Patents

Literature

35results about How to "Increased mechanical engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

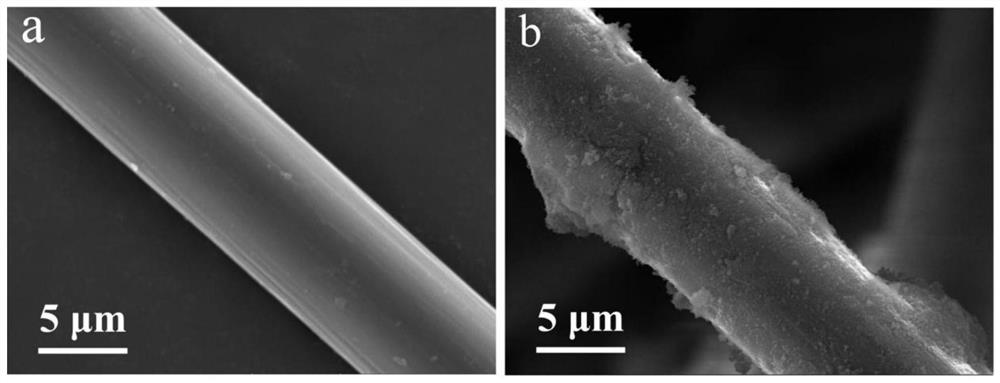

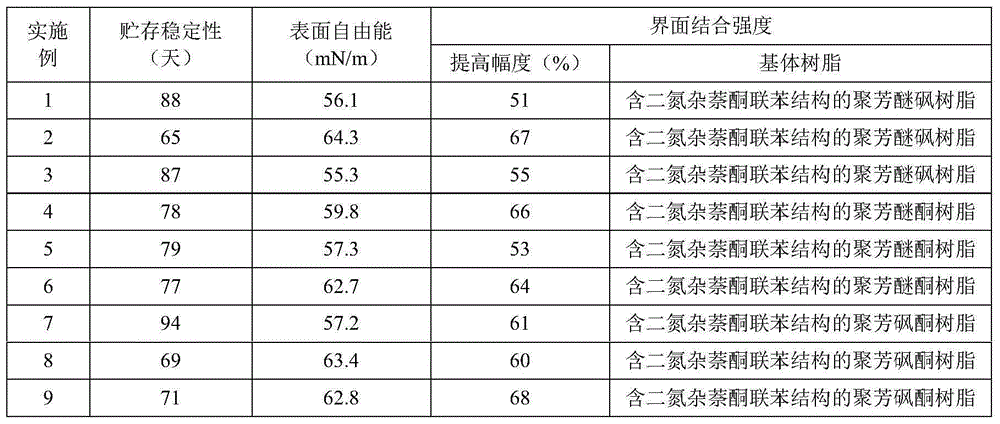

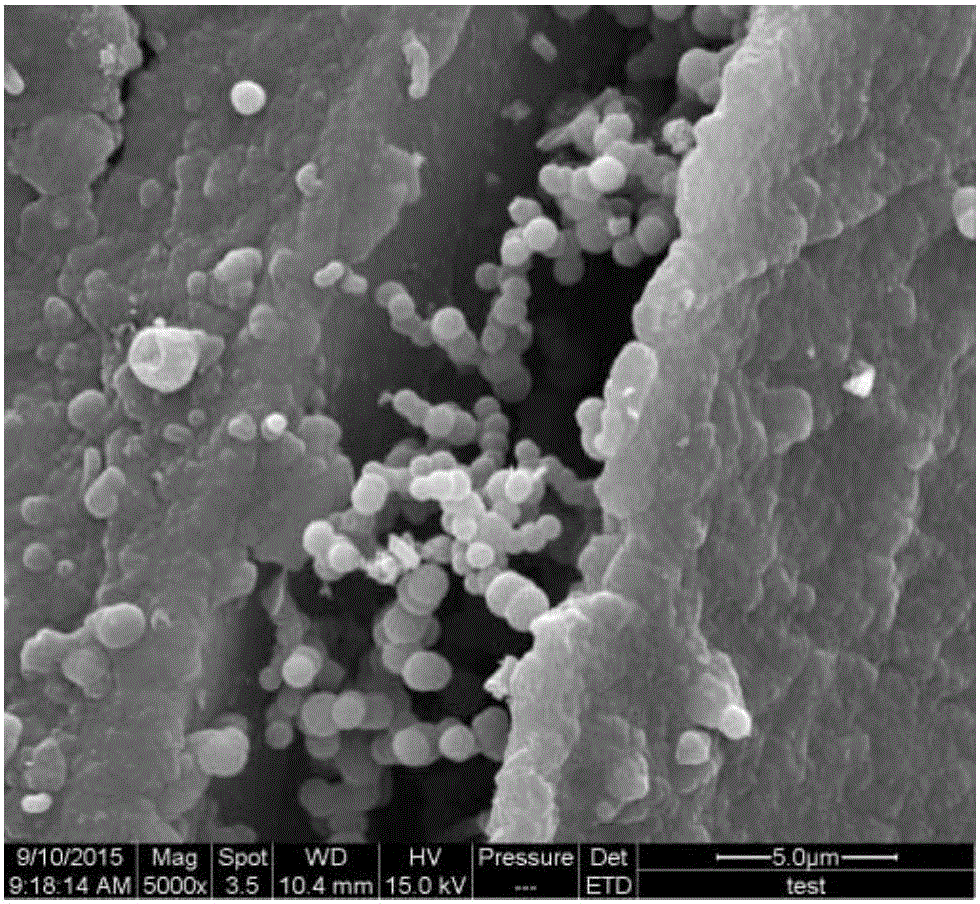

Emulsion type carbon fiber sizing agent containing nano material and preparation method of sizing agent

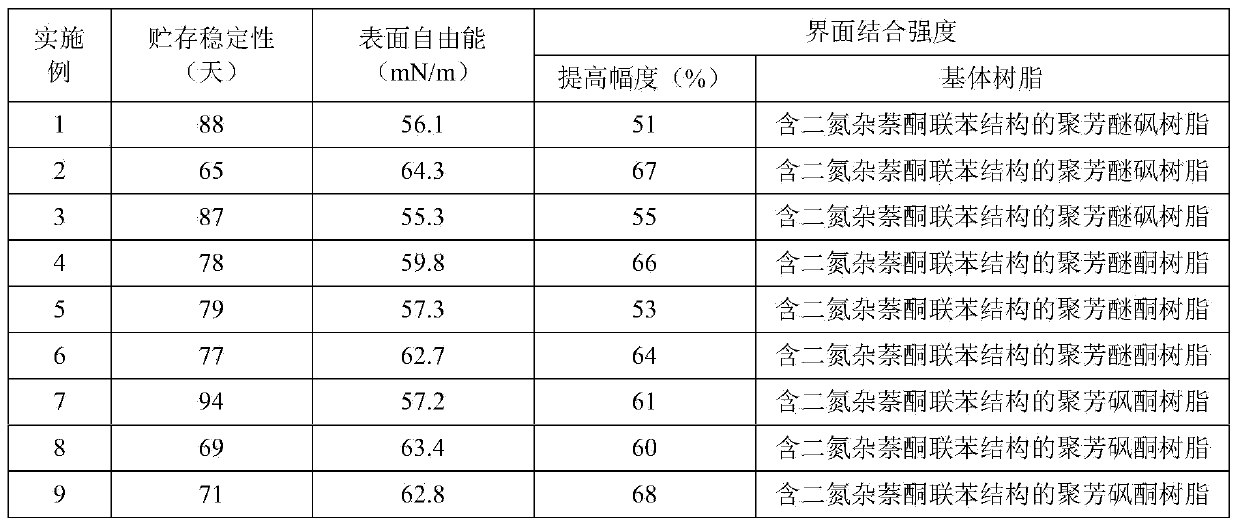

The invention discloses an emulsion type carbon fiber sizing agent containing a nano material. The sizing agent comprises the following components in percentage by mass: 0.1-2% of a main sizing agent, 0.01-1% of a nano material, 0.05-2% of an emulsion agent, 0.05-0.1% of a dispersing agent, 0.15-8% of an organic solvent and 86.9-99.64% of deionized water. The sizing agent has the advantages the interface binding strength with carbon fibers is high and the surface free energy of the sized carbon fibers is no less than 55mN / m.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

