Automatic bus duct riveting line

A technology of bus duct and riveting wire, applied in the field of bus duct processing equipment, can solve the problems of low processing efficiency and large workload of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-13 The present invention is described in further detail.

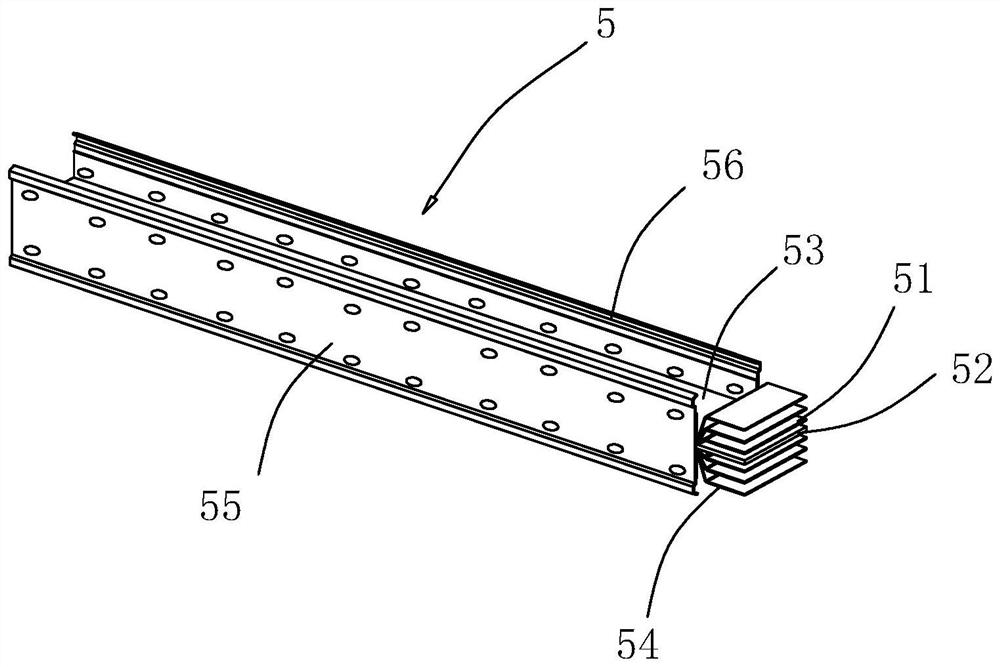

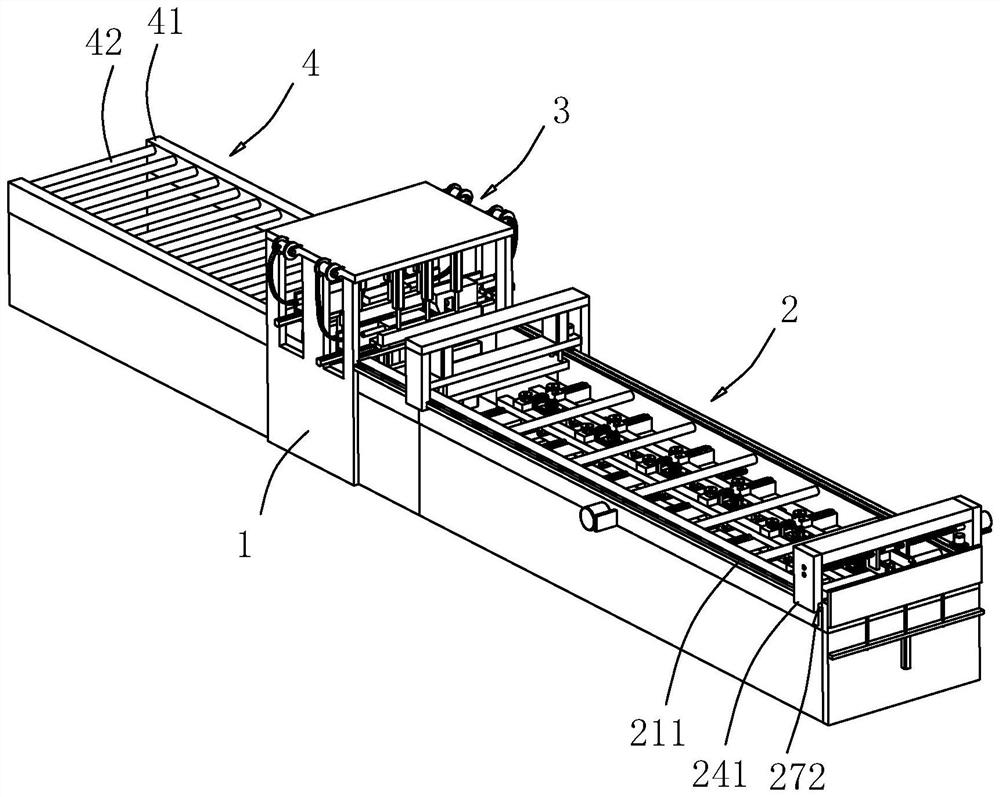

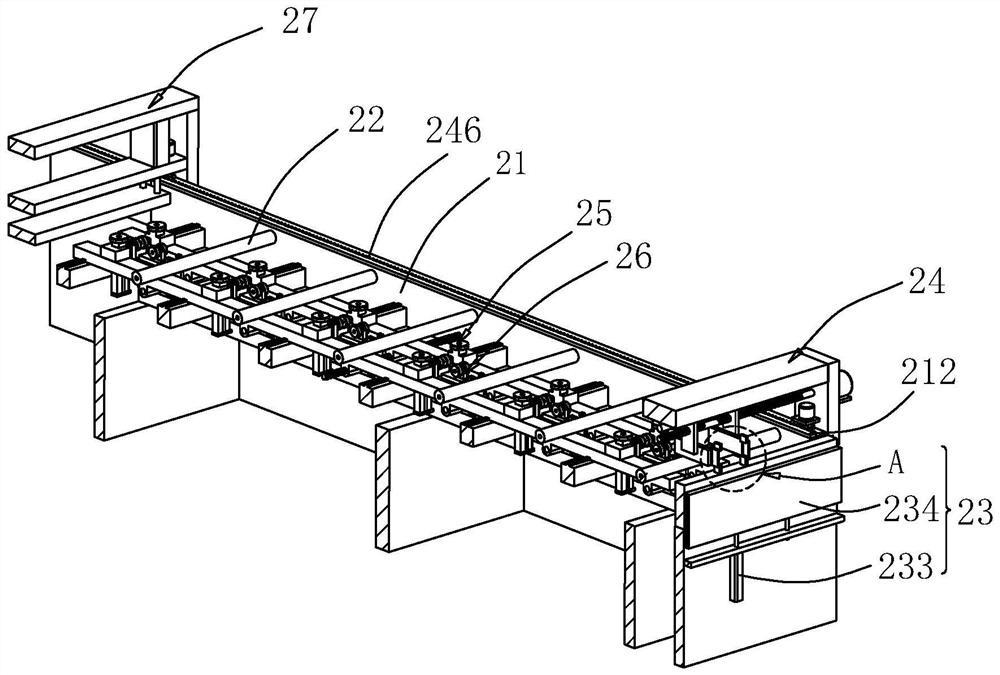

[0042] The embodiment of the invention discloses an automatic busway riveting line. refer to figure 2 , an automatic busway riveting line includes a frame 1, a riveting device 3 is arranged on the frame 1, an automatic feeding device 2 is arranged on one side of the frame 1 located at the riveting device 3, and a discharging device 4 is arranged on the other side The automatic feeding device 2 automatically pushes the spliced busway 5 to the riveting device 3, and the riveting device 3 rives and fixes the two sides of the left side plate 55 with the upper cover plate 53 and the lower cover plate 54 respectively, and simultaneously the right Both sides of the side plate 56 are riveted and fixed with the upper cover plate 53 and the lower cover plate 54 respectively, so as to realize automatic feeding and automatic riveting of the busway 5, improve processing efficiency and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com