Air electrode for metal-air battery and preparation method thereof

A metal-air battery and air electrode technology, applied in battery electrodes, fuel cell half-cells, primary battery-type half-cells, circuits, etc., can solve the problem that the catalytic performance cannot be surpassed by precious metal catalysts, it is difficult to obtain, and there is a porous structure Difficult to control and other problems, to achieve the effect of contributing to catalytic activity and stability, preventing excessive heating rate, and excellent adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a method for preparing an air electrode of a metal-air battery, comprising the following steps:

[0045] S1. Preparation of nitrogen-doped porous carbon:

[0046] The metal organic framework material and the nitrogen source are prepared into a mixed solution, stirred evenly, and then left to stand for adsorption, then centrifuged, washed, and dried; then high-temperature carbonization treatment is performed in an inert gas atmosphere, and after the carbonization is completed, acid treatment is performed to remove the metal particles to obtain Nitrogen-doped porous carbon;

[0047] The high-temperature carbonization treatment includes the following steps: heating at a heating rate of 3-8 °C / min, first heating to 70-90 °C for 18-30 h, then heating to 130-180 °C for 5-10 h, and finally heating to 700 °C ~1000℃ for 5~10h.

[0048] Preferably, in step S1, the high temperature carbonization treatment includes the following steps: heating at a ...

Embodiment 1

[0073] A preparation method of an air electrode for a metal-air battery, comprising the following steps:

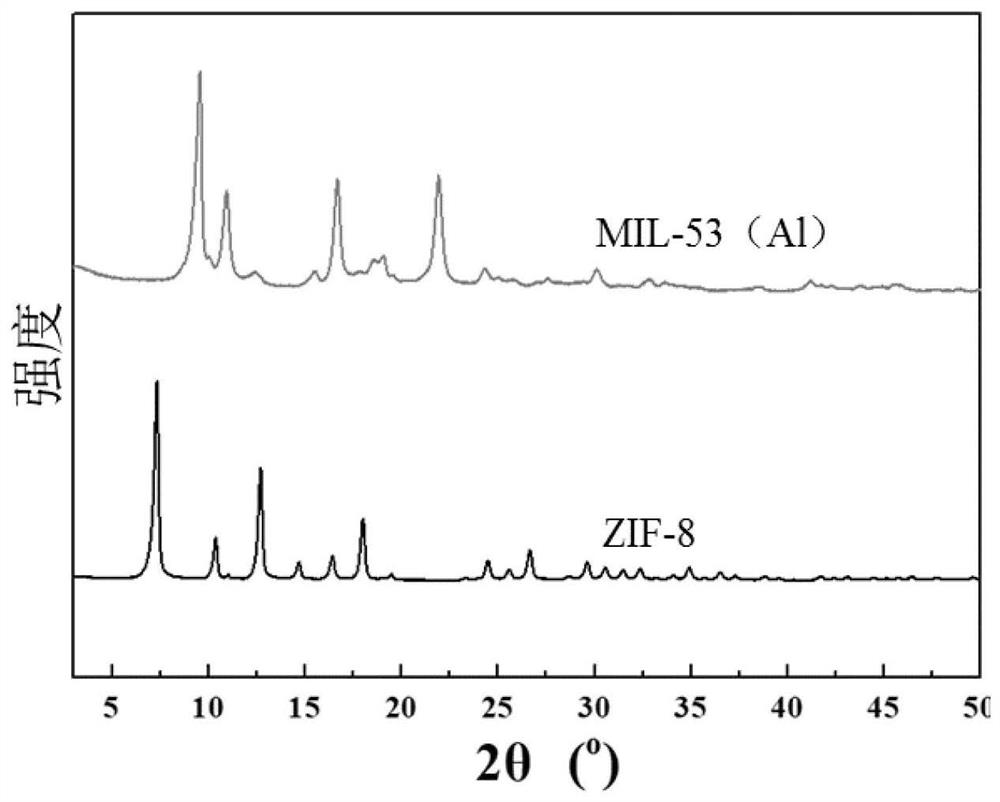

[0074] (1) Synthesis of MIL-53(Al) (Levassil framework material whose metal node is Al)

[0075] Al(NO 3 ) 3 ·9H 2 O and terephthalic acid were prepared according to the molar ratio of 1:2.25, added to 30ml of DMF to make it completely dissolved; then the mixed solution was transferred to a polytetrafluoroethylene reactor, placed in an oven, heated to 393K for constant temperature reaction After 72 hours, it was cooled to room temperature; the white solid obtained by the reaction was collected by centrifugation, washed with DMF for several times, and finally dried in a 413K oven to obtain MIL-53(Al) powder.

[0076] (2) Preparation of NPC (nitrogen-doped porous carbon)

[0077] 500mg activated MIL-53 (Al) powder, 20ml sugar alcohol (FA), 5ml NH 4 OH and 5 g of urea were prepared into a mixed solution, kept under stirring for 12 hours, and then allowed to stand overni...