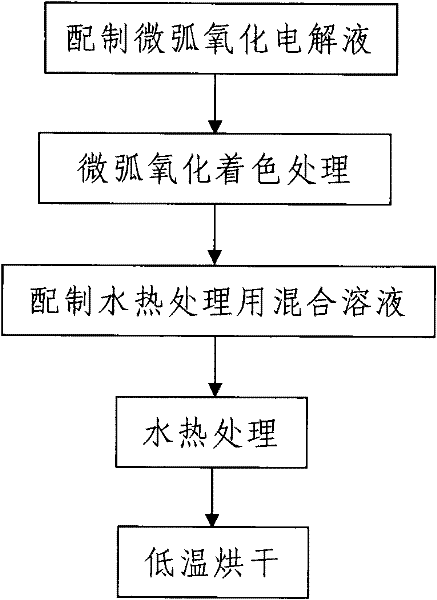

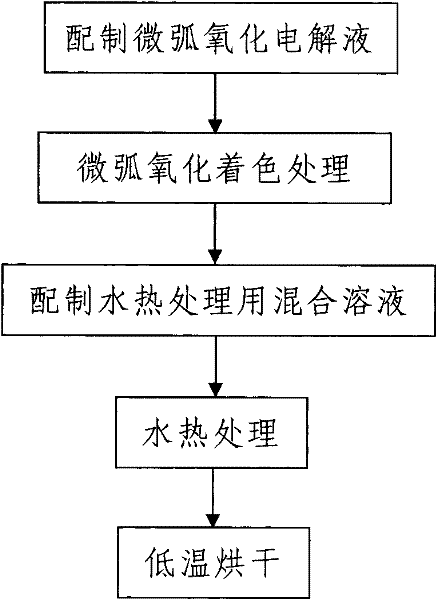

Preparation method of titanium and titanium alloy surface black protective film for surgical implantation

ActiveCN101660190AThe preparation process steps are simpleEasy to operateSurface reaction electrolytic coatingProsthesisTectorial membranePlasma electrolytic oxidation

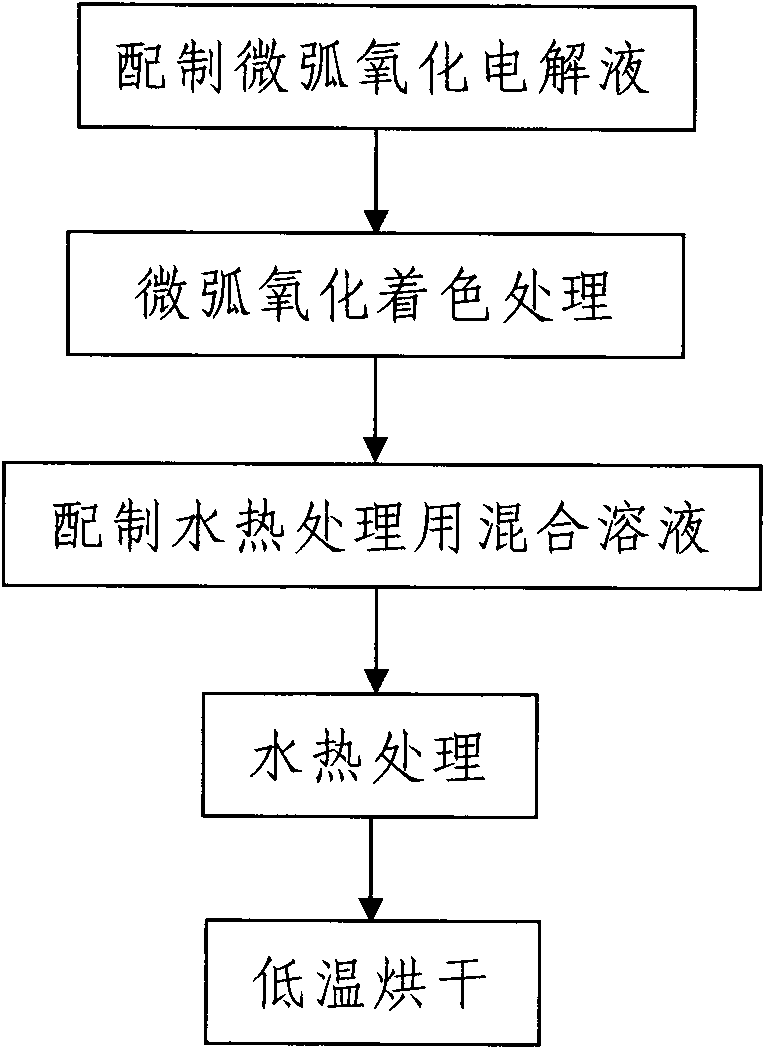

The invention discloses a preparation method of a titanium and titanium alloy surface black protective film for surgical implantation, comprising the following steps: step 1: carrying out micro-arc oxidation coloring processing on titanium and titanium alloy surface to be processed, in the process, firstly, preparing a micro-arc oxidation electrolysing solution, and then carrying out the micro-arcoxidation coloring processing; and step 2: carrying out subsequent processing on the micro-arc oxidation film, wherein the subsequent processing comprises the following steps: firstly, preparing a mixed solution for hydro-thermal processing, completely dipping the titanium and titanium alloy after micro-arc oxidation shading processing in the mixed solution, carrying out the hydro-thermal processing on the surface by adopting a hydro-thermal method, drying the titanium and titanium alloy under the condition of low temperature when the hydro-thermal processing is completed, and generating a layer of pure black micro-arc oxidation film with uniform and plump surface on the titanium and titanium alloy surface. The invention has simple and convenient operation, economy, high production efficiency, and high bonding strength between a generated ceramic film, i.e. the micro-arc oxidation film and a substrate, and the invention can effectively overcome various defects and deficiencies which exist in the prior coating processing techniques.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Supercritical fluid technology-based carbon fiber surface grafting method

ActiveCN104987532AEffective wettingImprove the interface binding forceBulk chemical productionCross-linkFiber

