Integral toilet and bathroom frame foam ceramic tile wallboard and making method thereof

A manufacturing method and frame technology, applied in the field of sanitary ware, can solve problems such as tiles are easy to fall off, quality is difficult to guarantee, and labor costs are high, and achieve the effects of saving construction labor costs, simple and convenient construction, and good sound insulation and heat preservation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is specifically described below in conjunction with specific embodiment and accompanying drawing:

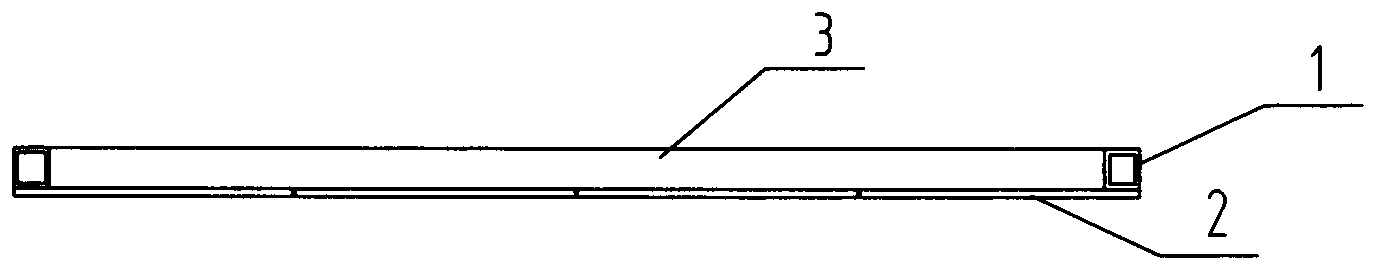

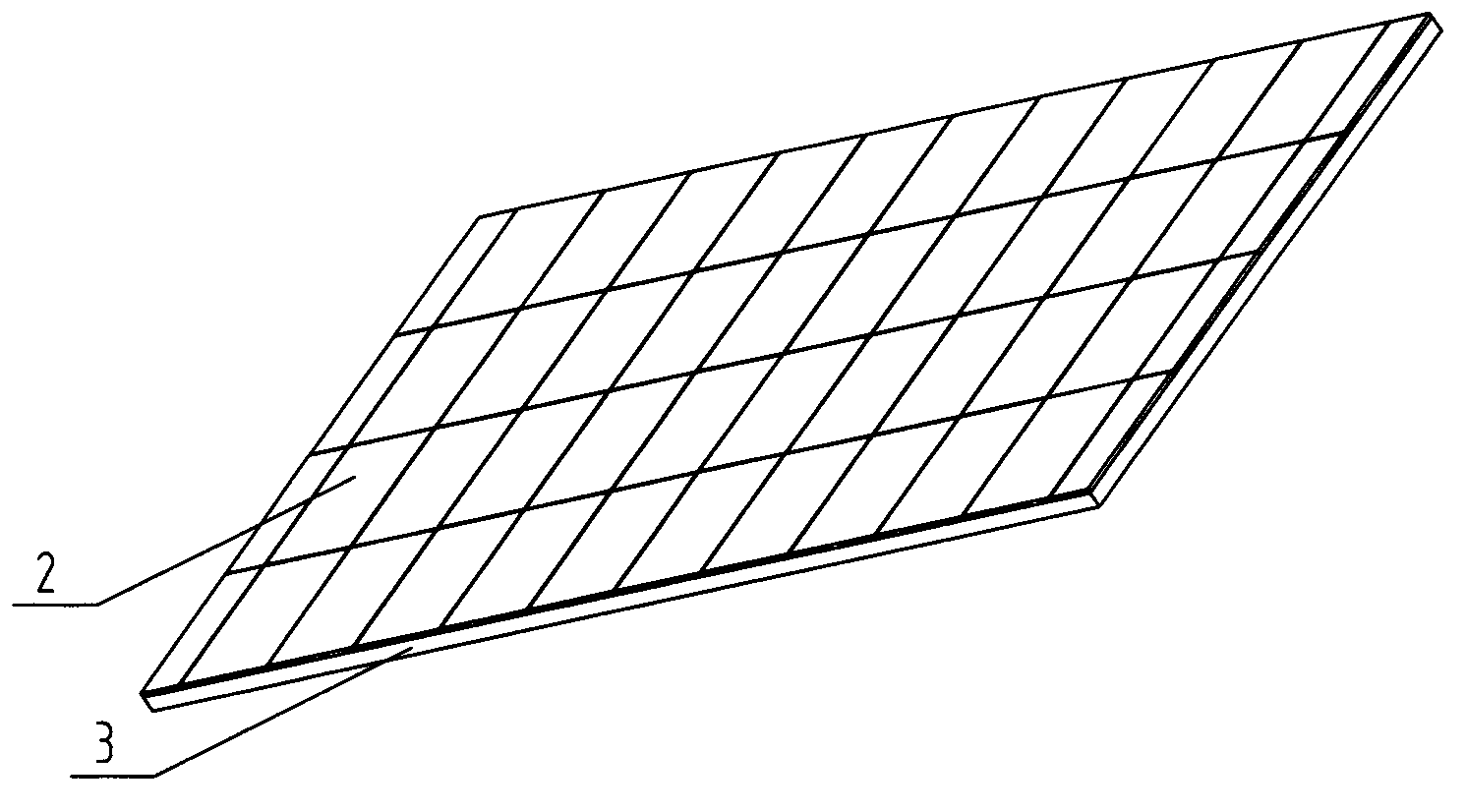

[0020] Such as figure 1 , image 3 As shown, an integral bathroom frame foam tile wall panel is composed of a reinforcement frame 1, a