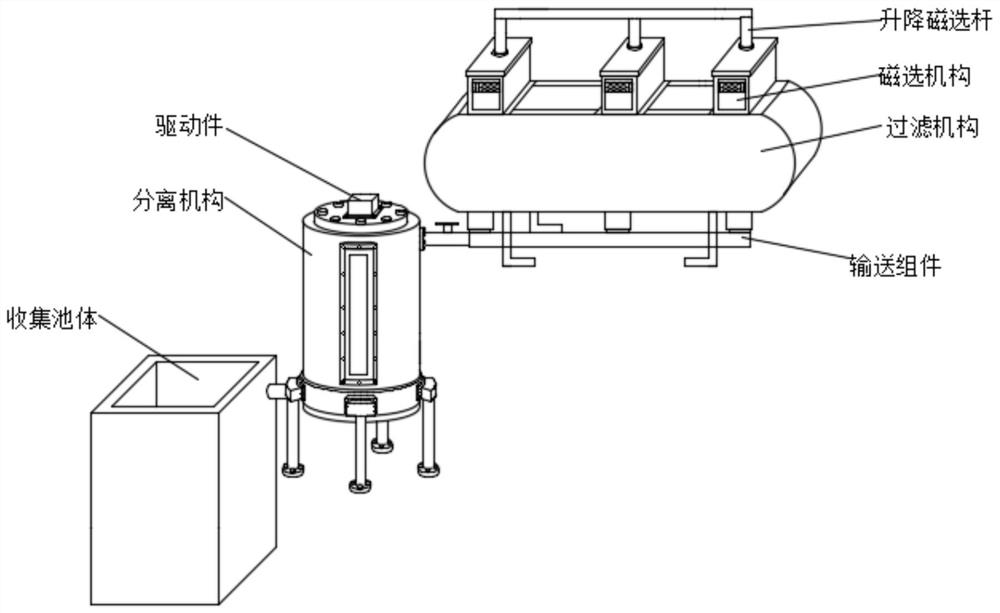

High-efficiency sewage treatment device

A sewage treatment device and high-efficiency technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, filtration treatment, etc., which can solve the problem of reducing the possibility of metal-rich water bodies and unfavorable efficient sewage treatment operations. and other problems to achieve the effect of ensuring conveying efficiency, facilitating separation, and ensuring contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

