Centralizing loader

A loading device and center positioning technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of one-way deformation, missing, and movement of specimens, achieve uniform force, and improve observation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

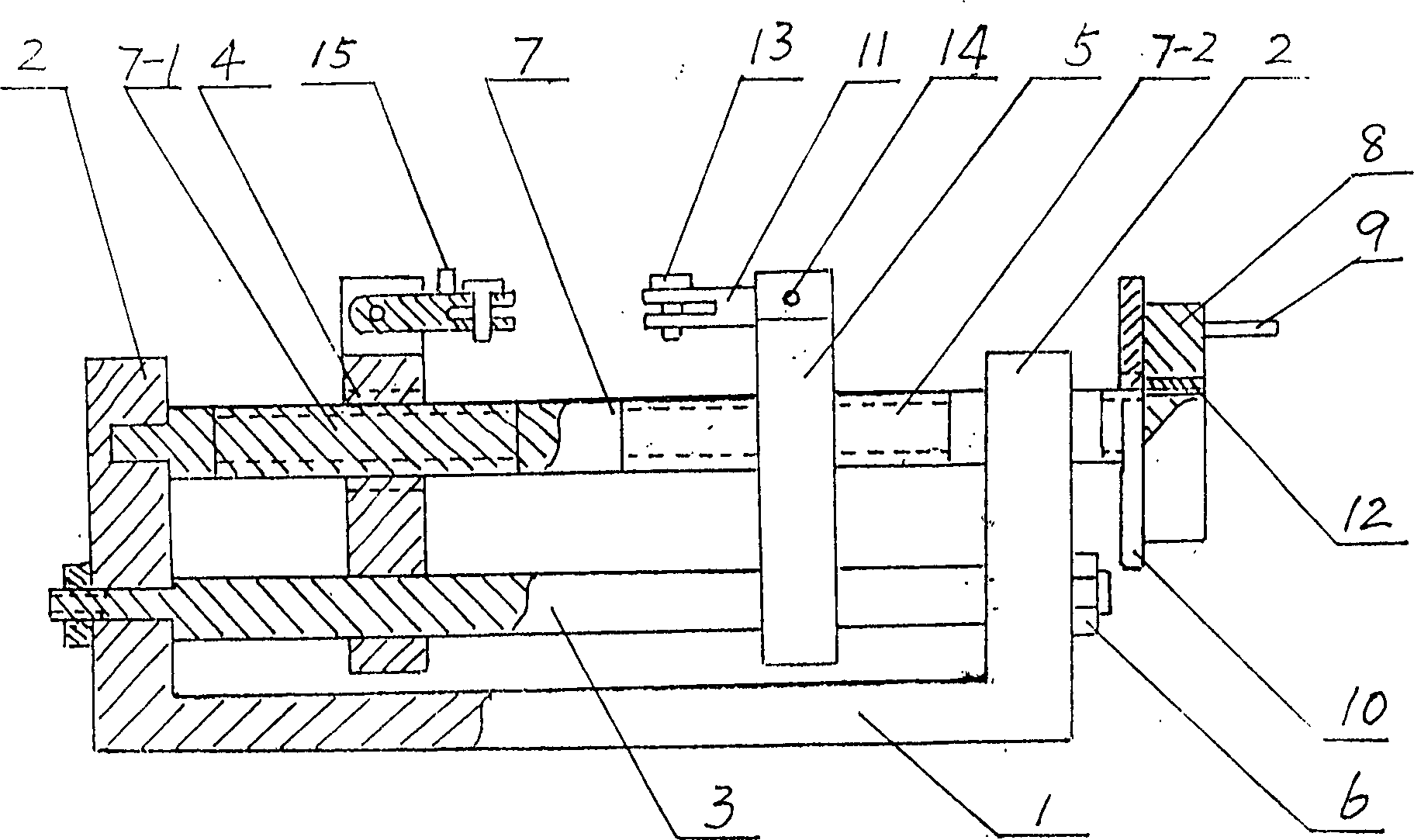

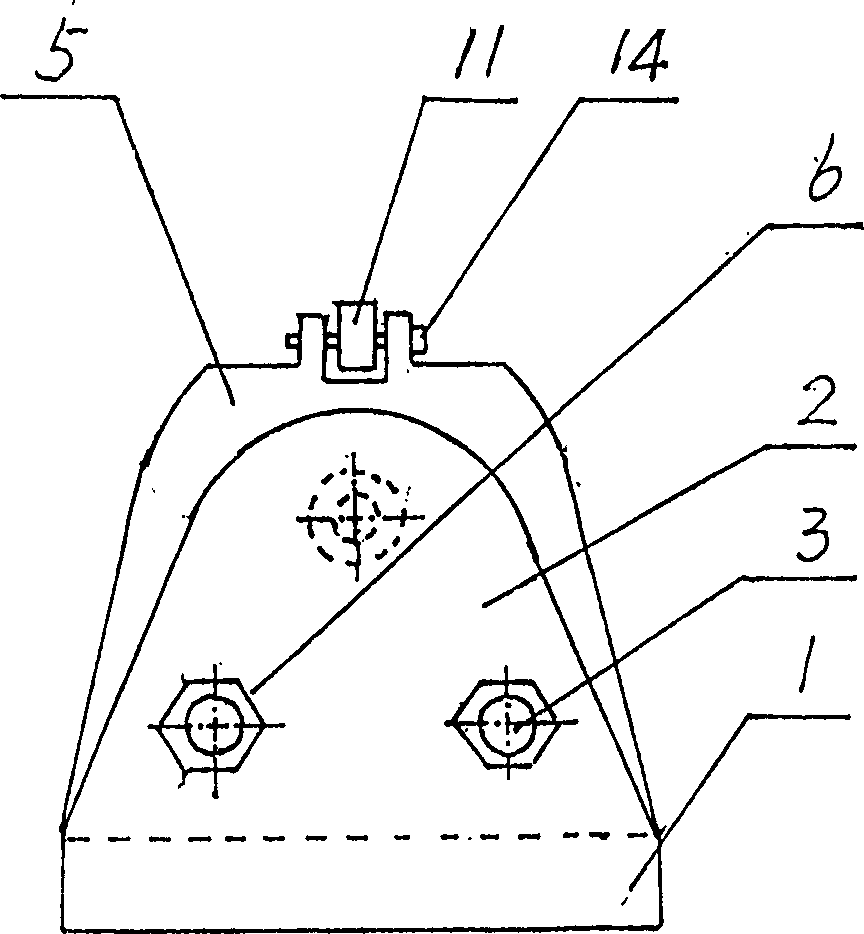

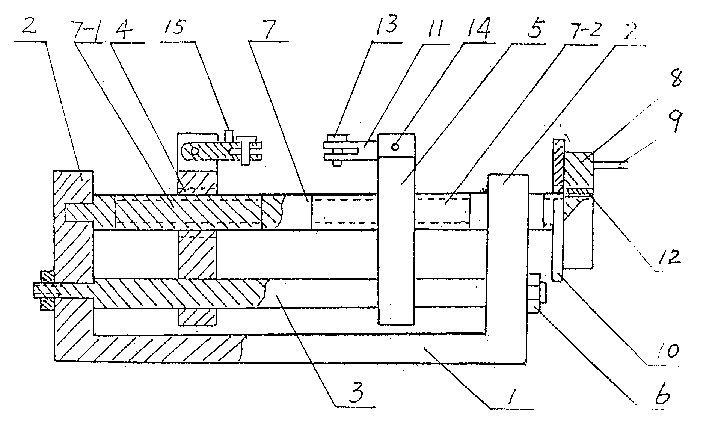

[0012] Below in conjunction with accompanying drawing, the implementation of the invention is described as follows:

[0013] exist figure 1 , figure 2 Among them, the bottom plate 1 can be made into a bar shape by using a metal plate, and its two ends can be made of a thick metal plate by welding or fastening with screws to form a fixing seat 2, and the fixing seat 2 can be made into an isosceles triangle, which increases the device's stability. Structural rigidity. The fixing seat 2 can also be made into one body with the base plate 1 . The bottom of the fixed seat 2 is provided with two through holes, equipped with two guide rods 3; the structure of the fixed ball bearing 4 and the two guide rods 3 is arranged as an isosceles triangle (three-axis center) from the end face, increasing the device Rigidity and stability; the two ends of guide rod 3 are respectively provided with shaft diameter and screw thread, device is in the through hole that the bottom of two holders 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com