Self-propelled temporary storage machine for PCBs (printed circuit boards)

A PCB board, self-propelled technology, applied in the field of PCB board self-propelled cache machine, can solve the problems of not having a good reclaiming effect and PCB board congestion, and achieve the effect of reducing friction and improving reclaiming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

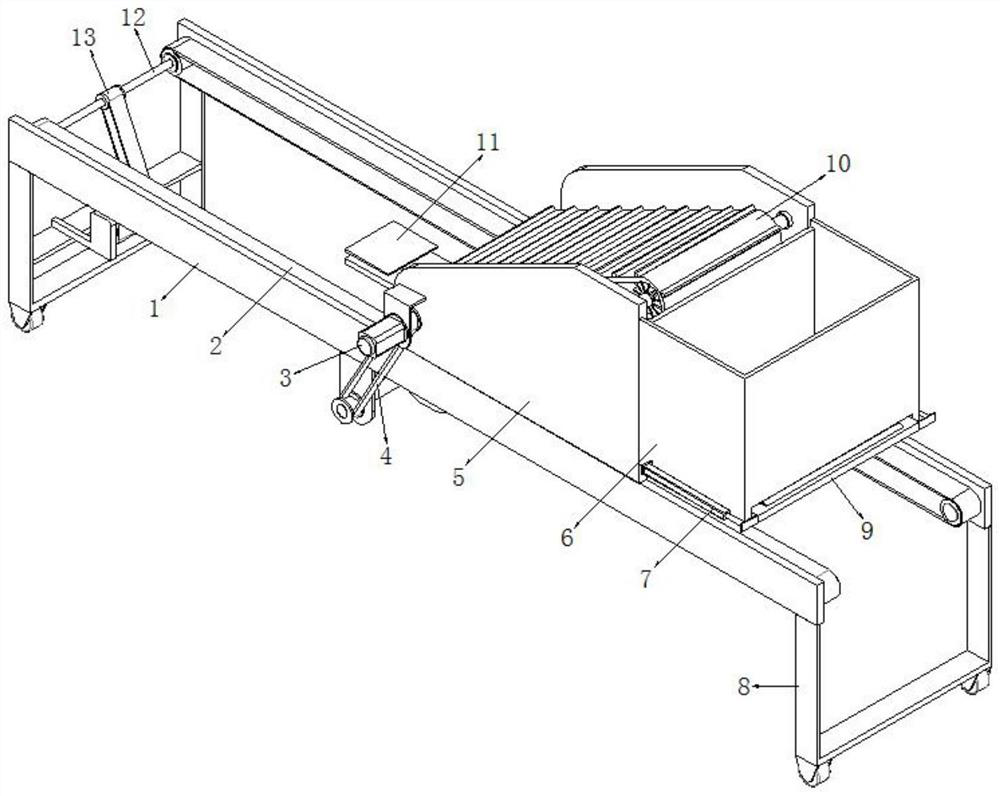

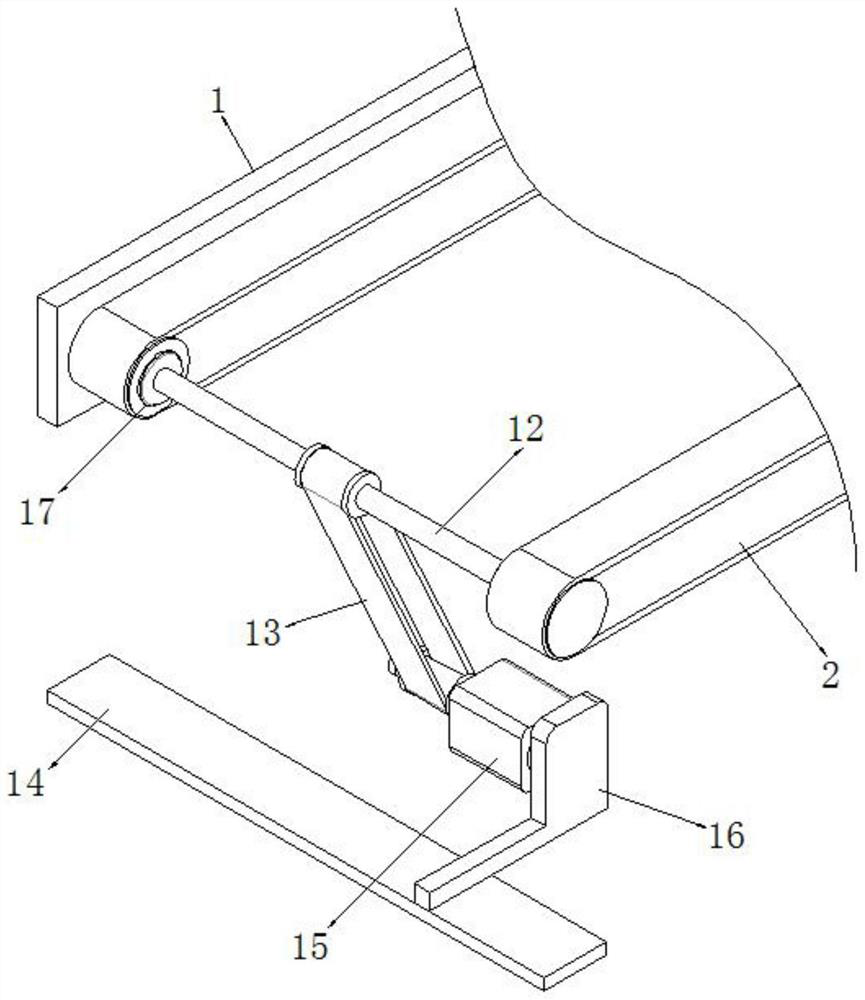

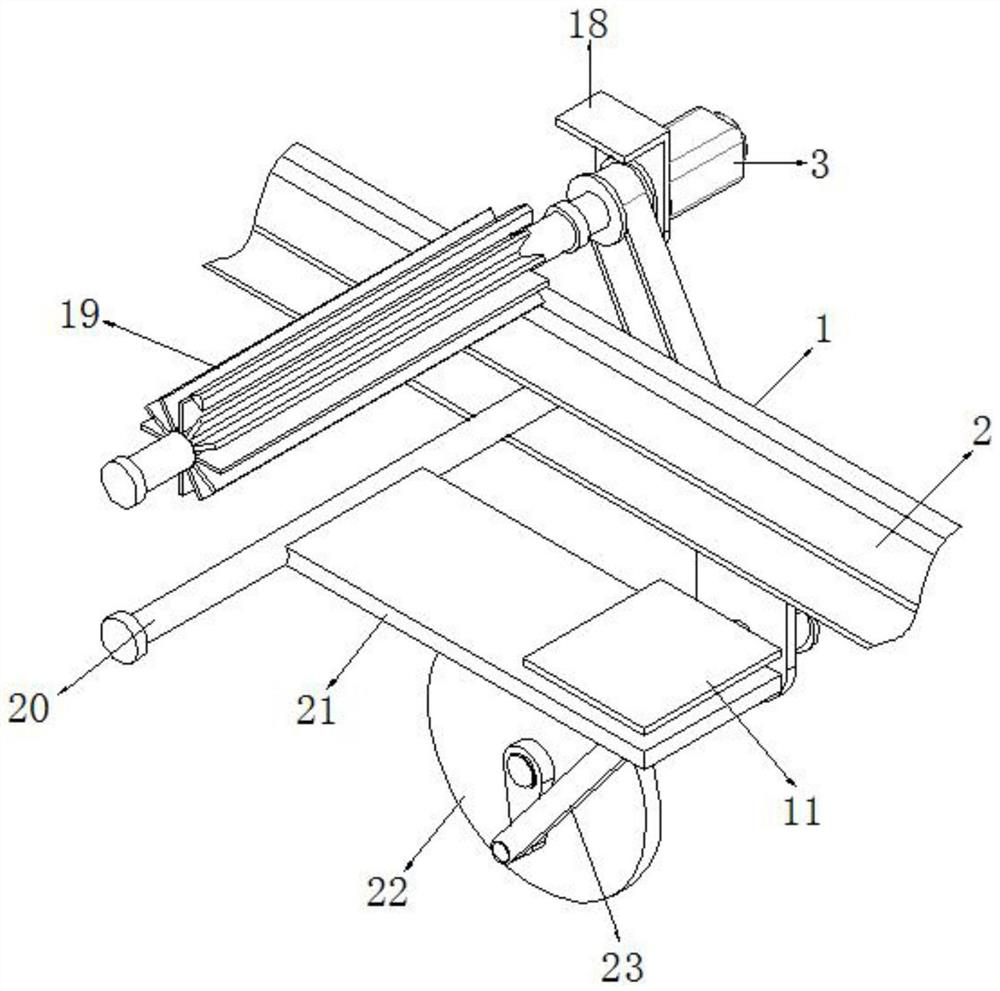

[0032] refer to Figure 1-6 , a self-propelled buffering machine for PCB boards, comprising a support plate 1, the number of support plates 1 is two, and a conveying structure is arranged between opposite sides of the support plate 1, and a first driving mechanism is arranged at one end of the conveying structure , the top sides of the two support plates 1 are connected with side plates 5 by bolts, and one side of the side plates 5 is connected with the same buffer frame 6 by bolts, and the bottom side of one support plate 1 is welded with a fixed plate 24 , and one side of the fixed plate 24 has a through hole, the inner wall of the through hole is connected with the drive shaft 25 through the bearing, a material lifting structure is arranged between the opposite sides of the side plate 5, and one end of the drive shaft 25 is connected to the material lifting structure. One side is provided with a second drive mechanism, the other end of the drive shaft 25 is connected with a...

Embodiment 2

[0042] refer to Figure 7 , a self-propelled buffering machine for PCB boards. Compared with Embodiment 1, one end of the rubber backing plate 11 is bonded with equidistantly distributed and L-shaped rubber rails 34, and the bottom of the rubber rails 34 A V-shaped frame 35 is hinged with one end of the rubber backing plate 11 .

[0043] Working principle: When in use, when the user uses the rubber pad 11 to pull the material, the PCB board can be prevented from falling off through the L-shaped rubber rail 34, and the rubber rail 34 can be prevented from appearing through the support of the V-shaped frame 35 Large deformation problem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com