Pay-off device of fine metal wire drawing machine

A wire-feeding device and thin metal wire technology are applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., which can solve problems such as lack of guiding functions, inaccurate positioning of incoming wires, and knotted wires. , to achieve the effect of optimizing the wire drawing effect, avoiding messy wire ends, and accurately positioning the incoming wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

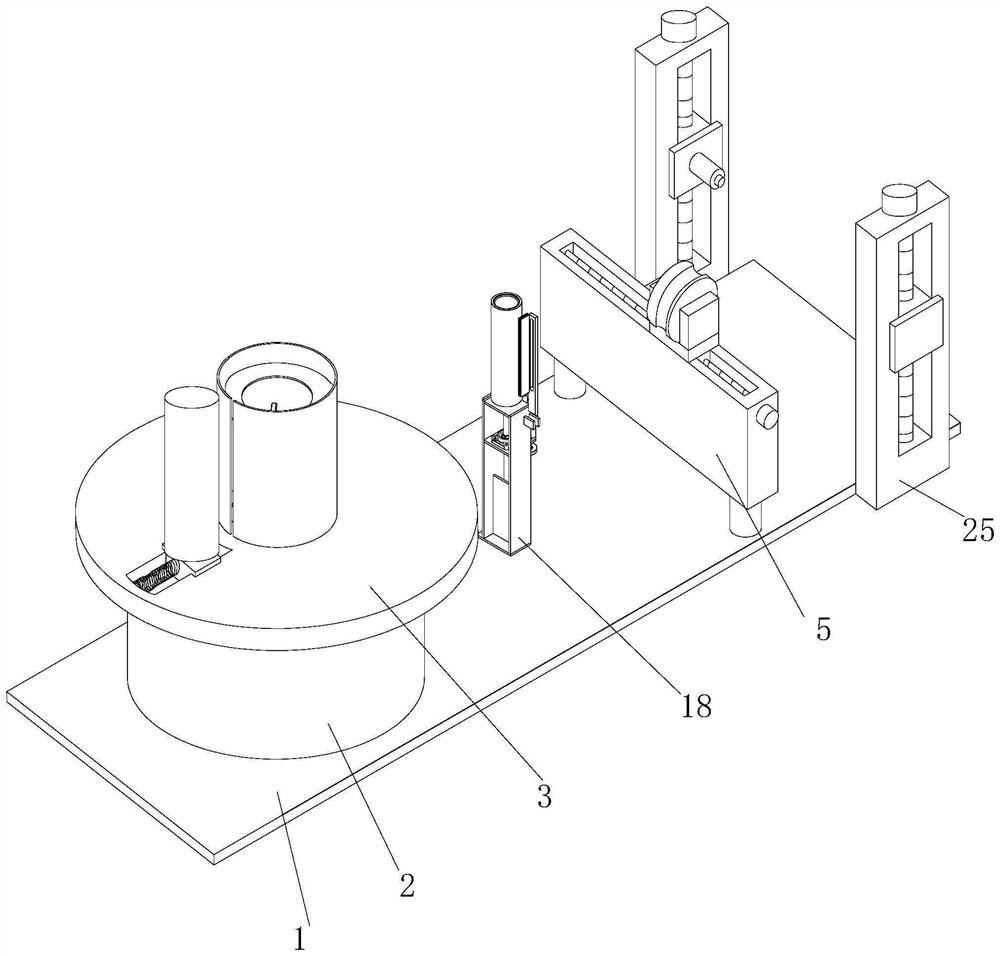

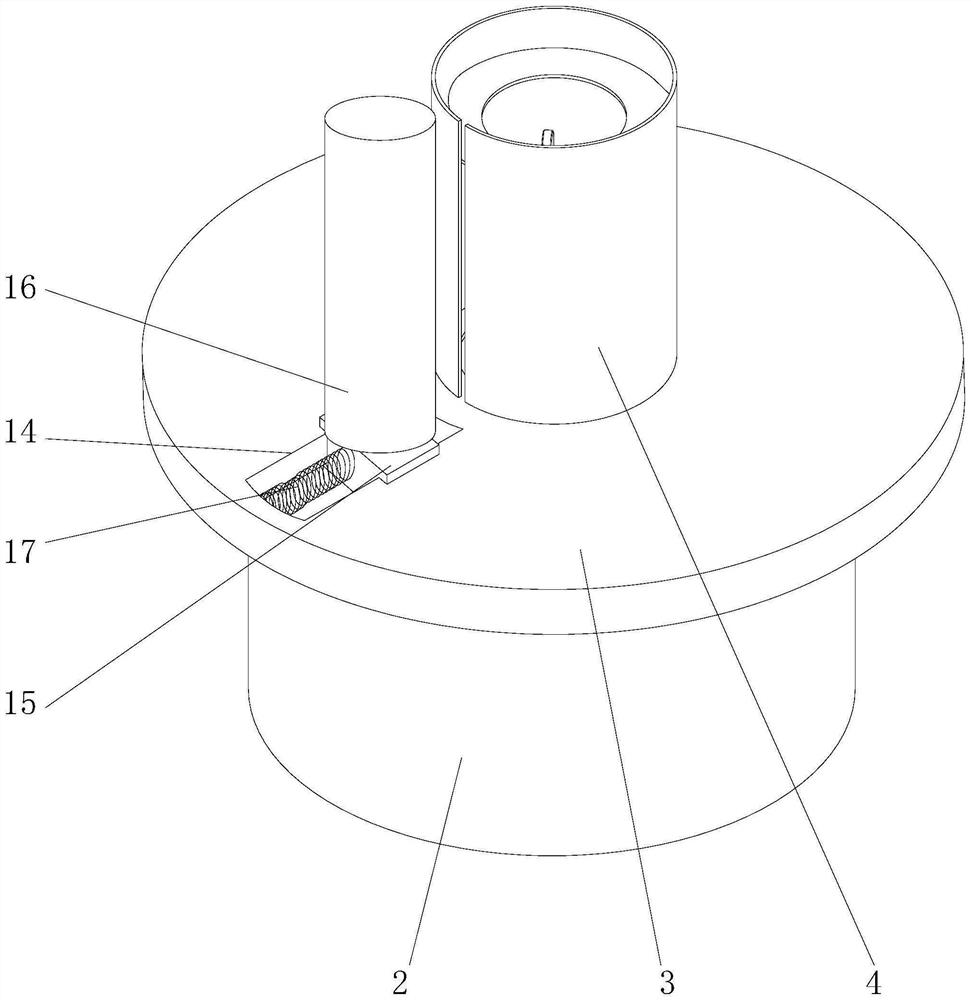

[0027] according to figure 1 , 2 , 3, and 4, this embodiment proposes a metal wire drawing machine pay-off device, including a base 1 and a pay-off assembly, a cleaning assembly, and a guide assembly arranged on the base 1, and the pay-off assembly includes a support Seat 2, mounting plate 3 and pay-off roller 4, said mounting plate 3 is arranged on the support 2, and said pay-off roller 4 is rotatably installed on the mounting plate 3;

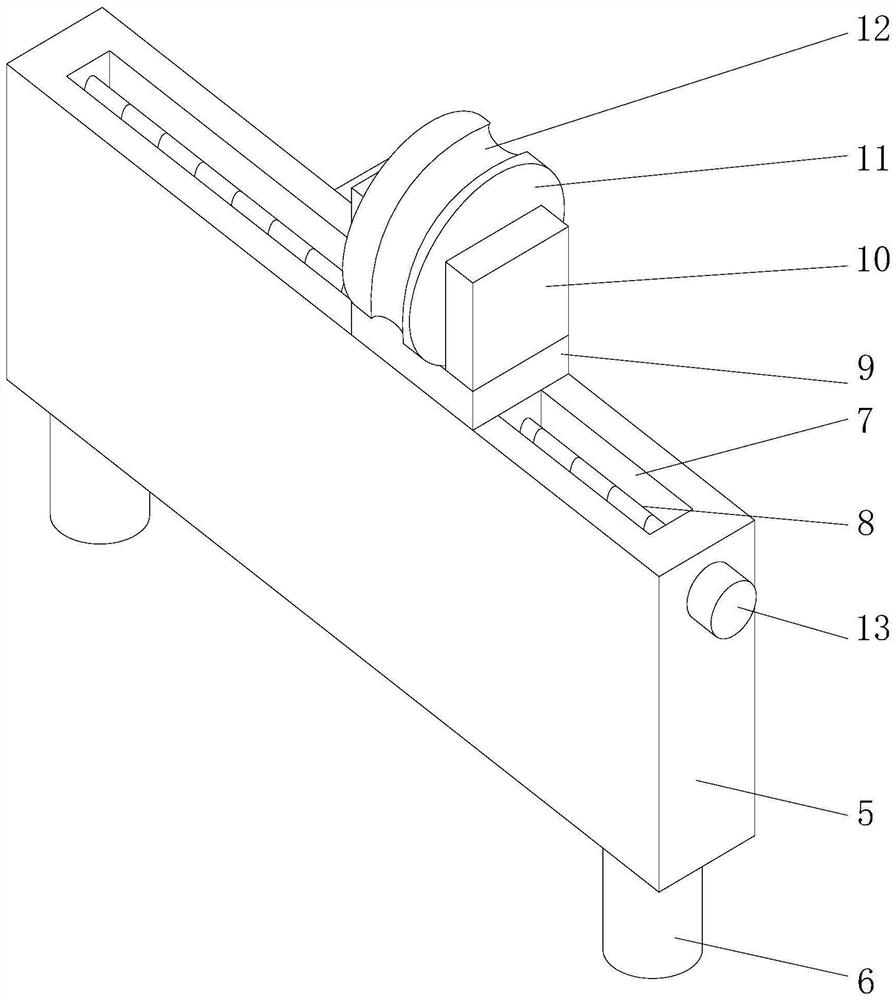

[0028] The guide assembly includes a guide seat 5 and a pneumatic cylinder 6, the two sides of the bottom of the guide seat 5 are provided with a pneumatic cylinder 6, and the lower end of the pneumatic cylinder 6 is fixed on the base 1, and the top of the guide seat 5 is provided with The first chute 7, and the inside of the first chute 7 is rotatably equipped with a first threaded screw 8, the first chute 7 is provided with a first slide block 9, and the bottom of the first slide block 9 is connected to the first slide block 9. A screw th...

Embodiment 2

[0033] according to figure 1 , 2 , 3, and 5, this embodiment proposes a metal wire drawing machine pay-off device, including a base 1 and a pay-off assembly, a cleaning assembly, and a guide assembly arranged on the base 1, and the pay-off assembly includes a support Seat 2, mounting plate 3 and pay-off roller 4, said mounting plate 3 is arranged on the support 2, and said pay-off roller 4 is rotatably installed on the mounting plate 3;

[0034]The guide assembly includes a guide seat 5 and a pneumatic cylinder 6, the two sides of the bottom of the guide seat 5 are provided with a pneumatic cylinder 6, and the lower end of the pneumatic cylinder 6 is fixed on the base 1, and the top of the guide seat 5 is provided with The first chute 7, and the inside of the first chute 7 is rotatably equipped with a first threaded screw 8, the first chute 7 is provided with a first slide block 9, and the bottom of the first slide block 9 is connected to the first slide block 9. A screw thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com