Preparation method and application of superfine gold-palladium nanoparticle/nitrogen-doped porous carbon composite material

A nitrogen-doped porous carbon, composite material technology, applied in chemical instruments and methods, non-metallic elements, chemical/physical processes, etc., can solve problems such as the inability to carry out large-scale practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

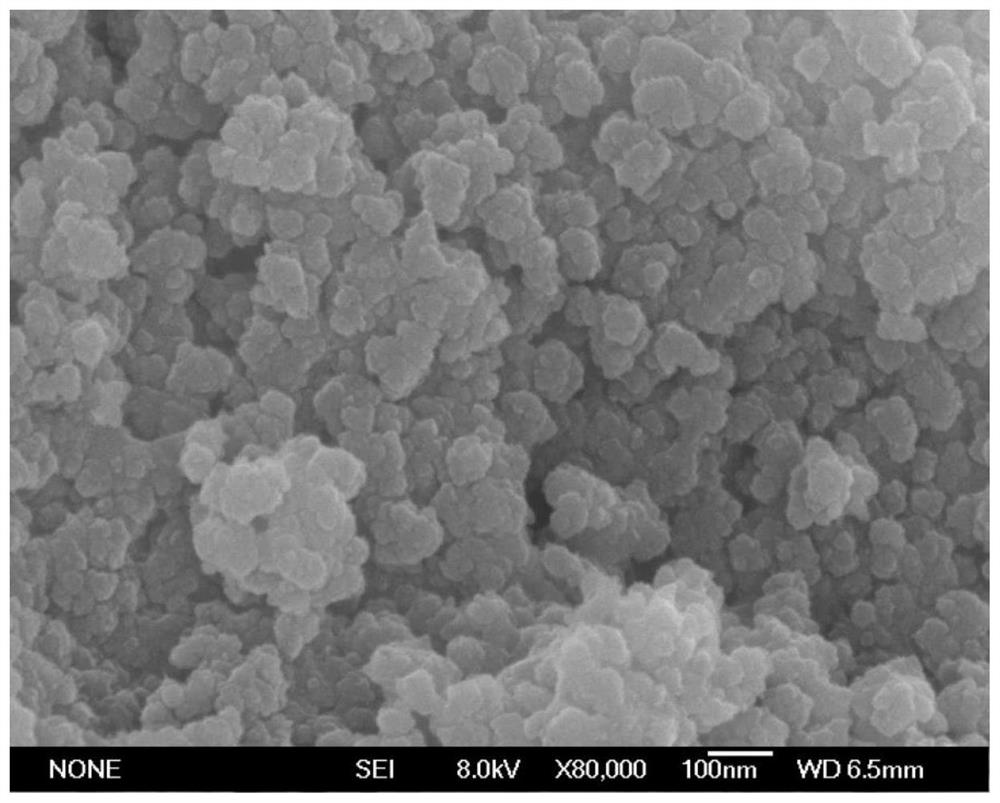

[0032] A preparation method of ultrafine gold-palladium nanoparticles / nitrogen-doped porous carbon composite material, specifically comprising the following experimental steps:

[0033] a. Nitrogen-doped porous carbon (N-C) substrate was prepared by high-temperature annealed peanut shell powder: first weigh 500 mg of peanut shell powder and place it in a cleaned and dried ceramic crucible, and place the crucible in the center of the tube furnace. In the center, after 3 times of vacuuming, start heating (the heating rate is set to 5°C / min, the annealing temperature is set to 600°C, 700°C, 800°C and 900°C in turn, and after reaching the set temperature, keep it warm for 2h, and throughout the The heating, heat preservation and cooling processes were all in an argon protective atmosphere). After natural cooling, the obtained samples were placed in 50 mL of deionized water, ultrasonically cleaned for 1 hour, centrifuged three times, and then dried in a vacuum oven at 60°C for late...

