Prefabricated frp-sea sand concrete sound and noise reduction wall panel

A prefabricated and concrete technology, which is applied in the processing of building materials, construction, building components, etc., can solve problems such as long construction period, poor mechanical properties, and lack of resources, and achieve small crack resistance, high ductility, and easy transportation and hoisting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The scheme of the present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

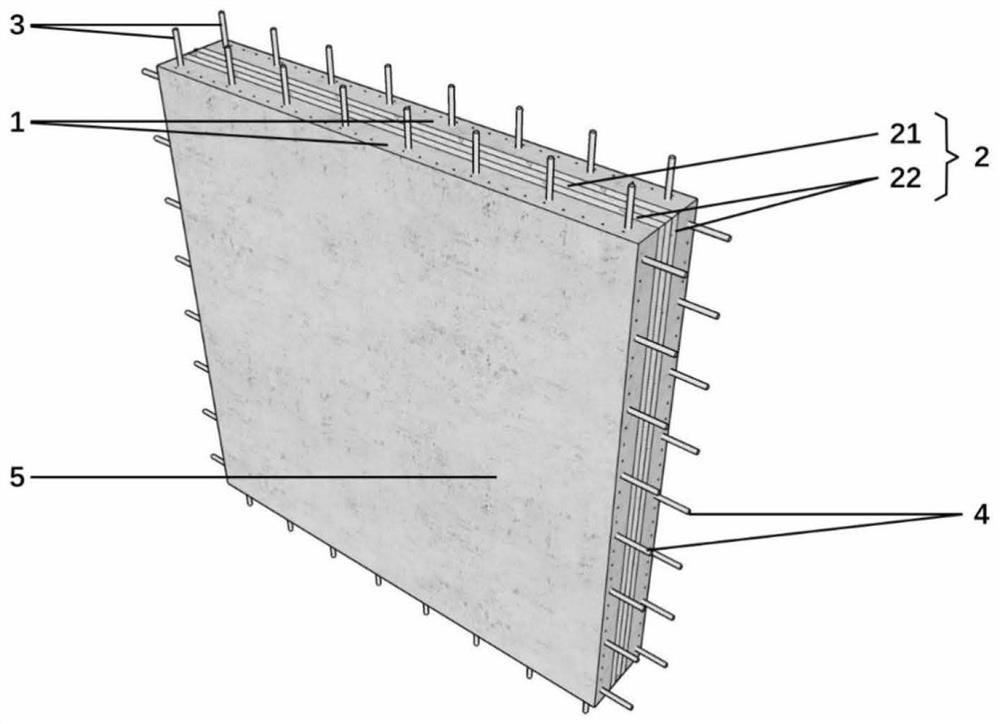

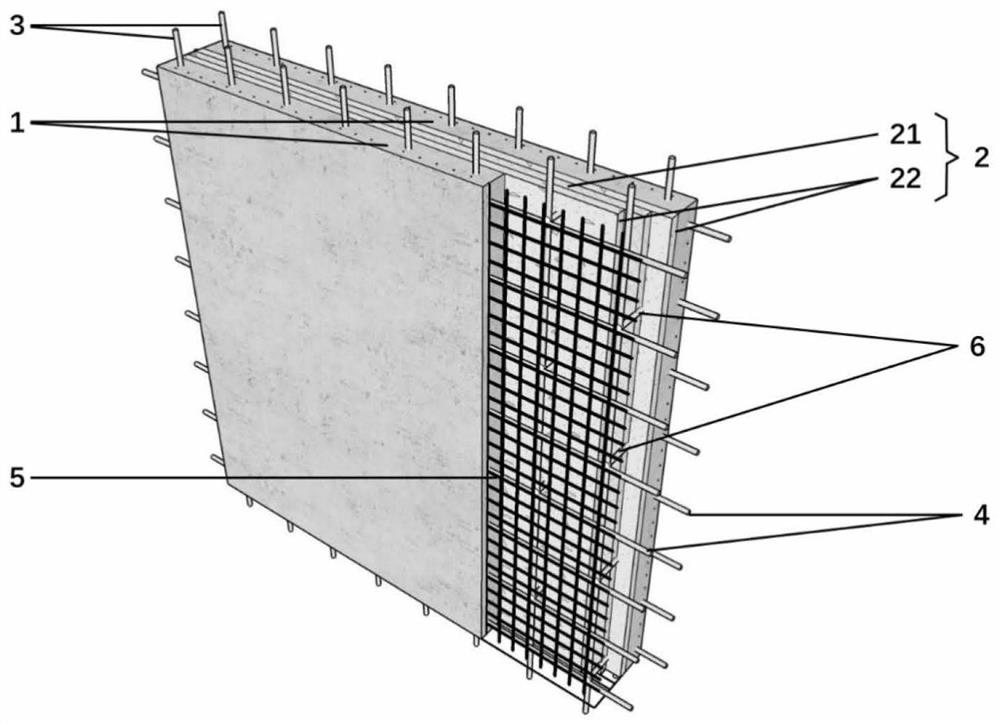

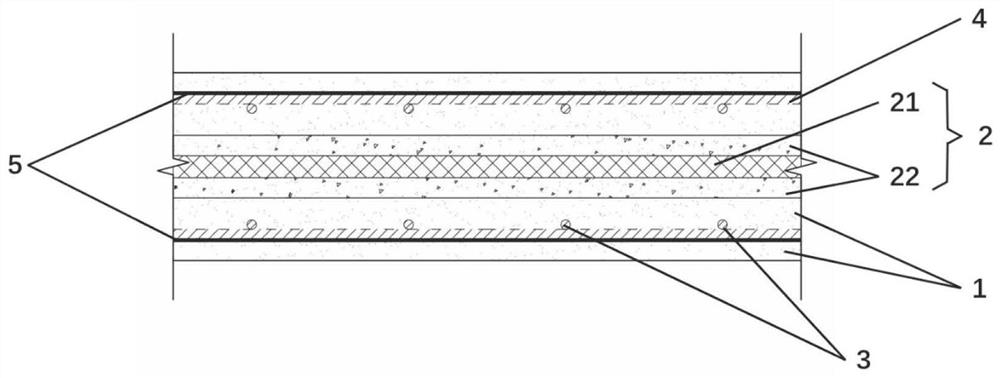

[0029]As shown in the figure, the prefabricated FRP-sea sand concrete sound insulation and noise reduction wallboard includes the main body of the prefabricated wallboard. The main body of the wallboard is composed of high ductility fiber reinforced seawater sea sand cement-based composite material layer 1 and sound insulation and noise reduction layer 2 on both sides. A symmetrical "sandwich" structure is formed; vertical FRP bars 3 and horizontal FRP bars 4 are arranged in the high ductility fiber-reinforced sea sand cement-based composite layers on both sides; the vertical FRP bars 3 and horizontal FRP bars 4 on both sides intersect in part The nodes are connected by connectors 6, so that the entire FRP bar forms an overall structural skeleton; FRP grids 5 are attached to the outside of the FRP bars on each side, and the FR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com