Embodiment 2

[0085] Compared with Example 1, the preparation method of a metal-air battery air electrode provided in Example 2 is different in that step (1) is the synthesis of ZIF-8 (the zeolite imidazolate framework material whose metal node is Zn), details as follows:

[0086] Zn(NO 3 ) 2 ·6H 2 O (2.933g, 9.87mmol) was added to 200ml of methanol and stirred to dissolve to form solution (I), and Hmim (2-methylimidazole) (6.489g, 79.04mmol) was added to 200ml of methanol to dissolve to form solution (II), and then the solution was dissolved (I) Quickly poured into solution (II) and stirred at room temperature for 1 h to form white crystals. The obtained product was collected by centrifugation, washed several times with methanol, and dried in a 413K oven.

[0087] The other steps are basically the same as those in Embodiment 1, and are not repeated here.

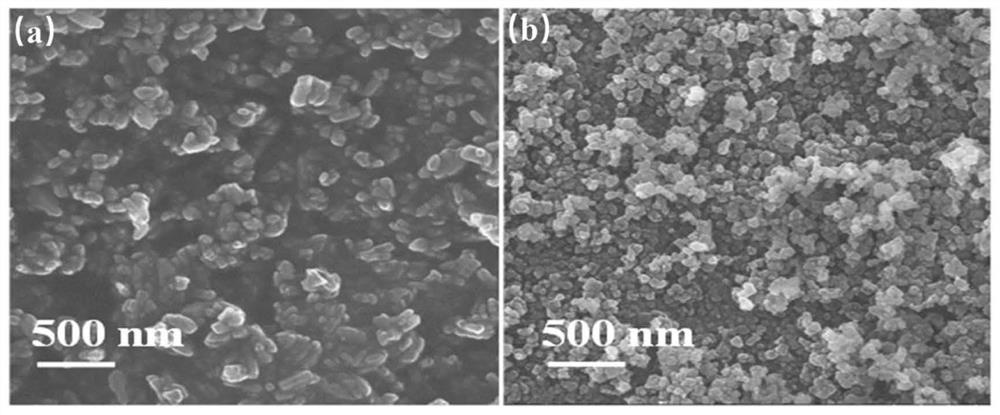

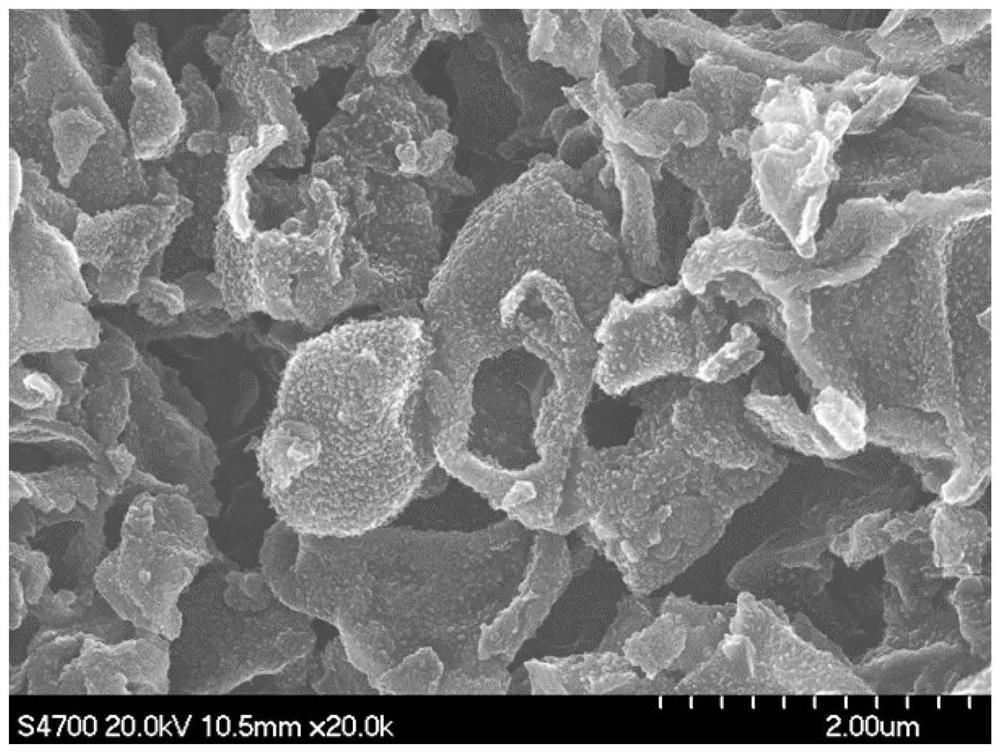

[0088] from Figure 1 to Figure 3 It can be seen that ZIF-8 was successfully prepared in this example, and the particle distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com