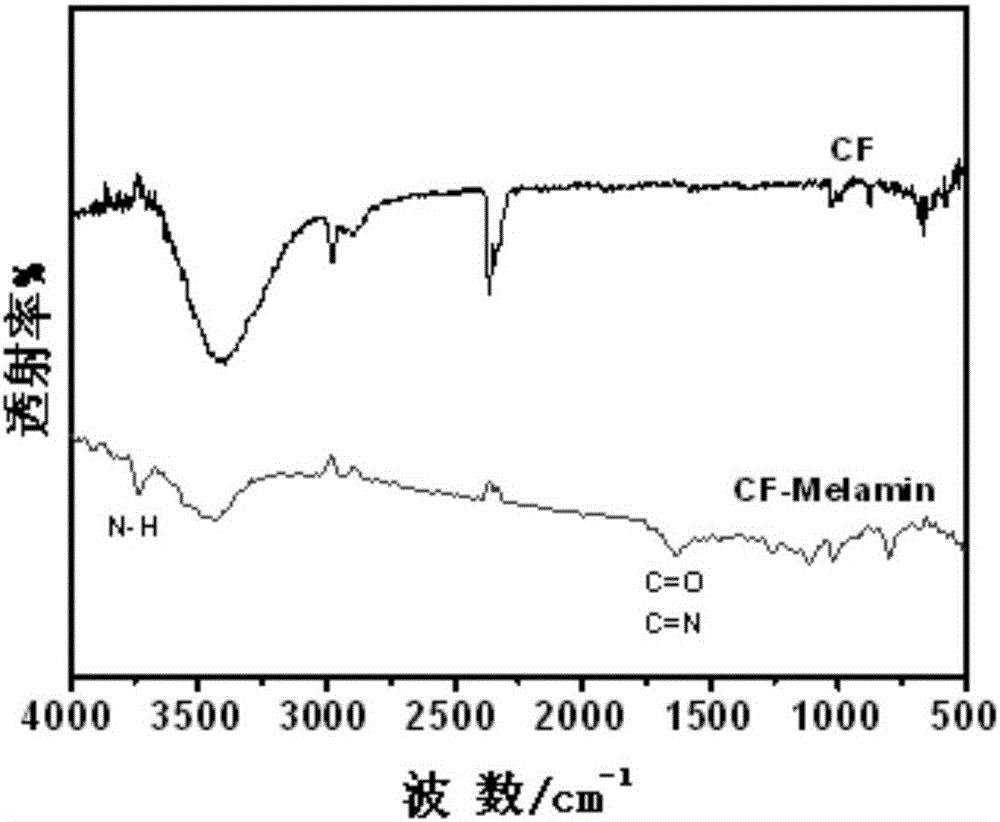

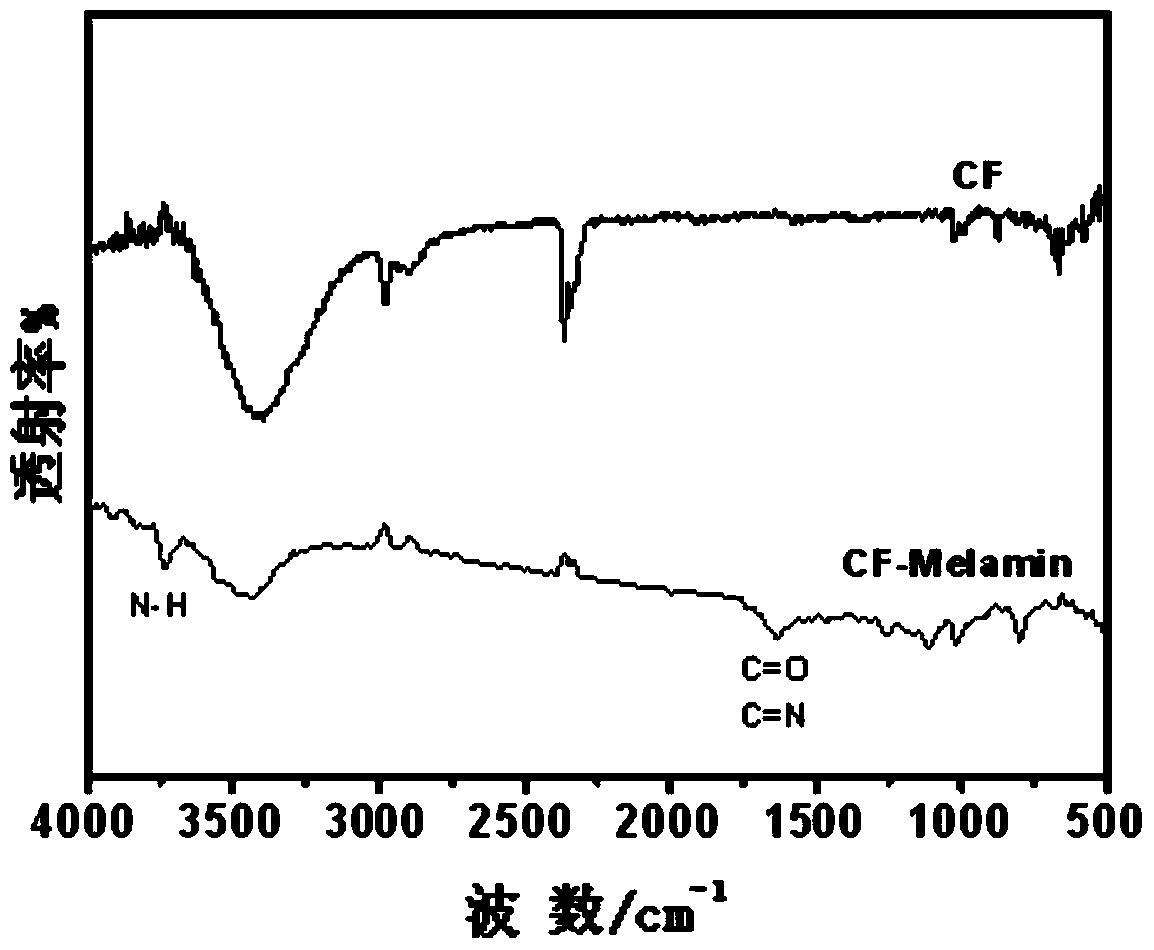

The invention discloses a supercritical fluid technology-based carbon fiber surface grafting method, and relates to a carbon fiber surface modifying method. The purpose of the invention is to solve the problems of few reaction sites of grafted micro-molecular substances, easy cross-linking of graft copolymers, and low bonding strength between modified carbon fibers and resin of present carbon fiber surface modifying methods. The method disclosed in the invention comprises the following steps: removing an epoxy coating layer on the surface of the carbon fibers; 2, oxidizing the carbon fibers; 3, carrying out acylchlorination on the carbon fibers; and 4, grafting the surface of the carbon fibers with melamine. The surface of the carbon fibers is grafted with melamine, and the quantity of reaction sites is large, so convenience is provided for a next step grafting reaction. The molecular weight of melamine is small, and melamine and polymers are difficult to cross-link, so melamine has very good dispersion, and undergoes a grafting reaction with good homogeneity on the surface of the carbon fibers in order to facilitate improvement of the interface performances of a composite material. The method is used for surface modification of the carbon fibers.

