Cathode electrophoretic coating and preparation method thereof and cathode electrophoretic coating method

A cathodic electrophoretic coating, content technology, applied in the direction of electrophoretic coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of poor storage stability and thermal stability of cathodic electrophoretic coating, achieve excellent storage stability and use stability, excellent Effect of Throwing Power and Film Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

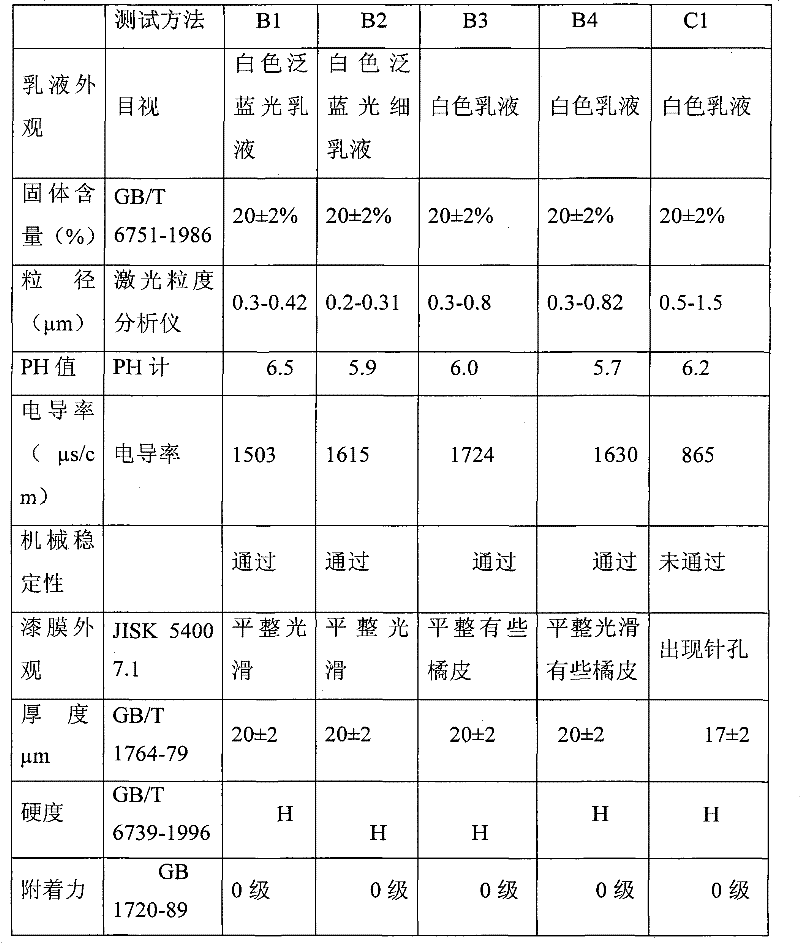

Examples

preparation example Construction

[0010] According to the preparation method of the cathodic electrophoretic coating provided by the present invention, based on the total weight of solid components of epoxy resin, chain extender, toughening agent, organic secondary amine compound and blocked polyisocyanate curing crosslinking agent, the ring The content of the oxygen resin is 10-40wt%, the content of the chain extender is 5-15wt%, the content of the toughening agent is 5-30wt%, the content of the organic secondary amine compound is 5-15wt%, The content of the blocked polyisocyanate curing crosslinking agent is 30-50wt%.

[0011] According to the preparation method of cathodic electrophoretic paint provided by the present invention, the method for preparing epoxy cationic resin is:

[0012] 1) dissolving epoxy resin, chain extender, toughening agent and blocked polyisocyanate curing crosslinking agent in a solvent to form a mixture;

[0013] 2) Under the protection of nitrogen, add the organic secondary amine ...

Embodiment 1

[0040] (1) Add 15 grams of methanol, 15 grams of ethanol, 60 grams of propylene glycol, 10 grams of trimethylolpropane and 20 grams of methyl isobutyl ketone in a four-necked flask equipped with a condenser, nitrogen protection, stirring paddle and dropping funnel gram, stirred at a certain rate and heated up to 50°C under nitrogen protection, slowly mixed 400 grams of Desmodur (Desmodur ) VL (aromatic polyisocyanate based on diphenylmethane diisocyanate, Bayer company) was added dropwise to the system within 2 hours while the temperature was raised to 110°C, 20 grams of methyl isobutyl ketone was added, and the mixed system was maintained at 110°C until Infrared spectroscopy detects that -NCO disappears, and then 80 grams of methyl isobutyl ketone is added to the mixed system to finally obtain a cured crosslinking agent system with a solid content of about 80%.

[0041] (2) Add bisphenol A epoxy resin EPON82810 grams in the four-necked bottle equipped with condenser, nitroge...

Embodiment 2

[0046] (1) Add 40 grams of methanol, 55 grams of propylene glycol, 10 grams of trimethylolpropane and 20 grams of methyl isobutyl ketone in a four-necked flask equipped with a condenser, nitrogen protection, stirring paddle and dropping funnel, to a certain extent Stir at a constant rate and raise the temperature to 50°C under the protection of nitrogen, slowly add 150 grams of 4,4-diphenylmethane diisocyanate (Yantai Wanhua) dropwise to the system within 2 hours while raising the temperature to 100°C, add 14 grams Methyl isobutyl ketone, the mixed system is kept at 100°C until the infrared spectrum detects that -NCO disappears, then 30 grams of methyl isobutyl ketone is added to the mixed system, and finally a cured crosslinking agent system with a solid content of about 80% is obtained.

[0047] (2) Add bisphenol A epoxy resin EPON82840 grams, bisphenol A 5 grams, BPE 20 grams in the four-necked bottle that condenser, nitrogen protection, stirring paddle and dropping funnel a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com