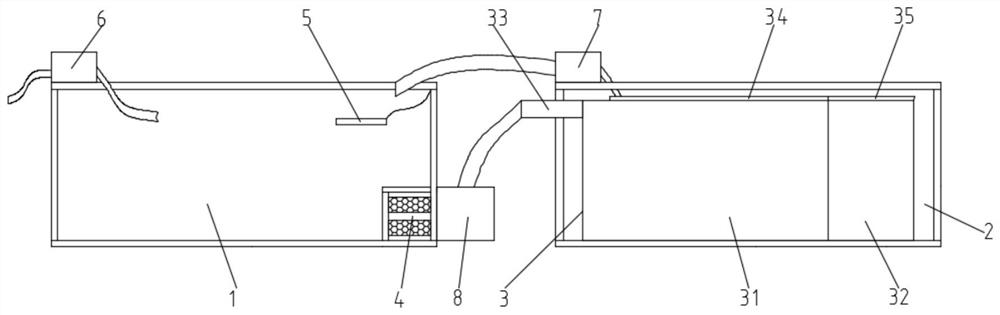

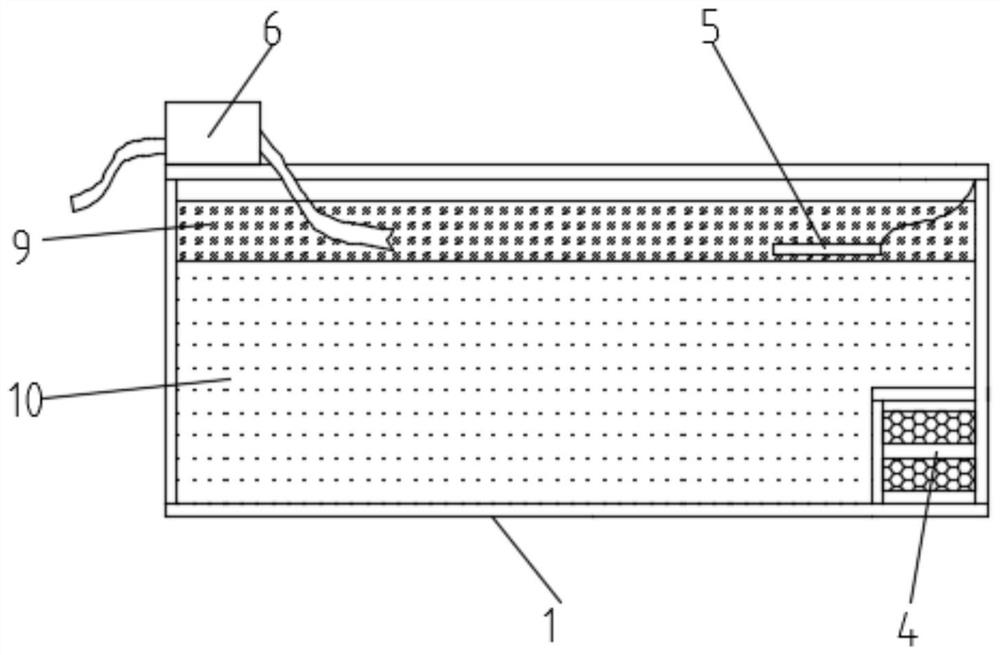

[0030] see figure 2 As shown, in the present invention, the inside of the oil-water separation box 1 is provided with an indicator circle 5, and an elastic pull cord is connected between the indicator circle 5 and the top inner wall of the oil-water separation box 1, wherein the density of the indicator circle 5 is greater than that of the oil-water separation box 1. density of the oil body 9, and the density of the indicator circle 5 is less than that of the water body 10, under the action of the elastic pull cord and the physical property factors of the indicator circle 5 itself, the indicator circle 5 sinks inside the oil body 9, and finally floats in the oil body 9. On the interface between body 9 and water body 10, start pump body one 6 again, when the oil body 9 that is positioned at the upper end of water body 10 is pumped out by the pump body one 6 that is provided with, indicator ring 5 will finally float on water body 10, by observing indication The floating conditi...

Embodiment 2

[0032] see figure 2 As shown, in the present invention, one side inner wall of the oil-water separation box 1 is provided with a first-level separation block 4, and a filter tank is provided on the outer surface of the first-level separation block 4, and a filter plate is clamped inside the filter tank, and the filter plate There are several filter holes arranged in a rectangular array on the top, and the inside of the first-level separation block 4 is provided with a cavity, and the whole is a hollow structure, that is, the front, rear and upper ends of the first-level separation block 4 are not separated from oil and water. A filter tank is provided on one side of the box body 1 where the inner wall is attached to one end shell, and the first-stage separation block 4 is provided to perform a first-stage filtration operation on the sewage, specifically, to remove the fixed residue with a particle size larger than the filter hole. For interception, the fixed residues that can...

Embodiment 3

[0034] see image 3 - Figure 6 As shown, in the present invention, the separation mechanism includes a solid-liquid separation box 3, and the solid-liquid separation box 3 is composed of a filter box 31 and a buffer box 32 clamped on one side of the filter box 31, and the filter box 31 The other side of the filter box 31 is equipped with a liquid inlet pipe 33, one end of the liquid inlet pipe 33 penetrates to the outside of the collection box 2 and is connected with the output end of the pump body 6, and the upper end of the filter box 31 is fixed with a cover plate 34 by bolts , the upper end of the buffer box 32 is fixed with a cover plate 2 35 by bolts, and the inside of the filter box 31 is provided with several secondary separation blocks 39 arranged equidistantly. In the present invention, the inside of the filter box 31 is provided with There is a buffer plate 38 positioned at one side of the secondary separation block 39, and the inside of the filter box body 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com