Preparation method of nitrogen-doped porous carbon film and product thereof

A technology of nitrogen-doped porous carbon and nitrogen-doped carbon, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

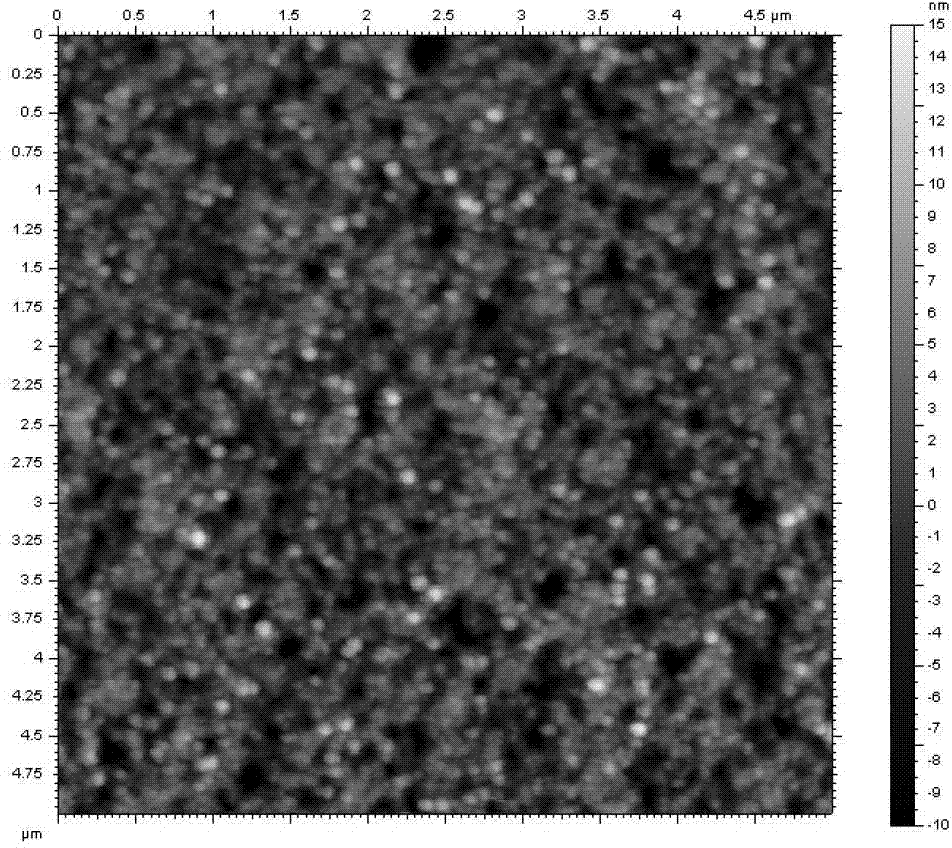

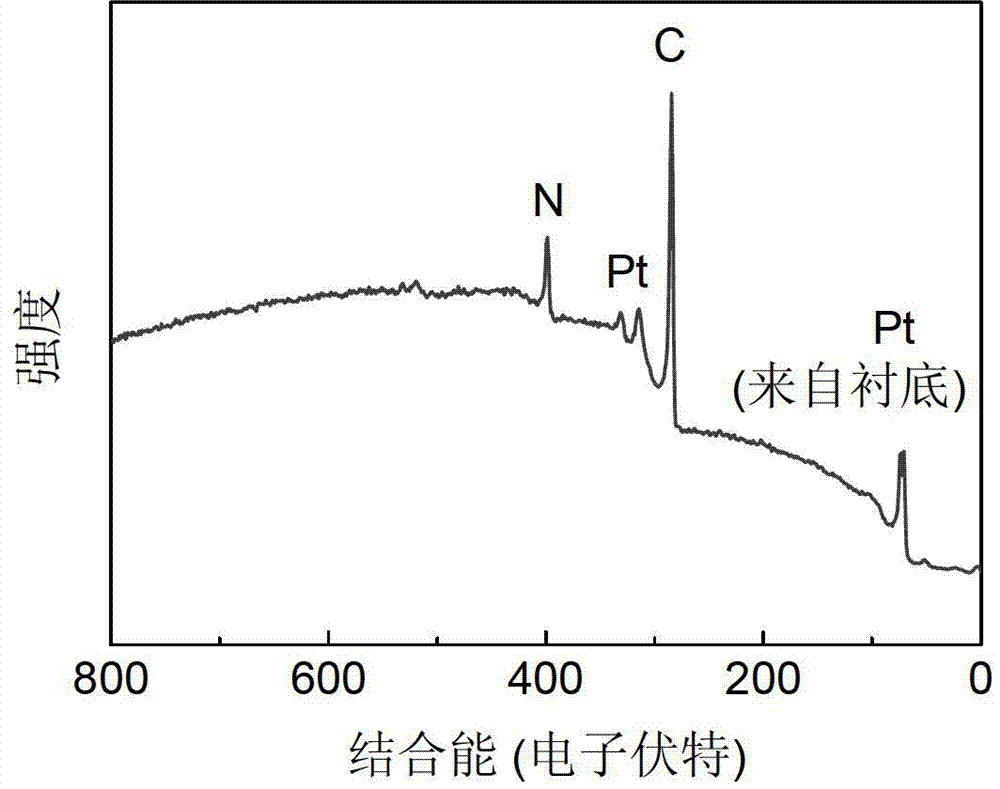

[0024] DC magnetron sputtering is adopted, graphite is used as the sputtering target, nitrogen is used as the sputtering atmosphere, and platinum-coated silicon wafers (Pt / Ti / SiO 2 / Si) as the substrate, the substrate temperature is room temperature, the sputtering power is 70W, the thickness of the N-doped carbon film obtained by sputtering is 60nm, and the atomic percentage of N in the film is 20% as determined by X-ray photoelectron spectroscopy. Place the N-doped carbon film in a rapid annealing furnace with argon as a protective atmosphere, raise the temperature of the carbon film to 600°C, keep it at 600°C for 10 minutes, and then cool it to room temperature. The surface morphology of N-doped porous carbon film after heat treatment is shown in figure 1 - the atomic force microscope image of the N-doped porous carbon film obtained in this embodiment, by figure 1 It can be seen that the pores with a size of 10-200 nm are evenly distributed on the surface of the film, such...

