Patents

Literature

51results about How to "Increase N content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed for weaned piglet

ActiveCN1810147AMaintain nutritional balanceNutritional balance meetsAnimal feeding stuffAccessory food factorsAntioxidantFodder

The feed for weaned piglet contains vitamin additive 0.2-3 weight portions, trace mineral element additive 2-20 weight portions, enzyme preparation 0.2-5 weight portions, antioxidant 1-3 weight portions, amino acid additive 5-70 weight portions, growth promoter 1-20 weight portions, acid preparation 10-100, seasoning 5-60 weight portions, enzymolyzed protein 50-700 weight portions and feed carrier 80-150 weight portions. It is puffed to form puffed feed. It is superior to available feed for weaned piglet, which results in diarrhea and weight loss of weaned piglet, and is environment friendly.

Owner:北京劲能生物科技股份公司

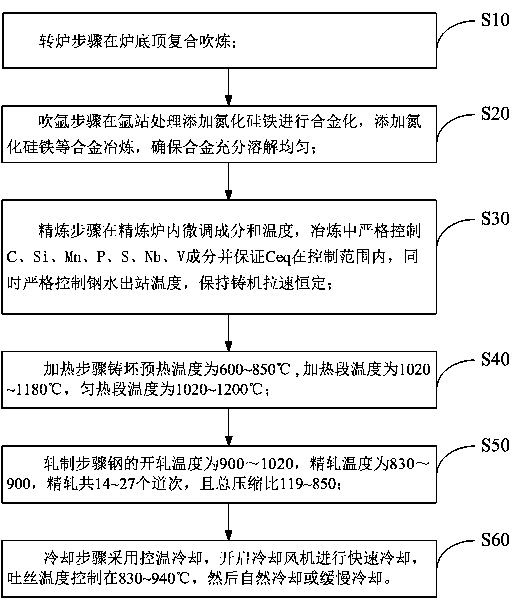

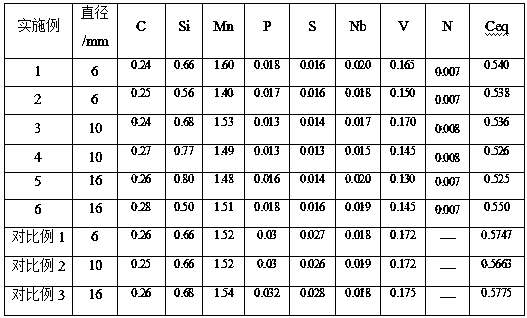

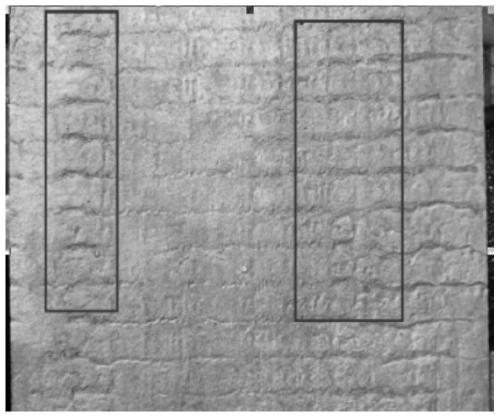

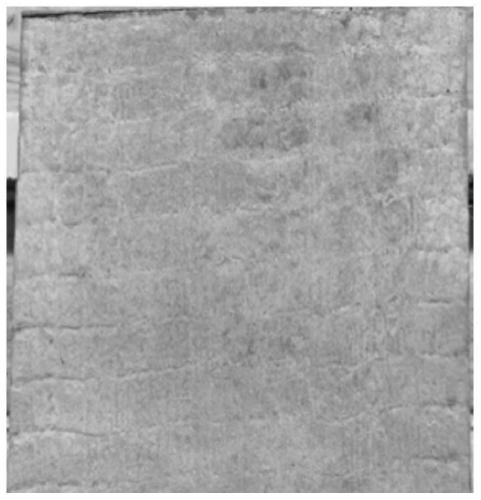

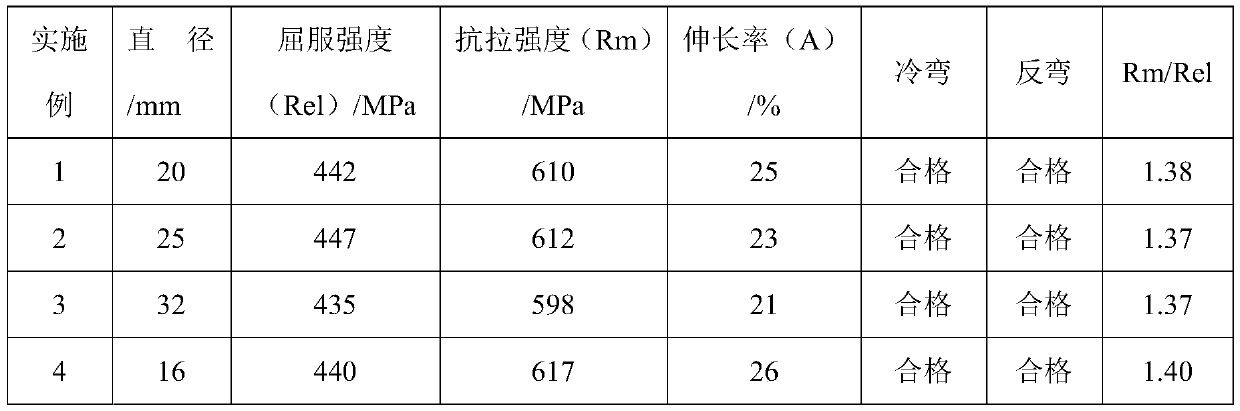

HRB600 high-strength hot-rolling ribbed reinforcing bars with added ferro-silicon nitride and manufacturing method thereof

The invention discloses an HRB600 high-strength hot-rolling ribbed reinforcing bars with added ferro-silicon nitride and a manufacturing method thereof. Components of the reinforcing bars comprise C,Si, Mn, P, S, Nb, V and the balance of Fe and impurities; the contents of the component elements simultaneously meet the condition that the carbon equivalent Ceq equaling to C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15 is less than or equal to 0.58 percent. The manufacturing method comprises the following steps: performing treatment on the added ferro-silicon nitride on an argon station and performing alloying,wherein the added ferro-silicon nitride is more easily bonded with N in steel because the affinity of V and N is greater than the affinity of V and C, so that VN is formed; and after the ferro-siliconnitride is added, a large quantity of V is separated out, so that VN and VC alloys are formed, and thus, precipitation and strengthening effects of the V and a crystal grain thinning effect are improved. According to the hot-rolling ribbed reinforcing bars provided by the invention, the ferro-silicon nitride is added in molten steel, and the VN alloy is replaced by a part of the ferro-silicon nitride, so that the use of the VN (Vanadium-Nitrogen) alloy is reduced, the cost is reduced a lot, the production processes are simple, and batch production is easily realized.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

