High-nitrogen austenitic stainless steel with post-welding intergranular corrosion resistance and pitting corrosion resistance superior to 316L and manufacturing method of high-nitrogen austenitic stainless steel

A high nitrogen austenite, intergranular corrosion technology, applied in the direction of manufacturing tools, metal rolling, heat treatment process control, etc., can solve the problems of high production cost, unable to reach 316L grade pitting corrosion resistance, long production cycle, etc. To achieve the effect of reducing the rate of intergranular corrosion after welding, reducing the sensitivity of intergranular corrosion, and reducing the rate of intergranular corrosion

Active Publication Date: 2022-03-29

福建青拓特钢技术研究有限公司

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This invention requires long-term heat preservation at 880-950°C to diffuse the intragranular Cr atoms to the grain boundaries, and the production efficiency is slow. Although the sensitivity to intergranular corrosion of 316L is reduced and the performance of intergranular corrosion resistance is improved, the production efficiency is reduced and the fuel is burnt. higher consumption, higher production cost

[0010] Chinese patent CN112458367A discloses "a high-strength intergranular corrosion-resistant twinning-induced plastic austenitic stainless steel", which improves the intergranular corrosion resistance by reducing the C content in stainless steel, but fails to make full use of the C element to expand the austenite phase region and improve The beneficial effect of Ni

