Nondestructive testing method for bubbles in liquid floated gyroscope

A liquid floating gyro and non-destructive testing technology, applied in the field of liquid floating gyroscopes, can solve problems such as complex operation methods, inability to completely eliminate hidden bubble products, and difficult data analysis, etc., to achieve high sensitivity detection, gyro accuracy and long-term stability guarantee , easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

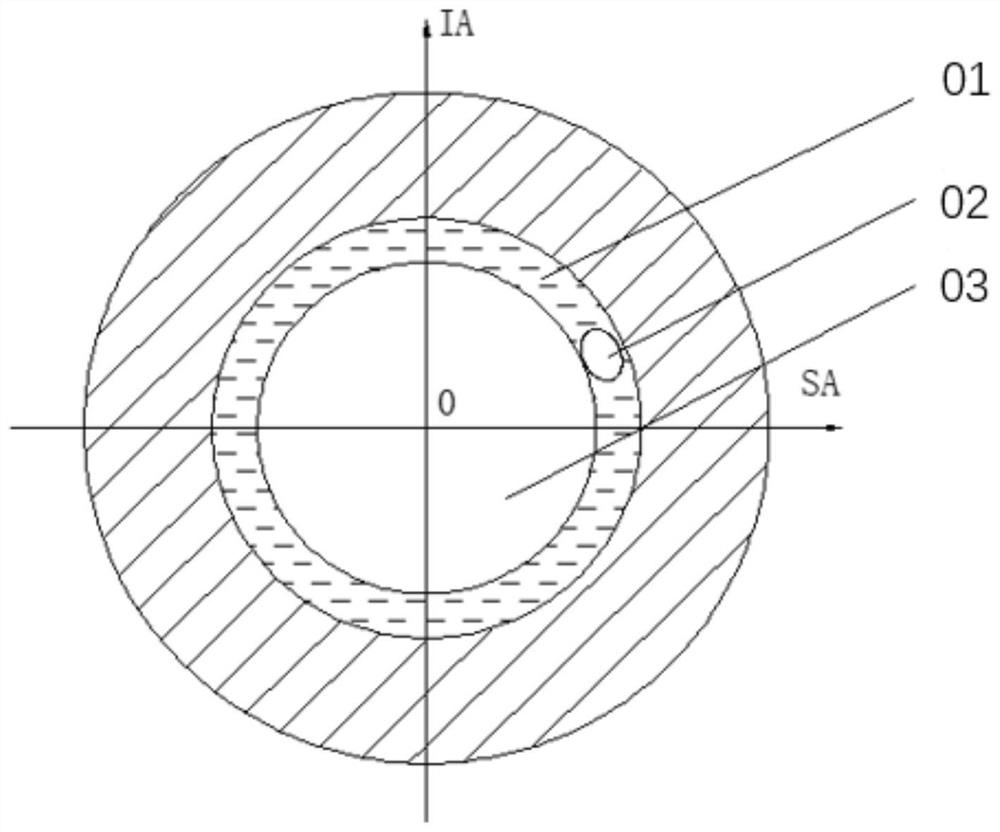

[0020] The present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments.

[0021] A non-destructive detection method for bubbles inside a liquid floating gyroscope, comprising the following steps:

[0022] Step (1): Seal the secondary floating gyroscope to be tested that has been filled with floating liquid, and check that it does not leak oil;

[0023] Step (2): Put the gyro base into the bottom surface of the vacuum tank, place the second floating gyroscope to be tested on the gyroscope base, and expose the bellows assembly of the liquid floating gyroscope to be tested; put the height micrometer into the vacuum tank Inside, and ensure that the probe of the height micrometer is in contact with the bellows cover of the liquid floating gyroscope to be tested, and detect the standard height of the volume compensation components under a standard atmospheric pressure; after the height micrometer is cleared, seal the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com