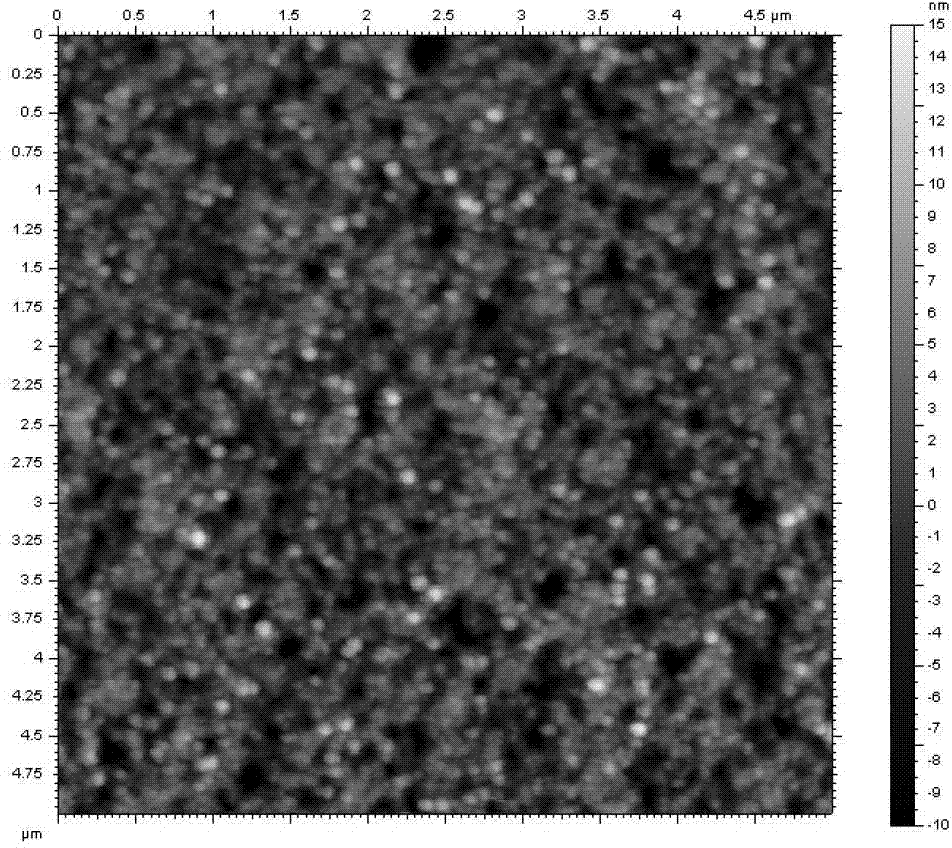

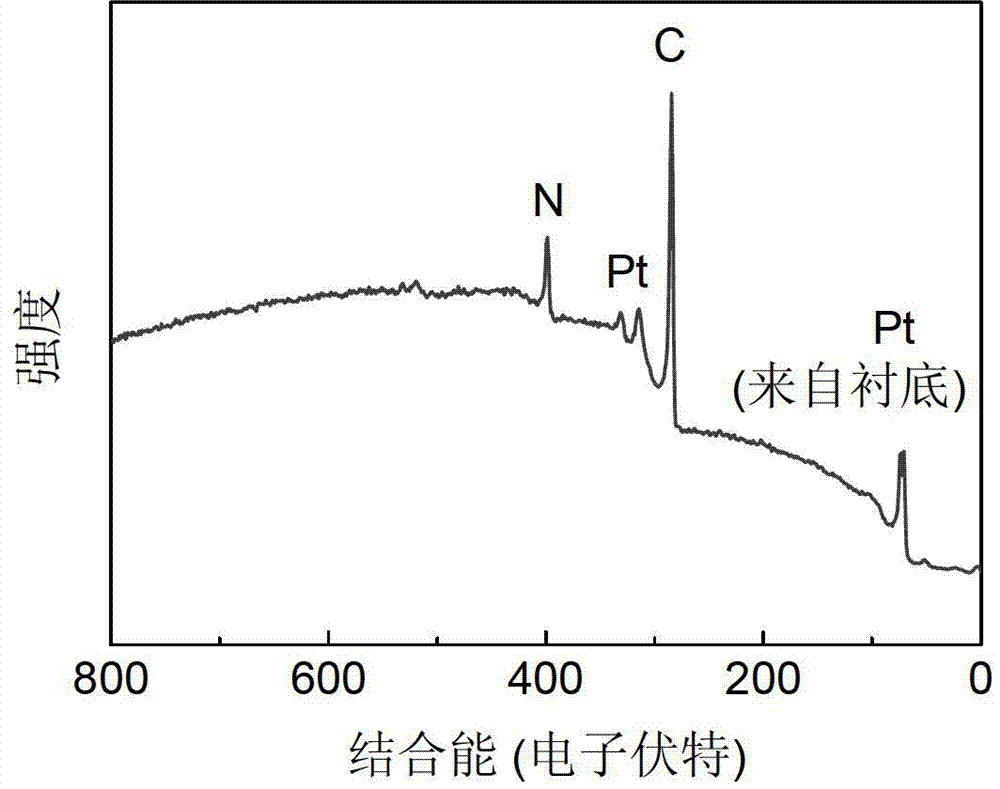

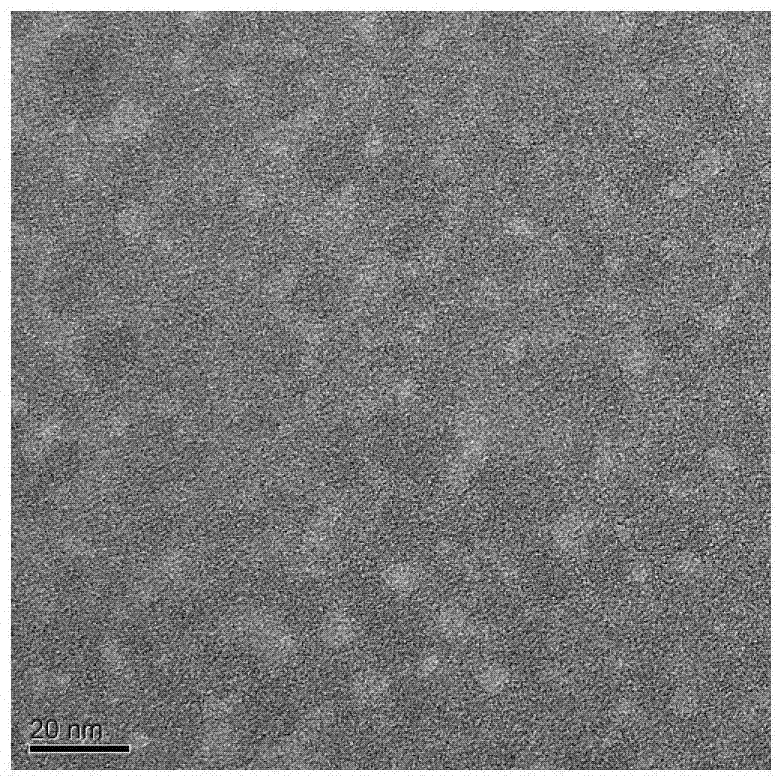

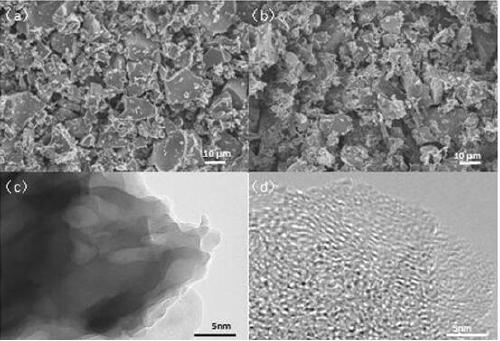

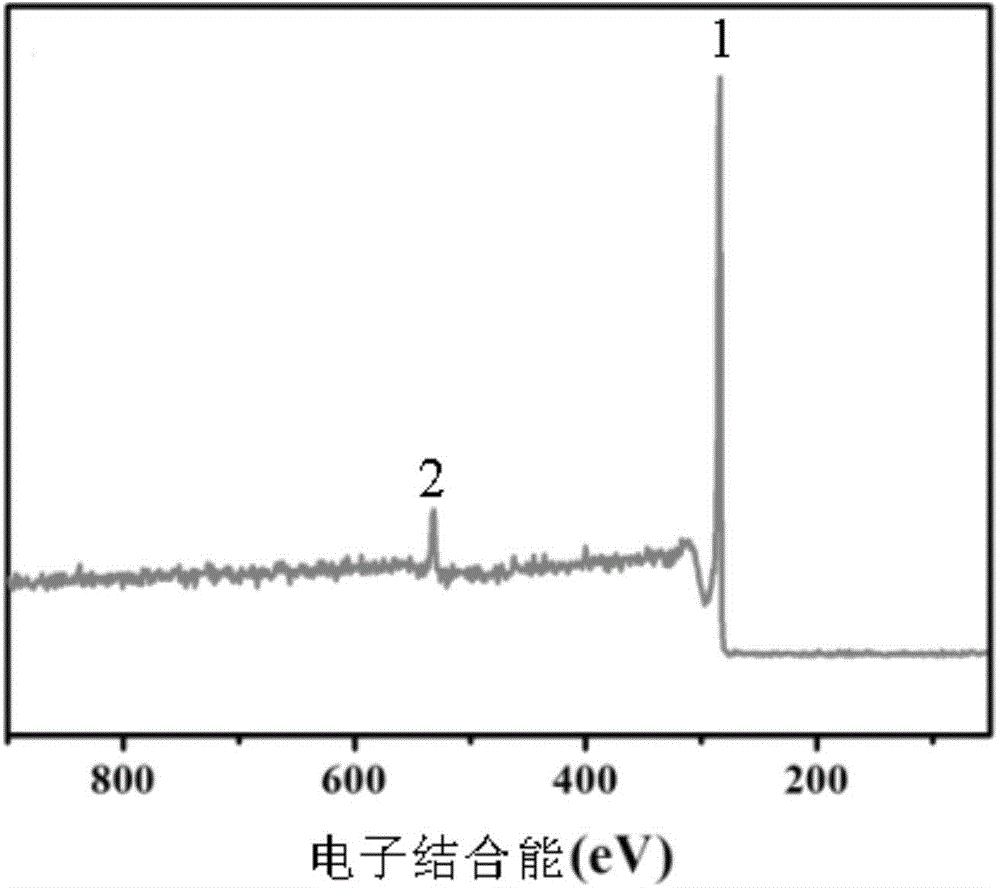

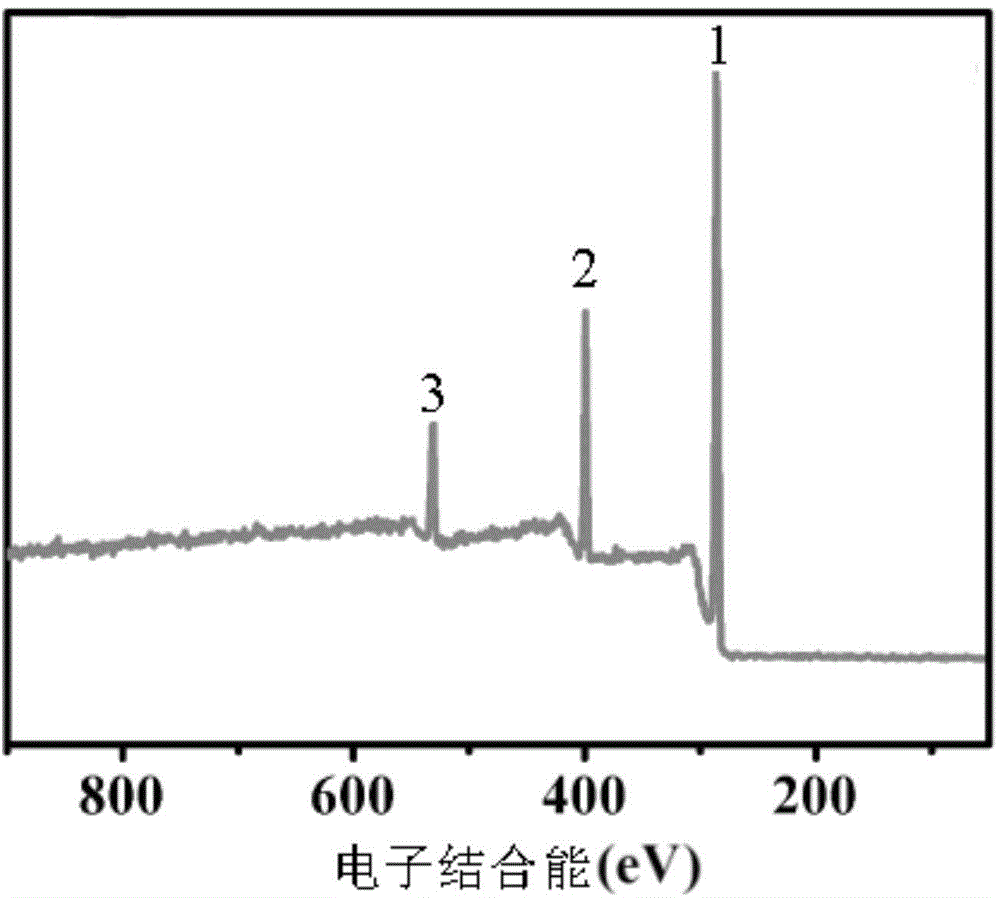

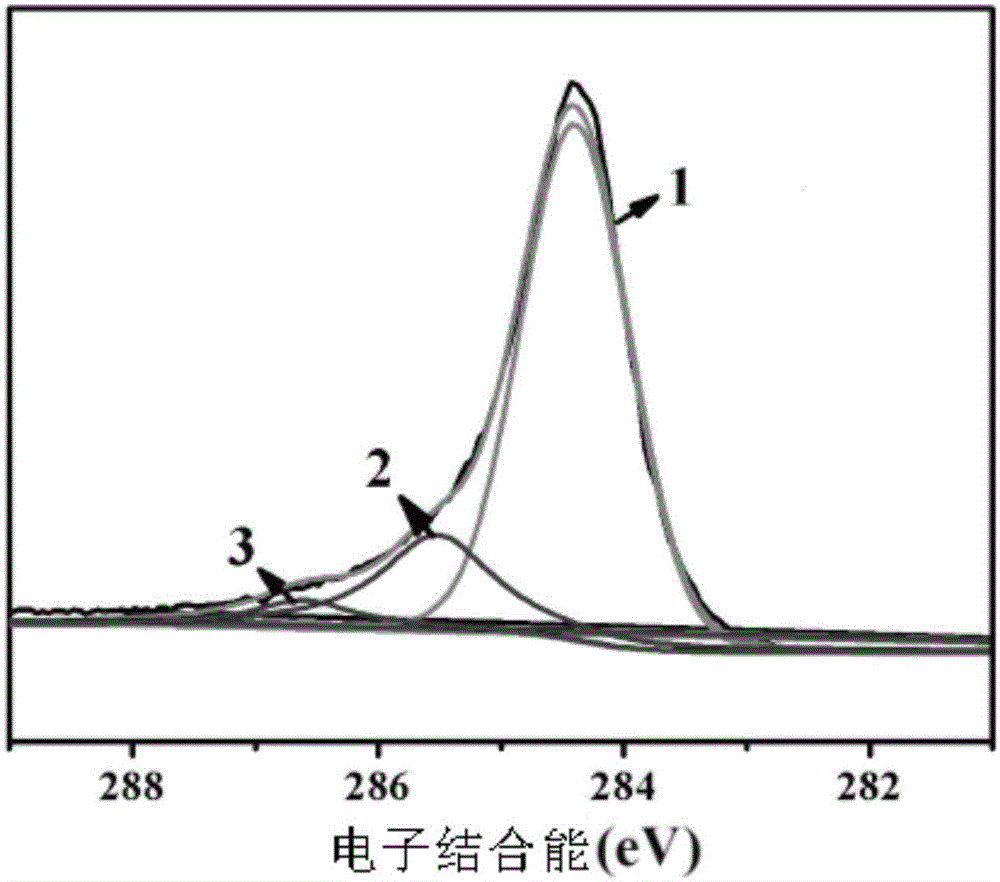

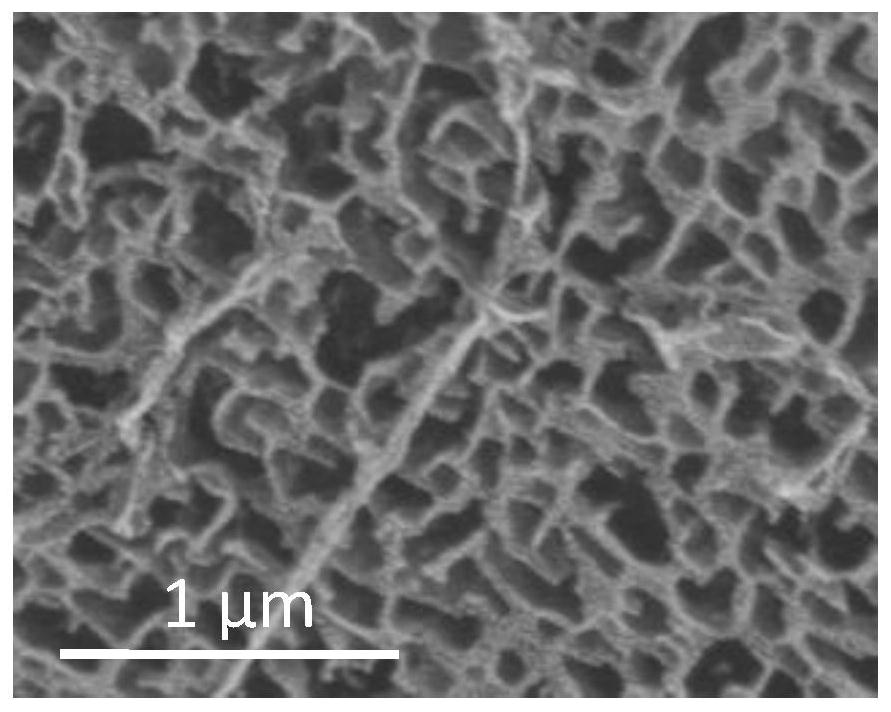

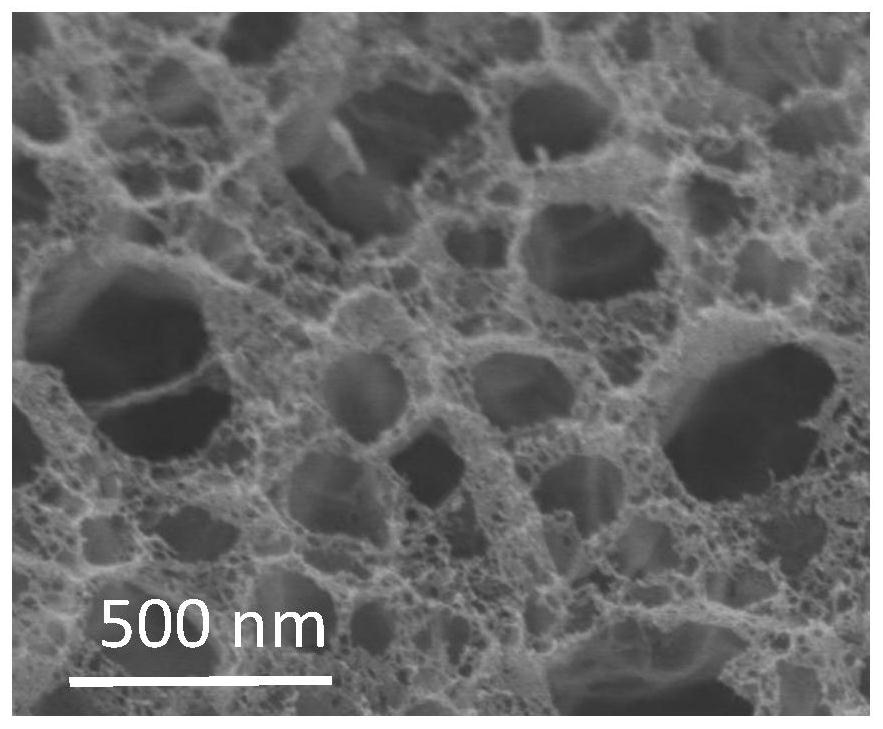

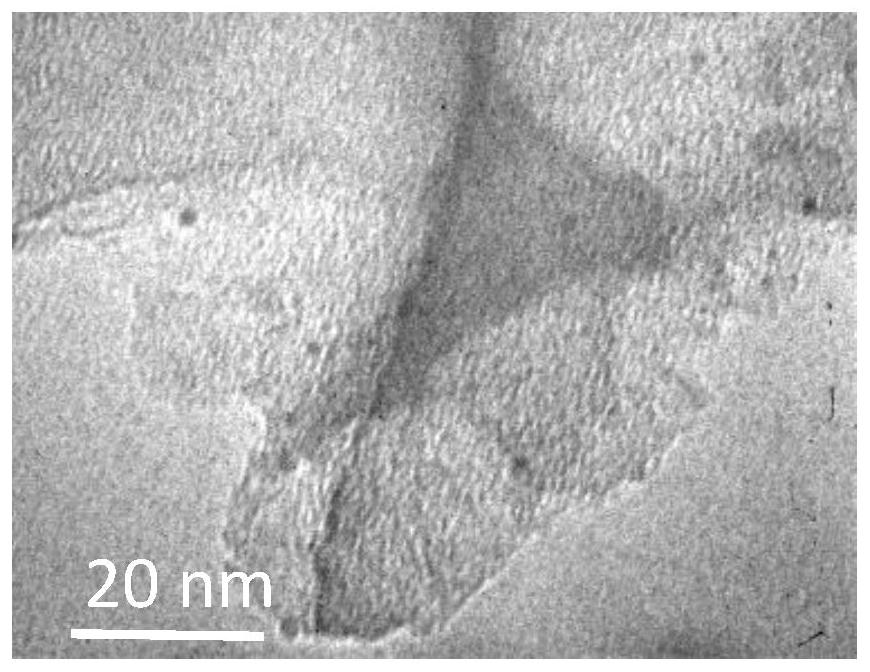

Preparation method of nitrogen-doped porous carbon film and product thereof

InactiveCN104513955ANo consumptionReduce manufacturing costVacuum evaporation coatingSputtering coatingCarbon filmSputtering

The invention discloses a preparation method of a nitrogen-doped porous carbon film and a product thereof. A magnetron sputtering method is adopted, a carbon-rich material is taken as the sputtering target material, nitrogen gas or a mixed gas of nitrogen gas and argon gas is taken as the sputtering atmosphere, a metal / inorganic semiconductor material or an inorganic insulation material is taken as the substrate to prepare a nitrogen-doped carbon film, the substrate temperature is 20 to 500 DEG C; and then the nitrogen-doped carbon film is subjected to a hot treatment for 10 seconds to 20 hours in vacuum / a nitrogen gas atmosphere / an inert atmosphere at a temperature of 300 to 1000 DEG C so as to obtain the nitrogen-doped porous carbon film material. The provided preparation method does not need a template, does not consume the organic solvent, and moreover is simple and practical. The prepared nitrogen-doped porous carbon film material has the characteristics of adjustable nitrogen content and pore size, and the nitrogen content can reach 30% at most. The thickness of the prepared nitrogen-doped porous carbon film can be as thin as several nanometers, and the nitrogen-doped porous carbon film can be produced in a large scale.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

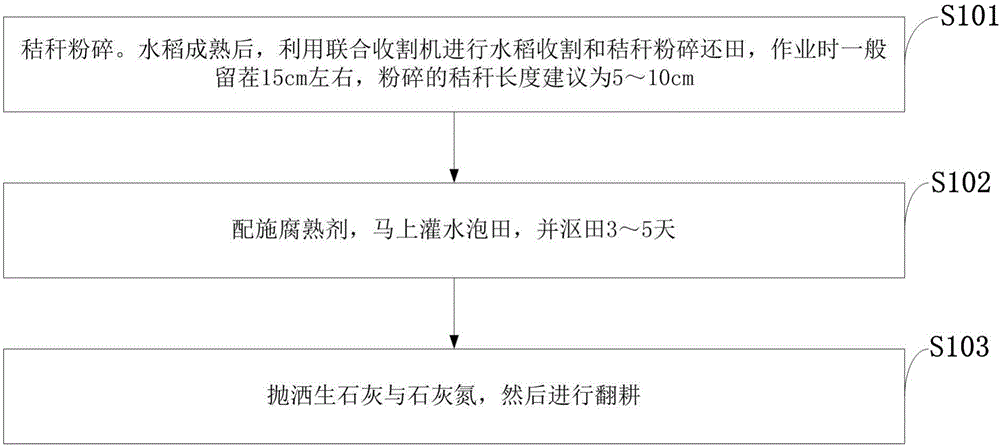

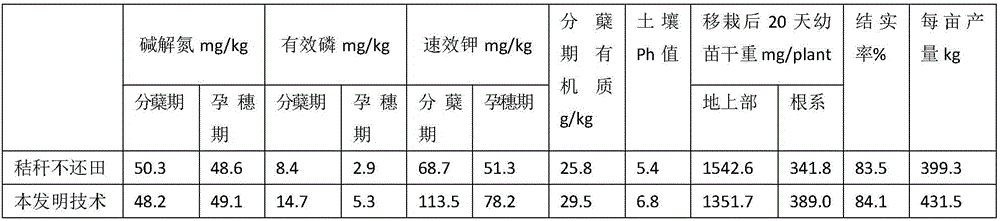

Method for disinfection and pH regulation of total straw application soil

InactiveCN106068739ARaise the pHIncrease N contentBiocideBio-organic fraction processingMicroorganismDecomposition

The invention discloses a method for disinfection and pH regulation of total straw application soil. The method for disinfection and pH regulation of the total straw application soil comprises the following step of smashing straw; after rice is ripe, utilizing a combine harvester to perform rice harvesting and straw smashing and returning to fields; performing combined application of decomposition agent and then turning over the fields; and dispersing quicklime and lime nitrogen. According to the method, the pH of the total straw application soil can be improved effectively, the straw decomposition speed is quickened, poisonous and harmful microorganisms and harmful bacteria are effectively killed, the N element content of the soil is increased, and the method is favorable for healthy growth of succession crop (late rice).

Owner:CHINA NAT RICE RES INST

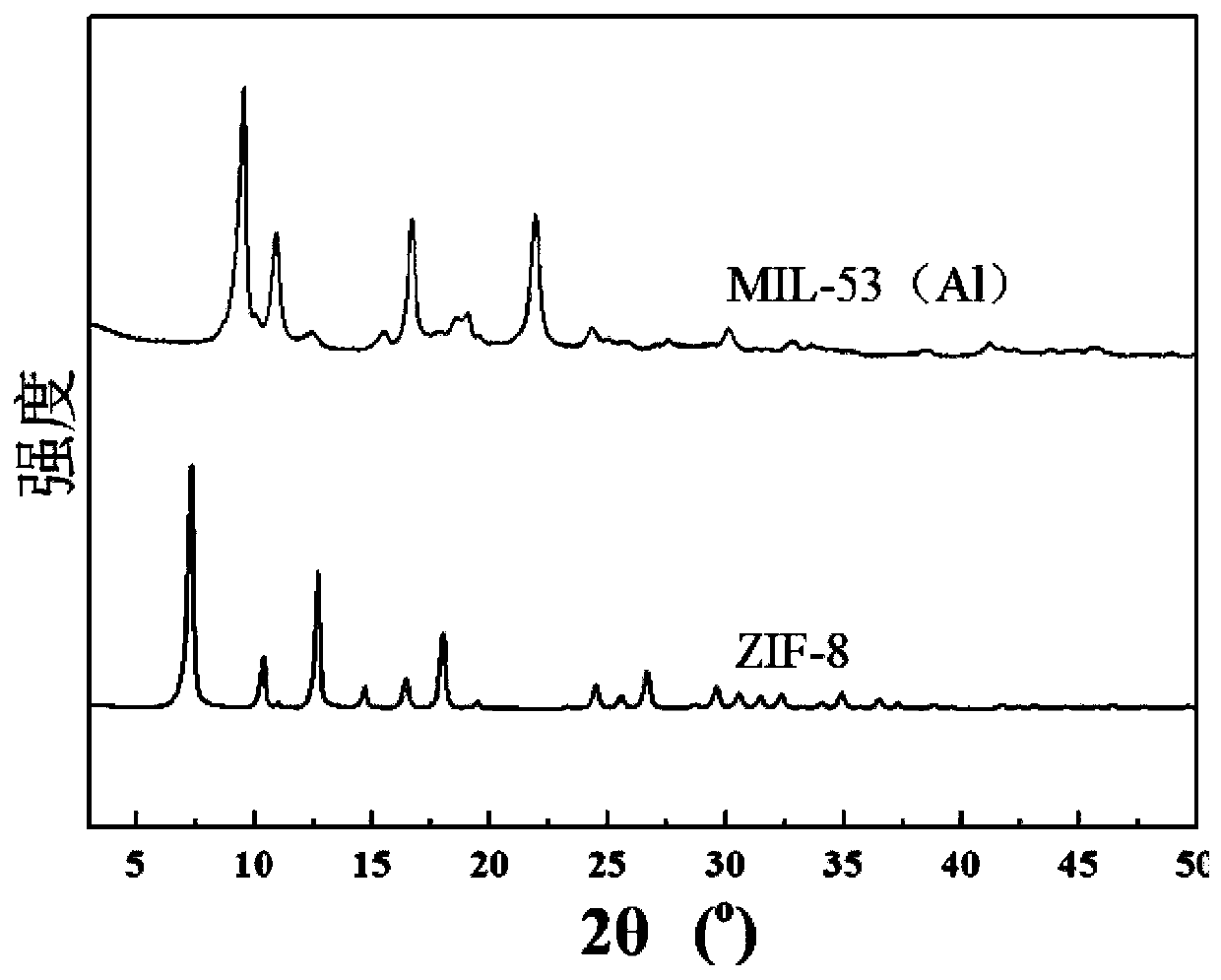

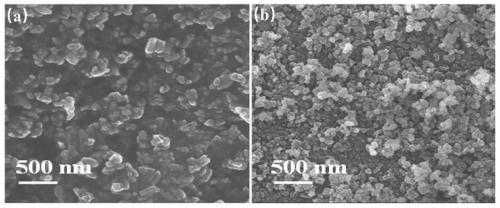

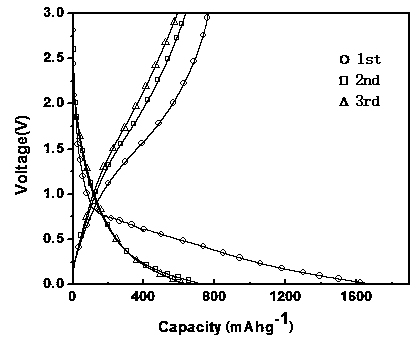

Metal-air battery air electrode and preparation method thereof

ActiveCN111180749APromote formationStable structureFuel and primary cellsCell electrodesElectrolytic agentPtru catalyst

The invention provides a metal-air battery air electrode and a preparation method thereof. The method comprises the steps: mixing a metal organic framework material with nitrogen source micromolecules, so that the nitrogen source micromolecules are adsorbed in the metal organic framework; then, carrying out high-temperature carbonization treatment in a nitrogen atmosphere; finally, carrying out acid treatment to remove metal particles to obtain a nitrogen-doped porous carbon material; and preparing the porous carbon material into slurry, and coating the surface of a conductive substrate with the slurry to obtain the air electrode of the metal-air battery. The nitrogen-doped porous carbon prepared by the method has high specific surface area, high nitrogen content and excellent oxygen reduction catalytic activity, the PVDF binder is added into the prepared slurry to ensure the connection between the catalyst and the substrate, and the erosion of electrolyte to the catalyst is resisted through the PTFE film, so that the stability of the electrode is maintained. The preparation method provided by the invention is simple and feasible, has good repeatability, is convenient for large-scale production, and can be used in the field of air batteries, especially air electrodes of lithium air batteries.

