Jacking stroke control method for slip-form construction of charging silo

A control method and sliding-form technology, which are applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of jacks not in place, jacks exceeding the preset height, etc., to improve accuracy , the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

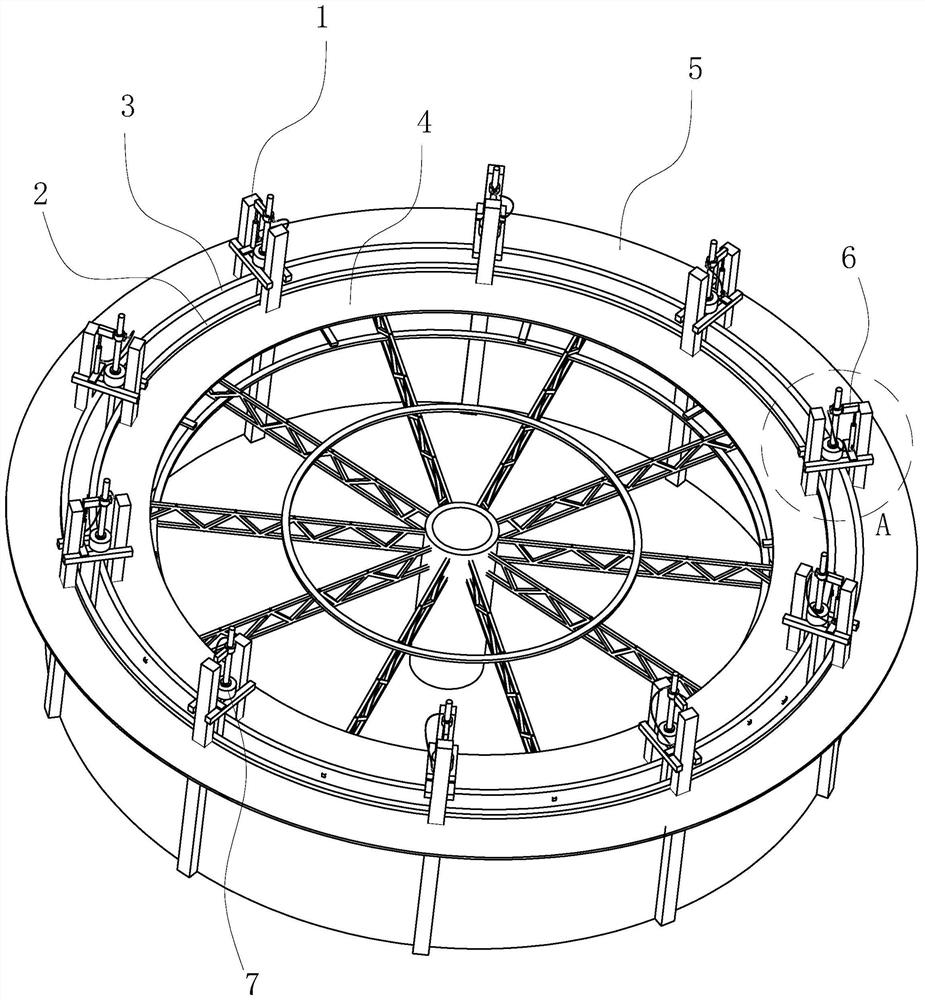

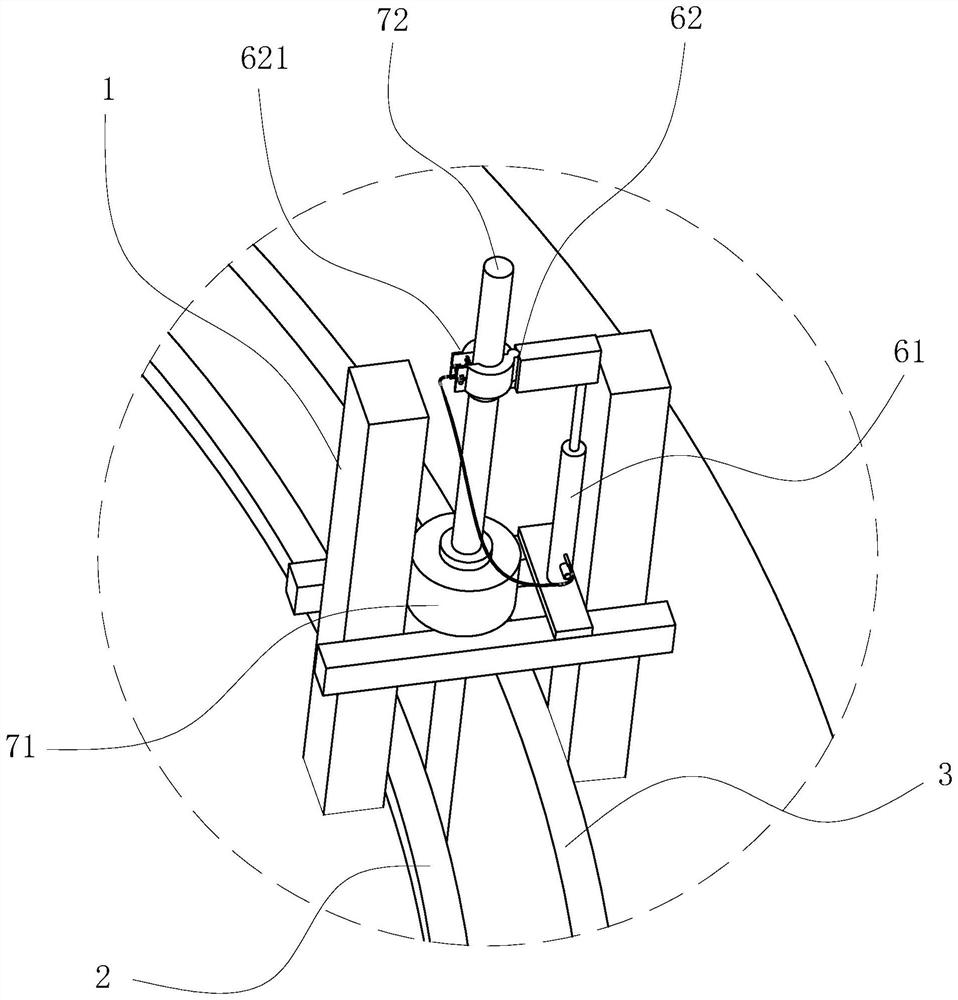

[0038] The following is attached Figure 1-4 The application is described in further detail.

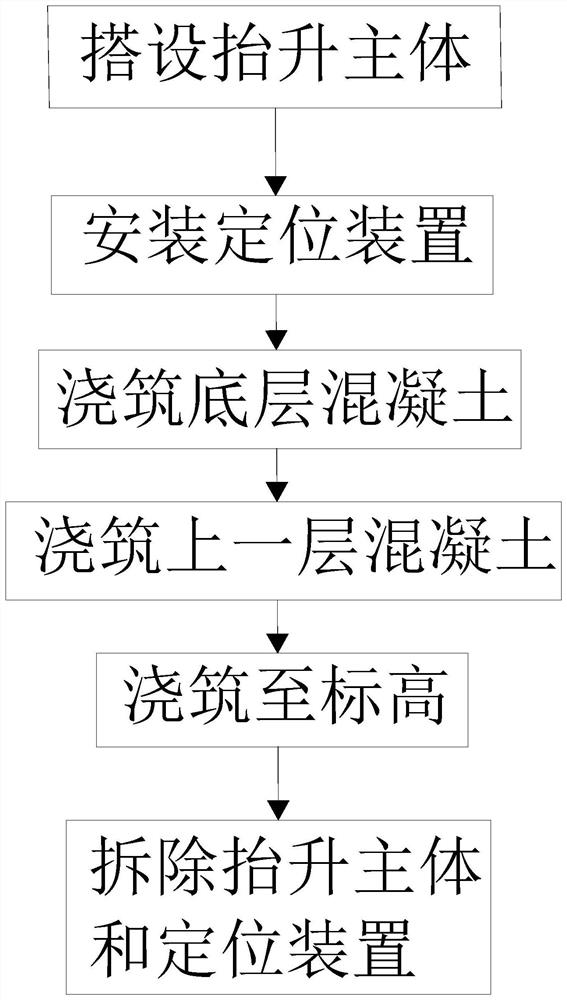

[0039] The embodiment of the present application discloses a method for controlling the jacking process of a material silo sliding form construction. refer to figure 1 , figure 2 and image 3 A method for controlling the jacking process of slipform construction of a material silo, comprising the following steps:

[0040] S1. Set up the lifting main body: the lifting main body includes the lifting frame 1, the inner sliding form 2, the outer sliding form 3, the inner operating platform 4, the outer operating platform 5 and the sliding form jack 7. When setting up the lifting main body, the inner sliding form 2 and the outer sliding form The molds 3 are respectively fixedly connected to the lifting frame 1 , the inner operating platform 4 is arranged on the inner side of the inner sliding mold 2 , and the outer operating platform 5 is arranged on the outer side of the outer slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com