Optical cable binding wire winding device

A winder and wire-tying technology, which is applied in the field of optical cable wire-tying winders, can solve problems affecting the use of optical cable attachment machines, high cost of wire-tying reels, and low efficiency of manual winding, and achieves simple structure, easy manufacture, and easy winding firming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

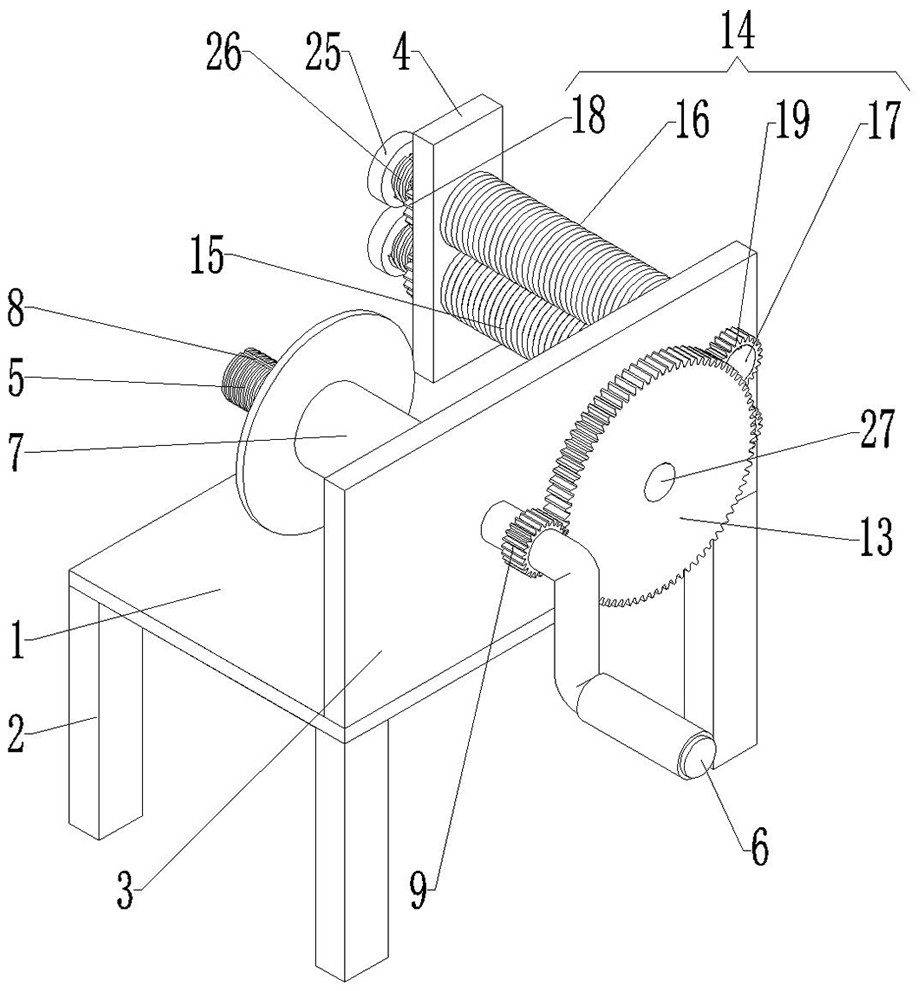

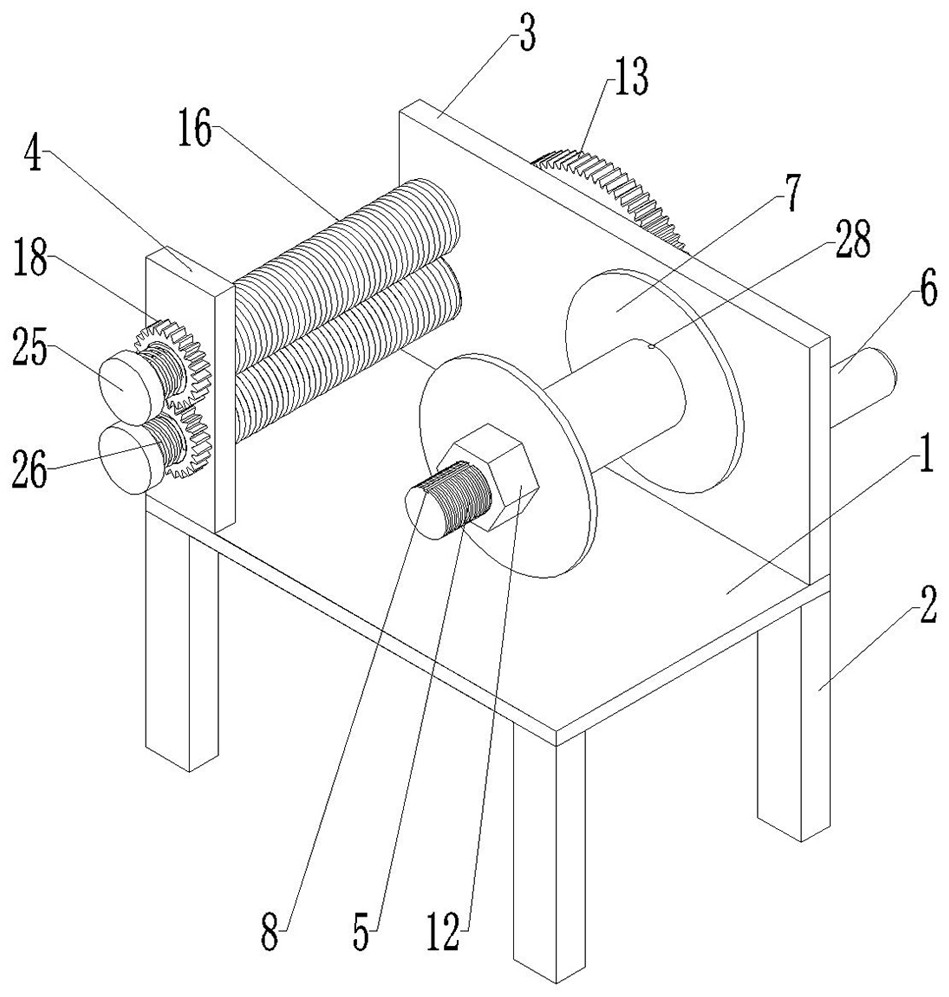

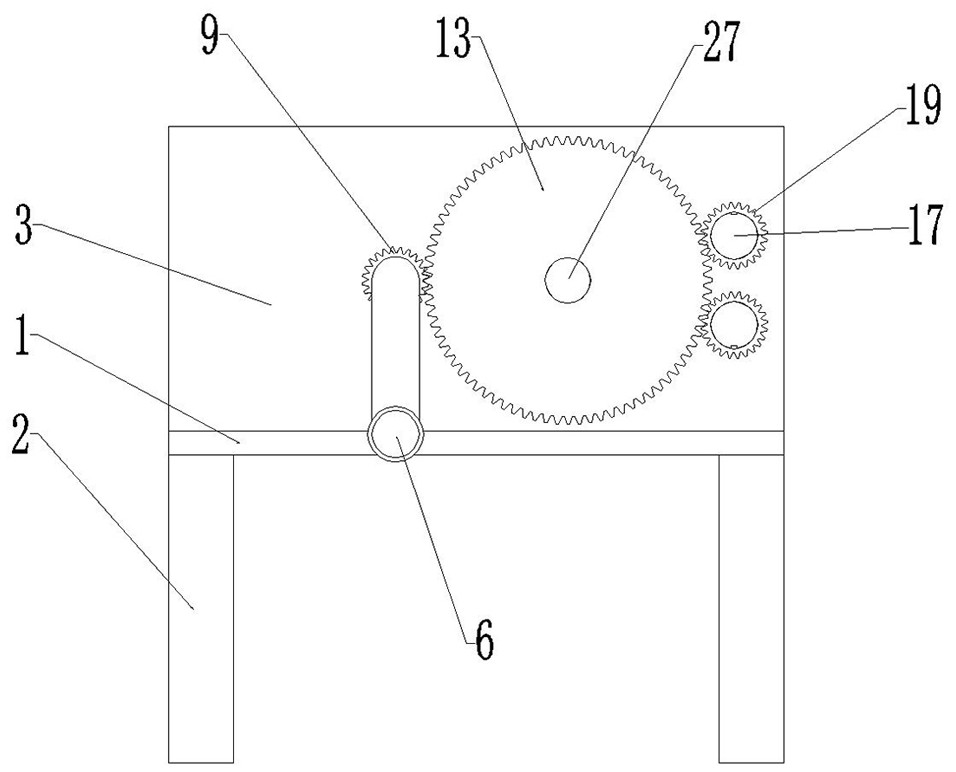

[0035] Such as Figure 1 to Figure 8 As shown, an optical cable binding winder includes a base, a winding portion and a guiding portion;

[0036] The base includes a base plate 1 and supporting legs 2, the base plate 1 is a square plate body, the four corners of the lower surface of the base plate 1 are provided with supporting legs 2, and the front end of the upper surface of the base plate 1 is provided with a bearing plate 3, and the bearing plate 3 is Vertical square plate body, carrying plate 3 is provided with the mounting hole that runs through the front and rear sides of carrying plate 3, and described mounting hole is the circular through hole, and the right end of carrying plate 3 is provided with the first circular through hole and the second circular through hole. Circular through holes, the first circular through hole and the second cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com