Mixing stock bin with suspension type mixing pipe

A blending material and suspension technology, applied in the field of blending silos, can solve problems such as limited support effect of rubber sleeves, falling off and damage of rubber sleeves, and large volume of blending silos, so as to improve vibration effect and reduce friction , The effect of low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

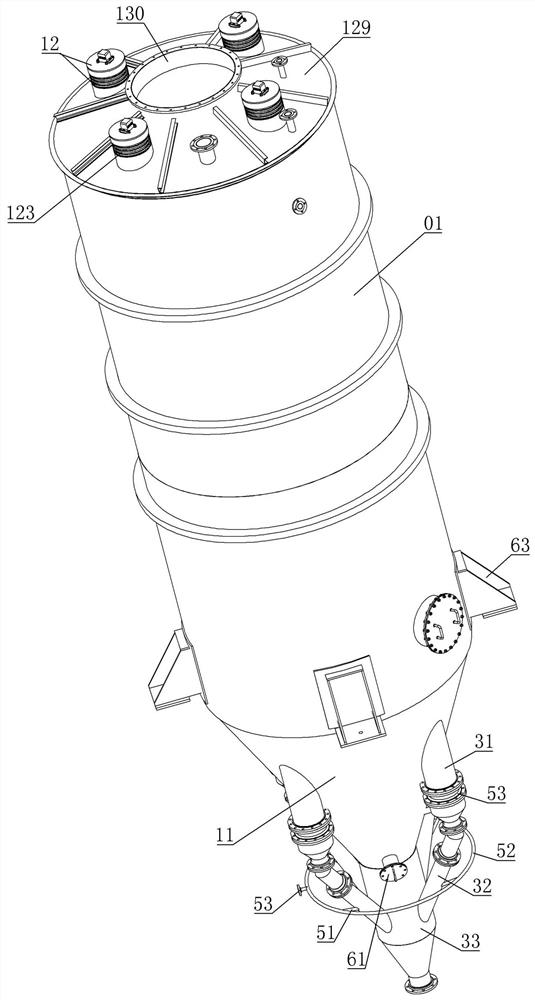

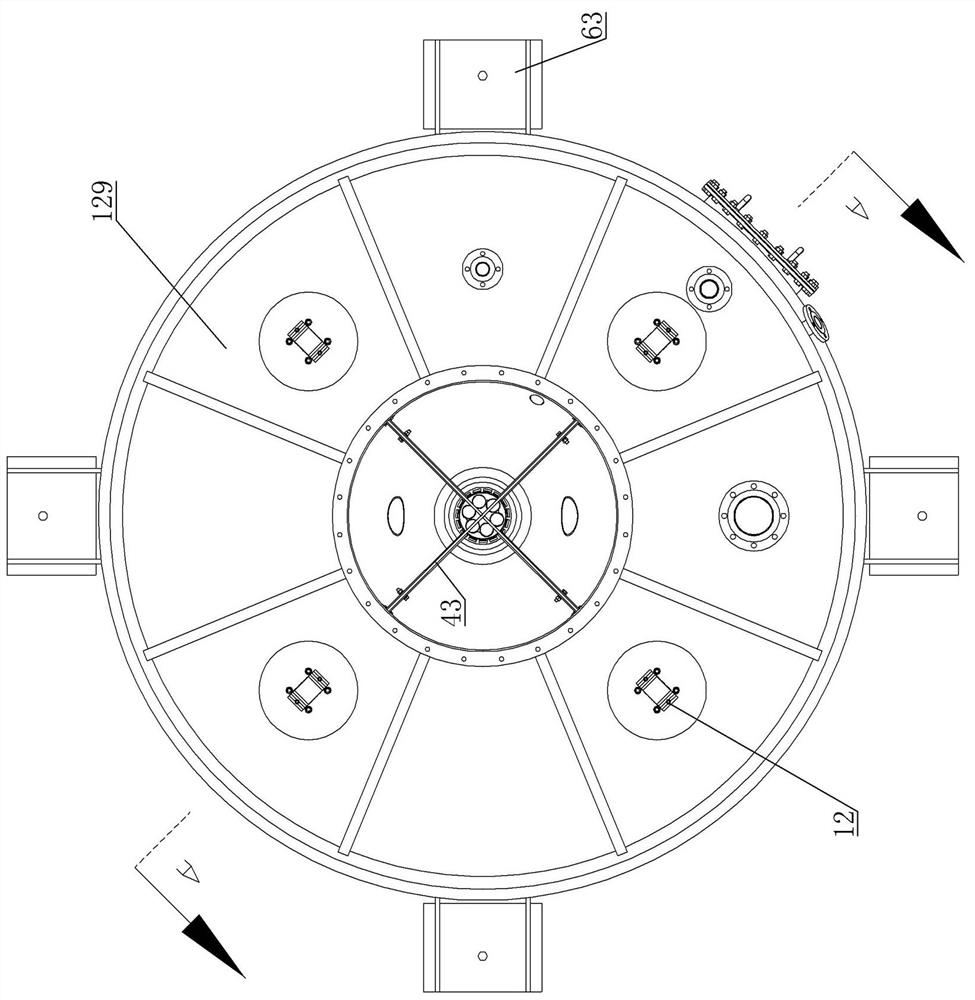

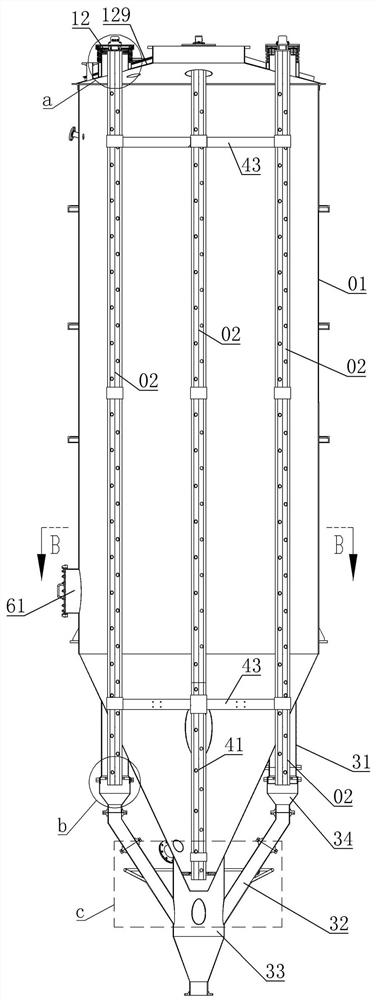

[0033] Embodiment one, refer to the description attached figure 1 - 12. A mixing silo with a suspended mixing pipe, comprising a cylindrical silo with a conical silo bottom at the lower end,

[0034] A plurality of vibrating devices are evenly distributed on the outer edge of the upper end cover plate of the cylindrical silo. The device includes a cylindrical bracket vertically fixed on the surface of the cover plate, a vibrator, and an annular spring. There is a through hole, the annular spring is sleeved on the outside of the cylindrical support, the lower part of the outer surface of the cylindrical support is provided with an annular boss supported on the lower end of the annular spring, the upper end of the annular spring protrudes upwards from the cylindrical support and the upper end of the annular spring is fixedly connected with a vibration The support plate, the vibrator is fixed in the middle of the upper surface of the vibration support plate; the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com