Embodiment

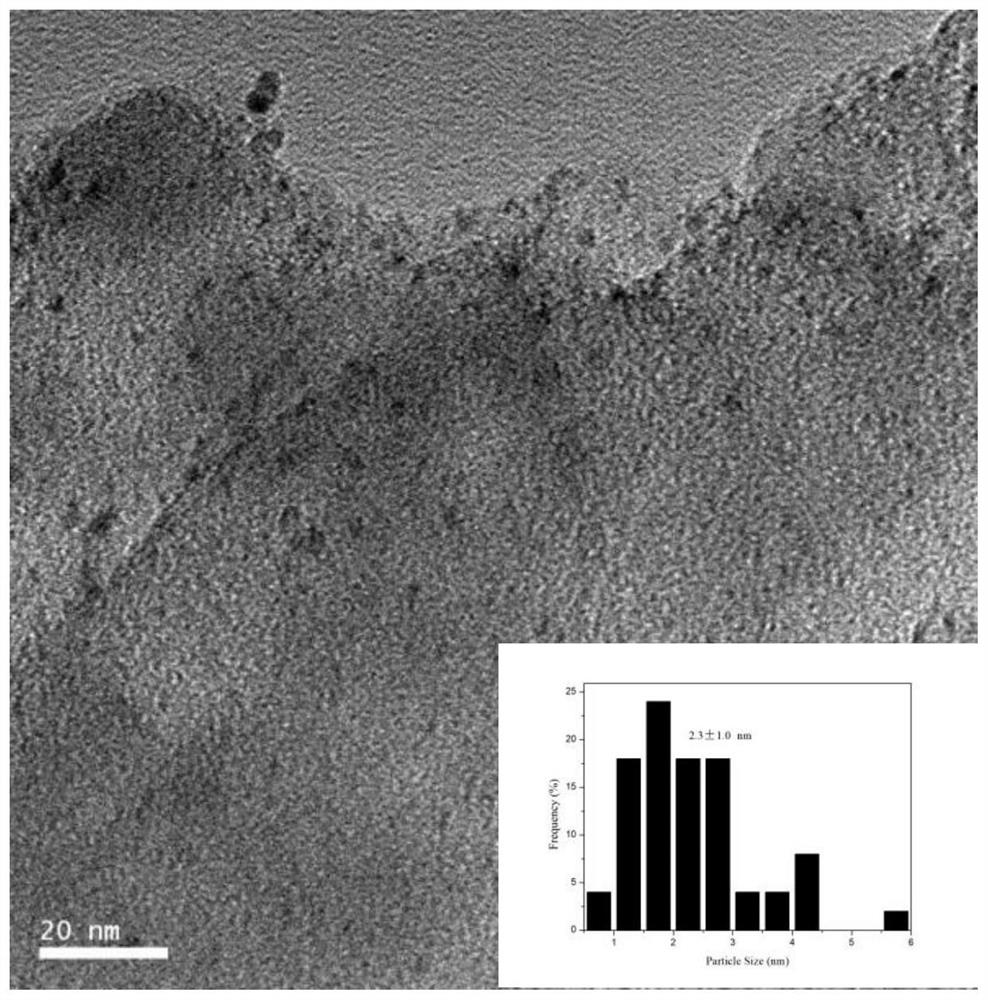

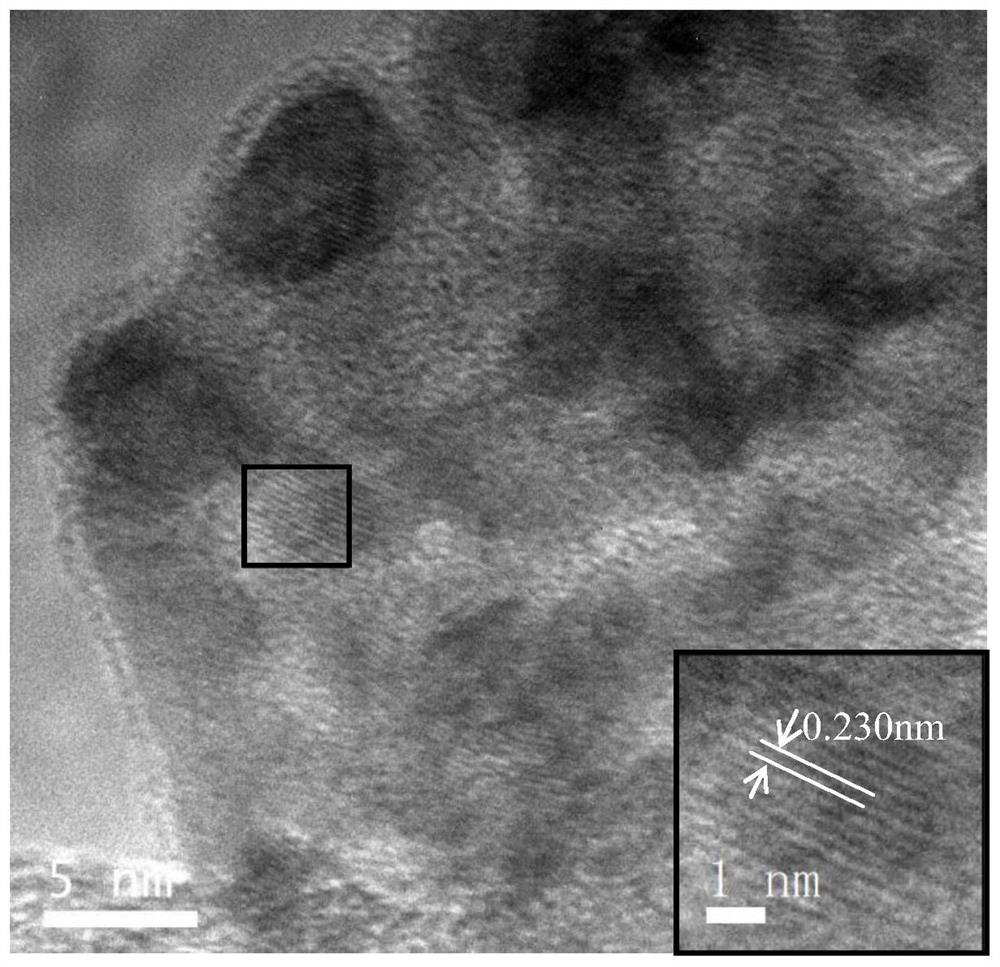

[0048] In this example, Au x PD 1-x The specific preparation process and steps of the / N-C catalyst are as follows:

[0049] (1) Preparation of nitrogen-doped porous carbon (N-C) substrate material: First, weigh 500 mg of peanut shell powder and place it in a cleaned and dried ceramic crucible. Heating starts after vacuum (heating rate is set to 5°C / min, annealing temperature is set to 600°C, 700°C, 800°C and 900°C in turn, after reaching the annealing temperature, keep warm for 2h, and during the whole heating, holding and cooling process are at in an argon atmosphere). After natural cooling, put the obtained sample into 50mL deionized water, after ultrasonic cleaning for 1 hour, and centrifugation for 3 times, place it in a vacuum oven at 60°C and dry it for later use;

[0050] (2) Preparation of Au by liquid phase reduction method x PD 1-x / N-C catalyst: First weigh 100mg of the above-mentioned dried N-C substrate, add it to 30mL of deionized water, then add 0.1mL of A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com