Indoor pipeline sound insulation and noise reduction structure convenient to expand and construct

A technology for inner pipes and pipes, applied in the field of sound insulation and noise reduction structure of indoor pipes, can solve the problems of easy deformation and aging, large floor space, complicated construction, etc., and achieve the effect of reducing floor space, facilitating expansion and construction, and facilitating construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

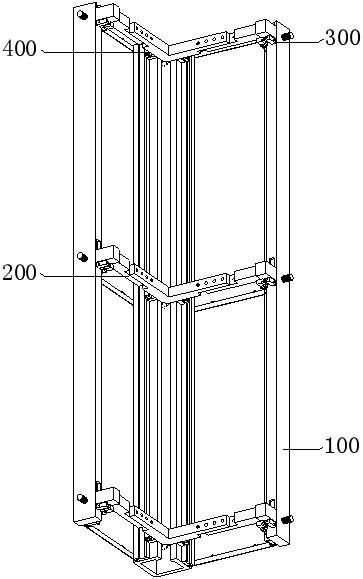

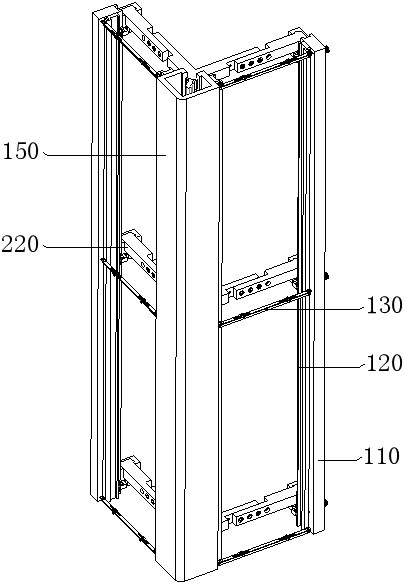

[0051] Such as Figure 1-Figure 15 As shown, the indoor pipeline sound insulation and noise reduction structure that is convenient for expansion and construction according to the embodiment of the present application includes a supporting and hanging mechanism 100, an adjusting frame mechanism 200, a frame limiting and locking mechanism 300, and a keel positioning and fixing mechanism 400. The frame mechanism 200 is set on the support and dry hanging mechanism 100, and can be flexibly adjusted and set according to the pipe size and the distance from the wall. On the frame mechanism 200, it is convenient to limit and lock the adjustment frame mechanism 200.

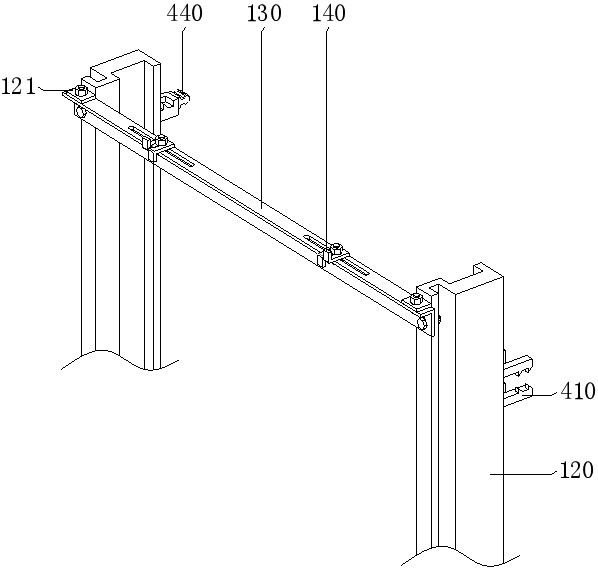

[0052] According to some embodiments of the present application, such as Figure 1-Figure 3 and Figure 5-Figure 8 As shown, the supporting and hanging mechanism 100 includes a vertical rod 110, a keel 120, an angle steel 130, a dry hanging piece 140 and a corner frame 150. The two vertical rods 110 are arranged side by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com