Multi-station crimping equipment and crimping method

A crimping equipment, multi-station technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of difficult to apply to different sizes of panel crimping, unable to meet product crimping at the same time, complex structure of crimping equipment, etc. Achieve the effect of improving the efficiency of crimping processing, low manufacturing cost, and ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

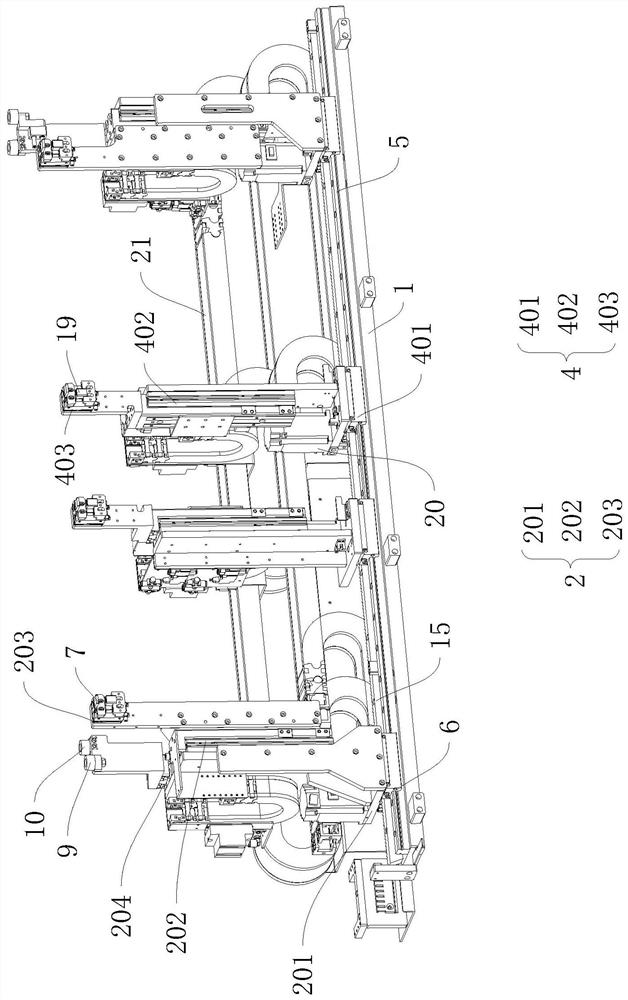

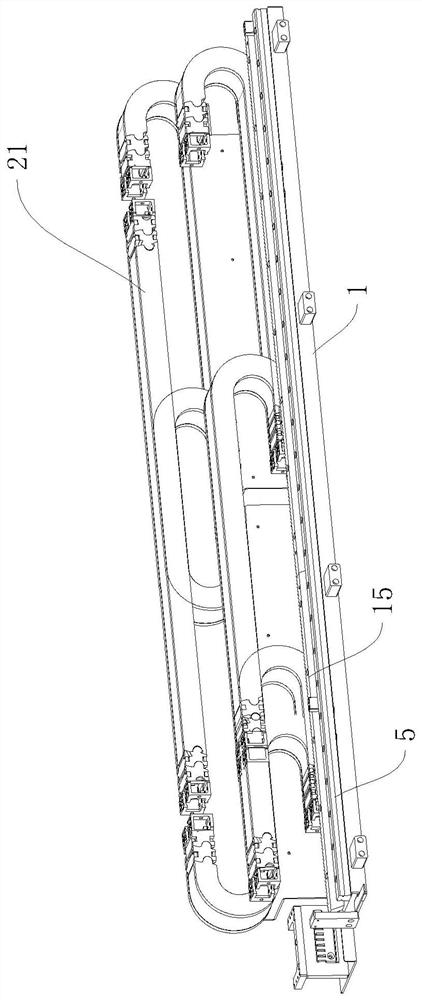

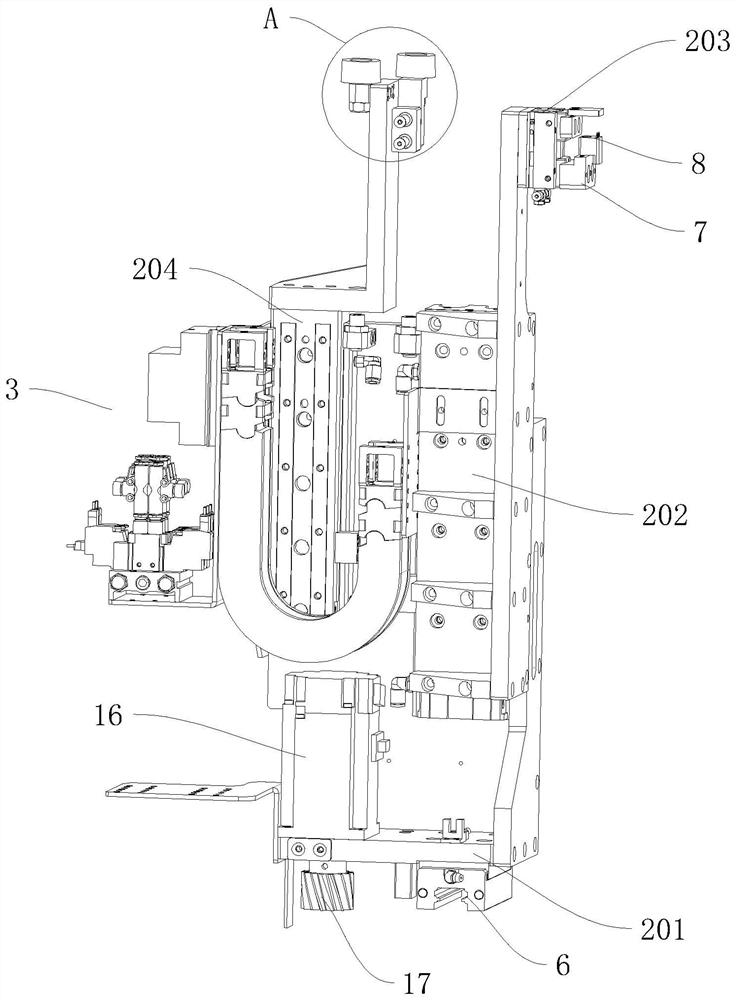

[0036] provides a multi-station crimping equipment such as figure 1 , 2 As shown in and 3 , it includes: a support plate 1 , a first crimping assembly 2 and a second crimping assembly 3 . Both the first crimping assembly 2 and the second crimping assembly 3 are slidingly connected on the support plate 1, and the first crimping assembly 2 and the second crimping assembly 3 are mirror images of each other; the first crimping assembly 2 and the second crimping assembly The crimping assembly 3 positions and crimps the workpiece along both ends of the workpiece. At the same time, an auxiliary crimping component 4 is provided between the first crimping component 2 and the second crimping component 3 . The auxiliary crimping component 4 is slidably connected to the support plate 1 and crimps the middle of the panel. There are two auxiliary crimping components 4 slidably arranged on the support plate 1 . On the side of the support plate 1 far away from the first crimping assembly 2...

Embodiment 2

[0050] Corresponding to the above-mentioned embodiments, the present application provides a crimping method based on the above-mentioned multi-station crimping equipment, the steps of which include: placing the panel to be crimped on the workbench, and driving the motor according to the size of the panel 16 Drive the gear 17 to rotate, and the gear 17 and the rack 15 mesh so that the first crimping assembly 2 and the second crimping assembly 3 move to both ends of the panel along the guide rail 5; the positioning wheel 205 on the first crimping assembly 2 moves along the panel The panel is positioned on one side of the panel, and the positioning wheel 205 on the second crimping assembly 3 is positioned on the panel along the other side of the panel; the crimping lifting cylinder 202 moves along the vertical direction, so that the jaw cylinder 203 moves to the panel The same height realizes the crimping of the crimping head 7 on the jaw cylinder 203 to the panel; at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com