Circuit breaker

A circuit breaker and arc extinguishing chamber technology, applied in the field of circuit breakers, can solve the problem that the output shaft of the mechanism and the crank arm rotating shaft of the arc extinguishing chamber cannot be connected in a transmission manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

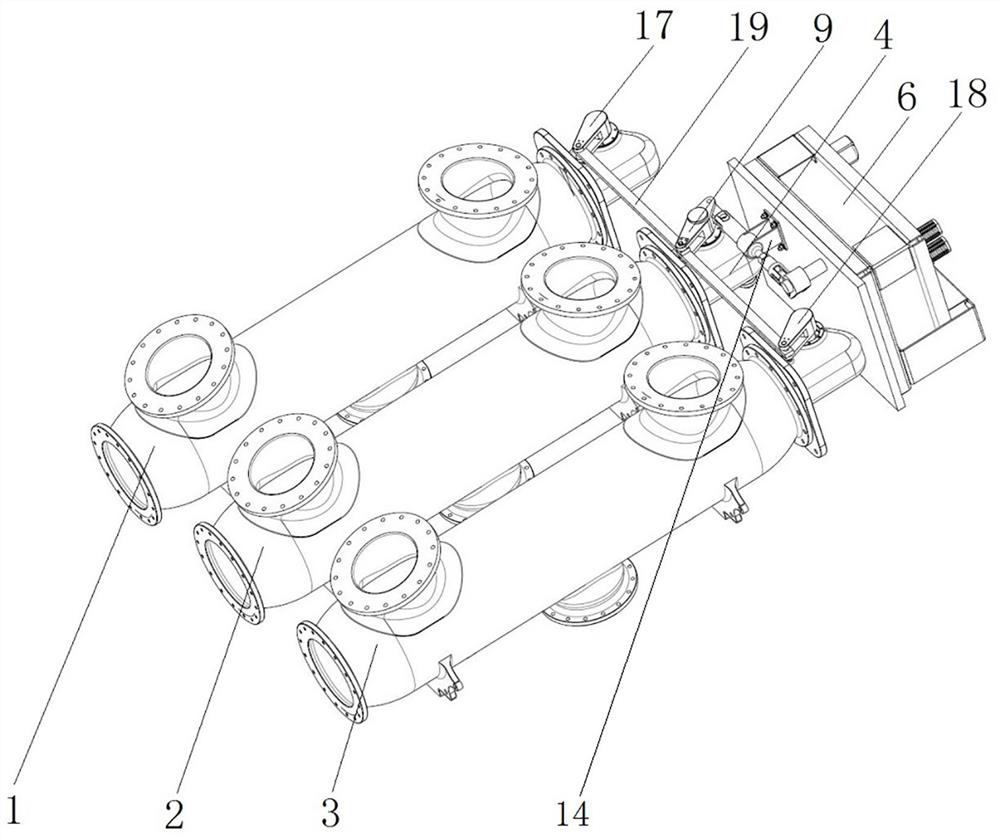

[0040] The structure of the circuit breaker provided in this embodiment is as follows figure 1 As shown in the figure, it includes A-phase arc-extinguishing chamber 1, B-phase arc-extinguishing chamber 2 and C-phase arc-extinguishing chamber 3. In order to drive the arc-extinguishing chamber to perform opening and closing actions, the end of each phase arc-extinguishing chamber is also provided with a driving mechanism, which drives the arc-extinguishing chamber. The mechanism is connected with the rod of the corresponding arc extinguishing chamber, so as to drive the rod action of the arc extinguishing chamber through the action of the driving mechanism, so as to realize the opening and closing of the arc extinguishing chamber, and then realize the opening and closing of the circuit breaker.