Owner:HARBIN INST OF TECH

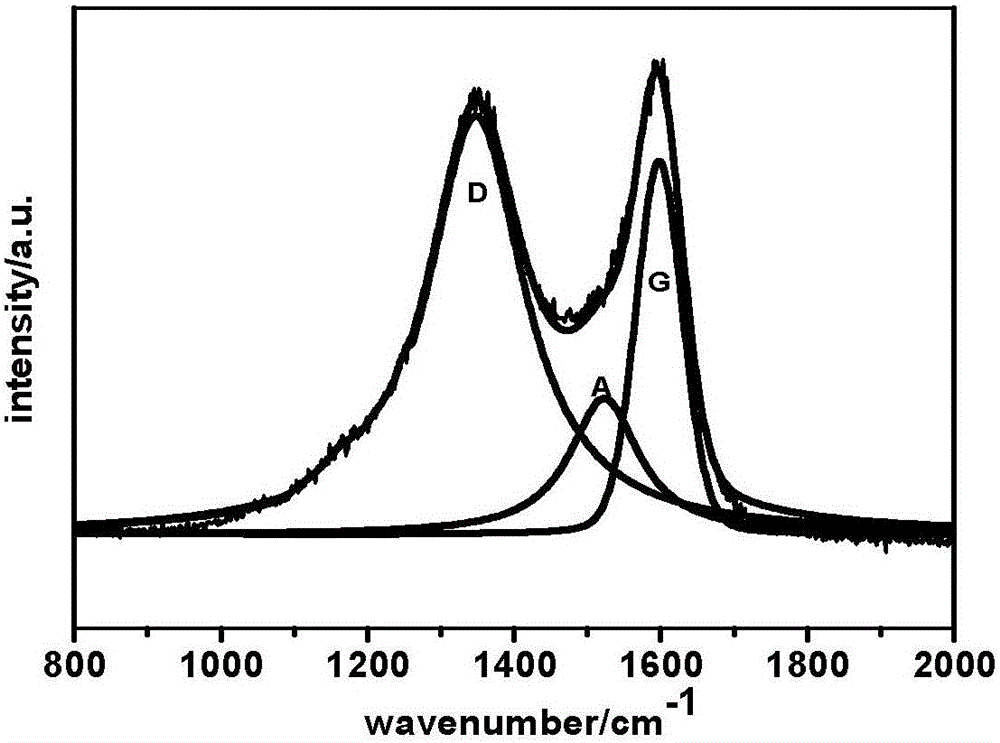

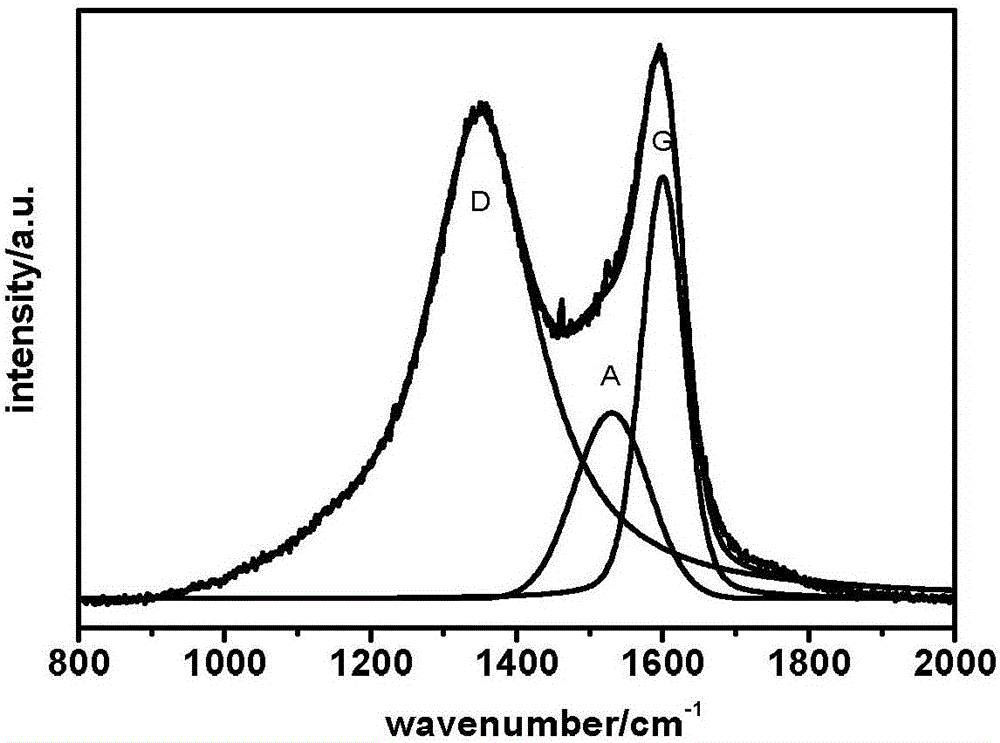

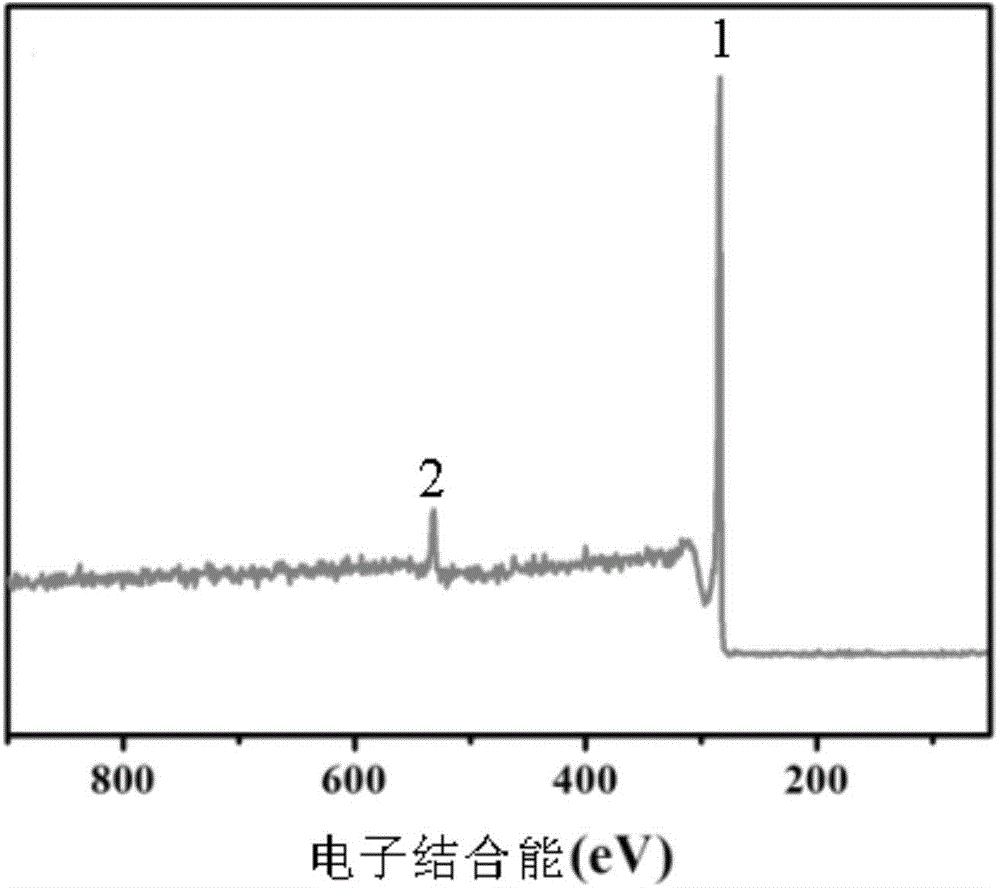

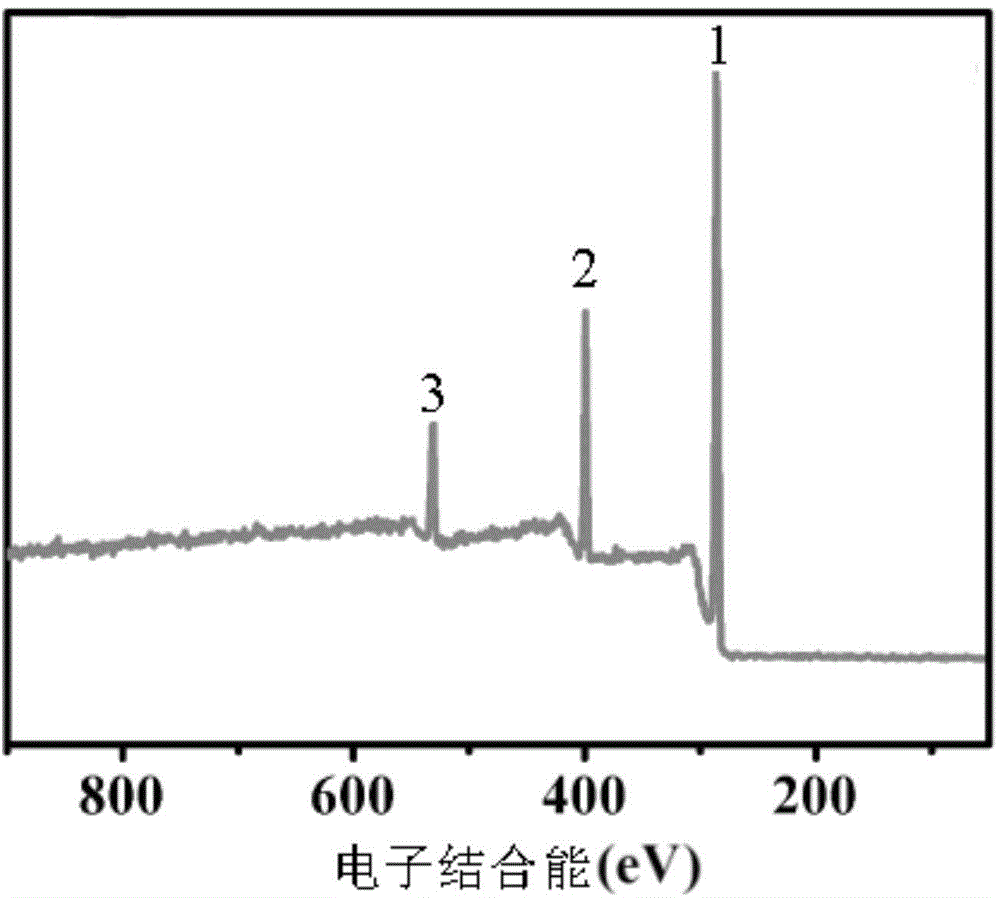

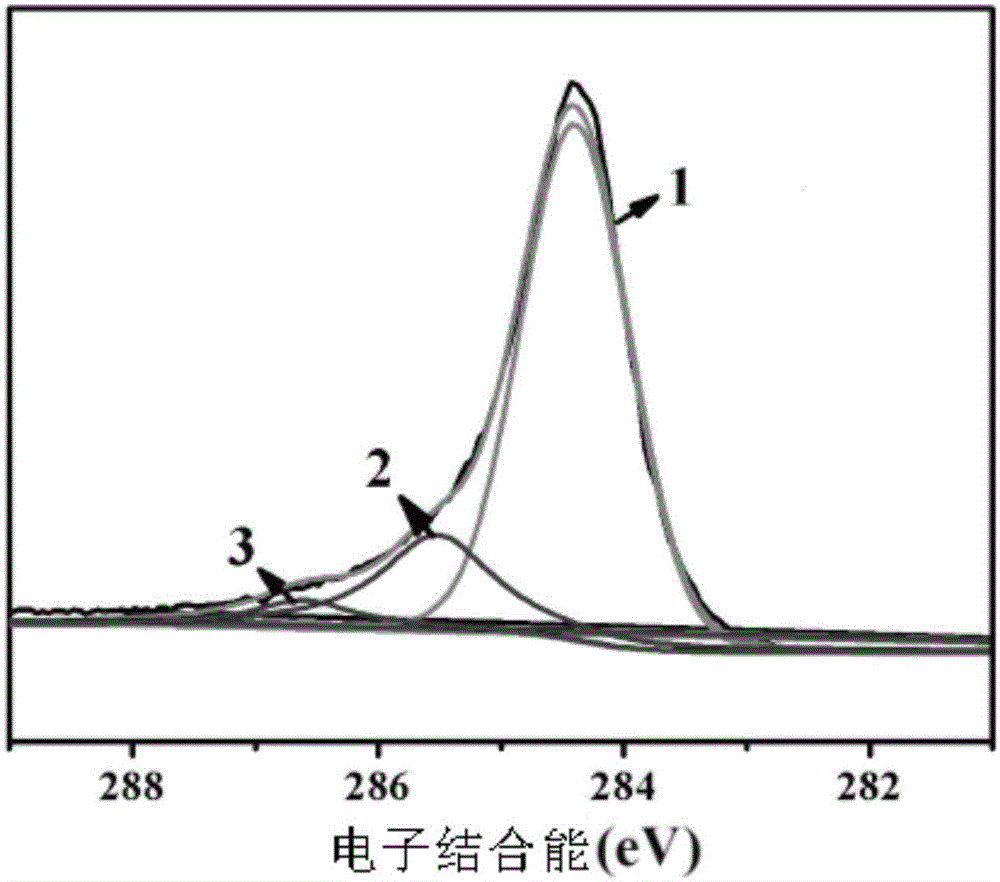

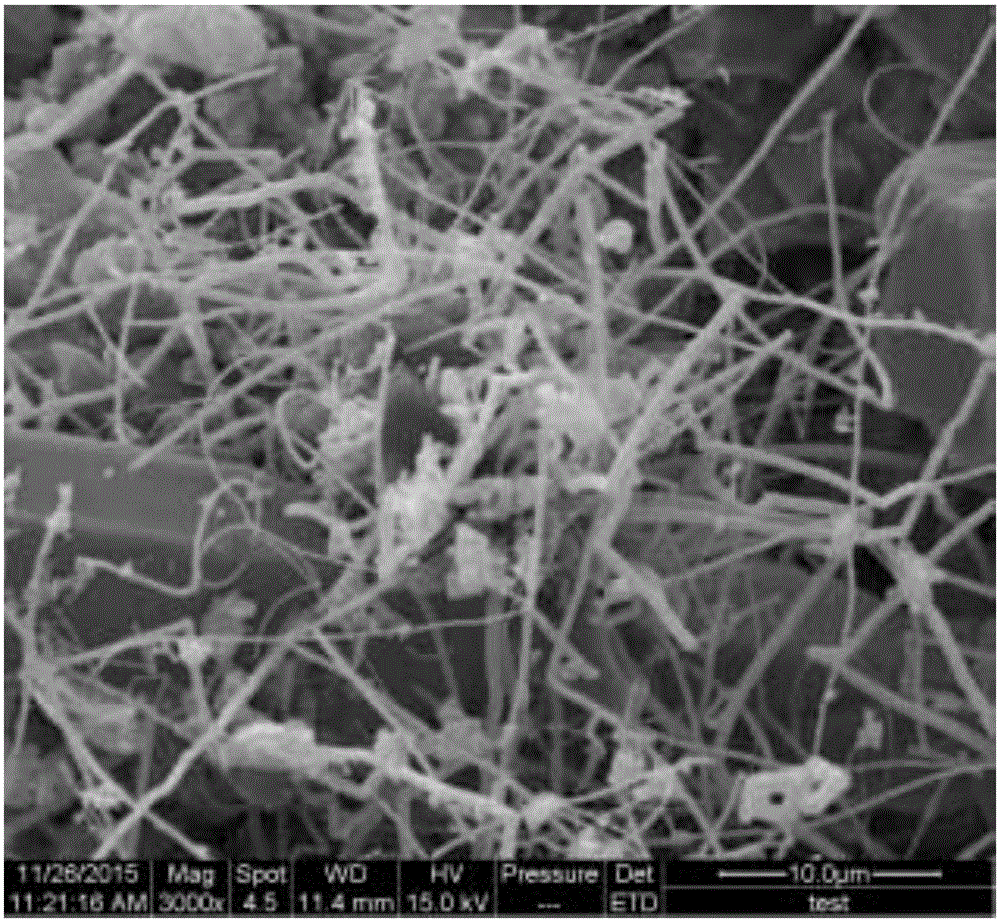

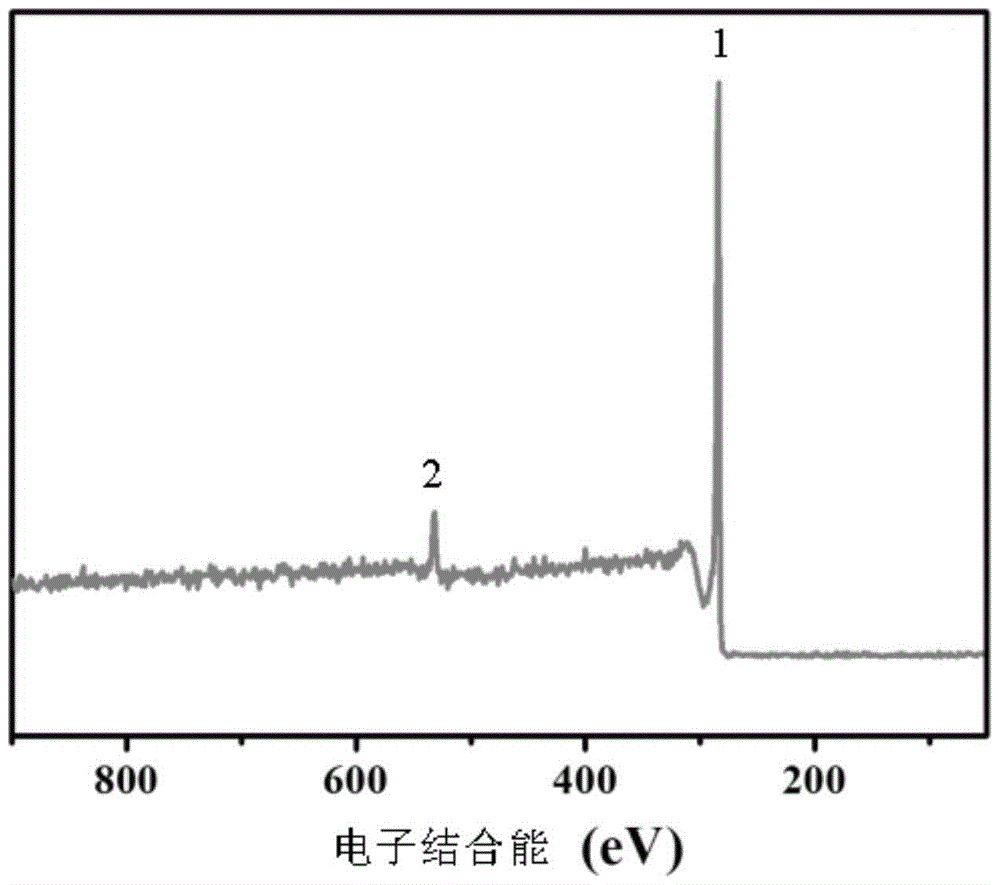

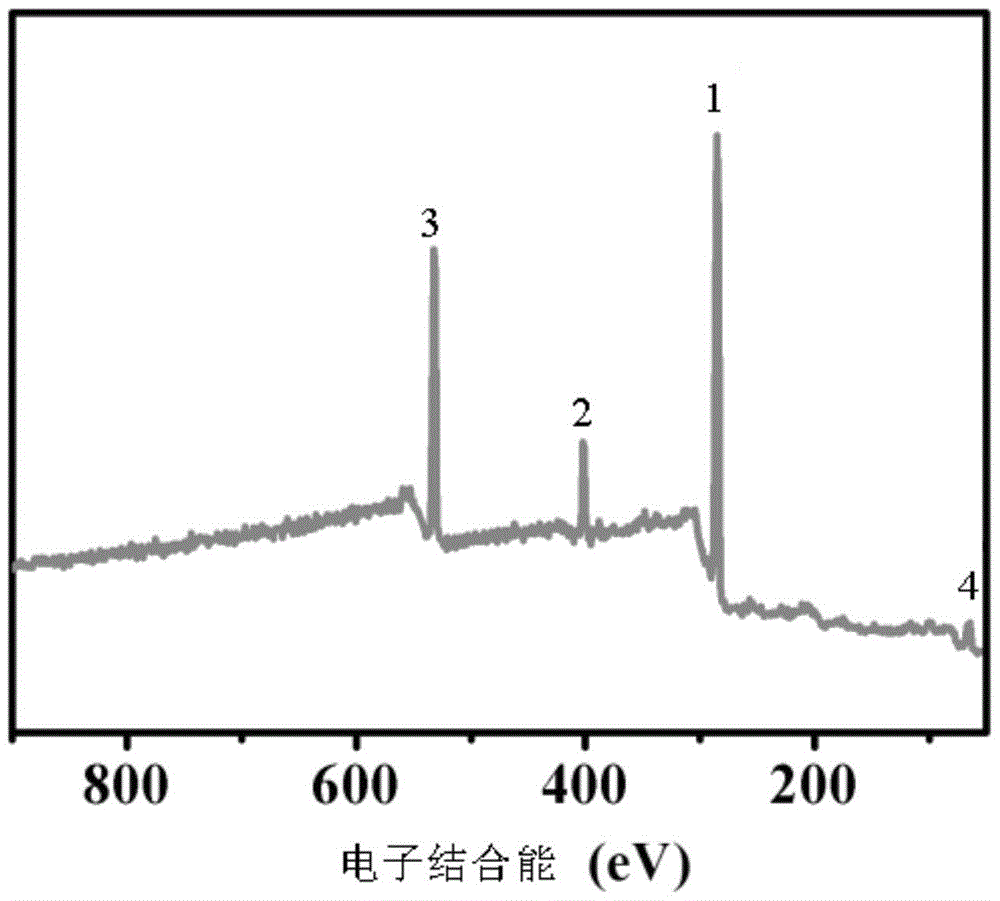

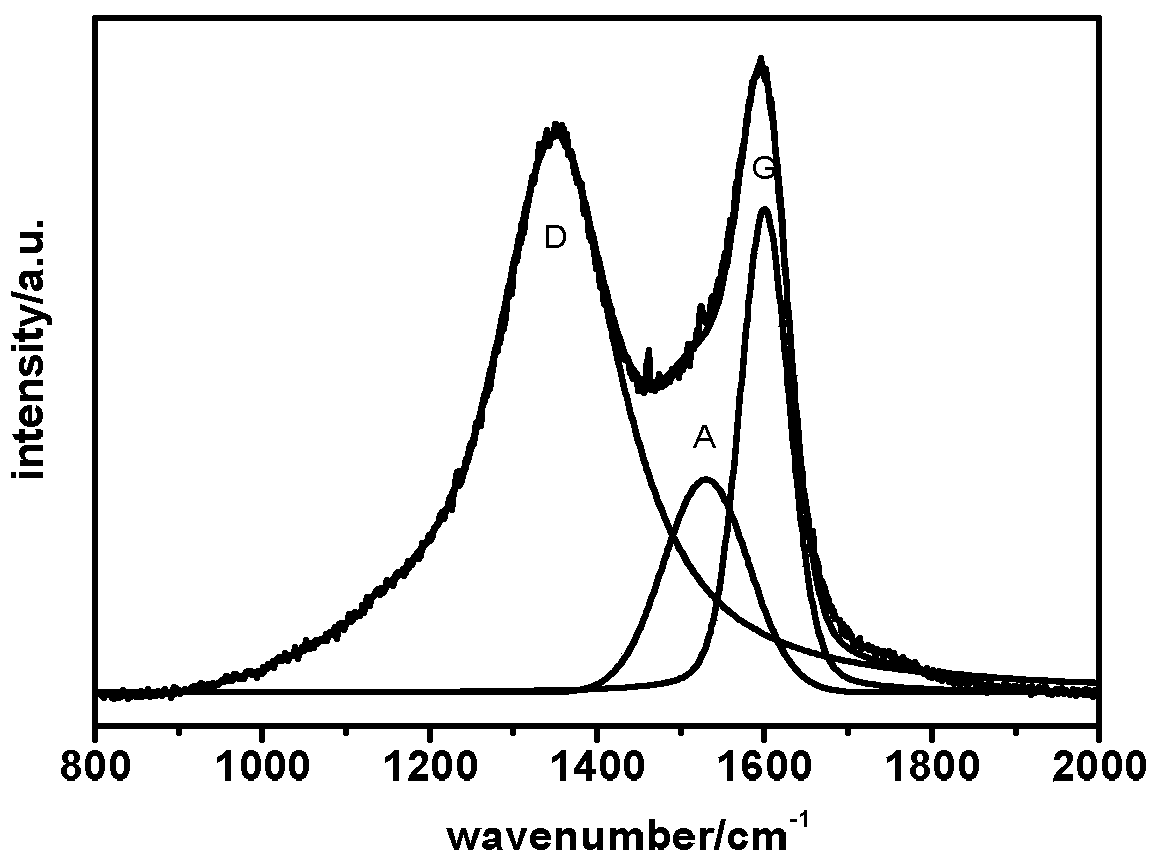

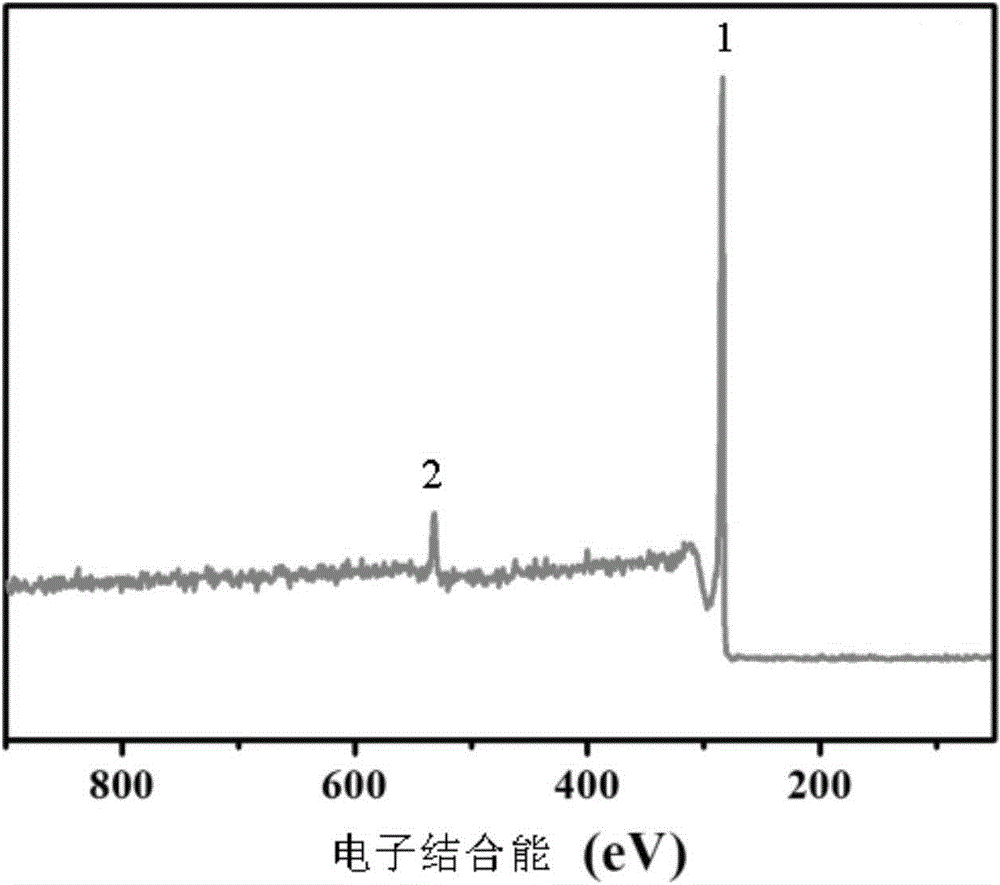