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Login to View More

Abstract

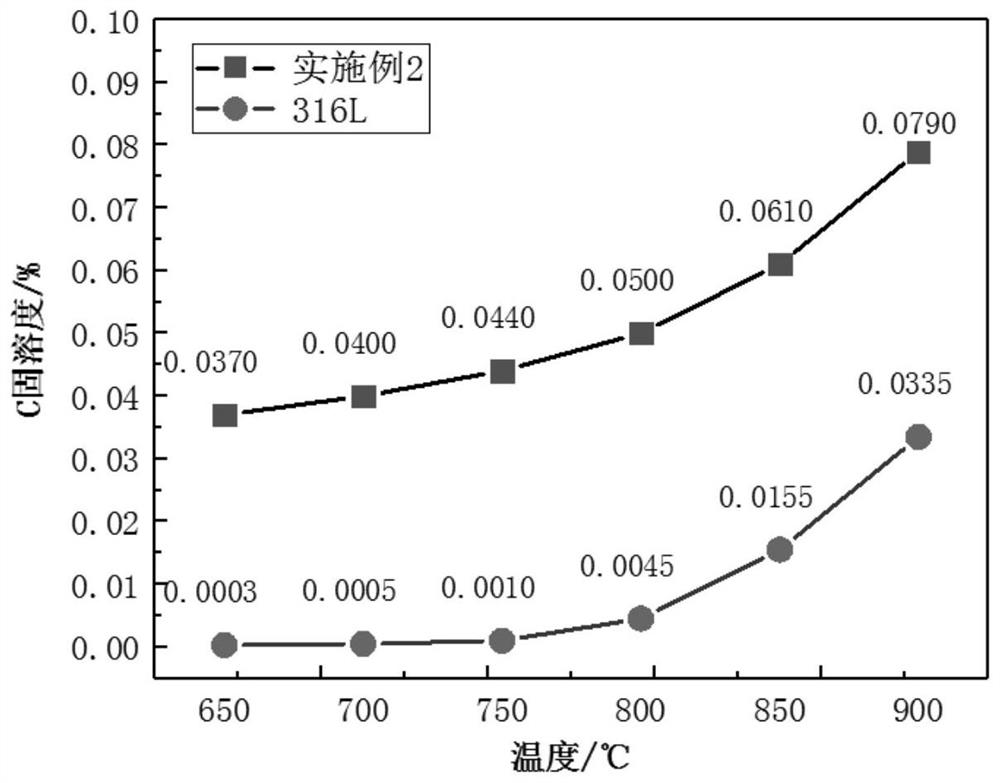

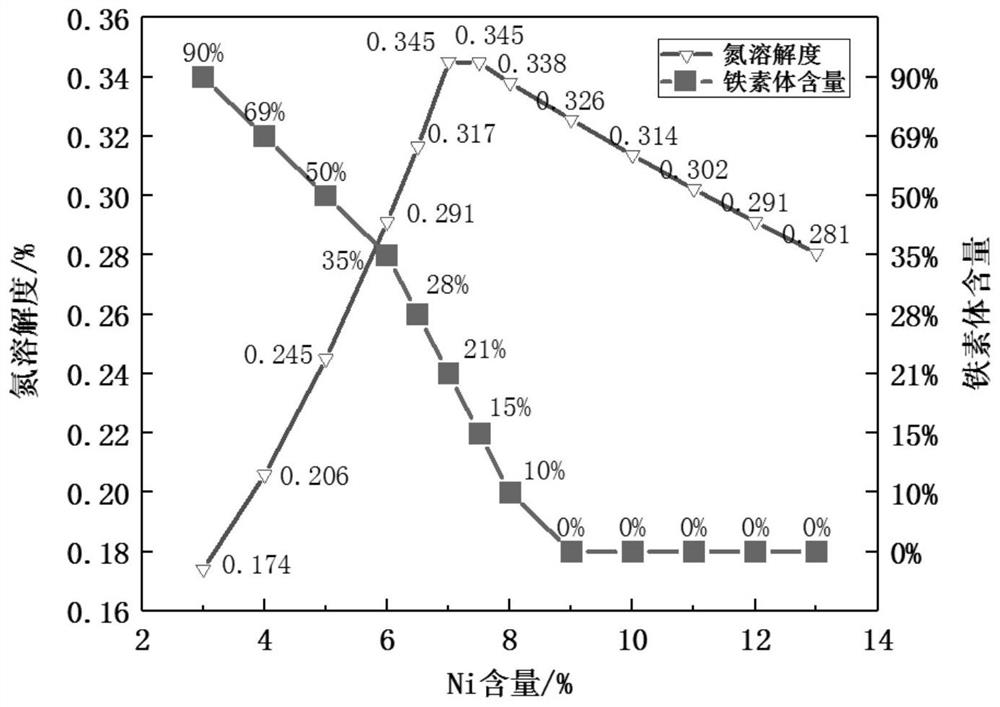

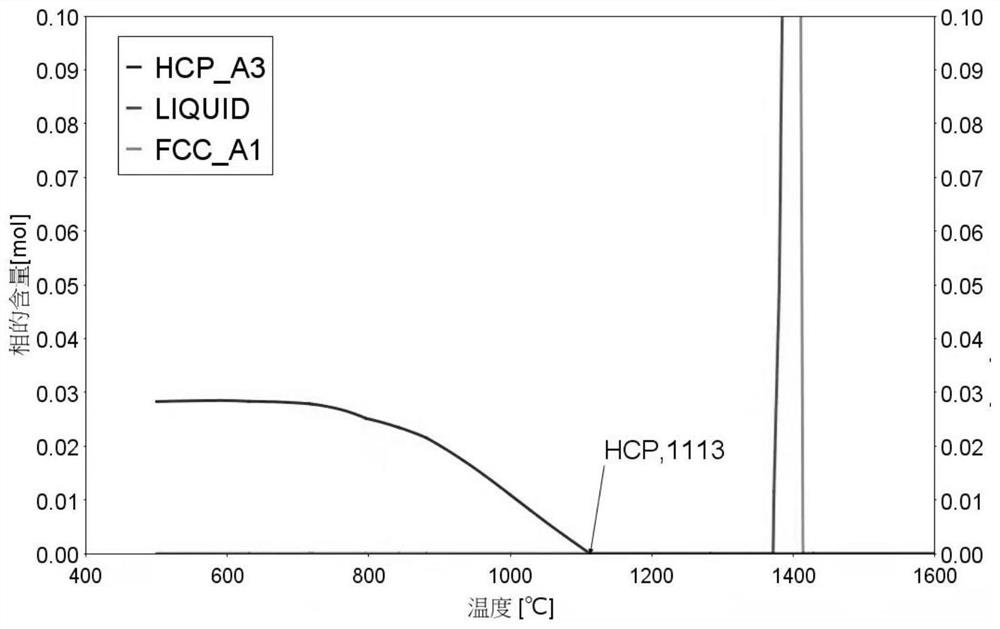

The invention discloses high-nitrogen austenitic stainless steel with intergranular corrosion resistance and pitting corrosion resistance superior to 316L after welding and a manufacturing method thereof. The high-nitrogen austenitic stainless steel comprises the following chemical components in percentage by mass: 0.03-0.06% of C, 0.25-0.80% of Si, 2.6-5.0% of Mn, 20.0-22.0% of Cr, 6.0-7.0% of Ni, 0.5-2.0% of Cu, less than or equal to 1.0% of Mo, less than or equal to 0.07% of V, less than or equal to 0.045% of P, less than or equal to 0.0020% of S, 0.2-0.3% of N and the balance of Fe and inevitable impurities. The C solid solubility concept is put forward for the first time, the C solid solubility of the material is improved, the C content is controlled to be smaller than the C solid solubility, Cr23C6 is prevented from being separated out in the welding process of the material, the intergranular corrosion resistance of the material after welding is improved, meanwhile, the pitting corrosion resistance equivalent PREN is controlled to be larger than or equal to 24.0, and the pitting corrosion resistance of the material is improved. Furthermore, an N solubility concept is provided, the N content is controlled to be smaller than the N solubility, the HCP phase precipitation temperature is controlled to be smaller than or equal to 1080 DEG C, the steel coil with good edge and surface quality is obtained, and the problem that corrosion resistance is reduced due to product surface defects is solved.

Description

technical field [0001] The invention relates to austenitic stainless steel and a manufacturing method thereof, in particular to a high-nitrogen austenitic stainless steel with better intergranular corrosion and pitting resistance after welding than 316L and a manufacturing method thereof. Background technique [0002] Intergranular corrosion is one of the main forms of corrosion in austenitic stainless steel. When austenitic stainless steel is heated to 450-850 °C and kept for a period of time, the supersaturated solid solution carbon diffuses to the grain boundary and combines with chromium near the grain boundary to form interstitial carbide Cr 23 C 6 And it precipitates at the grain boundary, resulting in the decrease of the chromium content at the grain boundary. Under the action of acidic medium, the grain boundary dissolves rapidly and continues to deepen, and the bonding force between the grains is lost, so that the matrix loses its corrosion resistance. Usually, in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/02C22C38/58C22C38/42C22C38/44C22C38/46C22C33/04B22D11/18B22D11/22C21D8/02C21D1/26C21D11/00B21B1/46

CPCC22C38/02C22C38/58C22C38/42C22C38/44C22C38/46C22C38/001C22C33/04B22D11/002B22D11/18B22D11/22C21D8/0205C21D8/0226C21D8/0236C21D8/0247C21D1/26C21D11/00B21B1/463C21D2211/001

Inventor 孔庆毛石显云江来珠姜美雪杨成周庆龙蒋一

Owner 福建青拓特钢技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com