Production method for copper-contained low-temperature high-magnetic-induction-oriented silicon steel

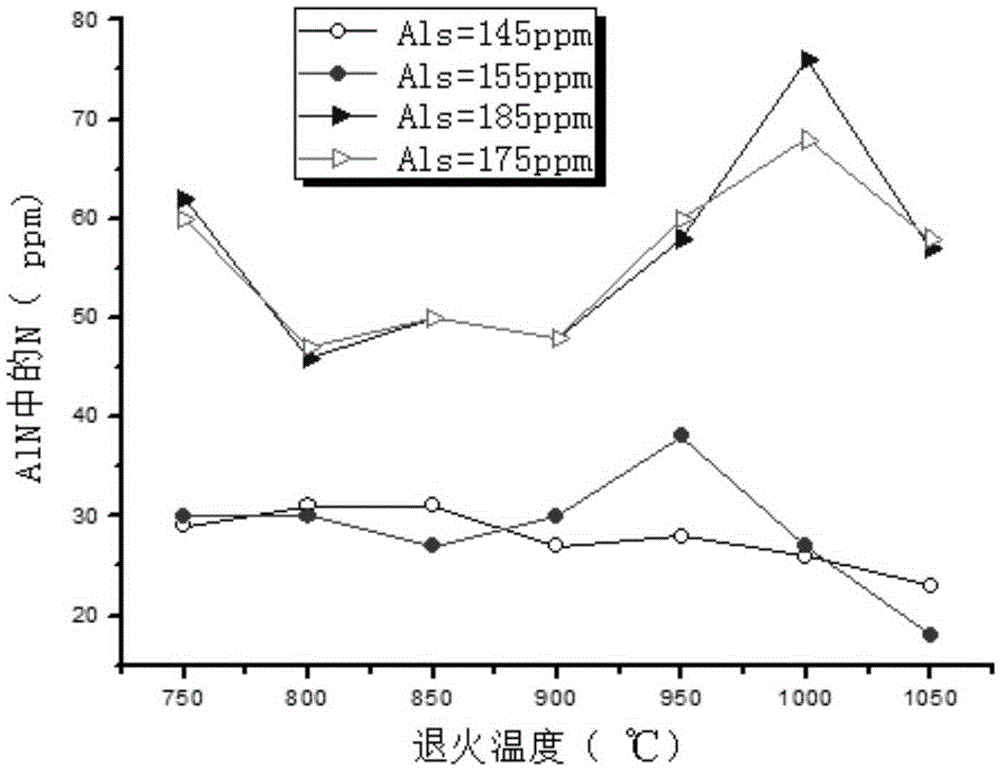

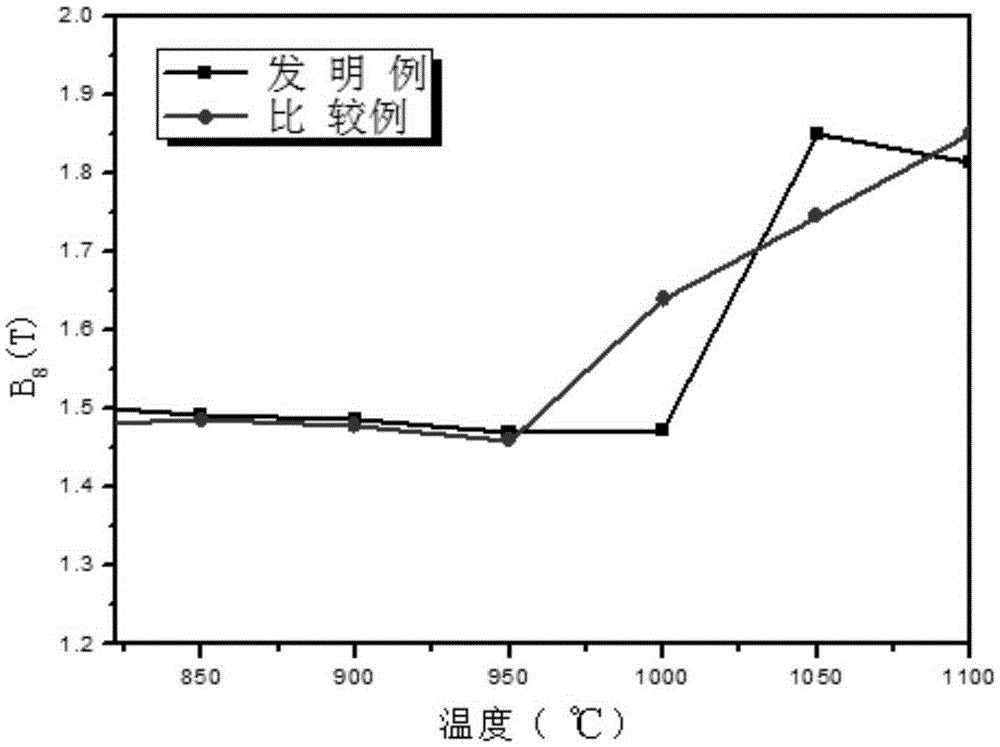

A technology of high magnetic induction orientation and production method is applied in the production field of copper-containing low temperature high magnetic induction oriented silicon steel, which can solve the problems of improving magnetic properties of grain boundary segregated elements, improve the degree of grain orientation, and prevent premature decomposition. , the effect of increasing the secondary recrystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The mass percent content of main elements in the silicon steel raw material composition is: C: 0.03%, Si: 3.0%, S: 0.001%, Als: 0.017%, N: 0.085%, Sn: 0.04%, Cu: 0.45%, and the rest are Fe and impurities are added to the steelmaking furnace, after steelmaking, hot rolling, pickling, primary cold rolling, intermediate decarburization annealing, secondary cold rolling, recovery annealing, MgO coating, high temperature annealing, coating and stretch leveling annealing Finally, the finished product is obtained, among which: the hot rolling temperature is 1250°C, the thickness of the first cold rolling is 0.65mm, the intermediate decarburization annealing temperature is 835°C, the carbon content is controlled at 10ppm, and the atmosphere in the heating section of the high temperature annealing process is N 2 :H 2 The ratio is 1:1, and the thickness of the finished product obtained after stretching, leveling and annealing is 0.269mm. Detect the magnetic induction intensity B...

Embodiment 2