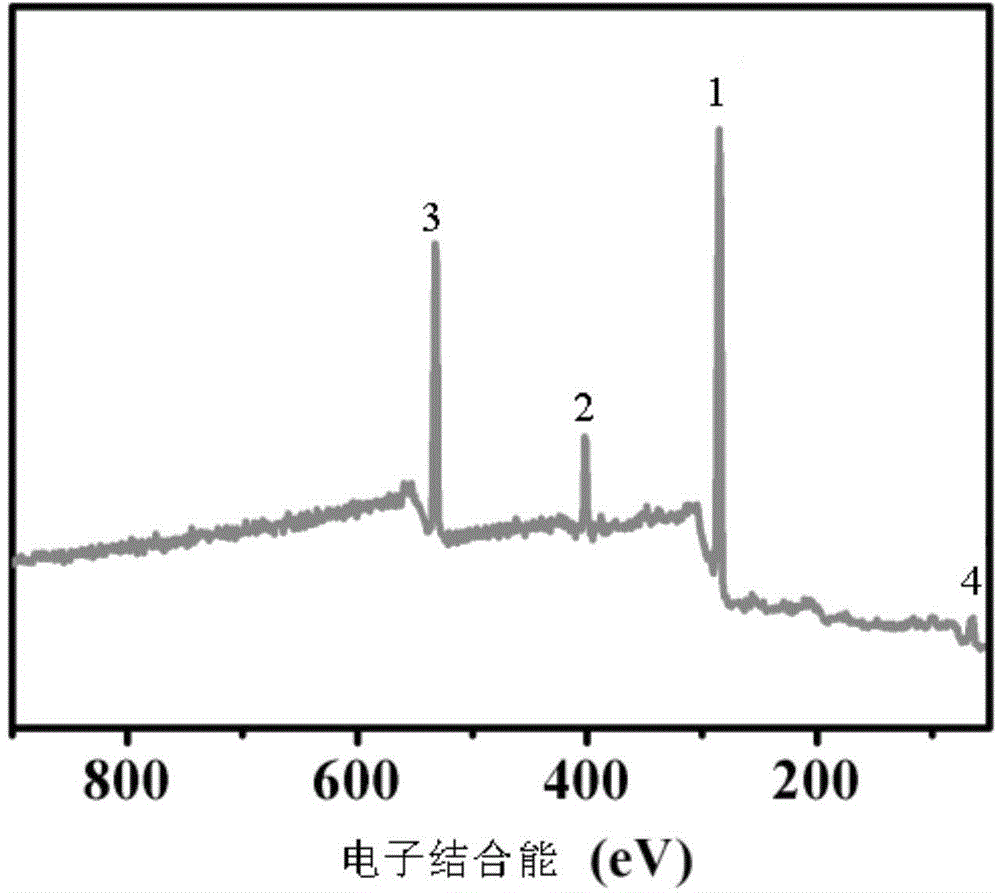

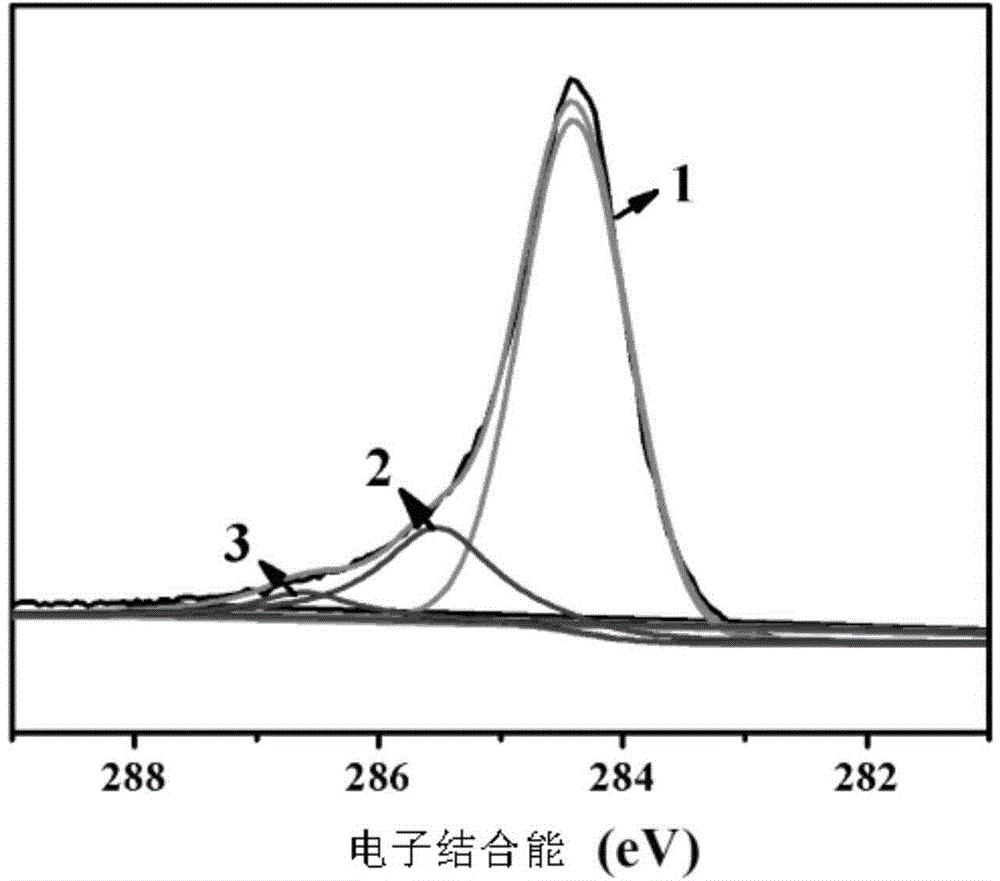

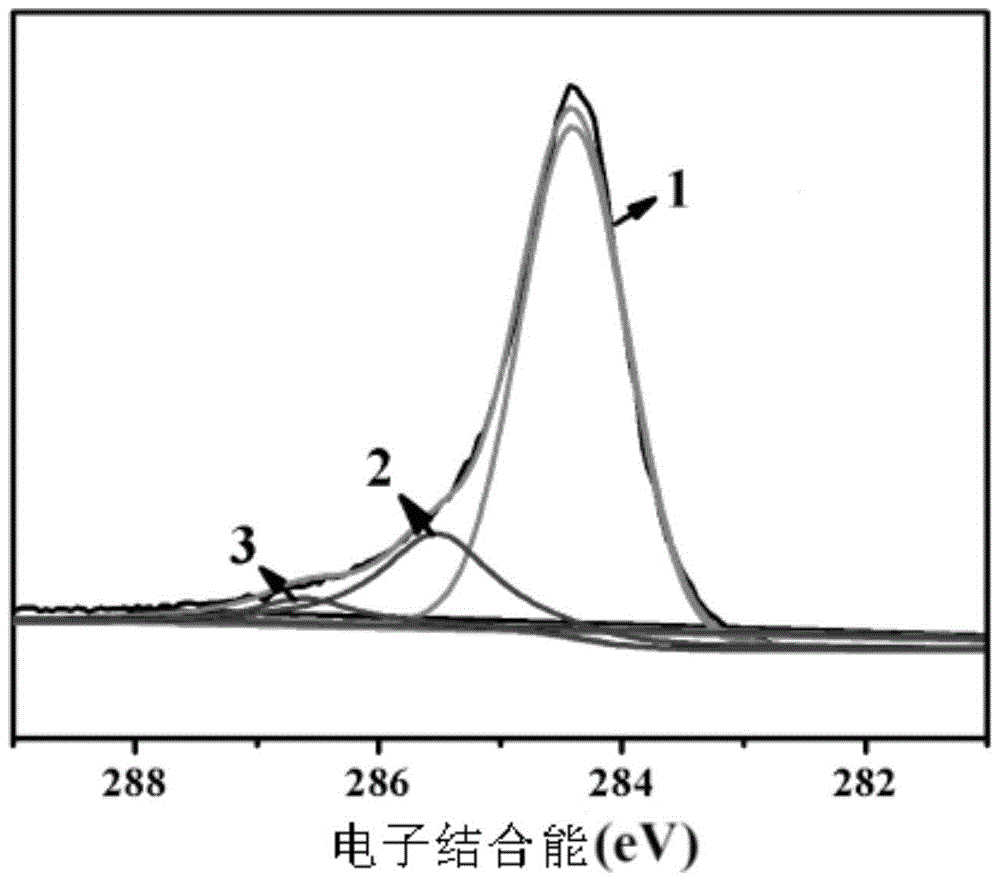

Method for adsorbing polymine on carbon fiber surface in supercritical methanol

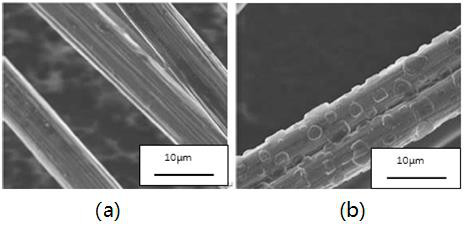

InactiveCN104562707AIncrease N contentIncreased mechanical engagementCarbon fibresFiberCarbon fibers

The invention discloses a method for adsorbing polymine on a carbon fiber surface in supercritical methanol, relates to a carbon fiber surface adsorption method, and aims to solve problems that an existing carbon fiber modifying method causes severe strength loss to the carbon fiber, is complex to operate, not suitable for being performed, low in bonding strength with resin. The method comprises the following steps: I, cleaning; II, oxidizing; III, adsorbing polymine in supercritical methanol to obtain carbon fiber, surface of which is adsorbed with the polymine, thereby completing grafting hexamine on the carbon fiber surface in the supercritical methanol. According to the method, interface shearing strength of the carbon fiber, surface of which is adsorbed with the polymine, is increased to 101.8 MPa-103 MPa from unmodified 64.9 MPa, and increased by 56.9%-59.7%; impact strength is increased to 84.39 kJ / m<2>-86.7 kJ / m<2> from 55.77 kJ / m<2>. The invention discloses a method for grafting hexamine on the carbon fiber surface.

