Drying equipment for aquatic product processing

A technology for drying equipment and aquatic products, applied in food drying, dry preservation of meat/fish, food science, etc. It can solve the problems of inconvenient recycling of aquatic products and the inability to remove the drying rack at one time, so as to achieve convenient leveling, reduce impact, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

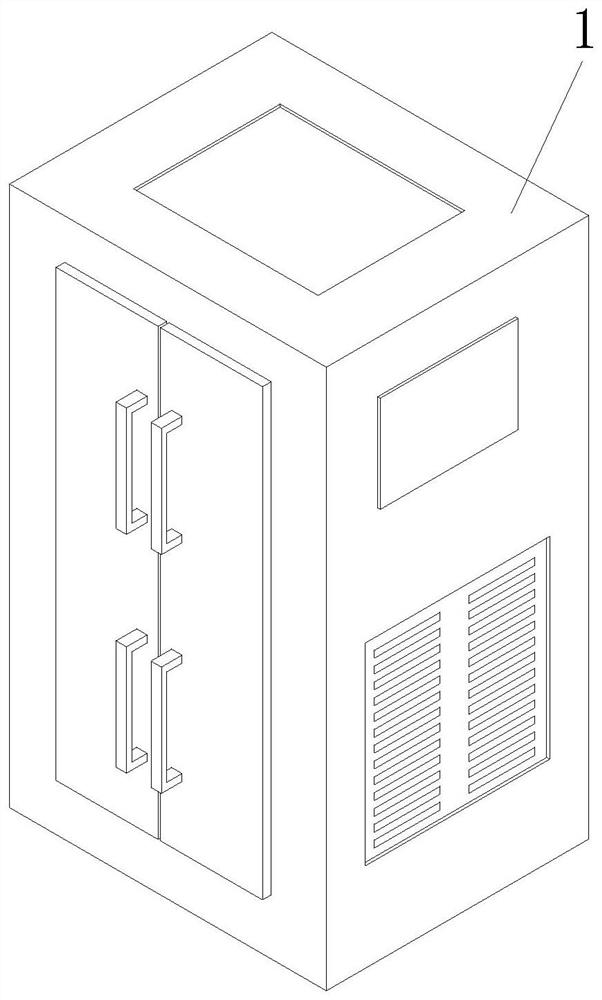

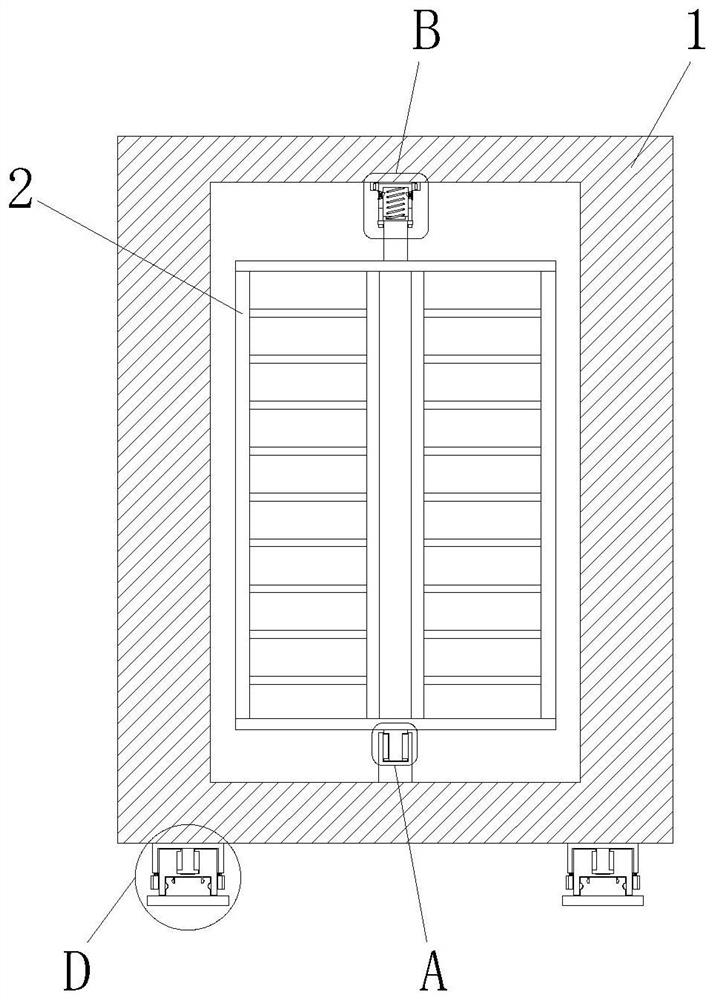

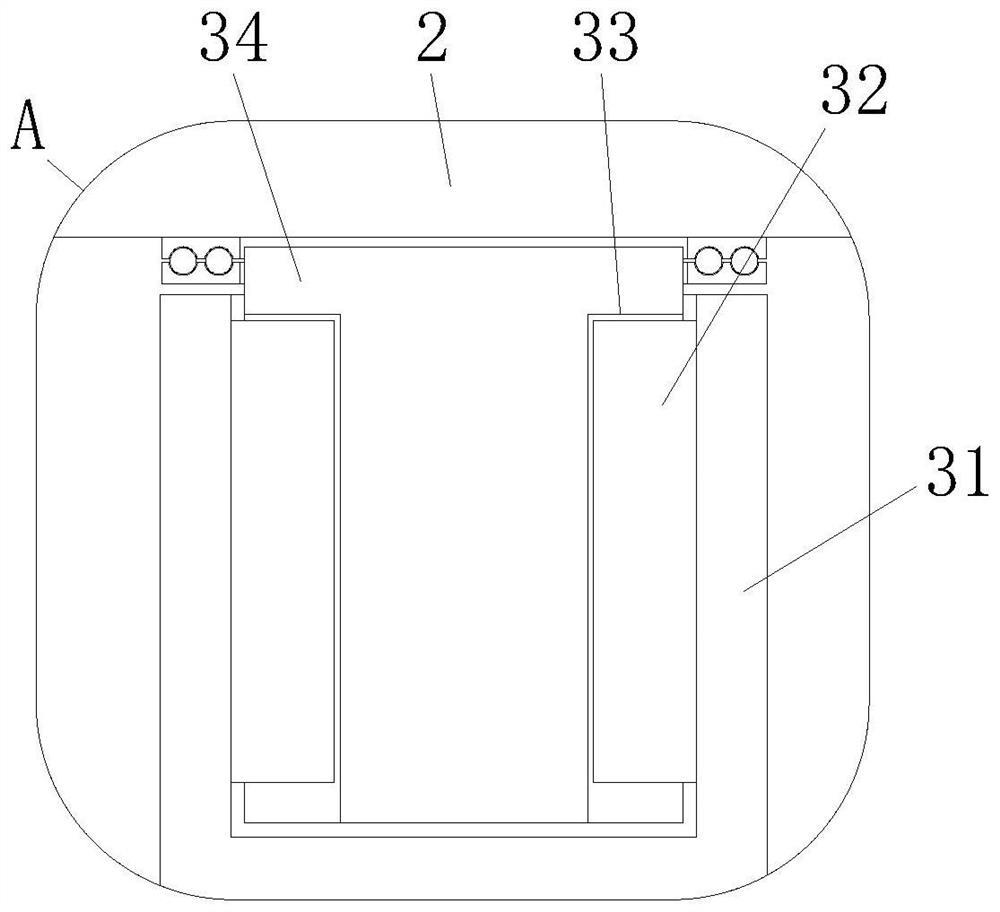

[0027] see Figure 1-6 As shown, a drying equipment for aquatic product processing includes a device main body 1 and a drying rack 2; the inside of the device main body 1 is provided with a drying rack 2, and both ends of the drying rack 2 are provided with assembly mechanisms; The assembly mechanism includes a clamping assembly, a sleeve rod 35, a connecting sleeve 36, a limiting block 37, a limiting groove 38, a reset assembly and an extruding assembly. The engaging assembly is arranged at the bottom of the drying rack 2, and the Sleeve rod 35 is fixedly connected on the top of drying frame 2, and described connecting sleeve 36 is movably connected on the top of device main body 1 inner wall by bearing, and described stopper 37 is fixedly connected on both sides of cover rod 35 tops, and stopper 37 is slidingly connected inside the limiting groove 38, and the limiting groove 38 is opened on both sides of the connecting sleeve 36, the reset component is arranged inside the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com