Embodiment 2

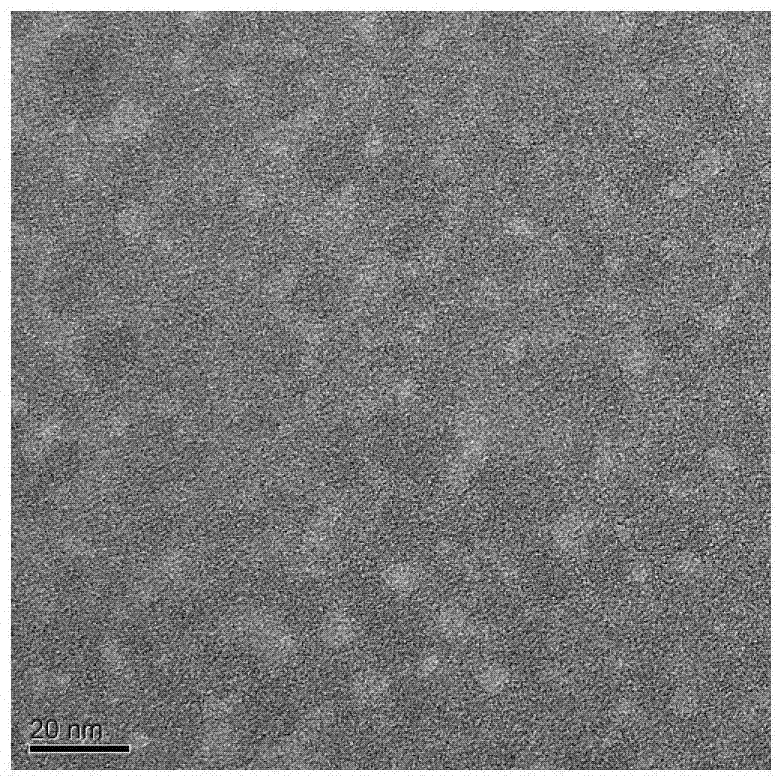

[0026] DC magnetron sputtering is adopted, graphite is used as the sputtering target, nitrogen is used as the sputtering atmosphere, and silicon wafers (SiO 2 / Si) as the substrate, the substrate temperature is room temperature, the sputtering power is 70W, and the thickness of the N-doped carbon film obtained by sputtering is 60nm. Place the N-doped carbon film in a rapid annealing furnace with argon as a protective atmosphere, raise the temperature of the carbon film to 600°C, keep it at 600°C for 10 minutes, and then cool it to room temperature. The transmission electron micrographs of N-doped porous carbon films after heat treatment are shown in image 3 ,Depend on image 3 It can be seen that the pores with a size of 2-10 nm are uniformly distributed in the film. The thickness of the porous carbon film after heat treatment is 30 nm, and the size is 5 × 5 cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com