[0019] The mass percent content of main elements in the silicon steel raw material composition is: C: 0.02%, Si: 3.15%, S: 0.002%, Als: 0.0175%, N: 0.098%, Sn: 0.05%, Cu: 0.50%, and the rest are Fe and impurities are added to the steelmaking furnace, after steelmaking, hot rolling, pickling, primary cold rolling, intermediate decarburization annealing, secondary cold rolling, recovery annealing, MgO coating, high temperature annealing, coating and stretch leveling annealing Finally, the finished product is obtained, wherein: the hot rolling temperature is 1280°C, the thickness of the first cold rolling is 0.68mm, the intermediate decarburization annealing temperature is 850°C, the carbon content is controlled at 10ppm, and the atmosphere in the heating section of the high temperature annealing process is N 2 :H 2 The ratio is 1:1, and the thickness of the finished product obtained after stretching and leveling annealing is 0.27mm. Detect the magnetic induction intensity B of ...

Embodiment 3

[0021] The mass percent content of the main elements in the silicon steel raw material composition is: C: 0.04%, Si: 3.3%, S: 0.003%, Als: 0.0185%, N: 0.010%, Sn: 0.046%, Cu: 0.50%, and the rest are Fe and impurities are added to the steelmaking furnace, after steelmaking, hot rolling, pickling, primary cold rolling, intermediate decarburization annealing, secondary cold rolling, recovery annealing, MgO coating, high temperature annealing, coating and stretch leveling annealing Finally, the finished product is obtained, wherein: the hot rolling temperature is 1300°C, the thickness of the first cold rolling is 0.70mm, the intermediate decarburization annealing temperature is 880°C, the carbon content is controlled at 20ppm, and the atmosphere in the heating section of the high temperature annealing process is N 2 :H 2 The ratio is 1:1, and the thickness of the finished product obtained after stretching, leveling and annealing is 0.29mm. The magnetic induction intensity B8 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com