Owner:HUAZHONG UNIV OF SCI & TECH

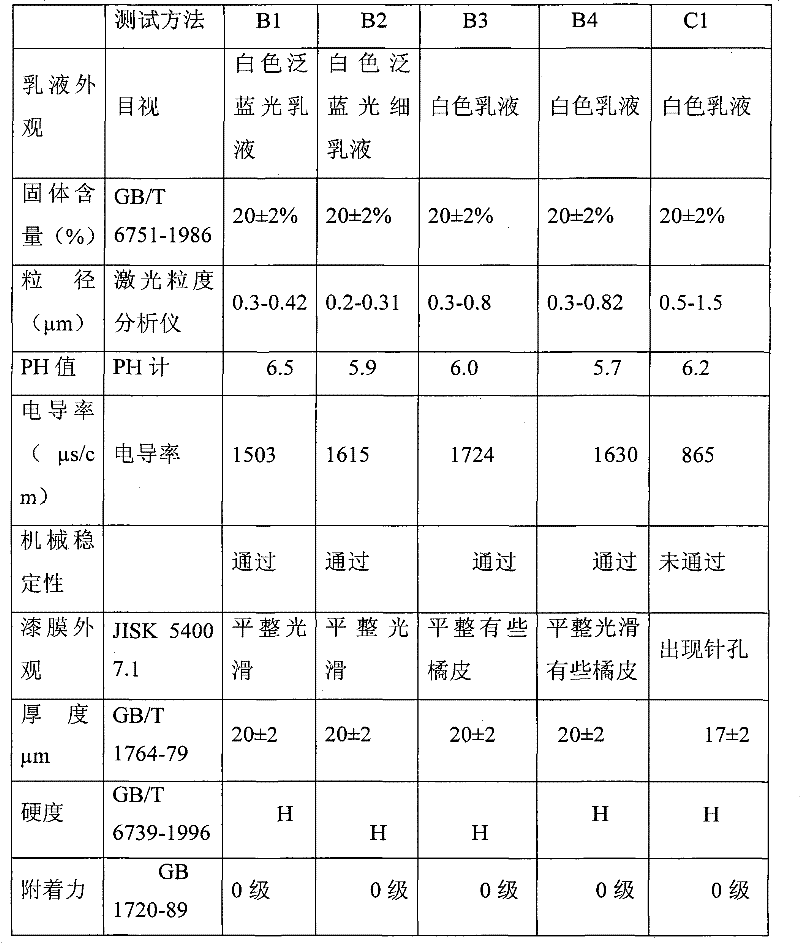

Cathode electrophoretic coating and preparation method thereof and cathode electrophoretic coating method

InactiveCN102533044AIncrease N contentGood storage stabilityElectrophoretic coatingsPaints for electrolytic applicationsCross-linkEpoxy

The invention provides a preparation method of a cathode electrophoretic coating. The method comprises the following steps of: performing hybrid reaction on epoxy resin, a chain extender, a toughening agent, an organic secondary amine compound and an enclosed polyisocyanate curing cross-linking agent to obtain epoxy cationic resin; and then adding organic acid into the obtained epoxy cationic resin to neutralize, wherein the number-average molecular weight of the epoxy resin is 360-500. The coating has high storage stability and application stability and meanwhile has superior throwing power and filming performance.

Owner:BYD CO LTD

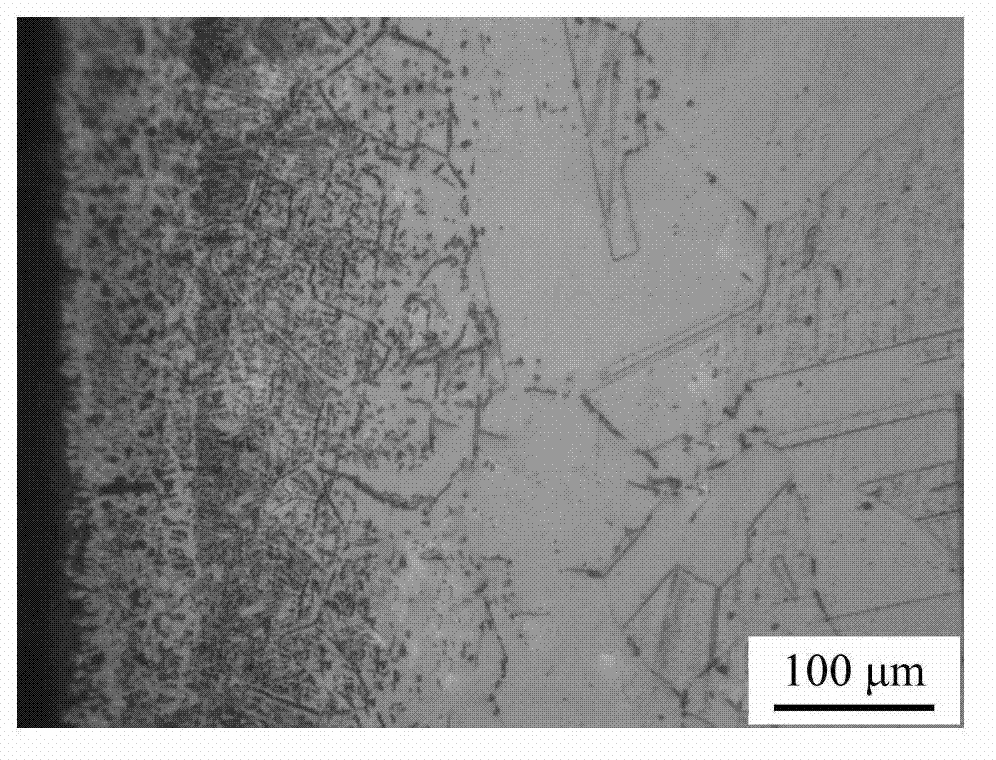

Sectional type pressurizing solid solution nitriding accelerating method of austenitic stainless steel

InactiveCN103088283AShorten nitriding timeShort processing cycleSolid state diffusion coatingRoom temperatureNitrogen

The invention disclosed a sectional type pressurizing solid solution nitriding accelerating method of austenitic stainless steel. The method mainly comprises the following steps of: putting the austenitic stainless steel in a solid solution nitriding furnace provided in an invention with the patent name of a pressurizing high-temperature nitriding device with a dual-pressure equilibrium structure and a patent number of 201210530358.6, introducing NH3 into the furnace at the flow velocity of 0.5-2L / min till the pressure in the furnace reaches 0.1-1.0MPa, carrying out NH3 nitriding pretreatment for 5-10 hours at the temperature of 500-700 DEG C, completely discharging the NH3 in the solid solution nitriding furnace, introducing N2 into the furnace at the flow velocity of 1-5L / min till the pressure in the furnace reaches 0.1-1.0MPa, rapidly heating the furnace till the temperature of the furnace reaches 900-1200 DEG C, carrying out N2 solid solution nitriding treatment for 1-20 hours under the conditions, rapidly cooling to room temperature by using water and forming a solid solution nitriding layer on the surface of the austenitic stainless steel. By means of the method disclosed by the invention, the nitriding efficiency can be improved; the whole nitrogen content of the diffusion layer is increased and the diffusion part grain coarsening in the nitriding process is effectively slowed and even avoided.

Owner:YANSHAN UNIV

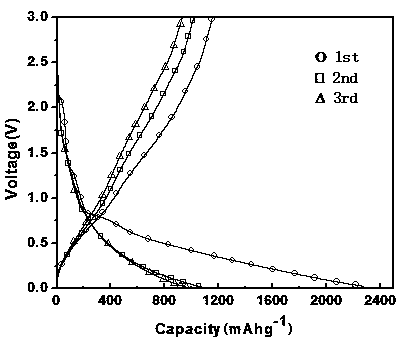

Preparation method of nitrogen-doped porous carbon material

InactiveCN109928384AHigh yieldSimple and safe operationCell electrodesSecondary cellsCarbon compositesLithium

The invention discloses a preparation method of a nitrogen-doped porous carbon material. A carbon nitrogen mixed precursor is sintered at high temperature; the control on the nitrogen doping proportion and form in the carbon material is realized; through mixing, metal salt can be decomposed; the control on the crystallization performance of the carbon material is realized. The method has the advantages that during the operation, simplicity, convenience and safety are realized; a prepared nitrogen-doped carbon composite material is suitable for being used as a lithium ion electrode material; the production cost is low; the yield is high; no by-products basically exist.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method for inducing test tube flowering of phalaenopsis

ActiveCN103477978AFlower buds develop normally and are robustSimple methodHorticulture methodsPlant tissue cultureFlower inductionBud

The invention discloses a method for inducing test tube flowering of phalaenopsis. The method comprises the following step: taking a robust sterile phalaenopsis bottle seedling after rooting of a robust seedling as an explant to perform induction of a flower bud. A flower stalk can be seen after the flower bud is induced by about 3-4 months. Then flowering induction culture is performed, the flower bud can develop normally, a bud appears, the bud develops normally and can bloom normally, and a deformed flower can be avoided. By adopting the method for inducing the flowering of the phalaenopsis, disclosed by the invention, the formation of the phalaenopsis flower bud can be accurately and effectively induced, and the induction rate of the flower bud can achieve 80.0-93.3%. The flower bud can normally develop and successfully induce the flowering in the probability of 60.0-73.3%. The complete flower of a flower organ is as high as 100.0%. The flowering period is lasting, which can be as long as 30-40 days. Generally, the bottle seedling after test tube field planting and rooting needs about 24 months for flowering after transplanting and planting, and the induction of the flowering in the test tube of the bottle seedling only needs 6-8 months.

Owner:SUBTROPICAL CROPS INST OF FUJIAN PROVINCE

Method for adsorbing polymine on carbon fiber surface in supercritical methanol

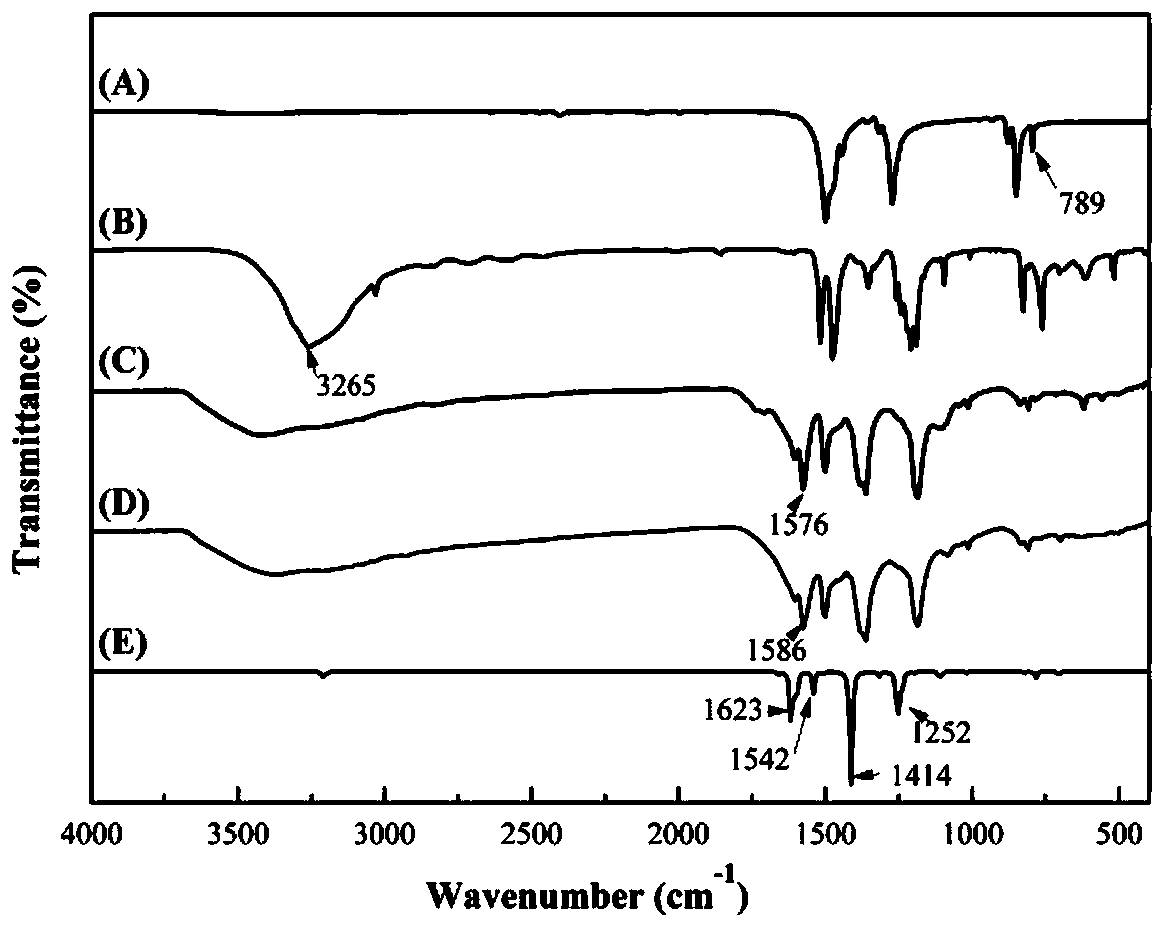

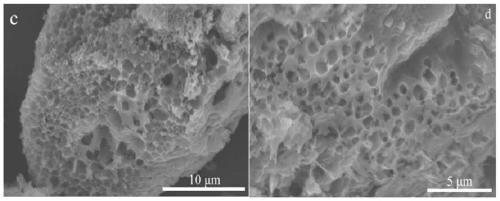

InactiveCN104562707AIncrease N contentIncreased mechanical engagementCarbon fibresFiberCarbon fibers

The invention discloses a method for adsorbing polymine on a carbon fiber surface in supercritical methanol, relates to a carbon fiber surface adsorption method, and aims to solve problems that an existing carbon fiber modifying method causes severe strength loss to the carbon fiber, is complex to operate, not suitable for being performed, low in bonding strength with resin. The method comprises the following steps: I, cleaning; II, oxidizing; III, adsorbing polymine in supercritical methanol to obtain carbon fiber, surface of which is adsorbed with the polymine, thereby completing grafting hexamine on the carbon fiber surface in the supercritical methanol. According to the method, interface shearing strength of the carbon fiber, surface of which is adsorbed with the polymine, is increased to 101.8 MPa-103 MPa from unmodified 64.9 MPa, and increased by 56.9%-59.7%; impact strength is increased to 84.39 kJ / m<2>-86.7 kJ / m<2> from 55.77 kJ / m<2>. The invention discloses a method for grafting hexamine on the carbon fiber surface.

