A kind of pH response type tannic acid/chitosan nanocapsule and preparation method thereof

A technology of chitosan nano and tannic acid, applied in the field of medicine, can solve the problems of limiting the application of microcapsule wall materials, high cost, cumbersome synthesis steps, etc., achieve good economic development potential, low manufacturing cost, and simple preparation technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 0.15g of cetyltrimethylammonium bromide, dissolve it in 40mL of deionized water, stir in a water bath at 50°C for 15min, and obtain cetyltrimethylammonium bromide with a concentration of 3.75mg / mL Ammonium Micellar Solution.

[0031] (2) Weigh 50 mg of tannic acid and dissolve it in 50 mL of aqueous solution (containing 50 μL of acetic acid in the aqueous solution) to obtain an aqueous solution of acetic acid containing tannic acid at a concentration of 1 mg / mL; Aqueous solution of sugar in acetic acid. Measure 5 mL of acetic acid aqueous solution containing tannic acid and add it to 5 mL of cetyltrimethylammonium bromide micellar solution, and stir for 20 min, so that the surface of the micelles is coated with tannic acid; The acetic acid aqueous solution of the polysaccharide was added to the above solution, and stirred for 20 minutes, so that the surface of the tannic acid was covered with chitosan again, and the tannic acid / chitosan nanocapsules with a co...

Embodiment 2

[0033] (1) Weigh 0.15g of cetyltrimethylammonium bromide, dissolve it in 40mL of deionized water, stir in a water bath at 50°C for 15min, and obtain cetyltrimethylammonium bromide with a concentration of 3.75mg / mL Ammonium Micellar Solution.

[0034] (2) Weigh 150 mg of tannic acid and dissolve it in 50 mL of aqueous solution (containing 150 μL of acetic acid in the aqueous solution) to obtain an aqueous solution of acetic acid containing tannic acid at a concentration of 3 mg / mL; Aqueous solution of sugar in acetic acid. Measure 5 mL of acetic acid aqueous solution containing tannic acid and add it to 5 mL of cetyltrimethylammonium bromide micellar solution, and stir for 20 min, so that the surface of the micelles is coated with tannic acid; The acetic acid aqueous solution of the polysaccharide was added to the above solution, and stirred for 20 minutes, so that the surface of the tannic acid was covered with chitosan again, and the tannic acid / chitosan nanocapsules with a ...

Embodiment 3

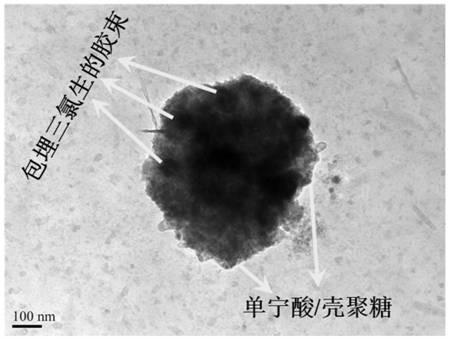

[0036] Taking triclosan as an example, prepare drug-embedded tannic acid / chitosan nanocapsules:

[0037] (1) Weigh 0.15g of cetyltrimethylammonium bromide, dissolve it in 40mL of deionized water, stir in a water bath at 50°C for 15min, and obtain cetyltrimethylammonium bromide with a concentration of 3.75mg / mL Ammonium Micellar Solution.

[0038] (2) Weigh 4g of triclosan, dissolve it in 50mL of dichloromethane, and prepare a 20mg / mL mother solution, take 200μL of the mother solution and add it to 40mL of cetyltrimethylammonium bromide micellar solution, and ultrasonicate for 60min. Stir overnight to volatilize the dichloromethane to obtain a triclosan-embedded hexadecyltrimethylammonium bromide micellar solution.

[0039] (3) Weigh 50 mg of tannic acid and dissolve it in 50 mL of aqueous solution (containing 50 μL of acetic acid in the aqueous solution) to obtain an aqueous solution of acetic acid containing tannic acid at a concentration of 1 mg / mL; Aqueous solution of sug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface potential | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com