Device for detecting falling of gluing positions of inner and outer lenses of automobile

A lens and gluing technology, applied in the direction of testing optical properties, etc., can solve problems such as affecting the work efficiency of workers, consuming physical strength, and low safety, and achieving the effect of saving physical strength, improving work efficiency, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

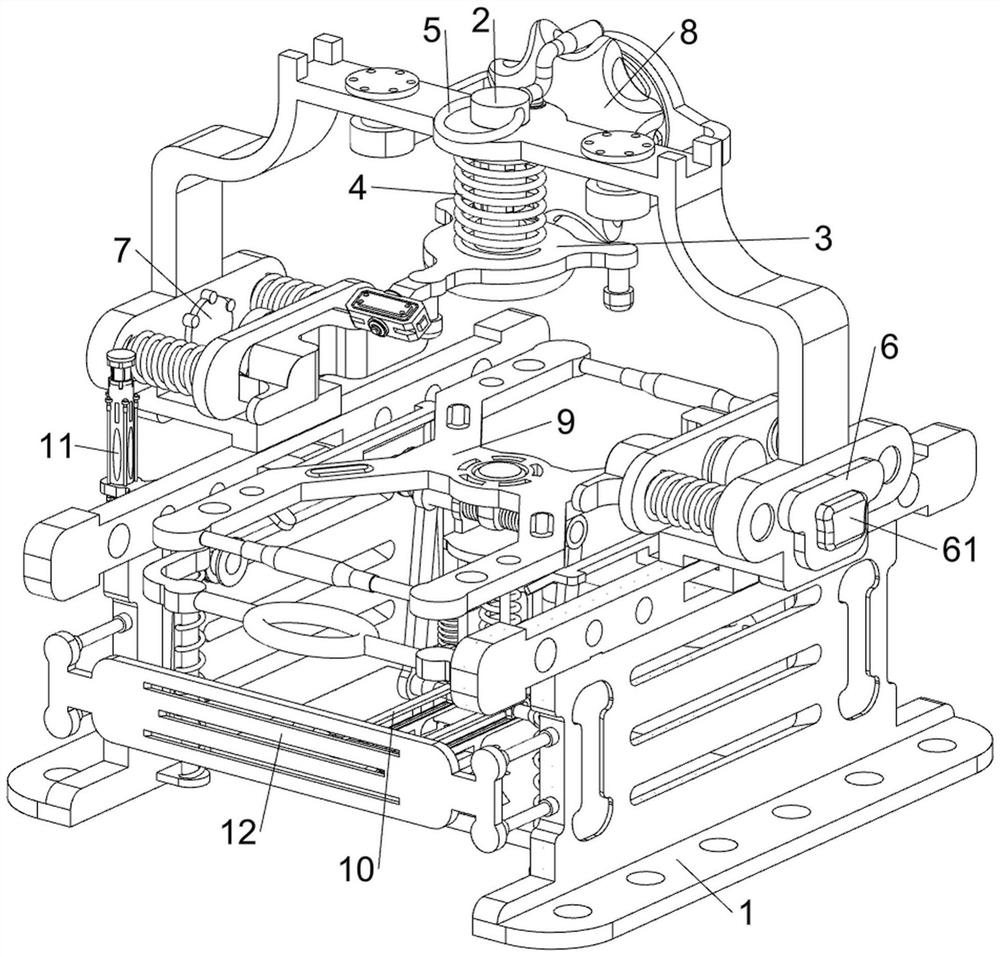

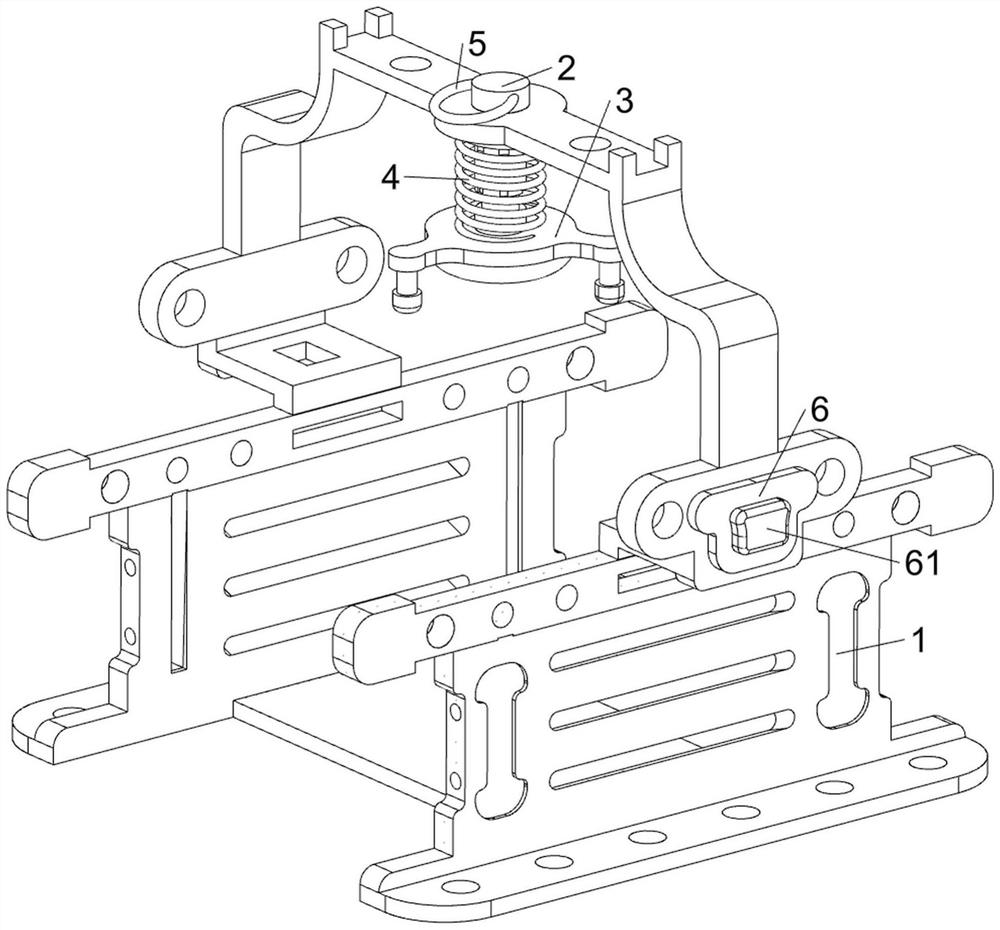

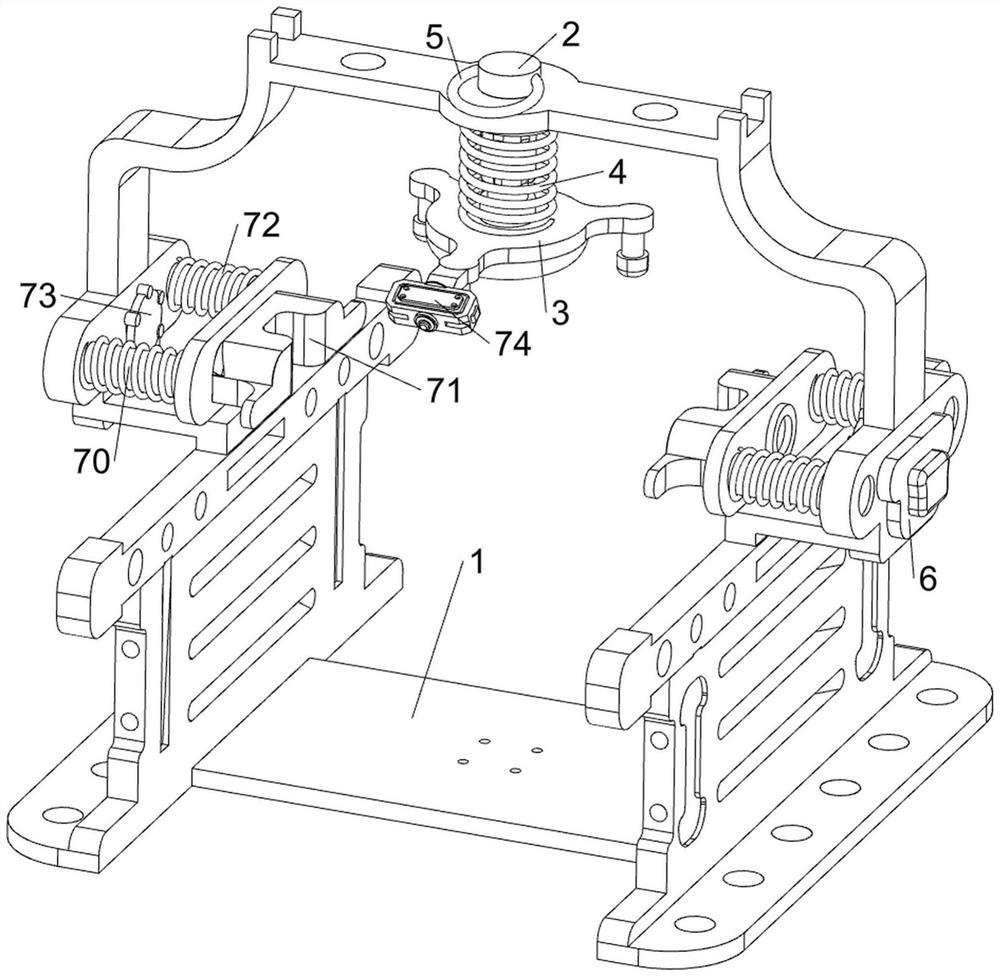

[0038] A device for detecting the falling off of the glued part of the inner and outer lenses of the automobile, including a support frame 1, a lifting rod 2, a hitting block 3, a compression spring 4, a pull ring 5, a control panel 6, a start switch 61, a clamping mechanism 7, Turning mechanism 8, unloading mechanism 9 and transmission mechanism 10, refer to Figure 1-Figure 10As shown, the lifting rod 2 is slidingly provided in the middle of the upper part of the support frame 1, and the bottom of the lifting rod 2 is welded with a hitting block 3. When the hitting block 3 moves to contact with the reflective mirror, it can knock on the reflective mirror. A compression spring 4 is provided between the top of the block 3 and the support frame 1, a pull ring 5 is provided on the upper side of the lifting rod 2 in a rotating manner, a control panel 6 is provided in the middle of the right side of the support frame 1, and a starter is provided on the right side of the control pan...

Embodiment 2

[0045] On the basis of Embodiment 1, a conversion mechanism 11 is also included, and the conversion mechanism 11 includes a second limit rod 110, a tension spring 111, a second rotating shaft 112, a reel 113, a pull cord 114, a second Connecting block 115, second electric push rod 116, control switch 117 and second pressure sensor 118, refer to figure 1 , Figure 11 and Figure 12 As shown, the front and rear sides of the lower part of the inner side of the support frame 1 are symmetrically provided with a second limiting rod 110, and the upper side of the second limiting rod 110 is slidably connected with the sliding frame 96 on the same side, and the left and right sides of the sliding frame 96 bottom Tension springs 111 are arranged between the side and the second limit rod 110 on the same side, and the front and rear sides of the inner lower part of the support frame 1 are symmetrically rotated left and right to be provided with a second rotating shaft 112, and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com