Owner:HARBIN INST OF TECH

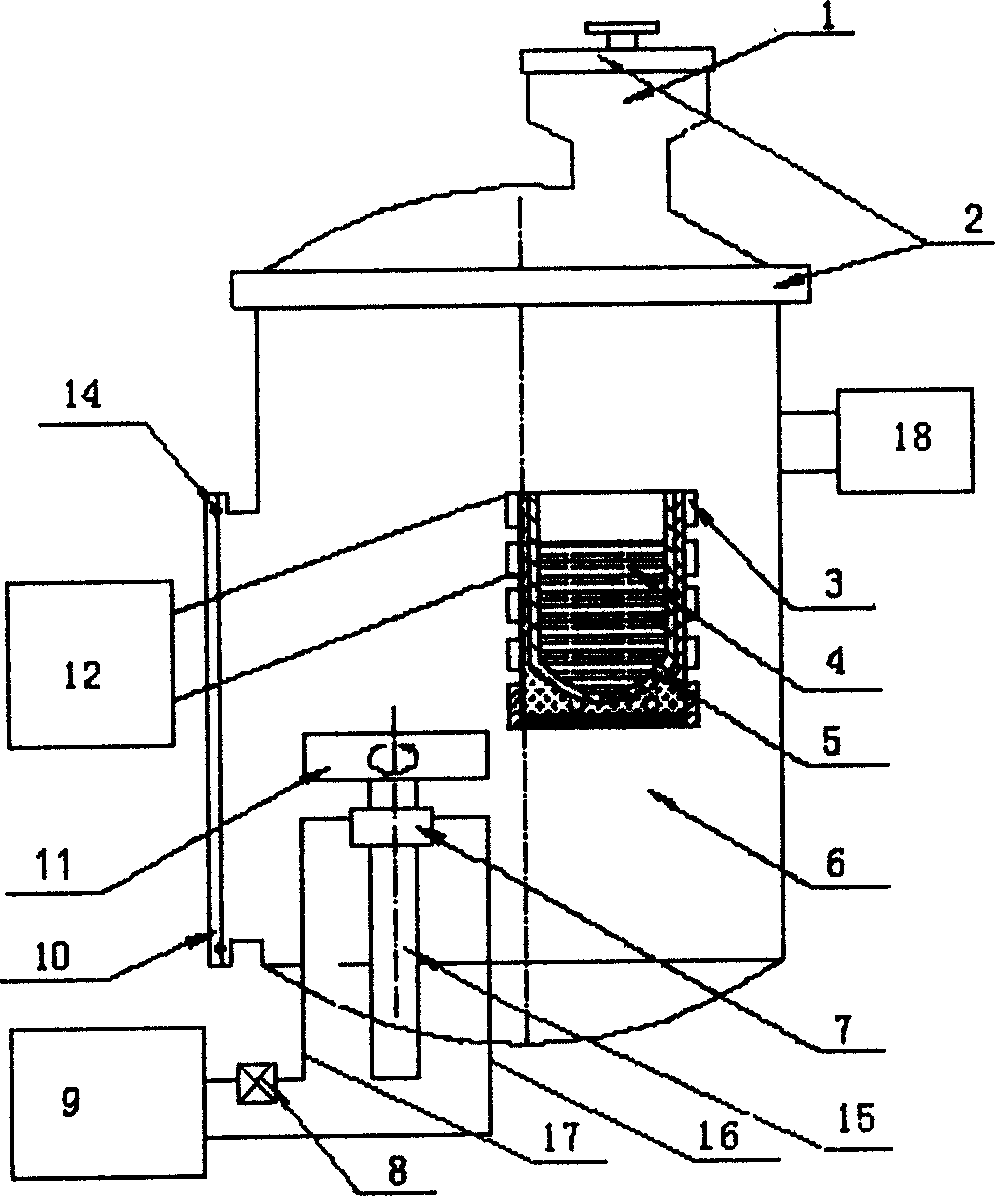

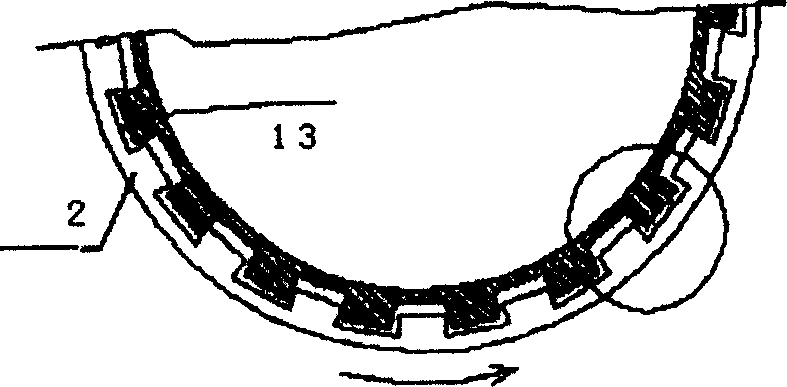

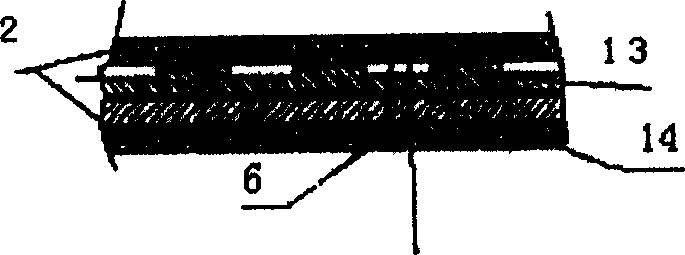

Positive pressure vertical centrifugal vacuum induction smelting and casting furnace

InactiveCN1511661AAccurate ingredientsIncrease N contentCrucible furnacesHydraulic cylinderManufacturing technology

The present invention relates to the manufacture technology of vacuum smelting and casting apparatus, and is especially positive pressure vertical centrifugal vacuum induction smelting and casting furnace. The configuration of the furnace includes feeding bin set on the upper furnace cover connected via elevating shaft to the hydraulic cylinder, lower furnace body, winding set inside the lower furnace body and connected to the control power supply, centrifuge inside the furnace, etc. There are retaining rings set in the joint between the upper furnace cover and the lower furnace body and that between the feeding bin and the feeding bin cover. The furnace may be used in alloy smelting and centrifugal or gravitational alloy casting at vacuum or positive pressure with less reaction between active element and oxide crucible material, accurate alloy components and ideal casting filling and casting-on effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

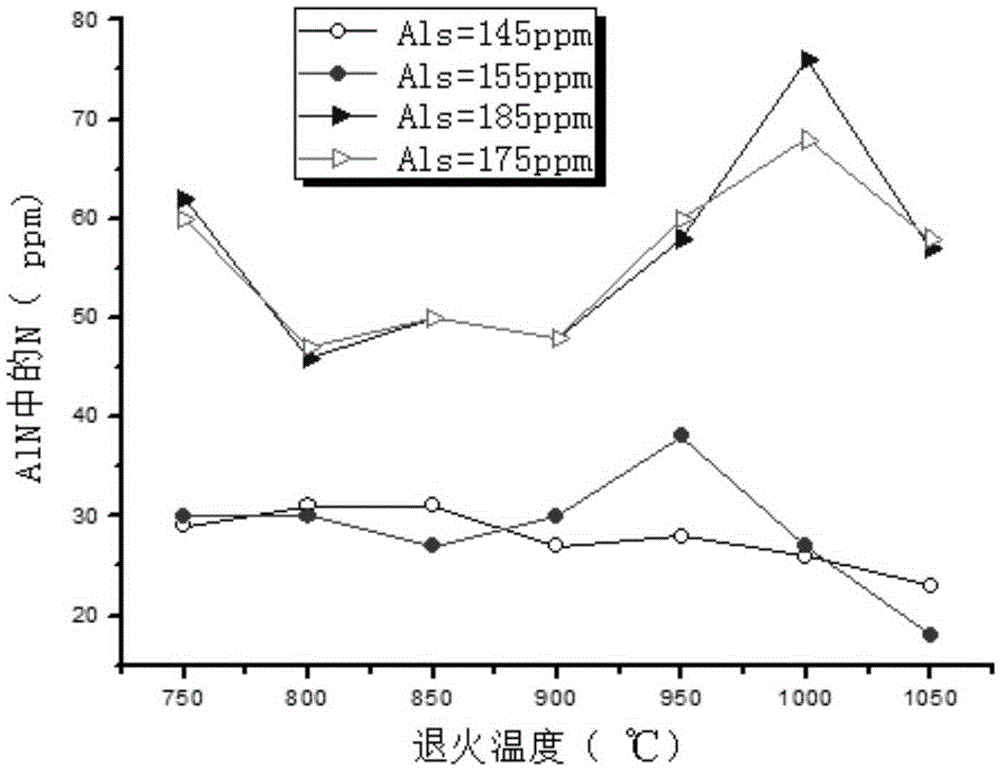

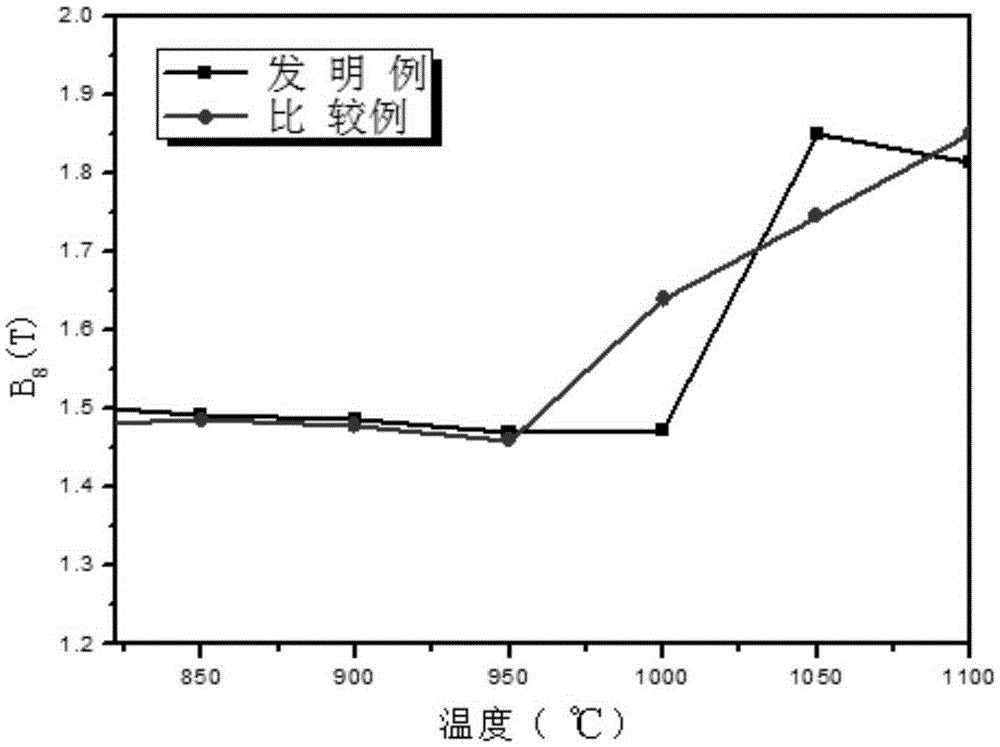

Production method for copper-contained low-temperature high-magnetic-induction-oriented silicon steel

The invention relates to a production method for oriented silicon steel, in particular to a production method for copper-contained low-temperature high-magnetic-induction-oriented silicon steel. According to the production method, the content of Als and the content of N in raw material components are increased, AlN serves as a main inhibitor, due to the fact that the content of the Als and the content of the N are increased, on the one hand, the quantity of the inhibitor is increased and the inhibition force is enhanced, and on the other hand, the secondary recrystallization temperature is increased and the stability of secondary recrystallization is improved; Sn is added to the raw material components, so that the inhibition force is further enhanced, and due to the fact that the grain boundary co-segregation element Sn is added to the components, the content of the Sn is controlled between 0.04% to 0.06%, and through grain boundary co-segregation of the Sn, other grains provided with the size advantage and deviating from the Gausian orientation can be effectively prevented from growing abnormally, the grain orientation degree obtained after secondary recrystallization is improved, and magnetic induction is improved; a high-temperature annealing process is adjusted, the rate of N2 to H2 of the atmosphere in the temperature increase stage is adjusted to 1 to 1 from 1 to 3, and due to the fact that a great amount of the AlN is formed in the low-temperature temperature increase stage, the proportion of the N2 is increased, generation of the AlN is promoted, the AlN is prevented from being decomposed too early, and the phenomenon that a tail iron loss curve fluctuates due to the increase of the content of the Als in continuous production is avoided.

Owner:武汉钢铁有限公司

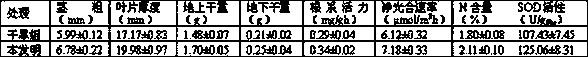

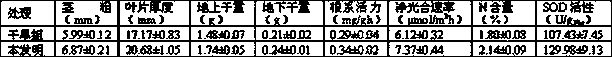

New method for improving drought resistance of brassica napus

InactiveCN108207515AImprove drought resistanceIncrease SOD activityBiocidePlant growth regulatorsDry weightLow temperature plasma

The invention relates to a new method for improving the drought resistance of brassica napus. Before sowing, dielectric barrier helium low temperature plasma treatment is conducted on brassica napus seeds, and the treatment conditions include: power 300-450 W, time 30-90 s, pressure intensity 50-150 Pa and pole plate spacing 2 cm; foliage spraying is conducted on drought-stressed brassica napus seedlings, a drought-resisting agent is irrigated to roots, and the drought-resistant agent component comprises 5-aminolevulinic acid 50-100 mg / L, hydrogen-rich water (hydrogen concentration of 0.05-0.2mmol / L), boric acid 1-3 g / L and tween-80 0.1%-0.3%. The method can significantly improve the drought resistance of the brassica napus. Under drought stress, by adopting the method, the stem diametersof the seedlings are increased by 14%-22%, leaf thickness is increased by 16%-22%, the dry weight of overground parts is increased by 14%-28%, the dry weight of underground parts is increased by 14%-24%, the root activity is increased by 17%-21%, the net photosynthetic rate is increased by 17%-24%, the N content of leaves is increased by 17%-22%, and the SOD activity of the leaves is increased by16%-36%. The method is low in cost, simple and easy to operate, safe and environmentally friendly, and can alleviate the damage caused by drought stress on the brassica napus seedlings and significantly improve the drought resistance of the brassica napus seedlings.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

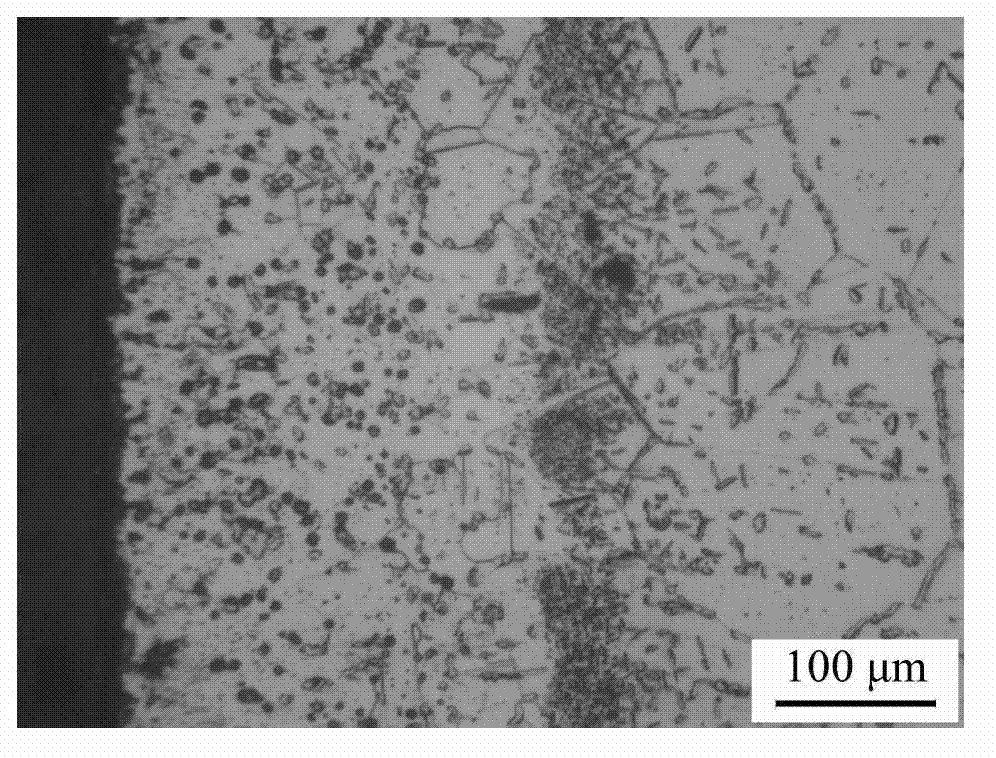

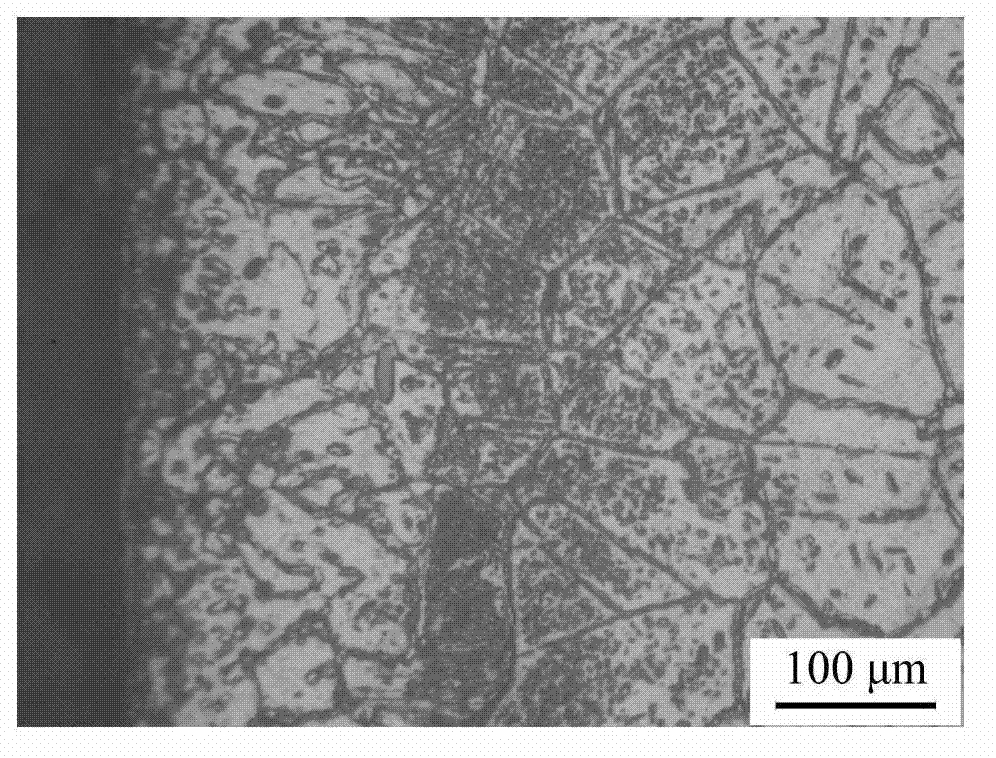

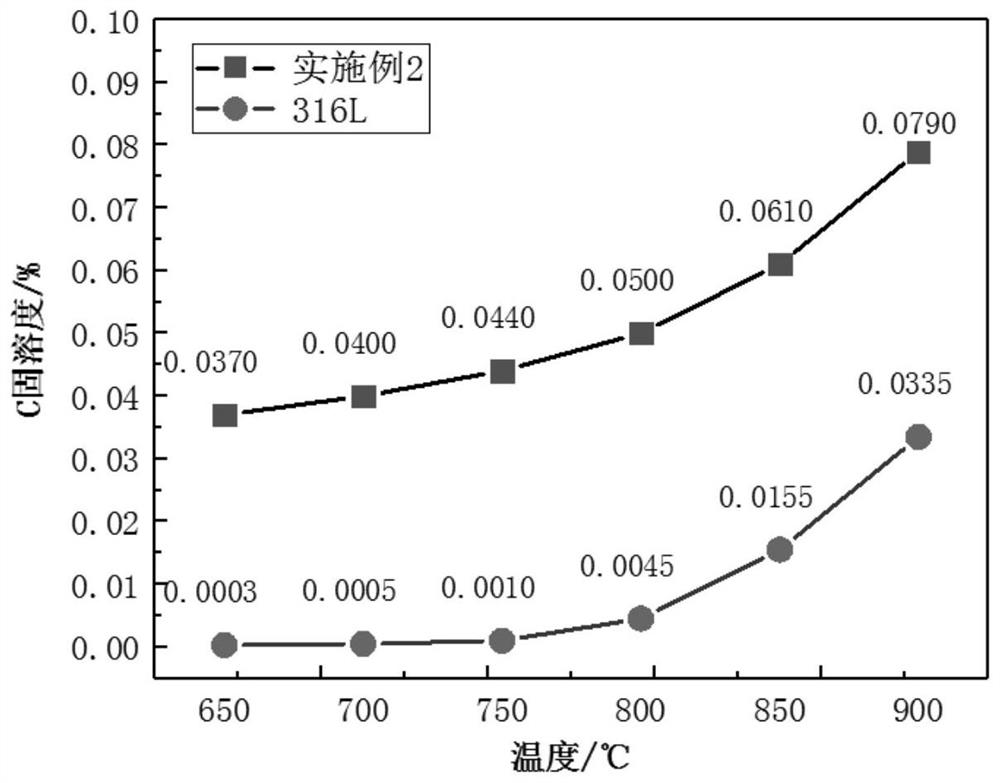

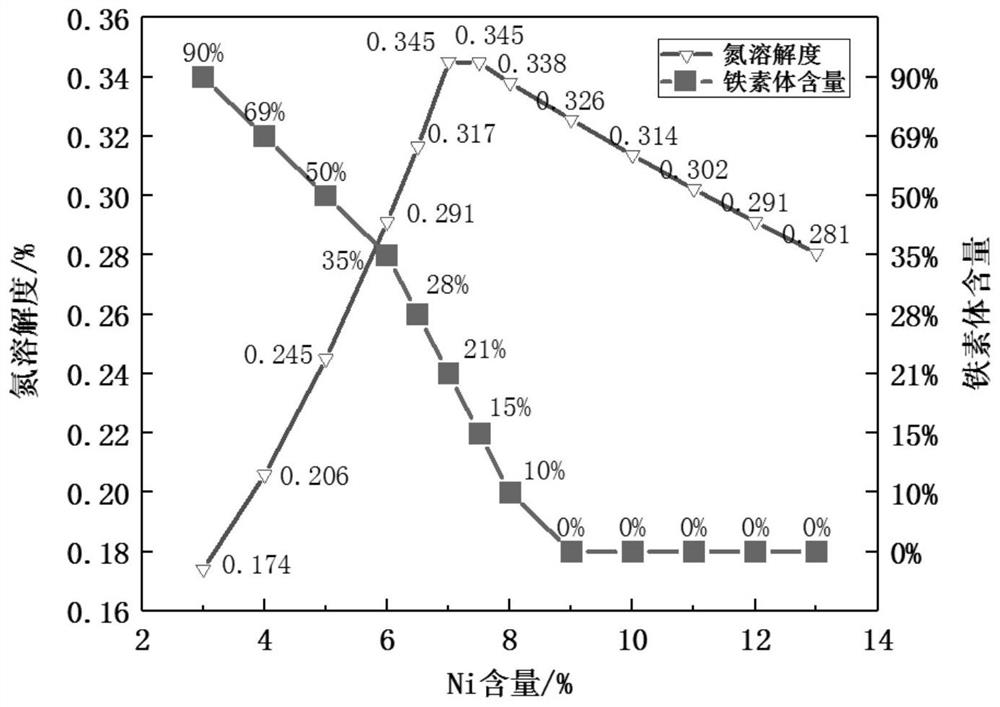

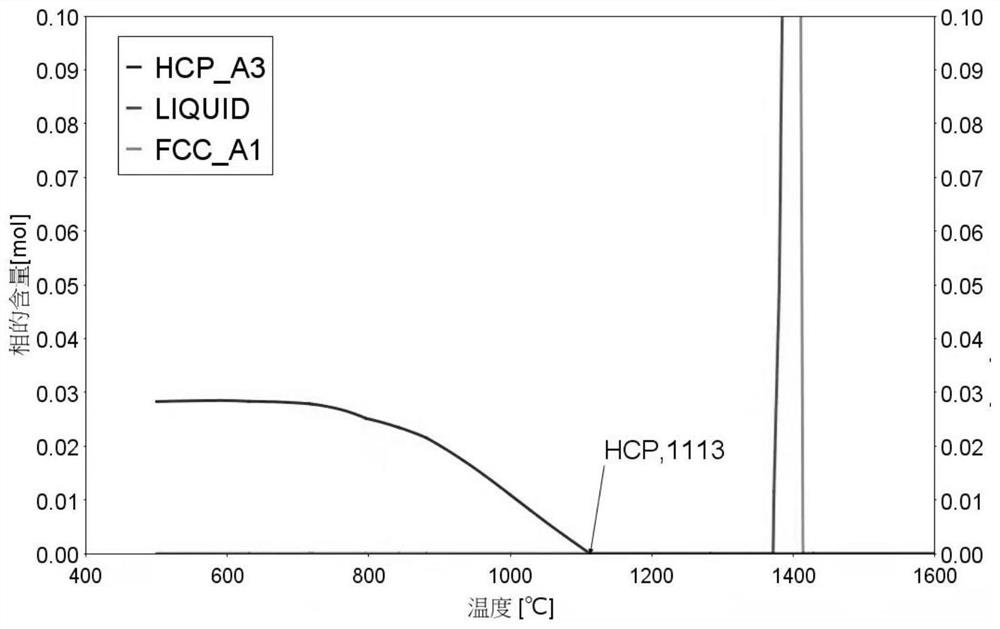

High-nitrogen austenitic stainless steel with post-welding intergranular corrosion resistance and pitting corrosion resistance superior to 316L and manufacturing method of high-nitrogen austenitic stainless steel

ActiveCN114250421ALow costIncrease nitrogen solubilityHeat treatment process controlMetal rolling arrangementsSS - Stainless steelAustenite

Owner:福建青拓特钢技术研究有限公司

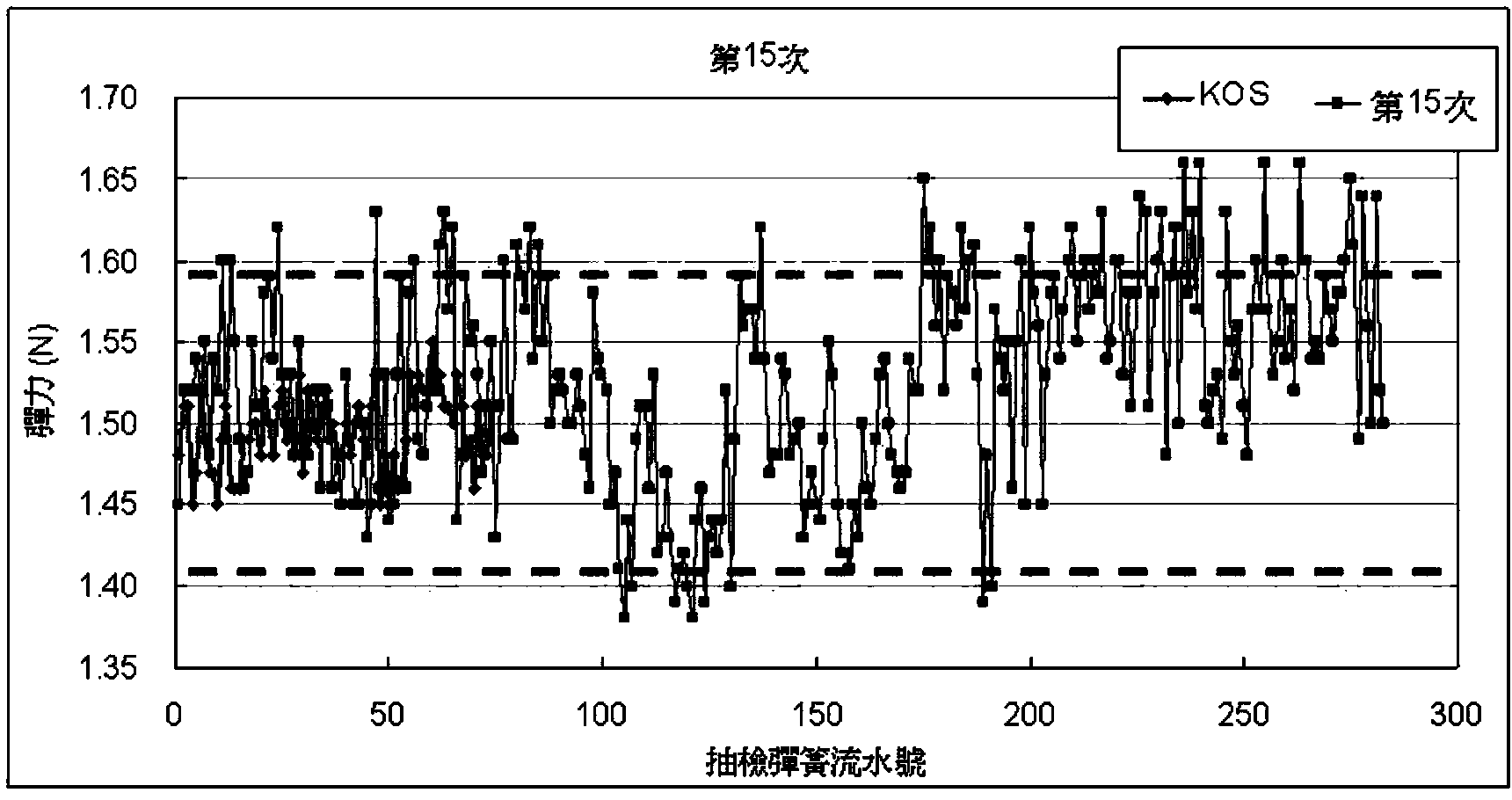

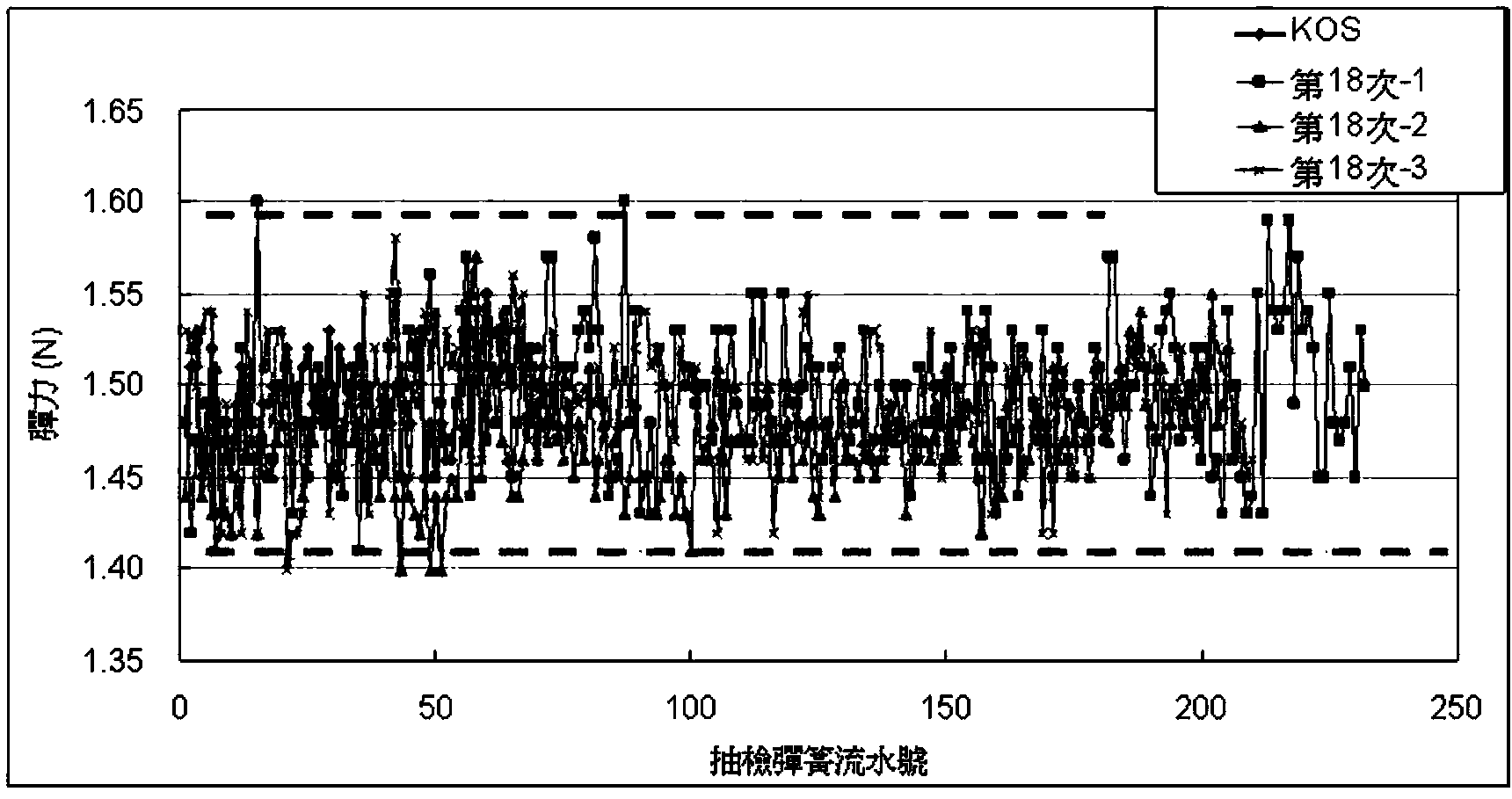

Spring wire

The invention discloses a spring wire comprising the chemical composition by weight percentage: 0.06%-0.09% of C, 18.0%-19.0% of Cr, not more than 2.0% of Mn, 0.08%-0.12% of N, not more than 1.00% of Si, 8.0-9.0% of Ni, not more than 0.040% of P, not more than 0.015% of S, not more than 0.5% of Mo, not more than 0.5% of Cu, and the balance Fe and non-removable impurities. Through increasing the N content, the strength and the toughness of the spring wire both can accord with standards.

Owner:WUXI XINGCHENG HUAXIN STEEL

Novel bio-organic-inorganic compound fertilizer and preparation method thereof

InactiveCN105061041ANo secondary burdenPrevent compactionBio-organic fraction processingOrganic fertiliser preparationSodium BentonitePotassium

The present invention discloses a novel bio-organic-inorganic compound fertilizer and a preparation method thereof. The fertilizer is prepared from the following raw materials by weight: 1-2 parts of lignin, 2-4 parts of a complex deodorant, 2-4 parts of isatis root, 2-4 parts of forsythia, 1-3 parts of bamboo vinegar, 3-5 parts of cow dung, 3-6 parts of eggshell powder, 1-2 parts of dry yeast, 1-3 parts of coralhead plant root, 5-15 parts of bentonite, 1-3 parts of potassium chloride, 1-3 parts of dicyandiamide, 0.3-0.5 part of a urease inhibitor PPD and 5-8 parts of urea.

Owner:MAANSHAN KEBANG ECO FERTILIZER

High-nitrogen alloy core-spun yarn

The invention discloses a high-nitrogen alloy core-spun yarn, and relates to the technical field of molten steel refining. The core-spun yarn consists of a coating layer, a core powder layer and a guide core; the core powder layer is compounded between the guide core and the coating layer; the guide core is filled with a high-nitrogen layer; the core powder layer comprises a silicon iron nitride alloy, a solid nitrogen alloy element iron alloy and silicon base rare earth alloy powder; and the high-nitrogen layer comprises a vanadium nitrogen alloy, vanadium iron nitride and silicon iron nitride powder. The core-spun wire adopts a novel alloy material with a nitrogen content above 25%, which is relatively lower in cost and is prepared by calcining general alloy silicon iron powder for steelalloying in a nitriding furnace; and the core-spun wire is simple in preparation of raw materials and low in cost, and prominently improves the steel structural strength.

Owner:SUZHOU YUANLIAN SCI & TECH PIONEER PARK MANAGEMENT CO LTD

Stainless steel material

The invention provides a stainless steel material, belonging to the technical field of metallic material, and comprising the following components in percentage by weight: 0.06-0.09% of C, less than or equal to 0.6% of Si, 1.10-1.40% of Mn, less than or equal to 0.040% of P, less than or equal to 0.010% of S, 18.00-19.00% of Cr, 8.00-8.50% of Ni, 0.70-1.20% of Cu, less than 0.5% of Mo, 0.07-0.12% of N and the balance of Fe. Compared with the prior art, the stainless steel material provided by the invention improves the fatigue resistance and the corrosion resistance, reduces abrasion on a die to a certain degree, improves the product quality, and reduces the production cost.

Owner:SHANDONG TENGDA STAINLESS STEEL PRODS

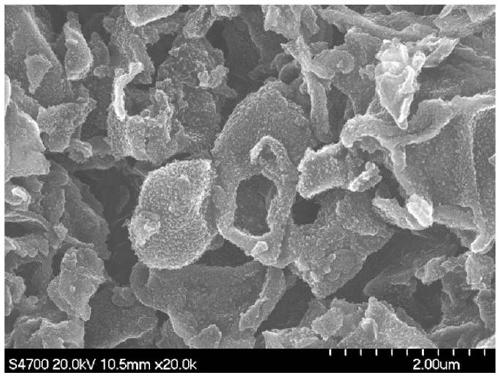

Novel high-efficiency adsorbent and application thereof

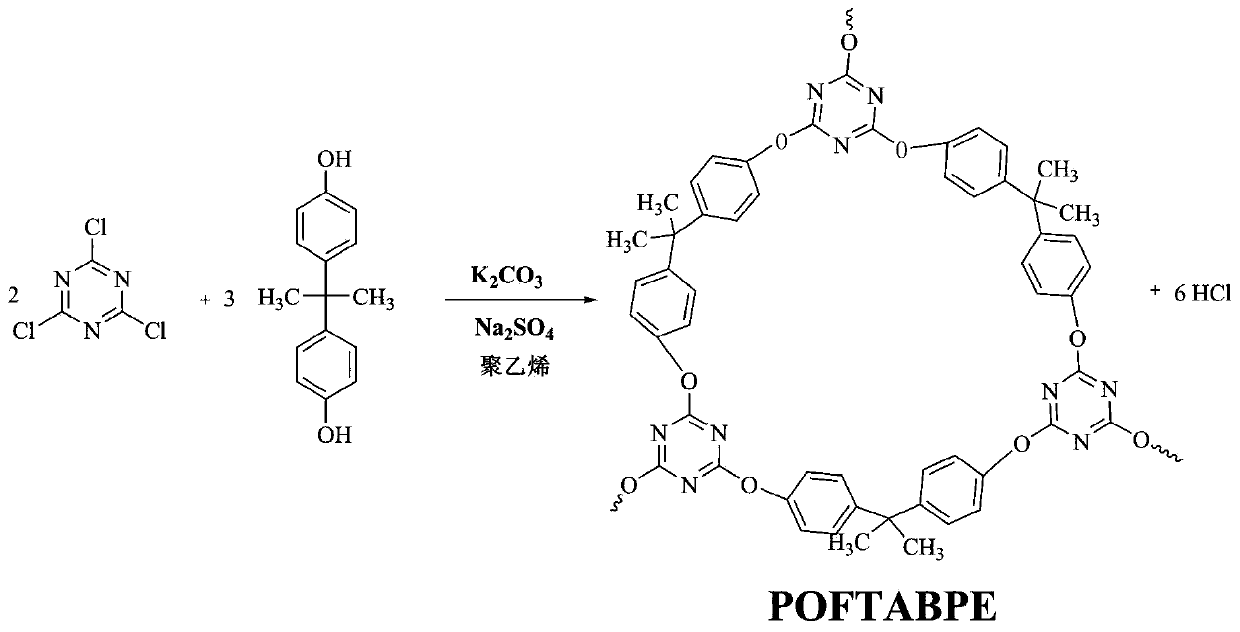

ActiveCN110152630AIncrease N contentImprove adsorption capacityOther chemical processesWater contaminantsSorbentSolvent

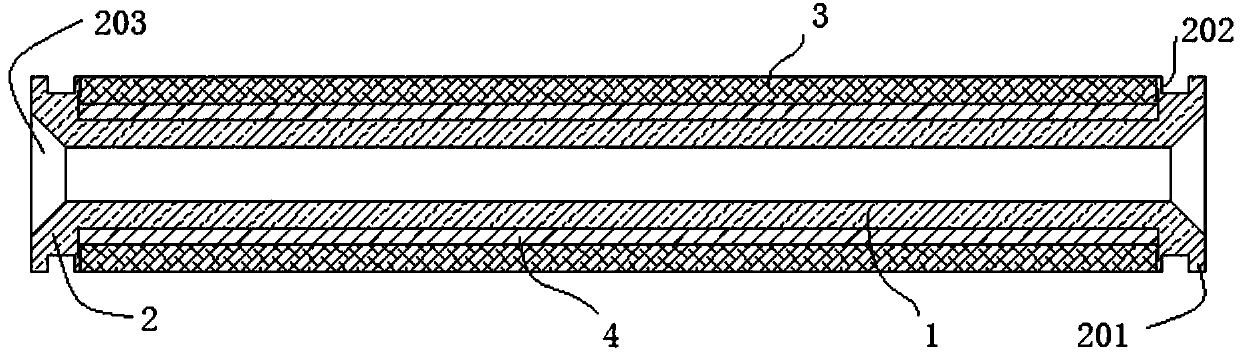

The invention provides a novel high-efficiency adsorbent and an application thereof, relates to a preparation method and an application of the novel high-efficiency adsorbent, and belongs to the fieldof sewage treatment. The preparation method of the novel high-efficiency adsorbent comprises the following steps: adding polyethylene to a solvent, heating the obtained solution, refluxing the solution, adding sodium sulfate, potassium carbonate, cyanuric chloride and bisphenol A, and carrying out a high-temperature polycondensation reaction to obtain the novel high-efficiency adsorbent. The cyanuric chloride used as a starting material reacts with the bisphenol A through a three-template process to synthesize a novel nitrogen-rich organic porous skeleton polymer. The material is a porous material with an obvious porous structure, has strong adsorption capability for various heavy metal ions, has a high adsorption efficiency, can be used for adsorbing heavy metal ions in water, generateseconomic and environmental benefits, and can meet the needs of environmental protection and green environment.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

A kind of low-carbon cr-ni series high-strength corrosion-resistant steel and its preparation method

The invention discloses a low-carbon Cr-Ni high-strength corrosion-resistant steel and a preparation method thereof, which belongs to the technical field of corrosion-resistant steels and solves the problem that the corrosion-resistant steels in the prior art cannot meet various corrosion environments. Alloy composition of low-carbon Cr-Ni high-strength corrosion-resistant steel in terms of mass percentage: C: 0.01%-0.03%, Cr: 3.0%-10.0%, Ni: 1.0%-2.0%, Si: 0.1%-0.5% , Mn: 0.5%‑1.0%, P: 0.04%‑0.10%, S: ≤0.005%, N: 0.02%‑0.06%, Cu: 0.2%‑0.5%, and the balance is Fe and unavoidable impurities. The low-carbon Cr-Ni high-strength corrosion-resistant steel of the present invention has excellent mechanical properties, excellent marine atmospheric corrosion resistance, industrial atmospheric corrosion resistance and seawater corrosion resistance.

Owner:CENT IRON & STEEL RES INST +1

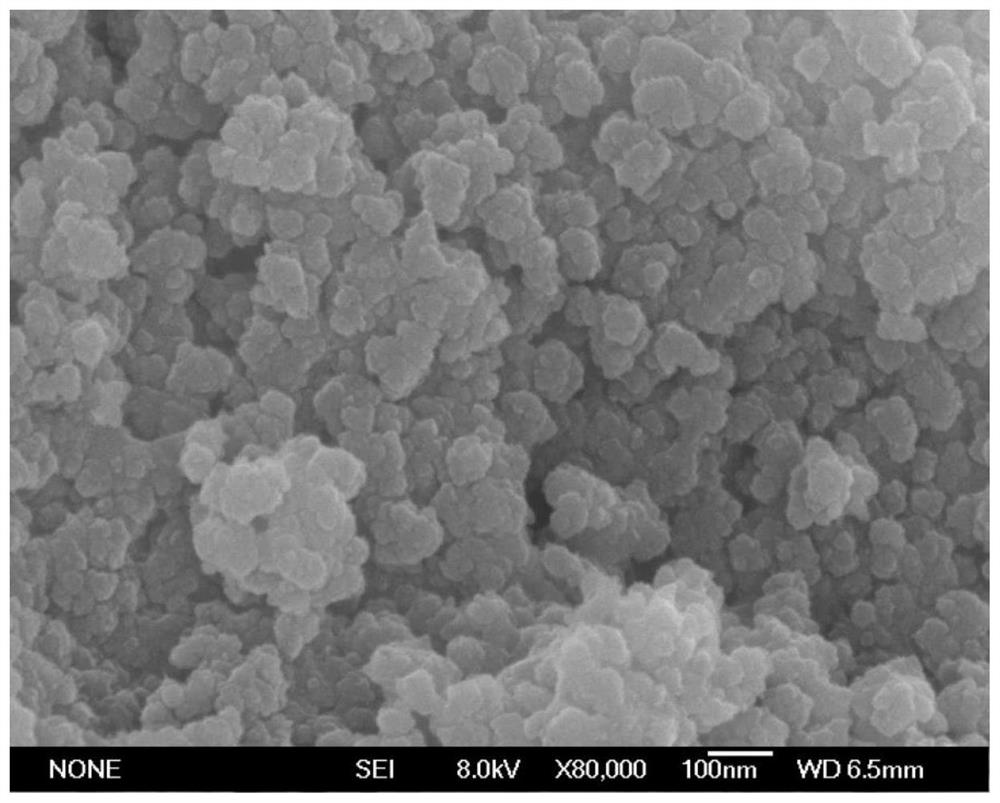

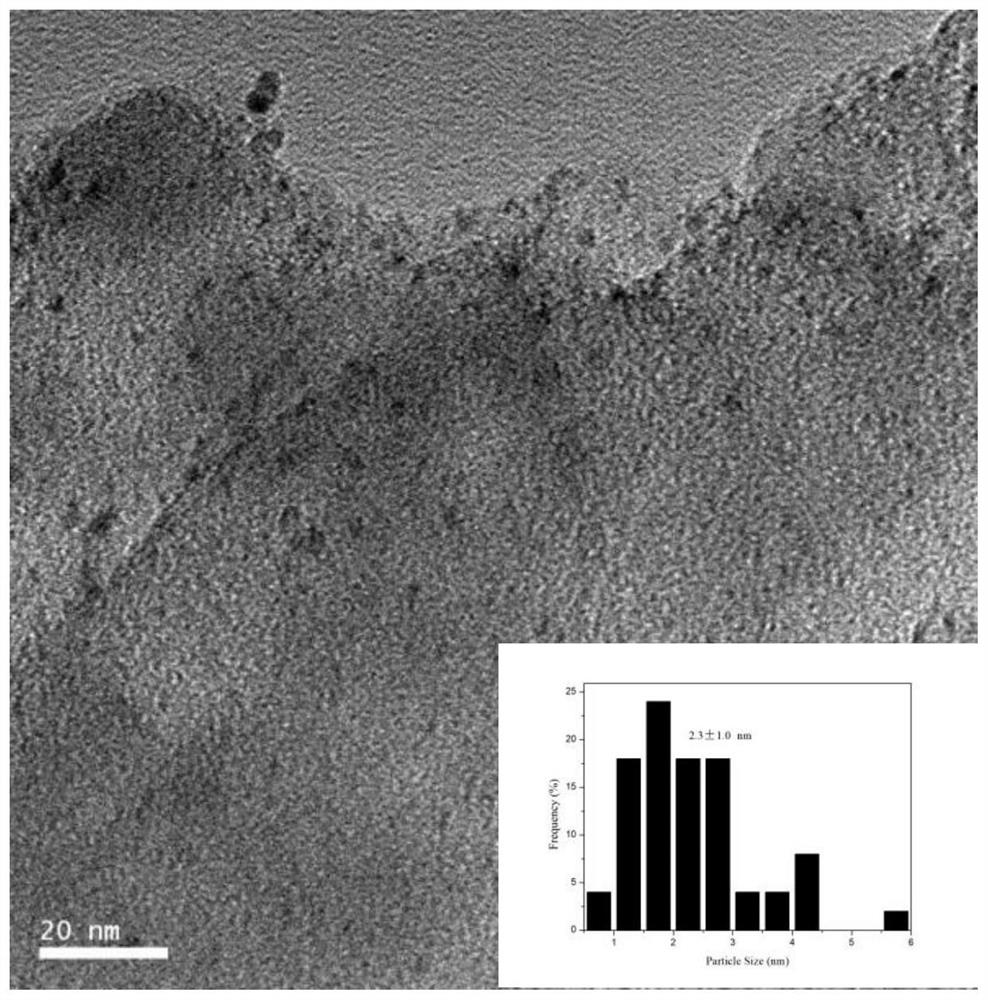

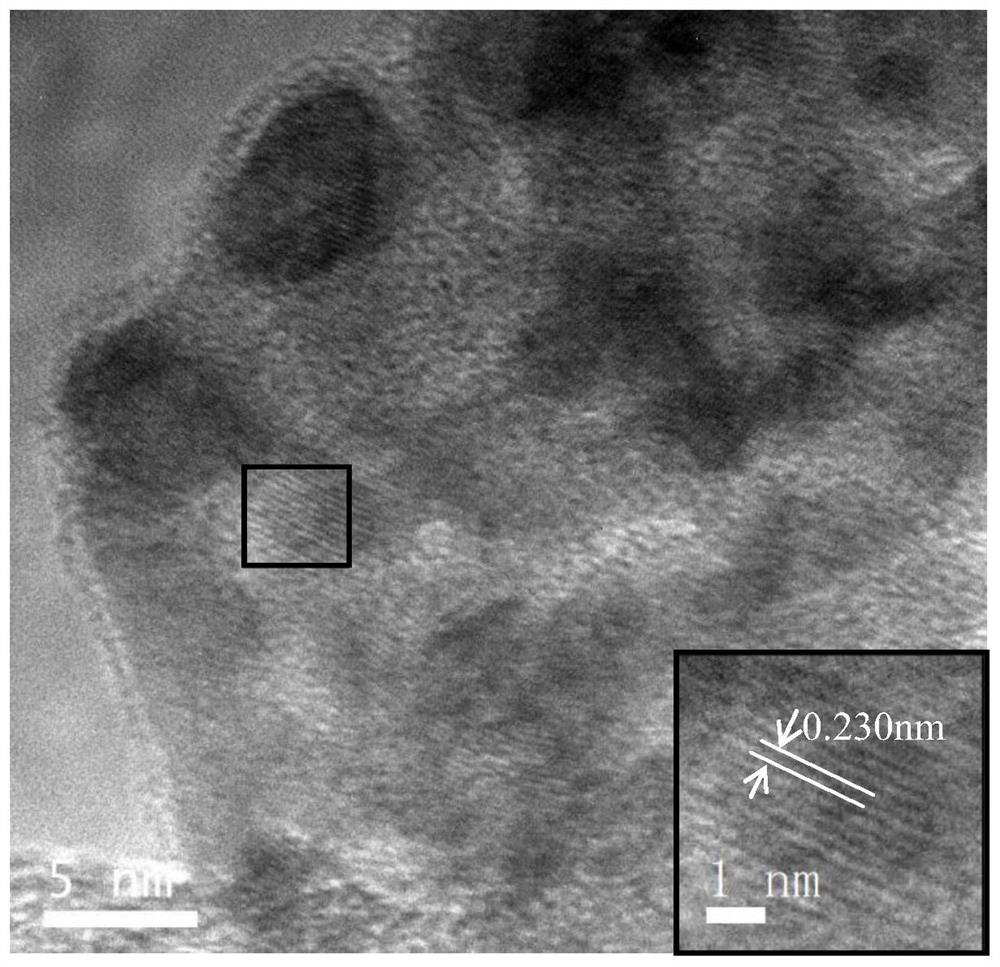

Preparation method and application of superfine gold-palladium nanoparticle/nitrogen-doped porous carbon composite material

PendingCN114471659AIncrease N contentLarge specific surface areaHydrogenPhysical/chemical process catalystsCarbon compositesPtru catalyst

The invention relates to a preparation method of a superfine gold-palladium nanoparticle / nitrogen-doped porous carbon composite material and application of the superfine gold-palladium nanoparticle / nitrogen-doped porous carbon composite material as a catalyst in a formic acid decomposition hydrogen production reaction. In an experiment, peanut shell powder is used as a raw material, and nitrogen-doped porous carbon (N-C) is obtained by performing high-temperature annealing on the peanut shell powder. Na2PdCl4 and HAuCl4 are used as metal precursors, nitrogen-doped porous carbon is used as a substrate, triaminopropyltriethoxysilane (APTES) is used as a dispersing agent, NaBH4 is used as a reducing agent, and the superfine gold-palladium nanoparticle / nitrogen-doped porous carbon composite material is prepared through a wet chemical reduction method. The composite material is used as a catalyst for formic acid decomposition hydrogen production reaction, and shows excellent catalytic activity at room temperature, and the TOF value of the composite material is up to 2118h <-1 >. The preparation method disclosed by the invention is simple, low in cost, capable of realizing batch production and high in catalytic activity, provides a new method for synthesizing a high-performance metal catalyst, and has a wide application prospect in a reaction for producing hydrogen by decomposing formic acid.

Owner:JILIN UNIV

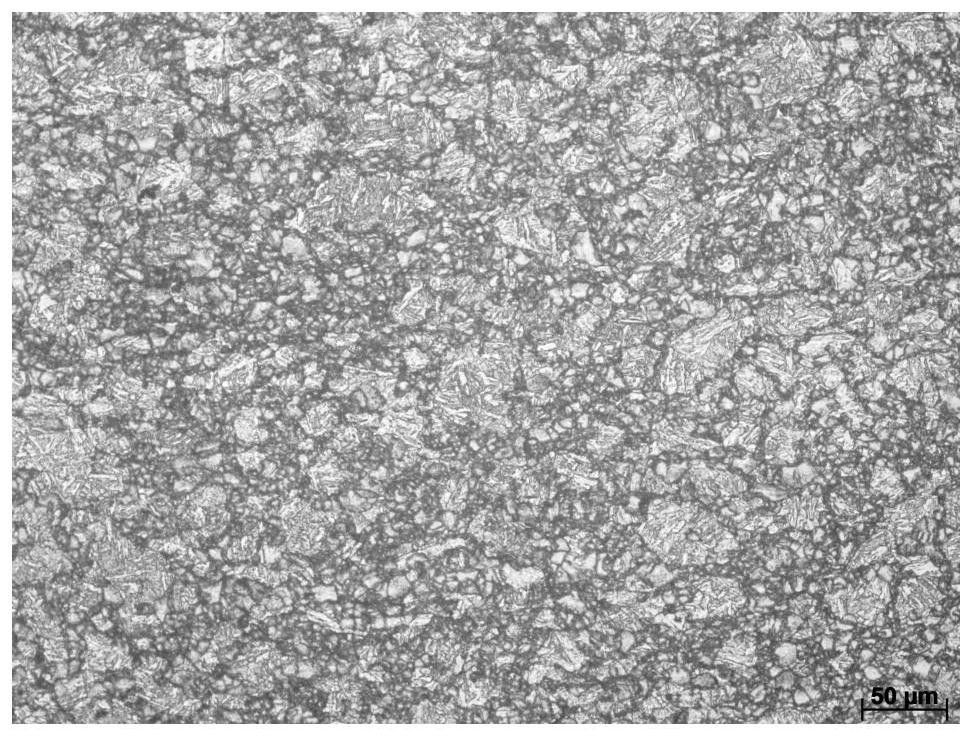

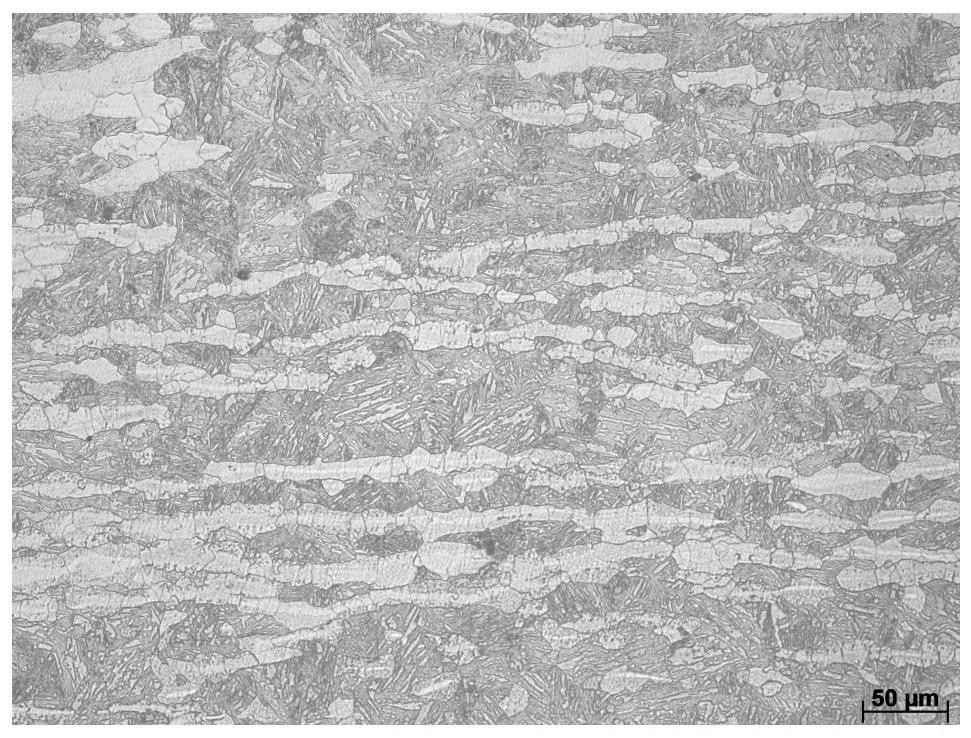

Nb-Ti-N micro-alloyed hot-rolled ribbed steel bar and production method thereof

The invention discloses an Nb-Ti-N micro-alloyed hot-rolled ribbed steel bar and a production method thereof. The Nb-Ti-N micro-alloyed hot-rolled ribbed steel bar comprises the following chemical components in percentage by weight: 0.22%-0.25% of C, 0.40%-0.60% of Si, 1.25%-1.35% of Mn, 0.012%-0.018% of Nb, 0.005%-0.015% of Ti, 0.0060%-0.0090% of N, P less than or equal to 0.045%, S less than orequal to 0.045%, and inevitable impurities. In the production process, converter tapping is subjected to bottom blowing of nitrogen, molten steel N and Nb are increased to be compounded to form NbN, technological parameters in the rolling process are controlled to enable grain boundary precipitation to achieve a precipitation strengthening effect, the strength is improved, and it is guaranteed that the mechanical property is qualified; and the straightening temperature in the continuous casting process is increased to 1000 DEG C or above, casting blank surface cracks caused by a third brittlearea are avoided, and various properties of the Nb-Ti-N micro-alloyed hot-rolled ribbed steel bar obtained through the method can meet the requirements of GB1499.2-2018.

Owner:WUHU XINXING DUCTILE IRON PIPES

A preparation method of cross-linked polyamino acid-based porous carbon material

ActiveCN110272034BIncrease the areaIncrease N contentNanotechnologyCarbon preparation/purificationCapacitanceFuel cells

Owner:BEIJING UNIV OF CHEM TECH

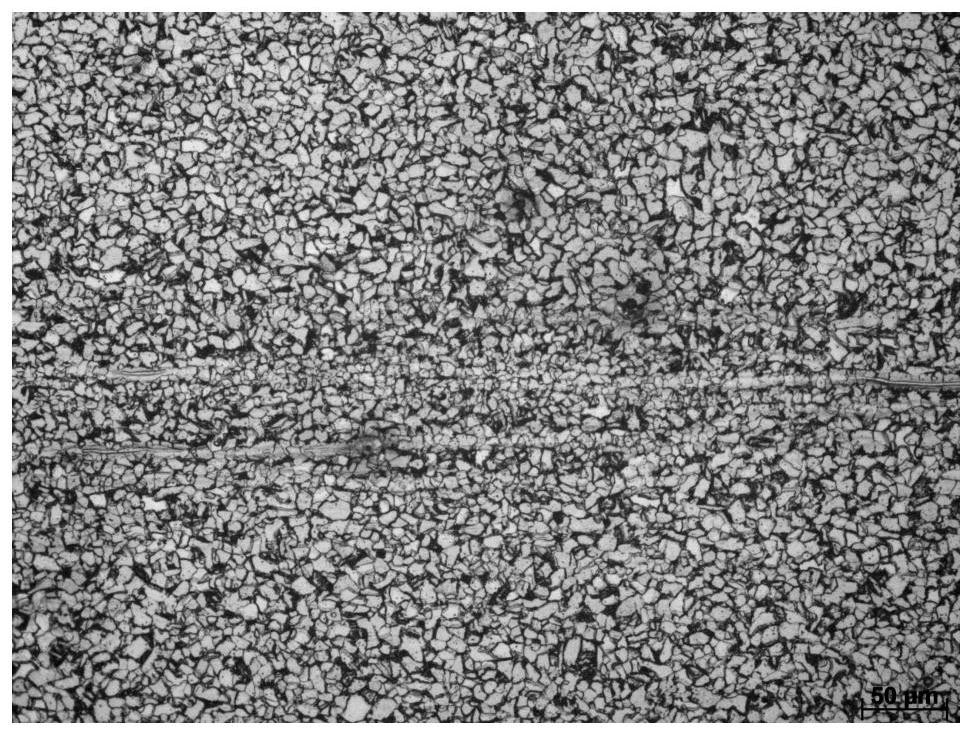

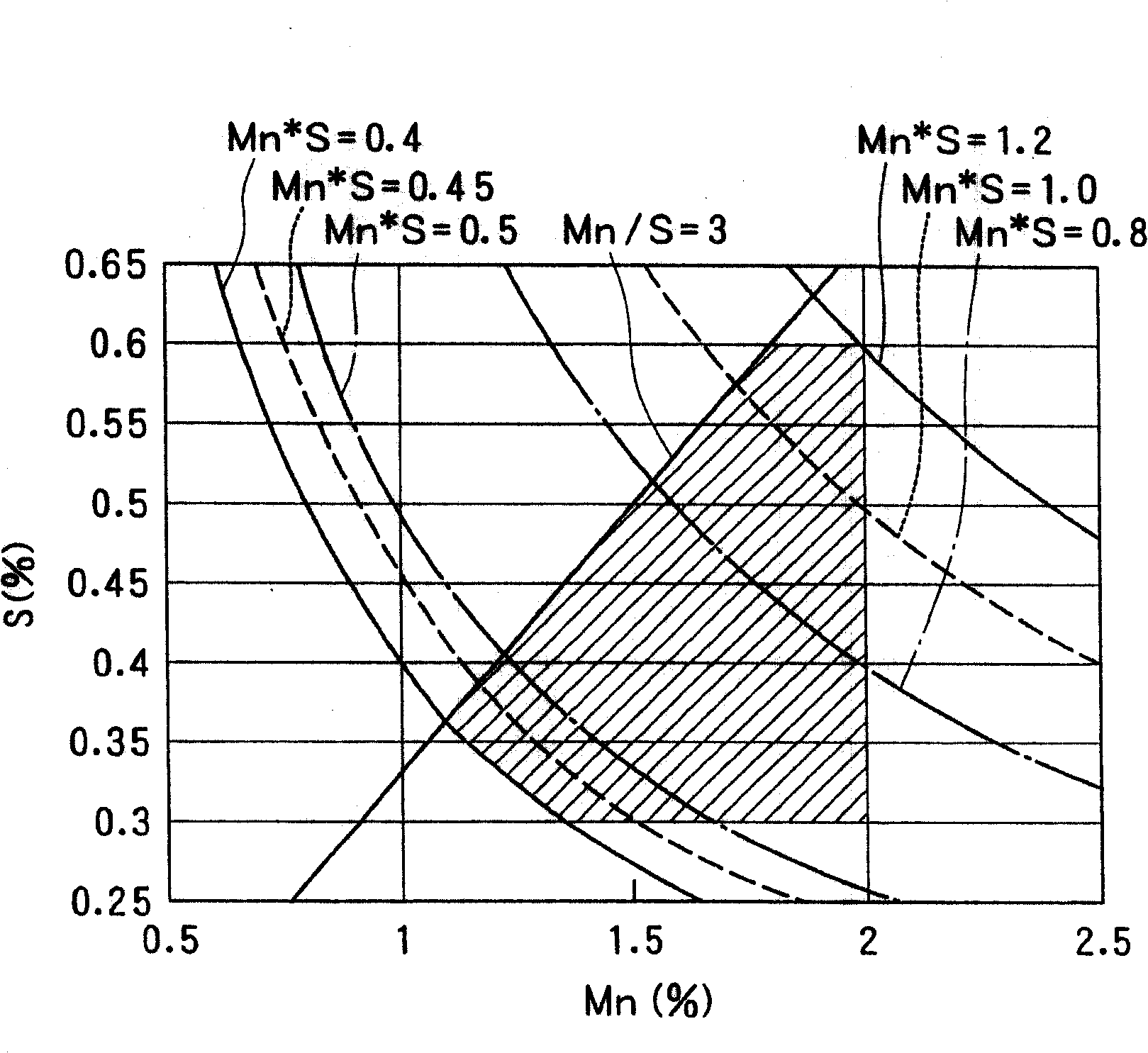

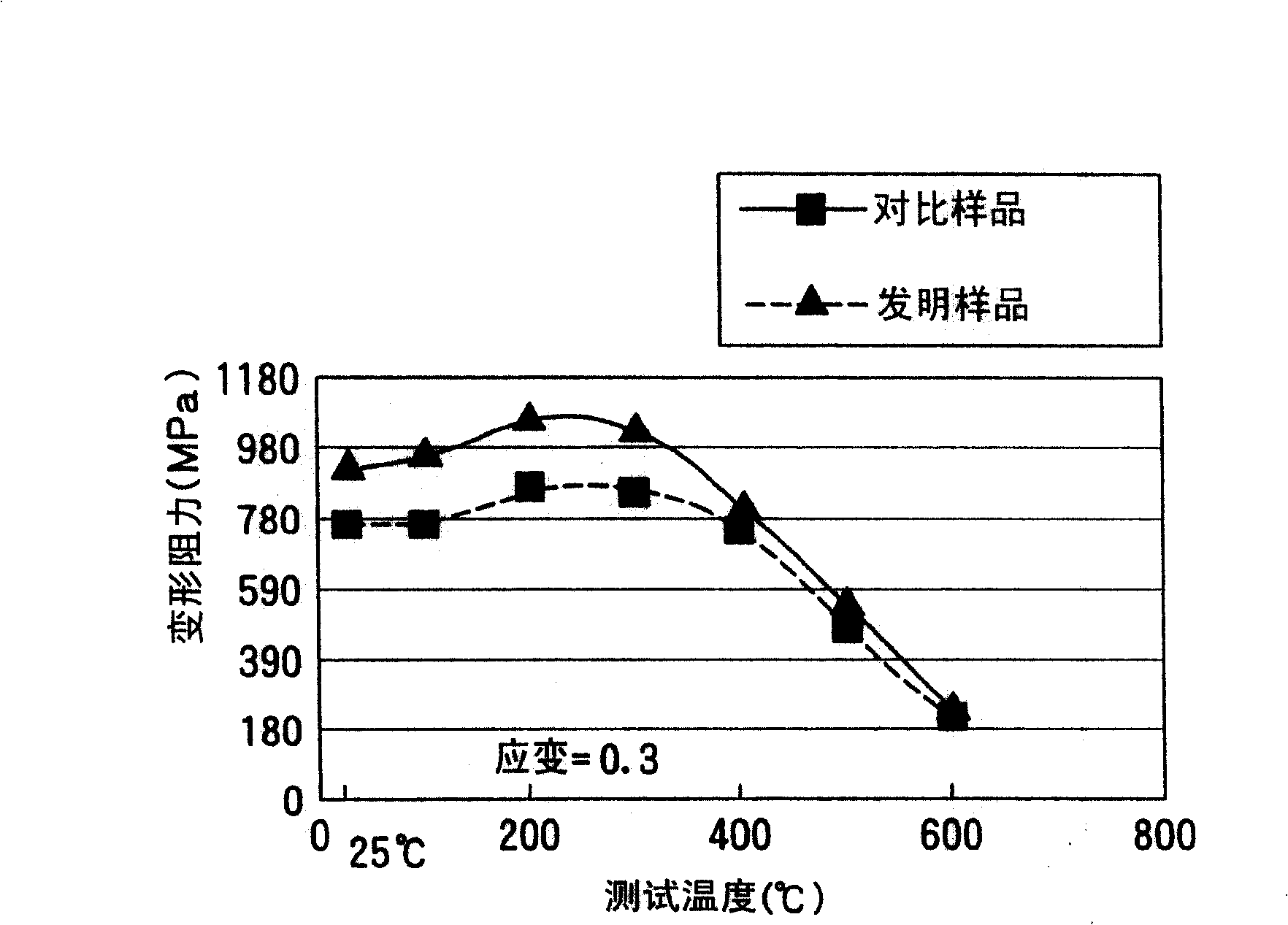

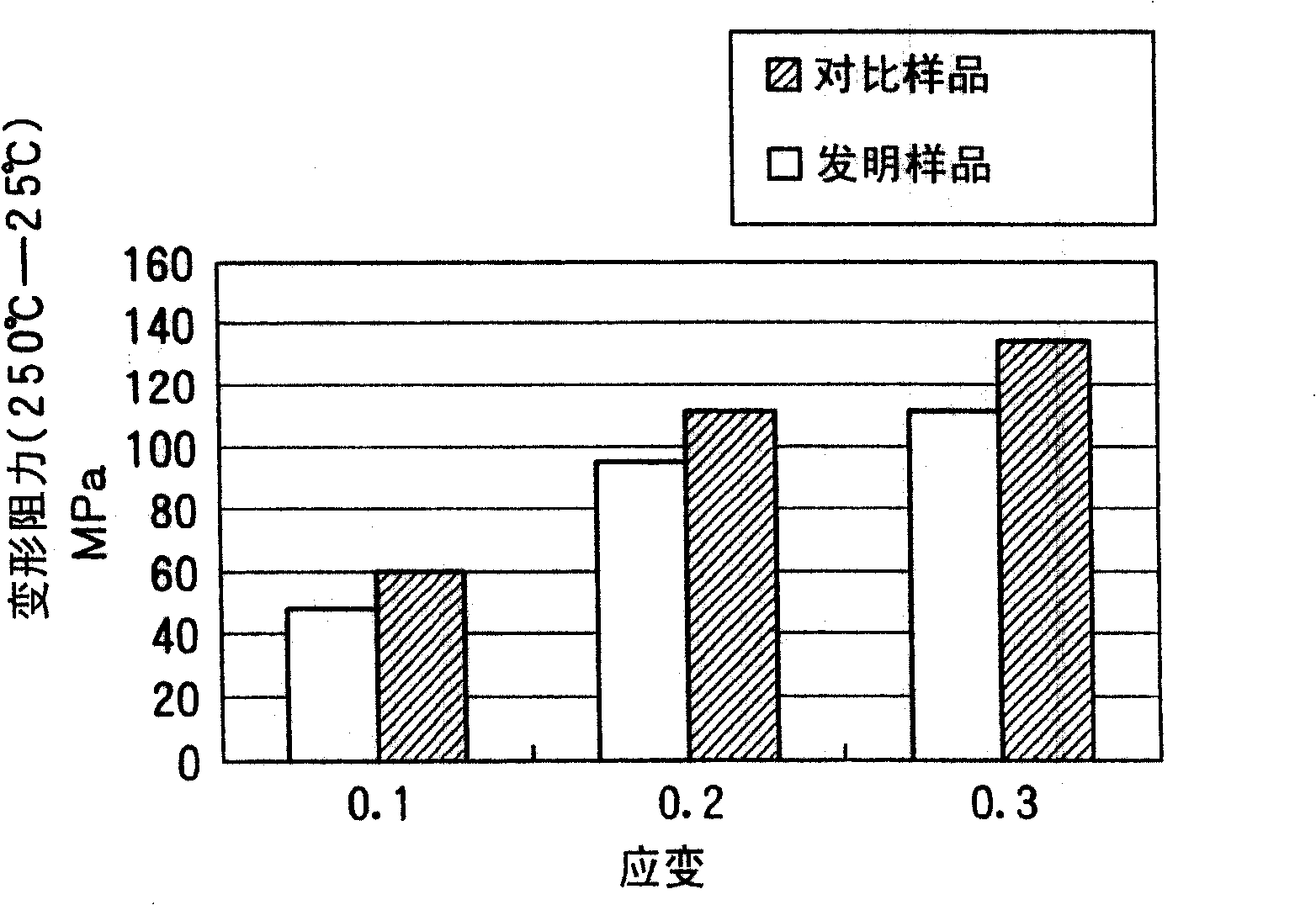

Low carbon composite free-cutting steel product excellent in roughness of finished surface and method for production thereof

The present invention provides a low-carbon resulfurized free machining steel product excellent in machinability typified by finished surface roughness even though toxic Pb or special elements such as Bi or Te are not added, and a suitable production method thereof. A steel product has a specific composition, has contents of Mn and S satisfying the following conditions: 0.40 Mn*S 1.2 and Mn / S 3.0, and contains a ferrite-pearlite structure as the metallographic structure, in which the average width ( m) of sulfide inclusions in the steel product is 2.8* (log d) or more, wherein d (mm) is the diameter of the steel product, and pro-eutectoid ferrite in the metallographic structure has a hardness HV of 133 to 150 or a difference in deformation resistance at a strain of 0.3 between 200 DEG C and 25 DEG C is 110 MPa or more and 200 MPa or less, the deformation resistances being determined in a compression test at a deformation rate of 0.3 mm / min.

Owner:KOBE STEEL LTD

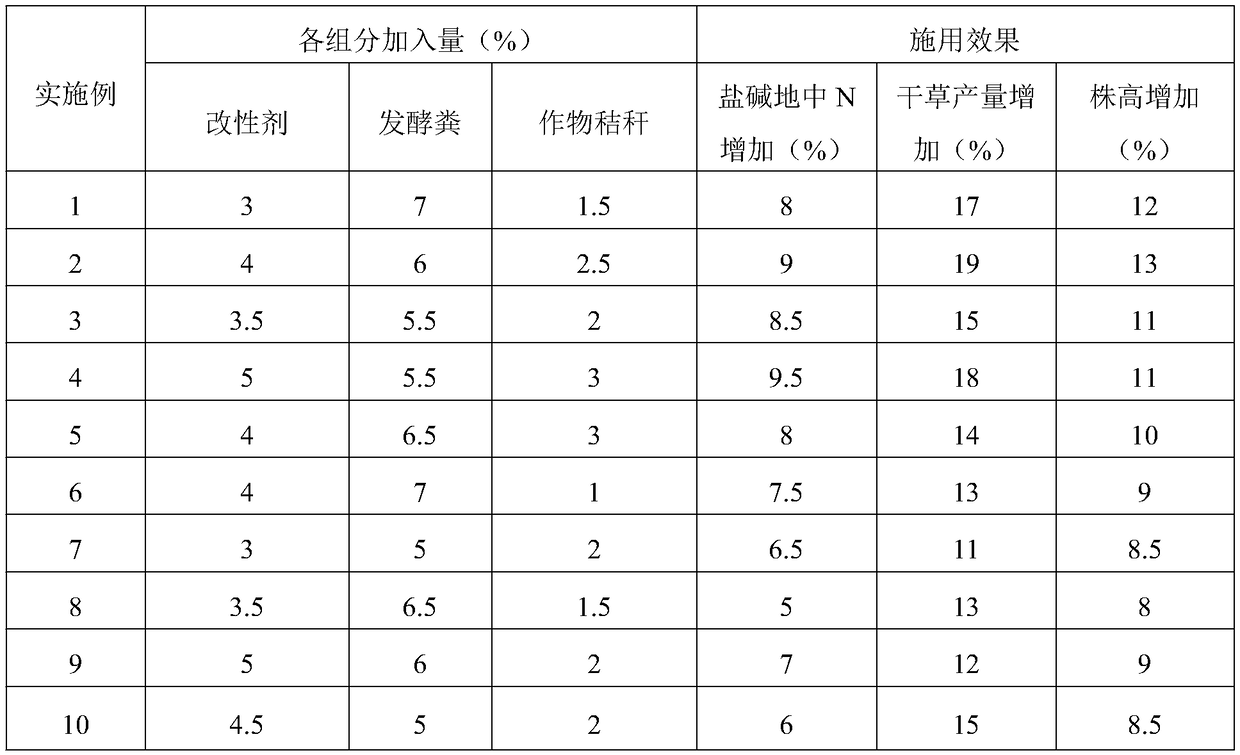

Method for producing crested myna feed from astragalus adsurgens pall produced by saline-alkali soil

InactiveCN108703272AIncrease productionImprove qualityFood processingAlkali orthophosphate fertiliserNutrientFertilizer

The invention relates to the technical field of saline-alkali soil transformation, and provides a method for producing crested myna feed from astragalus adsurgens pall produced by saline-alkali soil.The method includes the steps that astragalus adsurgens pall is planted in the saline-alkali soil by using a special fertilizer; after being harvested, the astragalus adsurgens pall is evenly mixed with peanut straw, fragrant taro straw, black corns and crickets, and the materials are smashed to obtain a mixture; then defatted bone meal, spina date seed powder, fish meal, walnut kernel powder, sesame oil, vinasse and water are added into the mixture and mixed and stirred evenly; the mixture is sealed, fermented and transferred into a drying tower for drying to obtain the crested mynas feed. Amodifier, an auxiliary agent and a regulator are evenly mixed to obtain the special fertilizer; a nutrient fertilizer is used for planting astragalus adsurgens pall in the saline-alkali soil, so thatthe yield and quality of astragalus adsurgens pall are improved; after the special fertilizer is used for planting astragalus adsurgens pall in the saline-alkali soil, the N content, hay content and plant height in the saline-alkali soil are remarkably increased. The prepared finished product also obtains remarkable economic benefits.

Owner:SHANDONG SHENGJING TOURISM DEV CO LTD

Water retaining fertilizer for potatoes and preparing method of fertilizer

InactiveCN108516910AMeet needsReduce water retentionCalcareous fertilisersMagnesium fertilisersMushroomBiochar

The invention discloses a water retaining fertilizer for potatoes. The fertilizer is prepared from, by weight, 20-30 parts of urea, 20-30 parts of potassium phosphate, 20-30 parts of potassium chloride, 5-8 parts of calcium chloride, 2-4 parts of zinc sulfate, 1-2 parts of potassium borate, 0.5-1 part of copper chloride, 3-4 parts of magnesium sulfate, 1-2 parts of vitamins, 20-40 parts of fermented needle mushroom residues and 5-8 parts of additives, wherein the additives include chitosan, carboxymethyl cellulose, lignite and ammoniated biochar. The invention further discloses a preparing method of the water retaining fertilizer for potatoes. The water retaining fertilizer is good in water retaining property and rich in nutrient and can improve the soil breathability and promote the potato growth.

Owner:WUHU JINCHENG AGRI TECH CO LTD

Chromium carbonitride strengthening agent and preparation method thereof

The invention provides a chromium carbonitride reinforcer and a preparation method thereof. The chemical components of the chromium carbonitride reinforcer include 70-75 wt% of Cr, 15-20 wt% of N, 3-9wt% of C, 0.5-4 wt% of L1, 0.3-4 wt% of L2 and 0.2-1.2 wt% of O, wherein the apparent density is 3800-4350 kg / m<3>, L1 includes at least one of Fe, Co and Ni, and L2 includes Si or / and Mn. The preparation method comprises the following steps that (1) burdening and forming are performed; and (2) sintering is performed, specifically, billets prepared in the step (1) are placed into a reaction furnace and heated, nitrogen or ammonia gas is introduced into the furnace and heat preservation is performed for 1-1.5 h when the furnace internal temperature reaches 650-680 DEG C, the furnace internaltemperature is raised to 950-1500 DEG C and reaction is performed for 1-4 h after the heat preservation time is ended, then the billets are subjected to furnace cooling under the protection of the nitrogen or ammonia gas atmosphere and taken out of the furnace after the temperatures reach 120 DEG C or below, and the chromium carbonitride reinforcer is obtained.

Owner:成都锦钛精工科技有限公司

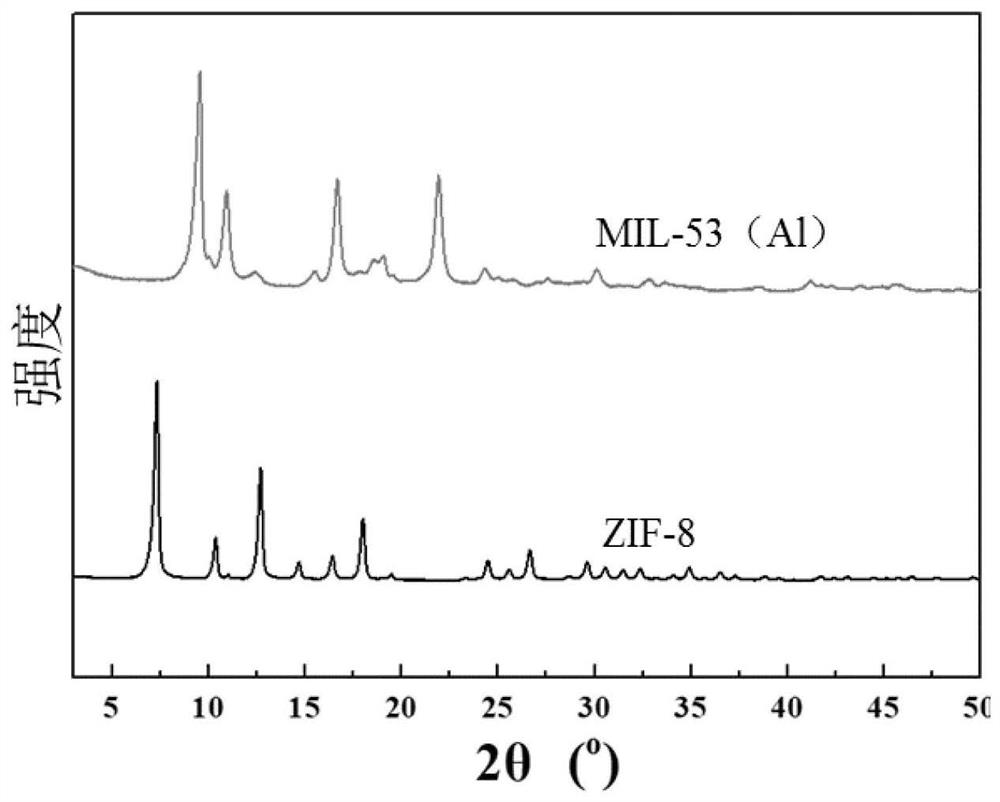

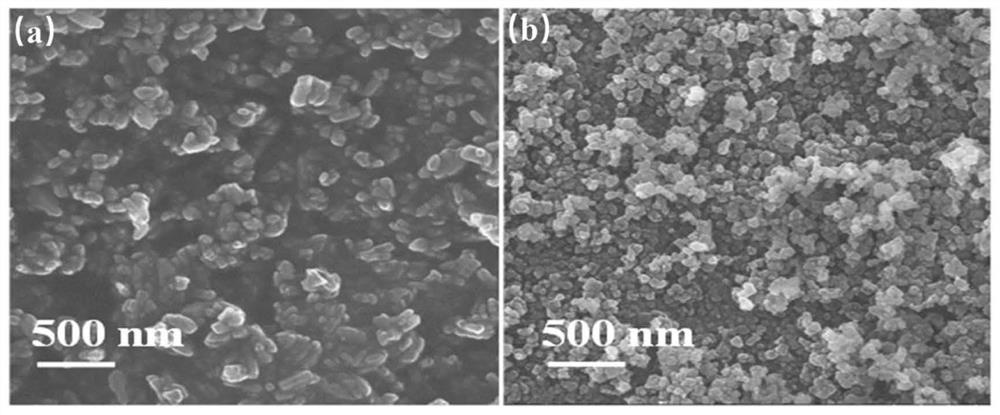

Air electrode for metal-air battery and preparation method thereof

ActiveCN111180749BPromote formationStable structureFuel and primary cellsCell electrodesElectrolytic agentPtru catalyst

The invention provides an air electrode of a metal-air battery and a preparation method thereof. Mix the metal-organic framework material with the nitrogen source small molecules, so that the nitrogen source small molecules are adsorbed in the metal-organic framework; then carry out high-temperature carbonization treatment in a nitrogen atmosphere, and finally carry out acid treatment to remove metal particles, and obtain nitrogen-doped porous carbon materials; The porous carbon material is made into slurry and coated on the surface of the conductive substrate to obtain the air electrode of the metal-air battery. The nitrogen-doped porous carbon prepared by the present invention has a high specific surface area, high nitrogen content and excellent oxygen reduction catalytic activity. A PVDF binder is added to the prepared slurry to ensure the connection between the catalyst and the substrate. Through the PTFE film, Resists the erosion of the catalyst by the electrolyte, thereby maintaining the stability of the electrode. The preparation method provided by the invention is simple and feasible, has good repeatability, is convenient for large-scale production, and can be used in the field of air batteries, especially the air electrodes of lithium-air batteries.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for Inducing Flowering of Phalaenopsis in Test Tube

ActiveCN103477978BNormal developmentHealthy and healthyHorticulture methodsPlant tissue culturePhalaenopsisBud

Owner:SUBTROPICAL CROPS INST OF FUJIAN PROVINCE

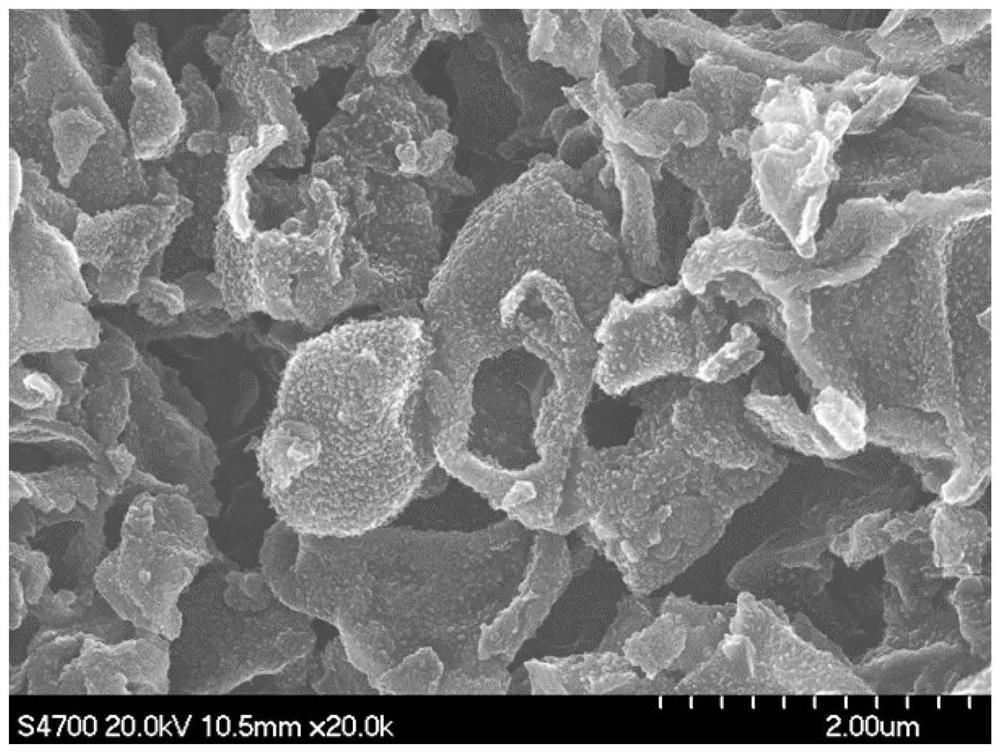

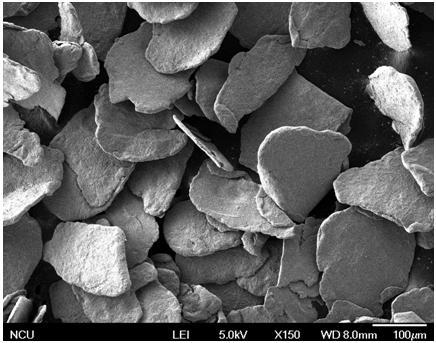

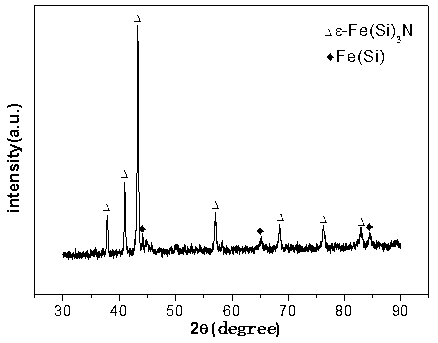

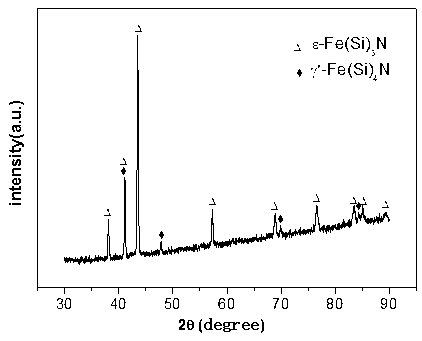

A kind of high-temperature chemical treatment process prepares the method for flaky Fesin alloy powder

The invention discloses a method for preparing sheet FeSiN alloy powder through a high-temperature chemical processing process. The preparing method includes the steps that (1) sheet FeSi alloy powder is prepared through intermediate frequency furnace smelting and a special casting technology, the powder ingredient scope is that Fe(100-x)Six(x=1wt%-15wt%); the powder with the grain size ranging from 45 micrometers to 75 micrometers and the powder with the grain size ranging from 75 micrometers to 150 micrometers enter a next step to be processed; and (2) non-toxic CO(NH2)2, NaCl, BaCl2, Na2CO3 and NaOH serve as raw materials, a reactant system is prepared according to the proportion that CO(NH2)2 / NaCl / BaCl2 / Na2CO3 / NaOH=(45-55) / (15-25) / (5-10) / (25-35) / (5-10), and the sheet FeSi alloy powder reacts for 0.5 h to 2 h in the reactant system with a temperature scope ranging from 530 DEG C to 590 DEG C to generate the sheet FeSiN alloy powder. The method adopting the high-temperature chemical processing process is used; and compared with an existing preparing method, the method is good in effect, process operation is convenient, the equipment requirement is low, and the outstanding beneficial effects of being efficient, small in energy consumption, high in N content in alloys and the like are achieved.

Owner:JIANGXI AITE MAGNETS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com