foam material 3, and a tile 2, the foam material is polyurethane foam material, the reinforcement frame 1 is on the back of the tile 2, and the reinforcement frame 1 is metal or plastic.

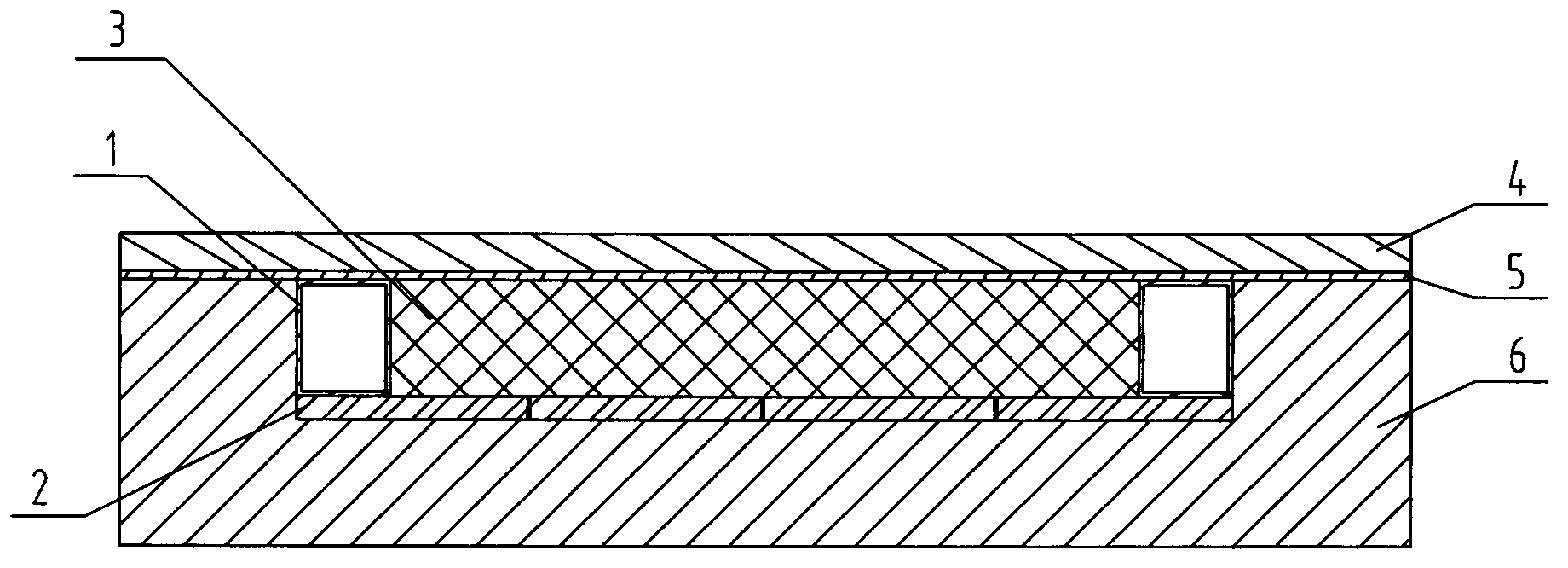

[0021] Such as figure 2 , image 3 Shown, a kind of integral bathroom frame foaming ceramic tile wall panel manufacturing method comprises the following steps:

[0022] 1. Place the tile 2 facing down on the bottom plane of the groove of the lower formwork 6 as required;

[0023] Two, put reinforcement frame 1 on the back plane that ceramic tile 2 is paved;

[0024] 3. Use an upper cover plate 4 to press and seal on the lower template 6 and the reinforcement frame 1;

[0025] 4. Heating the lower formwork 6 to raise the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com