Heat treatment and freezing treatment method for 9% Ni material

A treatment method, 9% ni technology, applied in the field of material heat treatment, can solve problems such as locking or vibration exceeding the standard, component size changes, etc., to achieve the effect of solving the problem of abnormal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

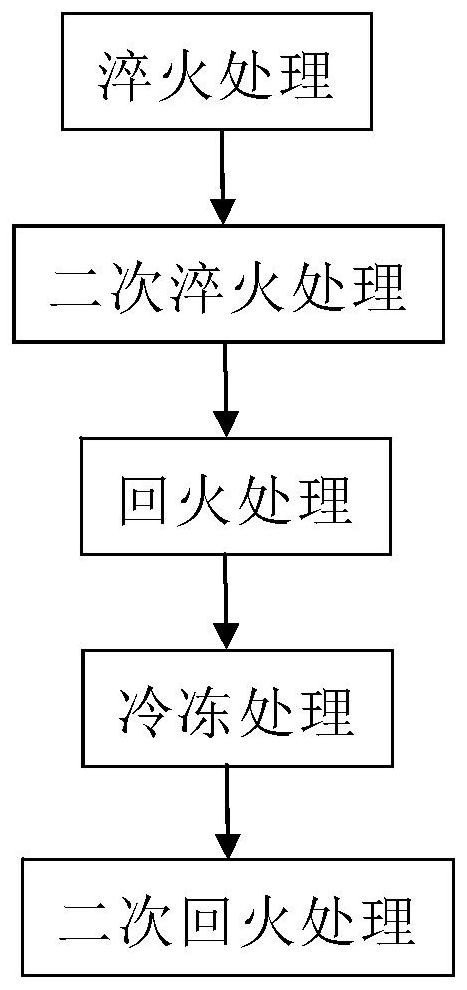

Method used

Image

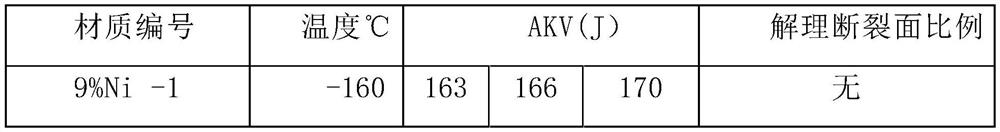

Examples

Embodiment 1

[0033] The low-temperature compressor parts made of 9% Ni are placed in a heat treatment furnace and nitrogen for heat treatment and freezing treatment, which sequentially includes quenching treatment, secondary quenching, tempering treatment, freezing treatment and secondary tempering treatment. The chemical composition and weight percentage of the 9% Ni material are: C≤0.10%; Mn≤0.80%; P≤0.025%; S≤0.025%; Si: 0.15-0.35%; Cu≤0.30%; 9.5%; Cr≤0.30%; Fe: balance. in,

[0034] Quenching treatment: at a heating rate of 80°C / hour, the temperature in the heat treatment furnace was raised to 815°C for 2 hours, and then water cooled to room temperature.

[0035] Secondary quenching treatment: at a heating rate of 70° C. / hour, the temperature in the heat treatment furnace was raised to 665° C., kept for 3 hours, and then water-cooled to room temperature.

[0036] Tempering treatment: raise the temperature in the heat treatment furnace to 585° C. at a heating rate of 50° C. / hour, keep...

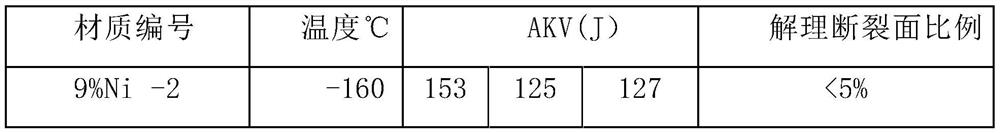

Embodiment 2

[0046]The low-temperature compressor parts made of 9% Ni are placed in a heat treatment furnace and nitrogen for heat treatment and freezing treatment, which sequentially includes quenching treatment, secondary quenching, tempering treatment, freezing treatment and secondary tempering treatment. The chemical composition and weight percentage of the 9% Ni material are: C≤0.10%; Mn≤0.80%; P≤0.025%; S≤0.025%; Si: 0.15-0.35%; Cu≤0.30%; 9.5%; Cr≤0.30%; Fe: balance. in,

[0047] Quenching treatment: With a heating rate of 90°C / hour, the temperature in the heat treatment furnace was raised to 820°C, kept for 1.5 hours, and then water-cooled to room temperature.

[0048] Secondary quenching treatment: raise the temperature in the furnace to 670°C at a heating rate of 60°C / hour, keep the temperature for 2.5 hours, and then cool to room temperature with water.

[0049] Tempering treatment: Raise the temperature in the furnace to 590°C at a heating rate of 75°C / hour, keep the temperatu...

Embodiment 3

[0059] The low-temperature compressor parts made of 9% Ni are placed in a heat treatment furnace and nitrogen for heat treatment and freezing treatment, which sequentially includes quenching treatment, secondary quenching, tempering treatment, freezing treatment and secondary tempering treatment. The chemical composition and weight percentage of the 9% Ni material are: C≤0.10%; Mn≤0.80%; P≤0.025%; S≤0.025%; Si: 0.15-0.35%; Cu≤0.30%; 9.5%; Cr≤0.30%; Fe: balance. in,

[0060] Quenching treatment: at a heating rate of 100°C / hour, the temperature in the heat treatment furnace was raised to 825°C, kept for 1 hour, and then water-cooled to room temperature.

[0061] Secondary quenching treatment: raise the temperature in the heat treatment furnace to 675° C. at a heating rate of 90° C. / hour, keep the temperature for 2 hours, and then cool to room temperature with water.

[0062] Tempering treatment: Raise the temperature in the heat treatment furnace to 595°C at a heating rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap