Novel high-efficiency adsorbent and application thereof

An adsorbent and high-efficiency technology, which is applied in the field of preparation of new high-efficiency adsorbents, can solve the problems of few types of heavy metals and low adsorption efficiency, achieve high adsorption efficiency, strong adsorption capacity, and reduce the harm to humans and animals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

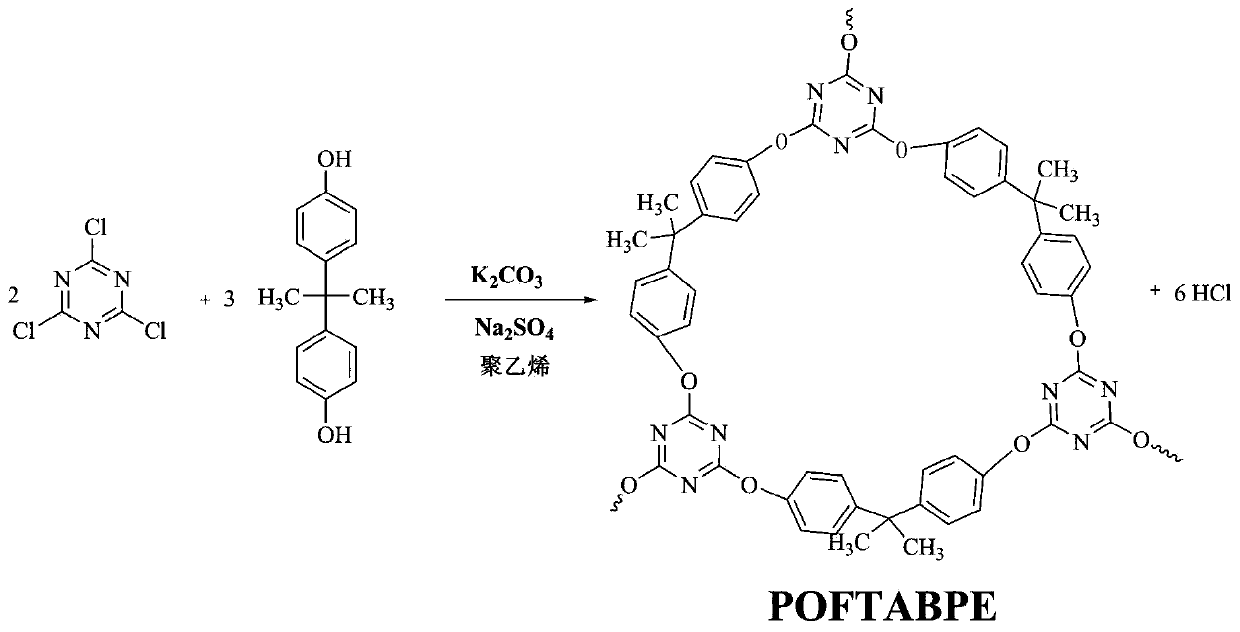

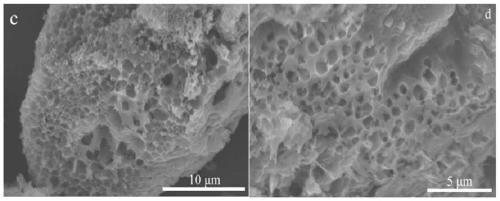

[0023] In 100mL of dichloromethane, add 2.70g of template agent polyethylene, heat and reflux for 1 hour to dissolve polyethylene in dichloromethane, then add 1.00g of cyanuric chloride, 1.86g of bisphenol A, 0.94g of sodium sulfate and 0.96g of potassium carbonate, stirred for 20 minutes, several materials were uniformly mixed, rotary evaporation removed dichloromethane, and the temperature was raised to 180° C. and carried out polycondensation reaction at this temperature for 24 hours, using methanol aqueous solution (volume percent concentration of 50 %) and dichloromethane for Soxhlet extraction to obtain 1.20 g of a black solid, that is, a nitrogen-rich organic porous framework polymer (abbreviated as POFTABPE), with a yield of 53.1%.

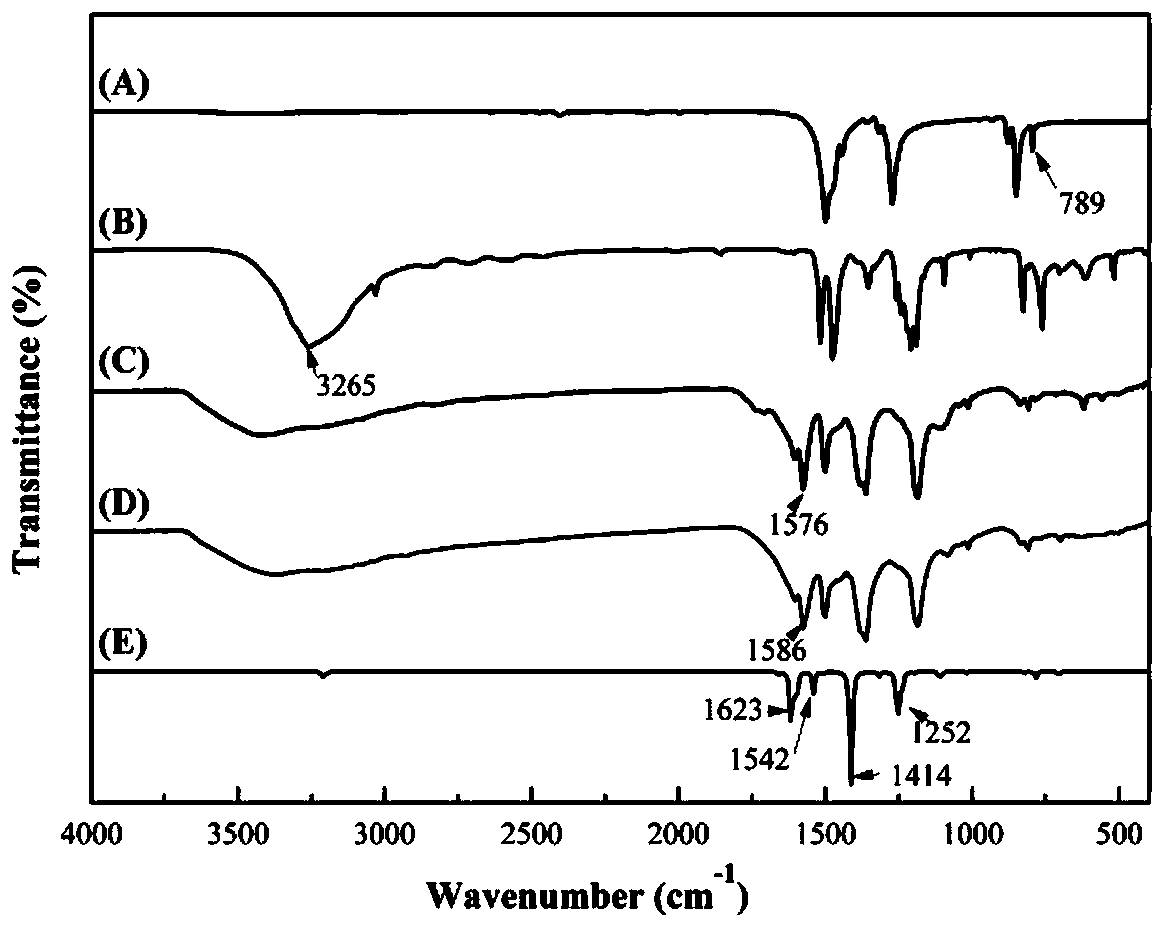

[0024] Characterization of nitrogen-rich organic porous framework polymers. 1 H SSNMR: δ (ppm) = 1.29 (H in CH 3 ),6.68(H in Benzene).Elem.Anal.Calcd.for C 51 h 42 N 6 o 6 (834.7): C, 73.32; H, 5.03; N, 10.06. Found: C, 71.56; H, 5.51...

Embodiment 2-13

[0027] Concrete reaction conditions in table 1 embodiment 2-13

[0028]

[0029]

[0030] Concrete reaction conditions in table 2 embodiment 14-15

[0031] Example 14 15 Cyanuric chloride / g 1 1 Bisphenol A / g 1.86 1.86 Polyethylene / g 2.7 2.7 Sodium sulfate / g 0.94 0.94 Potassium carbonate / g 0.96 0.96 Reflow time / h 1 1 Polycondensation time / h 24 24 Polycondensation temperature / ℃ 130 260 Yield / g 1.12 1.22

Embodiment 16

[0033] In 100mL of chloroform, add 2.70g of polyethylene, heat, reflux for 1 hour, then add 1.00g of cyanuric chloride, 1.86g of bisphenol A, 0.94g of sodium sulfate and 0.96g of potassium carbonate, and stir for 20 minutes to make several The materials were uniformly mixed, chloroform was removed by rotary evaporation, heated to 180° C., polycondensation reaction was carried out at this temperature, and the reaction time was 24 hours. Soxhlet extraction was carried out using methanol aqueous solution (volume percent concentration: 50%) and dichloromethane successively. 1.28 g of black solid was obtained with a yield of 56.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com