Hubbed flange easy to disassemble

An easy-to-disassemble, flange technology, applied in the direction of flange connection, rigid shaft coupling, pipe/pipe joint/pipe fitting, etc., can solve the time-consuming disassembly and assembly of neck flanges, reduce the efficiency of neck flange disassembly, etc. problems, to achieve the effect of improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

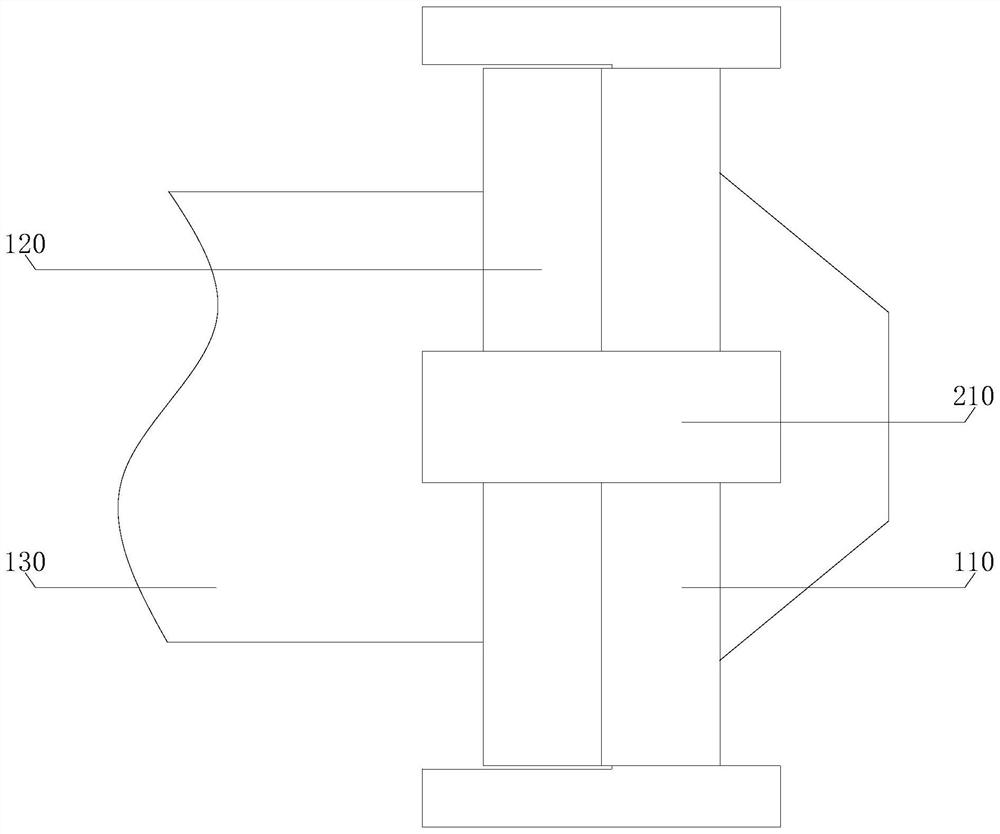

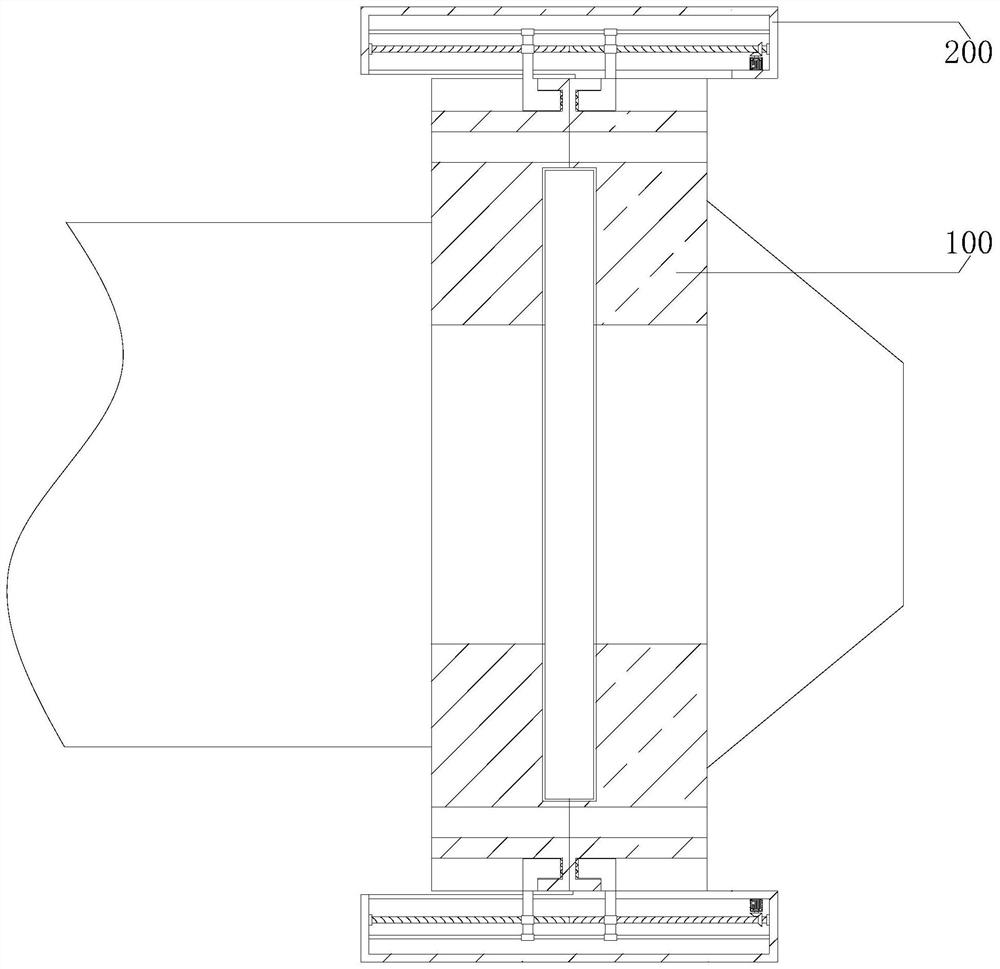

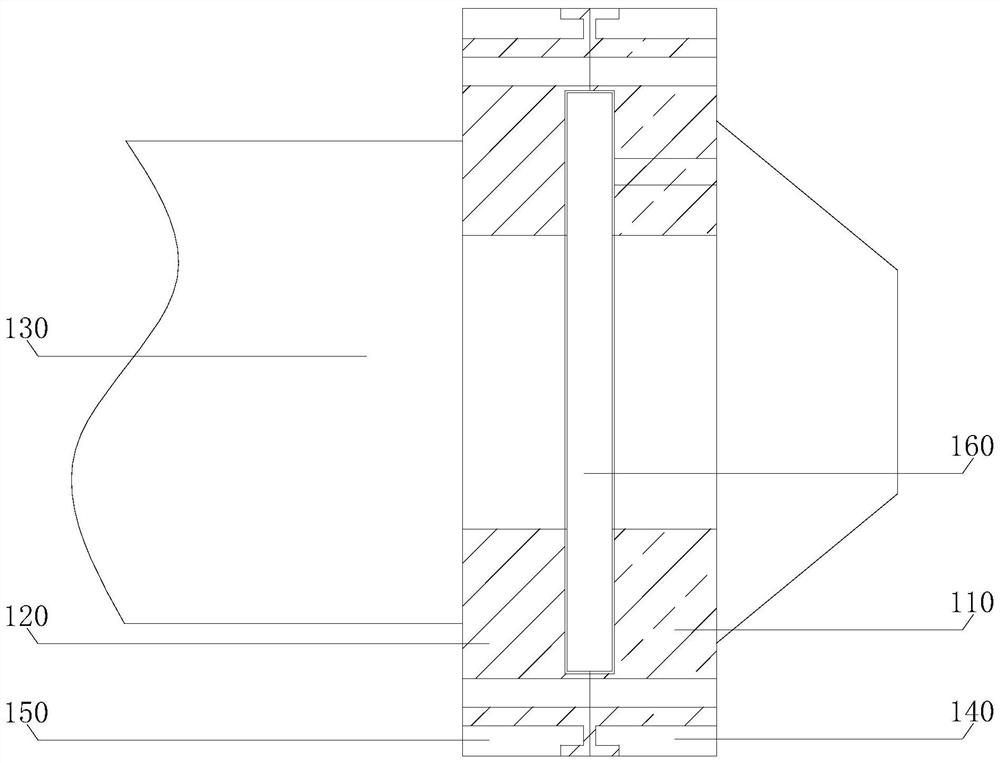

[0029] see Figure 1-5 , the present invention provides a technical solution: an easily detachable flange with a neck, including a base component 100 and a fixing component 200 . The fixing component 200 is fixed on the base component 100 , and the flange with neck can be disassembled without disassembling and assembling a plurality of bolts, which improves the efficiency of disassembling and assembling the flange with neck body 110 .

[0030] see Figure 1-Figure 3 , the basic assembly 100 includes a necked flange body 110, a connecting plate 120 and a connecting pipe 130, the necked flange body 110 fits on the connecting plate 120, the basic assembly 100 also includes a sealing ring 160, and the sealing ring 160 is arranged on the necked Between the flange body 110 and the connecting plate 120, the sealing ring 160 makes the sealing between the necked flange body 110 and the connecting plate 120 better, and the necked flange body 110 and the connecting plate 120 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com