Nb-Ti-N micro-alloyed hot-rolled ribbed steel bar and production method thereof

A hot-rolled ribbed steel bar and micro-alloying technology, which is applied in the field of steel bar preparation, can solve problems such as transverse cracks on the surface of the slab, increased production costs, warped steel bar surface, etc., to reduce surface cracks, improve straightening temperature, and composition easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

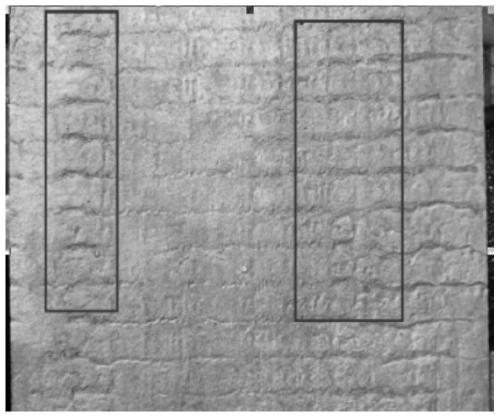

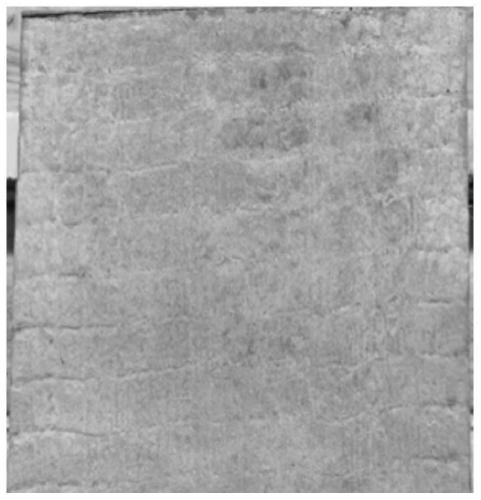

Image

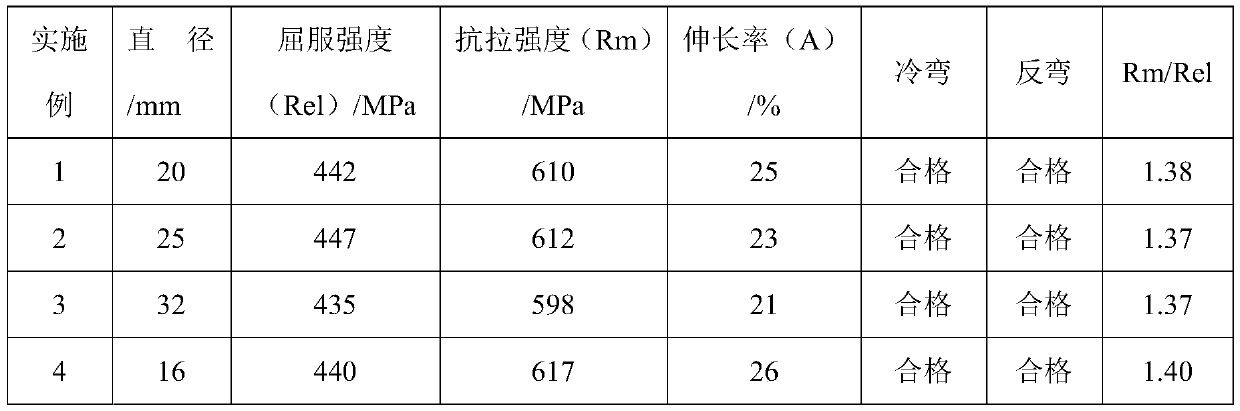

Examples

Embodiment 1

[0029] A Nb-Ti-N microalloyed hot-rolled ribbed steel bar, including the following chemical composition in weight percentage: C0.24%, Si0.46%, Mn1.29%, Nb0.013%, Ti0.008%, N0 .0070%, P≤0.030%, S≤0.015% and unavoidable impurities.

[0030] Its production process includes converter smelting, nitrogen blowing, refining, continuous casting and rolling;

[0031] Wherein, the converter smelting process adopts high-strength supplementary blowing, the control end point [C] is 0.11%, the end point temperature of tapping is 1635°C, and silicon-manganese, ferrosilicon, and niobium are evenly added to the steel flow during the 1 / 3 process of putting steel Alloying the ferroalloy, and adding 500kg of lime and 300kg of refining slag / furnace in the late stage of tapping, nitrogen blowing and stirring are carried out throughout the whole process, the flow of nitrogen gas is firstly blown strongly and then weakly blown, the flow rate is reduced from 750NL / min to 220NL / min, and the time is 5min...

Embodiment 2

[0036] A Nb-Ti-N microalloyed hot-rolled ribbed steel bar, including the following chemical composition in weight percentage: C0.23%, Si0.47%, Mn1.31%, Nb0.014%, Ti0.010%, N0 .0075%, P≤0.035%, S≤0.020% and unavoidable impurities.

[0037] Its production process includes converter smelting, nitrogen blowing, refining, continuous casting and rolling;

[0038] Wherein, the converter smelting process adopts high-strength supplementary blowing, the control end point [C] is 0.10%, the end point temperature of tapping is 1640°C, and silicomanganese, ferrosilicon, and niobium are evenly added to the steel flow during the 1 / 3 process of putting steel The iron alloy is alloyed, and the ladle is added with 500Kg of lime and 300Kg of refining slag / furnace. The whole process is carried out with nitrogen blowing and stirring. The nitrogen blowing at the bottom is 7 minutes, and the flow rate is 57NL / min.

[0039] In the refining furnace process, 46kg of ferrotitanium is added in the later...

Embodiment 3

[0043] A Nb-Ti-N microalloyed hot-rolled ribbed steel bar, including the following chemical components in weight percentage: C0.25%, Si0.46%, Mn1.31%, Nb0.015%, Ti0.009%, N0 .0082%, P≤0.024%, S≤0.017% and unavoidable impurities.

[0044] Its production process includes converter smelting, nitrogen blowing, refining, continuous casting and rolling;

[0045] Wherein, the converter smelting process adopts high-strength supplementary blowing, the control end point [C] is 0.11%, the end point temperature of tapping is 1635°C, and silicon-manganese, ferrosilicon, and niobium are evenly added to the steel flow during the 1 / 3 process of putting steel The iron alloy is alloyed, and the ladle is added with 500kg of lime and 300kg of refining slag / furnace. The whole process is carried out with nitrogen blowing and stirring. Bottom blowing nitrogen is 5min, flow rate is 55NL / min.

[0046] In the refining furnace process, 45kg of ferrotitanium is added in the later stage of refining, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com