A kind of high-temperature chemical treatment process prepares the method for flaky Fesin alloy powder

A treatment process and high-temperature chemical technology, applied in the field of iron-based magnetic materials, can solve the problems of high energy consumption, long time of passing N2, low alloy N content, etc., and achieve the effect of low energy consumption, good effect and high N content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

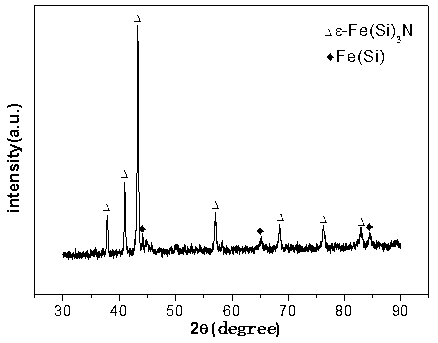

[0014] Embodiment 1: A kind of high-temperature chemical treatment process prepares the method for flaky FeSiN alloy powder as follows:

[0015] Step 1. Press Fe in the intermediate frequency furnace 95 Si 5 Proportion melting alloy liquid. The alloy liquid is poured at 1200~1350°C. The casting mold is a graphite plate with a thickness of 50 mm. The plate moves horizontally at a speed of 5cm / s. After pouring, the molten iron is cooled rapidly to obtain a plate-shaped ingot.

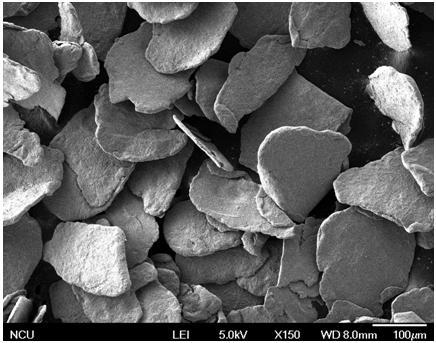

[0016] The plate-shaped ingot is pulverized by a pulverizer and sieved to obtain flake FeSi alloy powder with a particle size of 45-75 μm.

[0017] Step two, with non-toxic CO (NH 2 ) 2 , NaCl, BaCl 2 、Na 2 CO 3 , NaOH as raw material, by weight ratio CO(NH 2 ) 2 / NaCl / BaCl 2 / Na 2 CO 3 / NaOH = 50 / 20 / 8 / 30 / 8 ratio to prepare the reactant system, heated to 560°C in a corundum crucible, and the reactant system melted into a liquid state. Wrap the flaky FeSi alloy powder prepared in the fir...

Embodiment 2

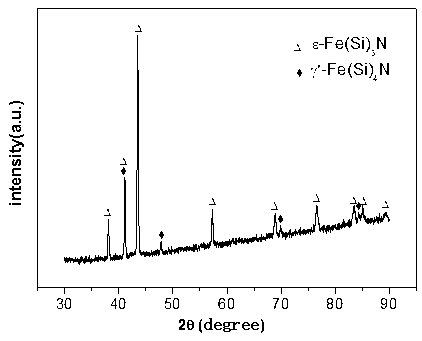

[0021] Embodiment 2: A kind of high-temperature chemical treatment process prepares the method for flake FeSiN alloy powder as follows:

[0022] Step 1. Press Fe in the intermediate frequency furnace 90 Si 10 Proportion melting alloy liquid. The alloy liquid is poured at 1200~1350°C. The casting mold is a graphite plate with a thickness of 60mm. The plate moves horizontally at a speed of 10cm / s. After pouring, the molten iron is cooled rapidly to obtain a plate-shaped ingot. The plate-shaped ingot is pulverized by a pulverizer and sieved to obtain flake FeSi alloy powder with a particle size of 75-150 μm.

[0023] Step two, with non-toxic CO (NH 2 ) 2 , NaCl, BaCl 2 、Na 2 CO 3 , NaOH as raw material, by weight ratio CO(NH 2 ) 2 / NaCl / BaCl 2 / Na 2 CO 3 / NaOH = 55 / 25 / 10 / 35 / 10 to prepare the reactant system, heated to 590°C in a corundum crucible, and the reactant system melted into a liquid state. Wrap the flaky FeSi alloy powder prepared in the firs...

Embodiment 3

[0024] Embodiment 3: A kind of high-temperature chemical treatment process prepares the method for flaky FeSiN alloy powder as follows:

[0025] Step 1. Press Fe in the intermediate frequency furnace 90 Si 10 Proportion melting alloy liquid. The alloy liquid is poured at 1200~1350°C. The casting mold is a graphite plate with a thickness of 55mm. The plate moves horizontally at a speed of 1cm / s. After pouring, the molten iron is cooled rapidly to obtain a plate-shaped ingot. The plate-shaped ingot is pulverized by a pulverizer and sieved to obtain flake FeSi alloy powder with a particle size of 45-75 μm.

[0026] Step two, with non-toxic CO (NH 2 ) 2 , NaCl, BaCl 2 、Na 2 CO 3 , NaOH as raw material, by weight ratio CO(NH 2 ) 2 / NaCl / BaCl 2 / Na 2 CO 3 / NaOH = 45 / 15 / 5 / 25 / 5 ratio to prepare the reactant system, heated to 530°C in a corundum crucible, and the reactant system melted into a liquid state. Wrap the flaky FeSi alloy powder prepared in the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com