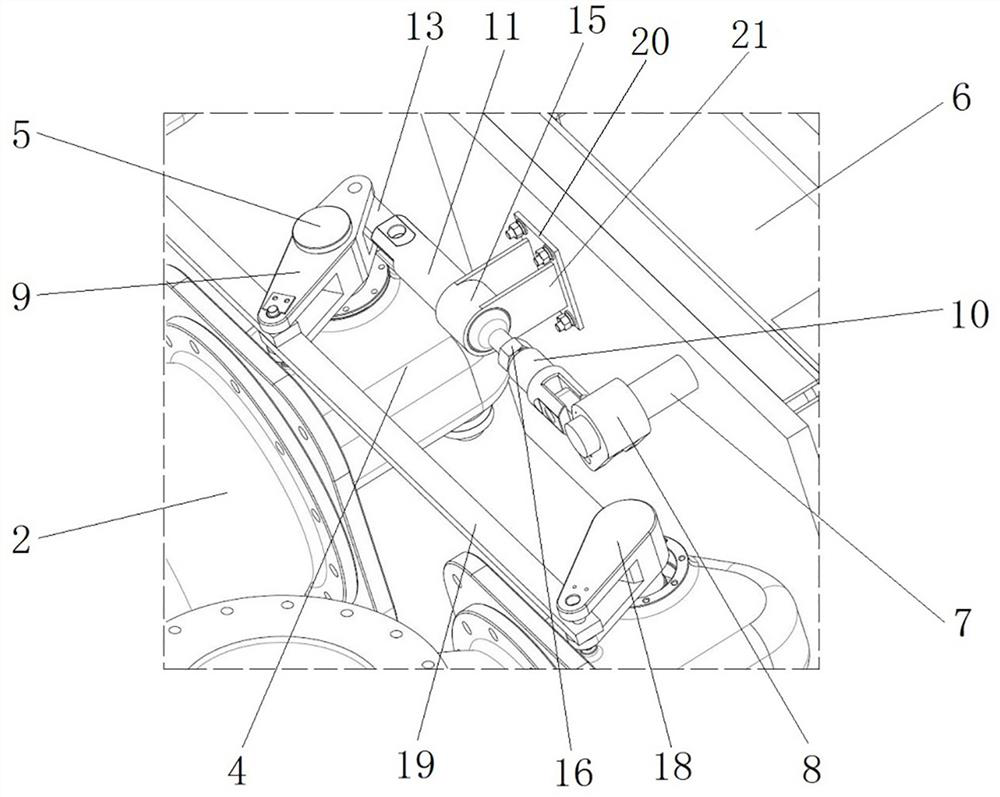

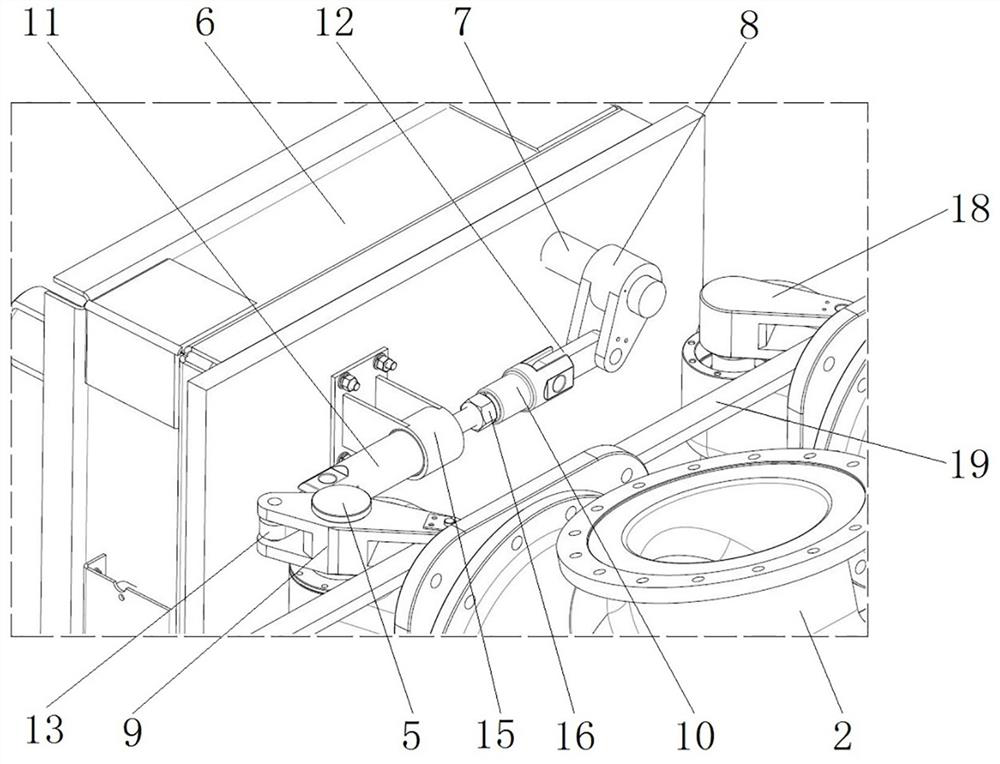

[0041] Specifically, taking the B-phase arc-extinguishing chamber 2 as an example, its driving mechanism includes a hinged arm box 4 and a hinged arm rotating shaft 5 arranged at the end...

specific Embodiment 2

[0050] The specific embodiment 2 of the circuit breaker provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the sliding member and the guide seat are fitted by a socket. In this embodiment, for the guiding and matching manner of the guide seat and the sliding member, a guide groove is provided on one of the guide seat and the sliding member, and a sliding block matched with the guide groove is provided on the other one.

specific Embodiment 3

[0051] The specific embodiment 3 of the circuit breaker provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the guide seat is fixed on the housing of the operating mechanism. In this embodiment, the guide seat is fixed on the arc extinguishing chamber. Of course, in other embodiments, a mounting base independent of the arc extinguishing chamber and the operating mechanism may also be provided to fix the guide seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com