Metal corrugated hose end connecting structure capable of avoiding torsion and metal corrugated hose

A technology for metal corrugated pipes and corrugated hoses, which is used in hose connection devices, pipes/pipe joints/pipes, mechanical equipment, etc., can solve problems such as low installation efficiency, inability to manufacture, and rupture and leakage of metal corrugated hoses. Achieve the effect of avoiding breakage and increasing the number of weld passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

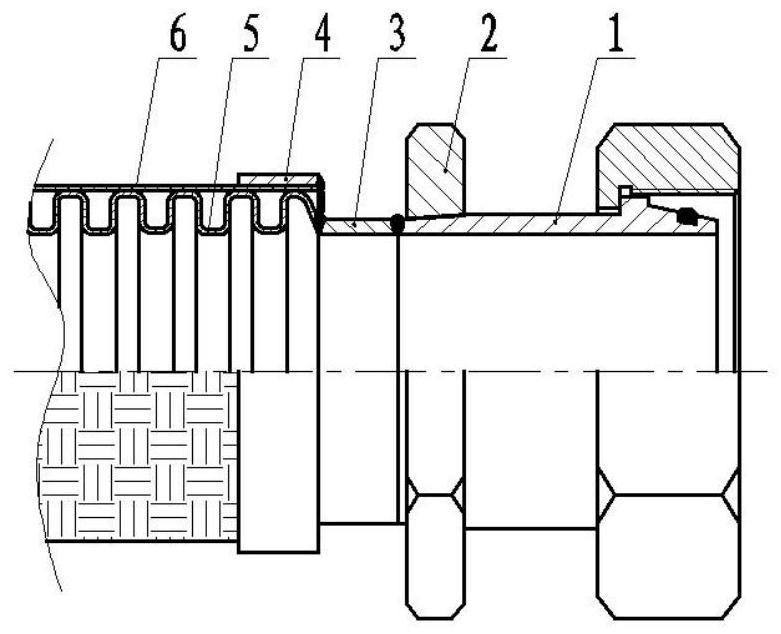

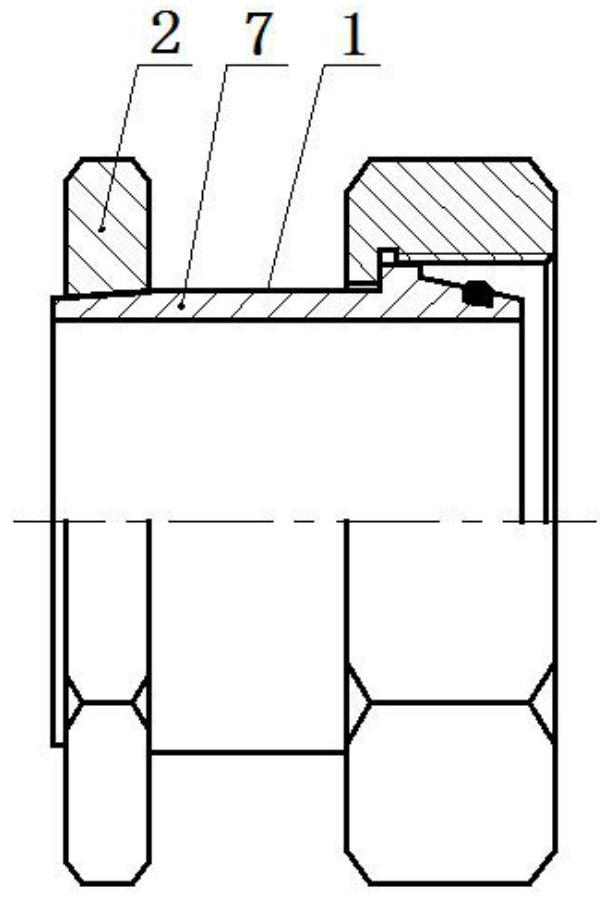

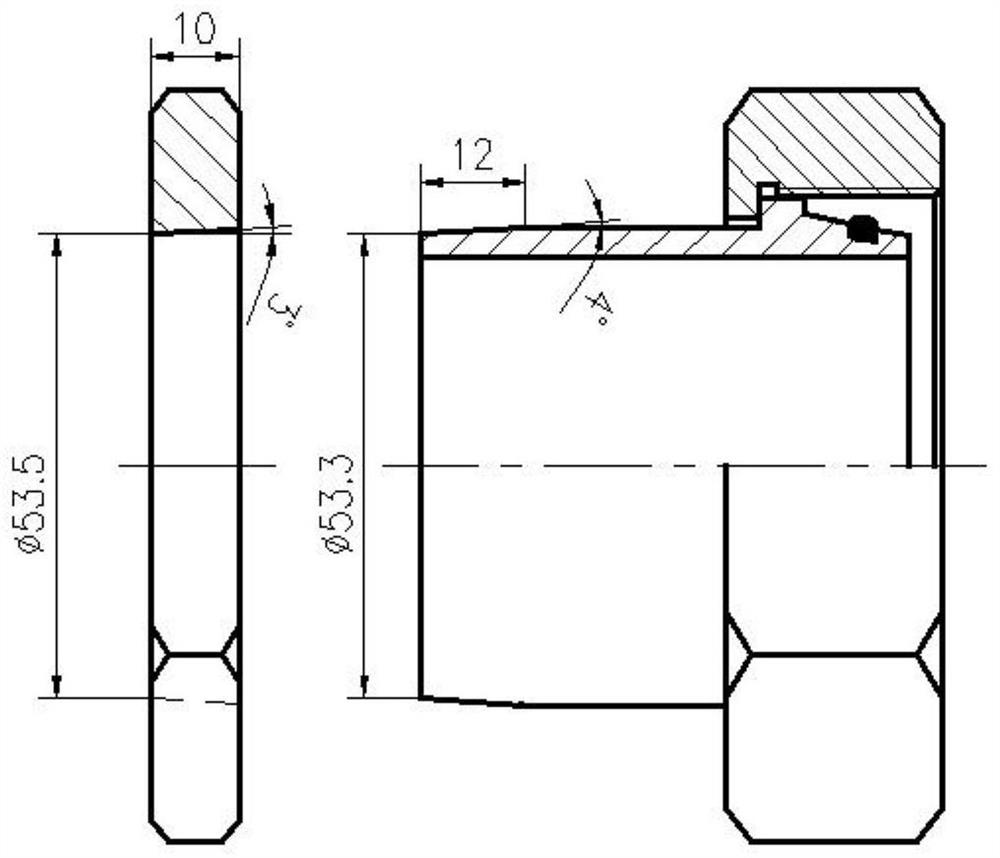

[0026] Embodiment 1: as image 3 As shown, the joint chamfering length is 12mm, the joint chamfering angle is 4 degrees, the diameter after chamfering is about 53.3mm, the inner circle chamfering hex nut 2 has a thickness of 10mm, and the diameter of the nut chamfering is increased by 0.2mm, that is 53.5mm, nut chamfer 3 degrees, can achieve interference fit through tooling. After the mating is completed, the end of the thin-walled end 7 of the joint will exceed the end face of the inner chamfered hexagonal nut 2, and the excess part and the ring 3 can be welded on one side and double-sided forming, and will not be welded to the inner rounded hexagonal nut 2 during welding. The seam also acts as an anchor point for the hex nut.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap