Manufacturing method for moss wall afforesting device

A technology of greening equipment and manufacturing method, which is applied in the fields of botanical equipment and methods, climate change adaptation, container cultivation, etc., can solve problems such as single species, and achieve the effects of simple production, long growth cycle and fluffy interior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

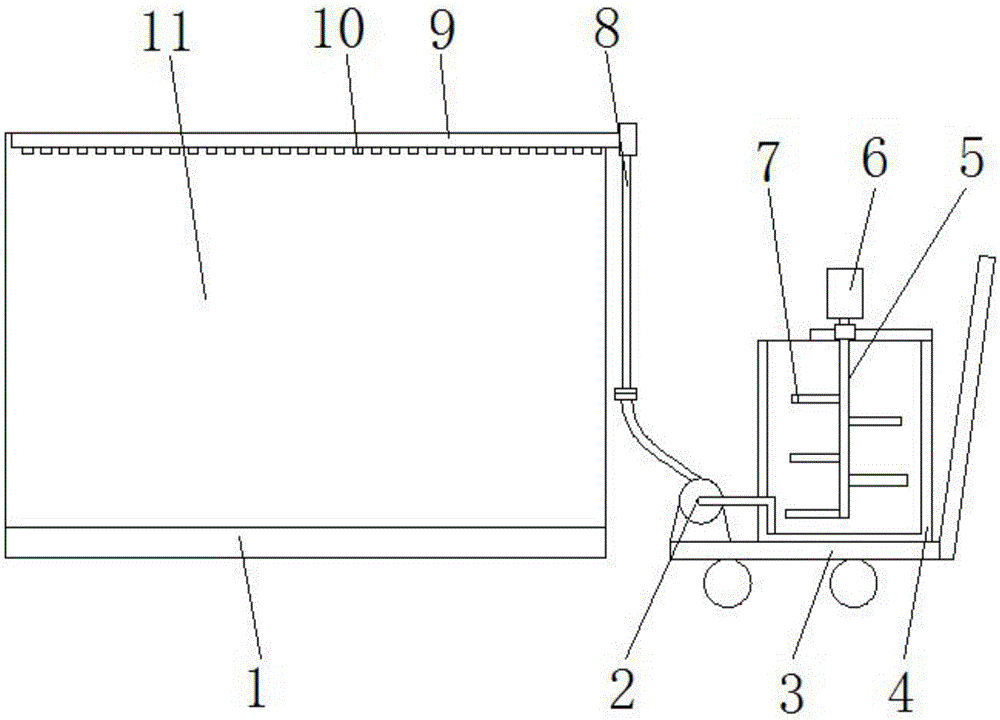

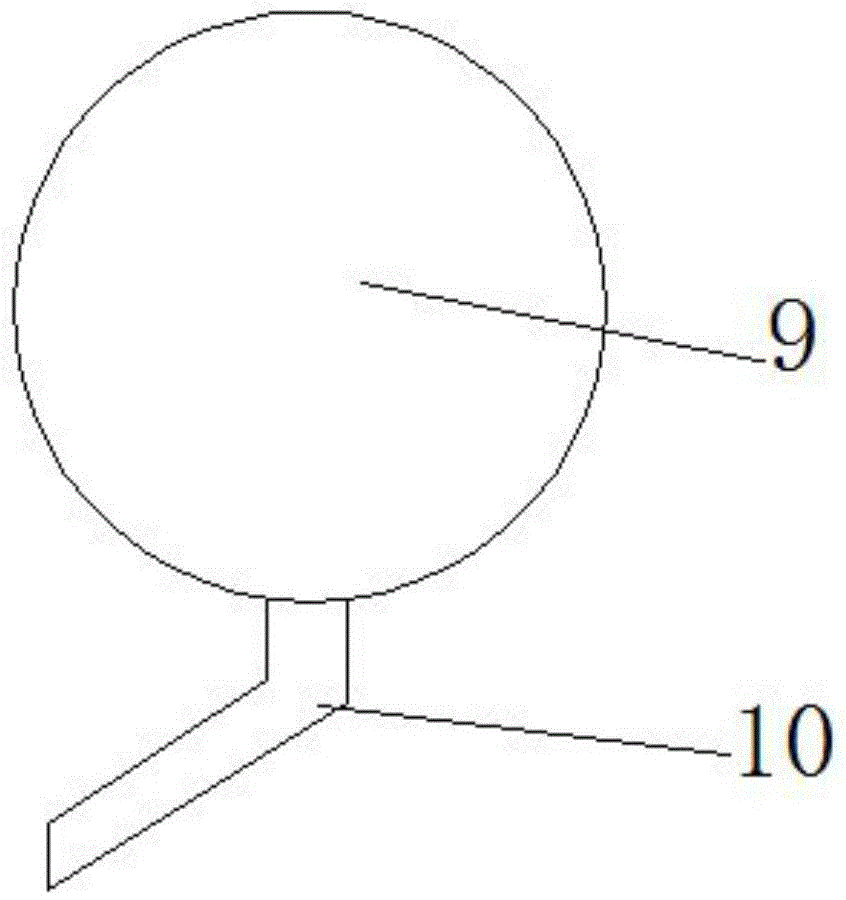

[0023] Example 1: See Figure 1-2 , a moss wall greening equipment, including a side tank 1, a low-pressure water pump 2, a cart 3, a tank body 4, a stirring shaft 5, a motor 6, a stirring paddle 7, an input interface 8, a main pipeline 9 and a branch pipe 10, the main The pipeline 9 is fixedly connected to the top of the wall 11, and the bottom of the main pipeline 9 is densely connected with several branch pipes 10. The nutrient solution that flows down on the surface, wall surface 11 can lay barbed wire;

[0024] One end of the main pipeline 9 is sealed, and the other end is provided with an input interface 8. The input interface 8 is connected to the output end of the low-pressure water pump 2 through a pipeline. Body 4, wherein the input end of low-pressure water pump 2 is connected to tank body 4 through a pipeline, and a culture solution containing moss seeds is arranged in the tank body;

[0025] The tank body 4 is provided with a stirring shaft 5, one end of the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com