Sound insulation and heat preservation material, sound insulation and heat preservation structure, preparation method and application

A thermal insulation material and sound insulation technology, applied in thermal insulation, structural elements, sound insulation, etc., can solve the problems of cracking of protective layer, affecting the comfort of living space, developers affecting floor height and economic benefits, etc., to meet the requirements of strength and sound insulation. Thermal insulation, good sound insulation and thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example 1

[0055]The room to be constructed is selected, and the ground vacuum dust and wall protective stickers are selected, and then the foam polyurethane spraying work, the thickness of the bubbles is 8 mm, and the strength of the polyurethane foam is 0.15 MPa, and the closed hole is 89%. 4 hours, adjacent to the top of the foamed polyurethane in the wall of 15 mm, the thickness of 3 mm is adjacent to the wall, and then the high strength fiber concrete is pouring, and the thickness of the pour is 15 mm, wherein the maximum bone particle diameter of high strength fiber concrete is 2.36 mm. 28 days anti-fold intensity 6.3MP. After 7 days, the sound insulation test was performed. When the truncation is not considered, the sound point is 86.5 dB, and the receiving point is 74.9 dB. Calculated, the heat transfer coefficient of the floor system is 1.8W / (m 2 K).

Example Embodiment

[0056] Example 2

[0057] The room to be applied is selected, and the ground vacuum dust and wall protective stickers are selected, and then foaming polyurethane spraying work, the thickness of the bubbles is 10 mm, and the strength of the polyurethane foam has a hardening strength of 0.15 MPa, and the closed hole is 89%. 4 hours, adjacent to the top of the foamed polyurethane in the wall of 15 mm, the thickness of 3 mm is adjacent to the wall, and then the high strength fiber concrete is pouring, and the thickness of the pour is 15 mm, wherein the maximum bone particle diameter of high strength fiber concrete is 2.36 mm. 28 days anti-fold intensity 6.3MP. After 7 days, the sound insulation test was performed. When the truncation value was not considered, the sound point is 85.3dB, and the receiving point is 73.7 dB. After calculation, the heat transfer coefficient of the floor system is 1.5W / (m 2 K).

Example Embodiment

[0060] Example 3

[0061] An insulating material comprising: an insulated insulation layer and a concrete protective layer; the insulating interpolation layer is made of a foamed polyurethane, wherein the polyurethane foam is 0.16 MPa, the closed hole is 86%; concrete protection The layer is a high-strength fiber concrete layer; the strength of the high-strength fiber concrete is greater than 6 MPa; the particle size of the bone particles in the high-strength fiber concrete is less than 2.36 mm, the holding insulation layer and the concrete protective layer have a total thickness of 16 mm.

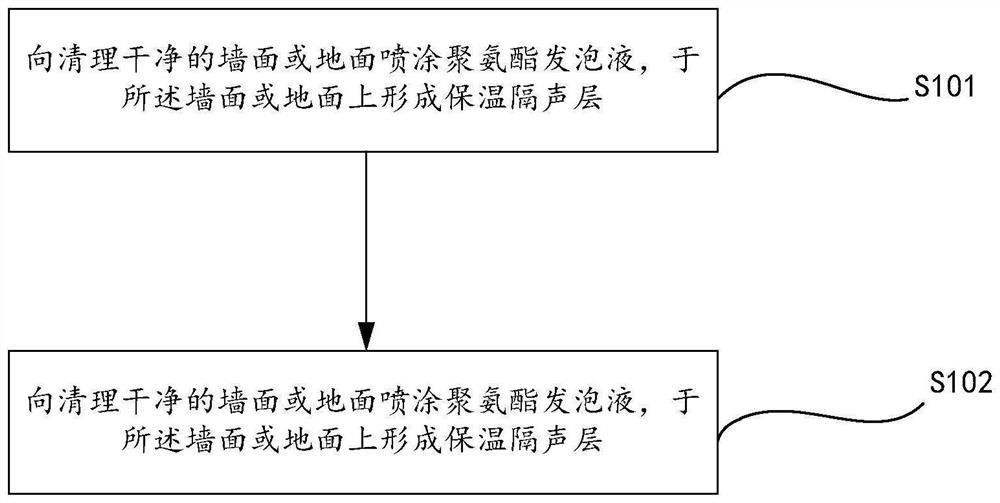

[0062] Preparation method, including: a cleaning of a clean wall or ground is sprayed with a polyurethane foaming solution, and a thermally-inline layer is formed on the wall or ground; pouring high-strength fiber concrete to the formed insulation interpolation layer to form high-strength fiber concrete. Floor. The strength of the polyurethane foam is 0.16 MPa, and the closed cell is greater t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com