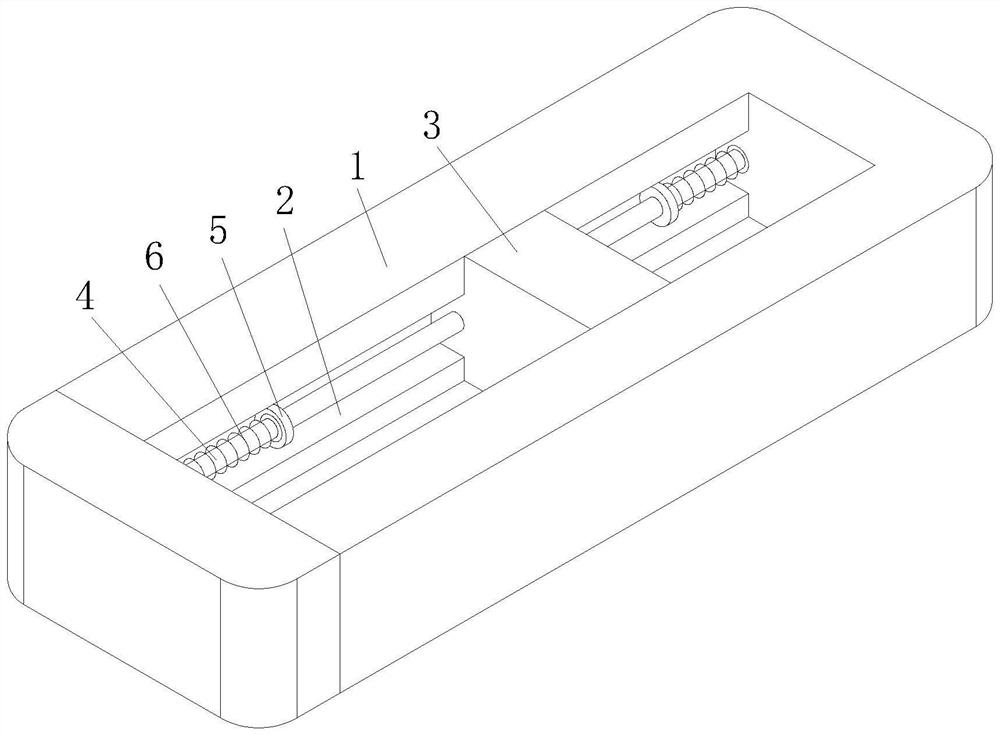

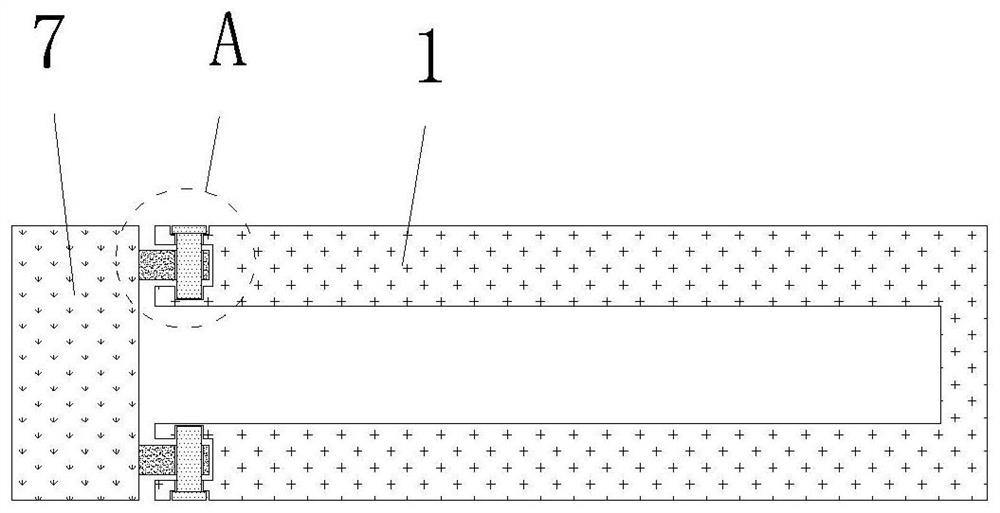

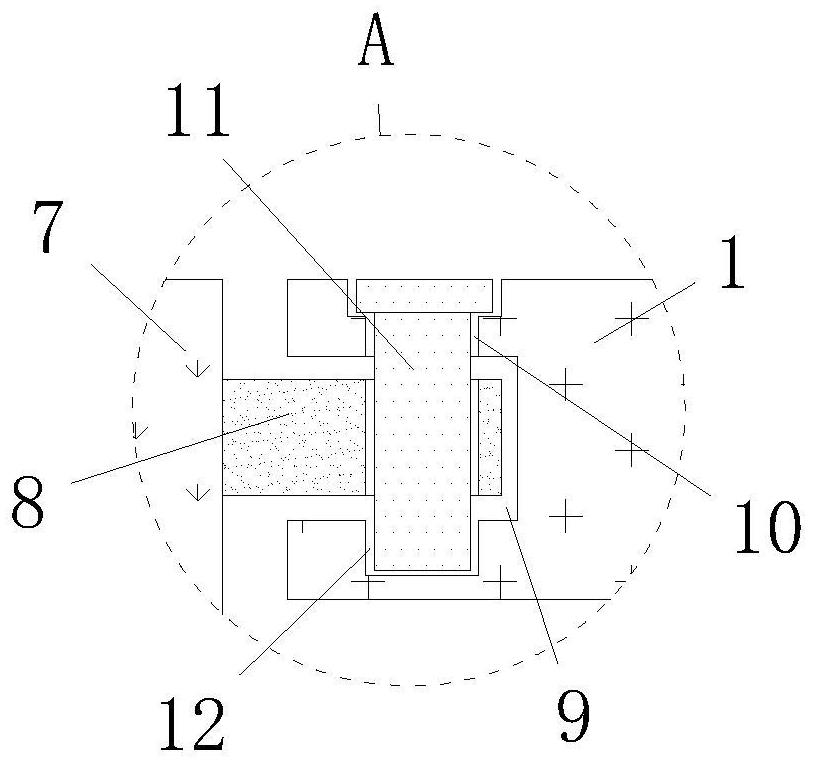

[0032] see Figure 1-6 , the present invention provides a technical solution: a high-safety double-girder bridge crane, including a double-girder lifting bracket 1, a fixed plate 7 is arranged on the left side of the double-girder lifting bracket 1, and the double-girder lifting bracket 1 There is a chute 2 on the inner side, and the inner wall of the chute 2 on the double-girder lifting bracket 1 is slidably connected to a crane 3, and the inside of the crane 3 is slidably connected to a sliding rod 4, and the right end of the sliding rod 4 is fixedly connected to the double-girder lifting bracket 1 The inner wall of the slide bar 4 is slidably connected with a slip ring 5, and the surface of the slide bar 4 is slidably sleeved with a first elastic component 6, and the left and right ends of the first elastic component 6 are respectively fixedly connected to the right side and the right side of the fixed plate 7. On the left side of the slip ring 5, under the control of the e...

Embodiment 2

[0035] see Figure 1-6 , On the basis of Embodiment 1, the lower side of the crane 3 is provided with a buffer tank 13, and the inner wall of the buffer tank 13 is provided with a protective device. The surface of the buffer rod 14 is slidingly sleeved with a second elastic component 15, the upper and lower ends of the second elastic component 15 are respectively fixedly connected to the upper end of the buffer rod 14 and the inner wall of the buffer groove 13, and the lower side of the buffer rod 14 is fixedly connected to Two auxiliary plates 16, the opposite sides of the two auxiliary plates 16 are rotatably connected with pulleys 17, the inside of the double girder lifting bracket 1 is provided with a limit groove 18 communicating with the chute 2, through the double girder lifting bracket 1 When sliding between the crane 3, a pulley 17 is set on the lower side of the crane 3 to slide through the limit groove 18 on the double beam lifting bracket 1, and the two auxiliary p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com