Owner:HARBIN INST OF TECH

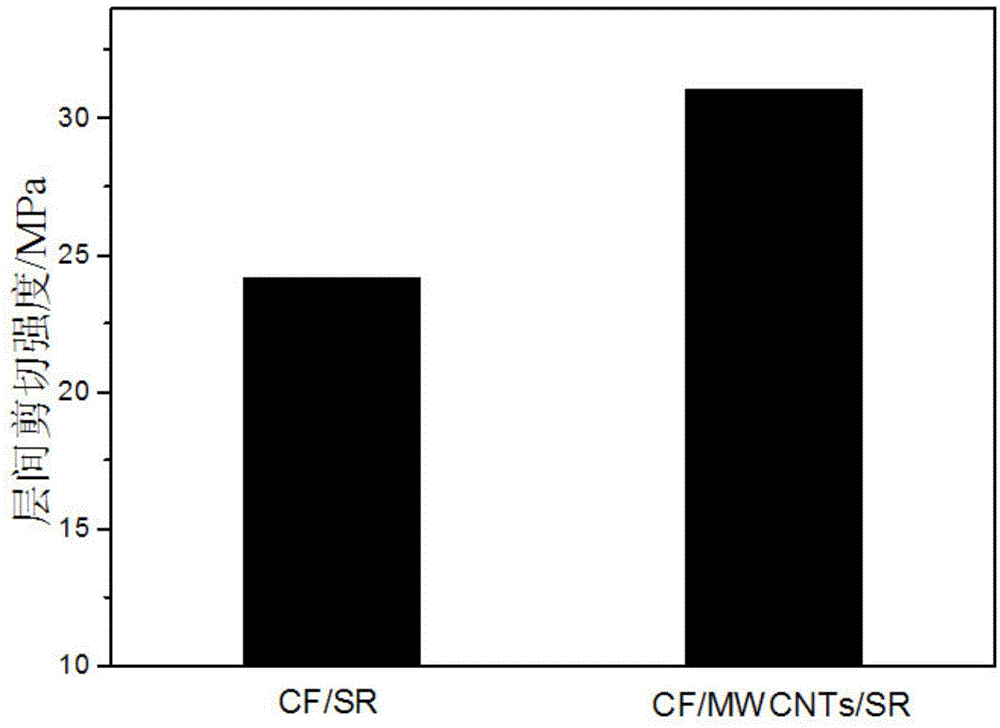

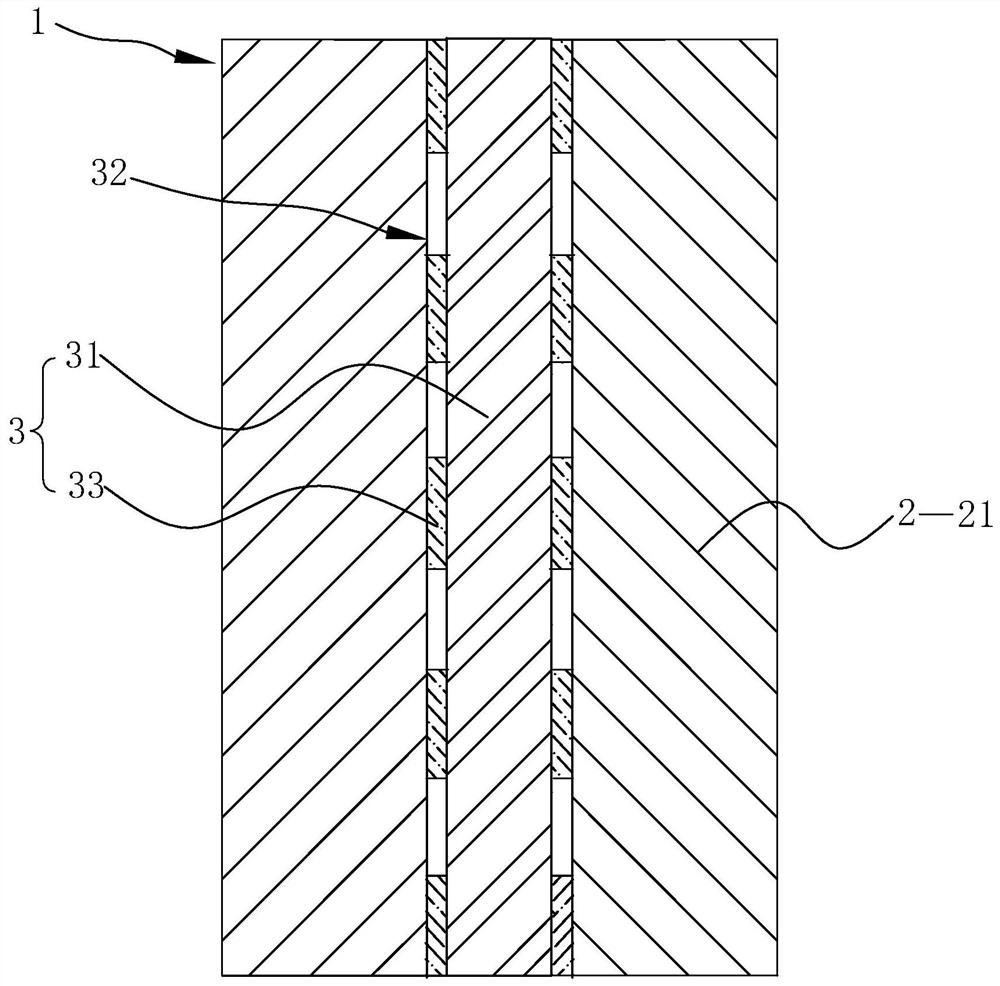

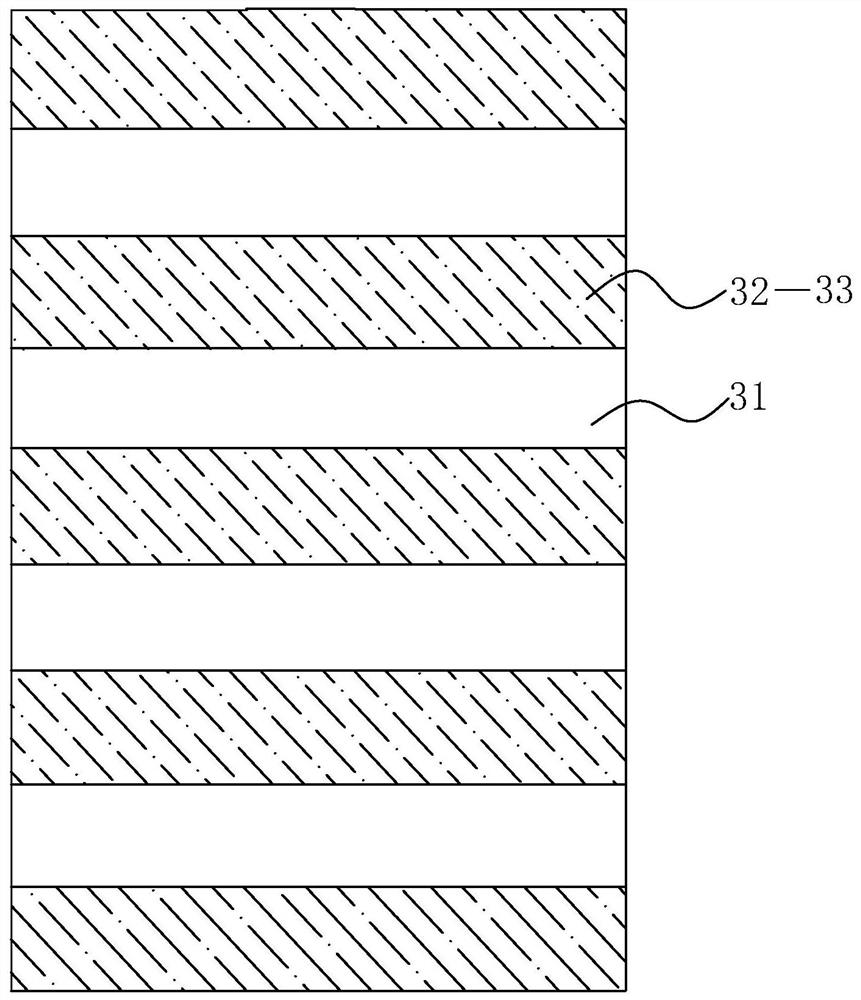

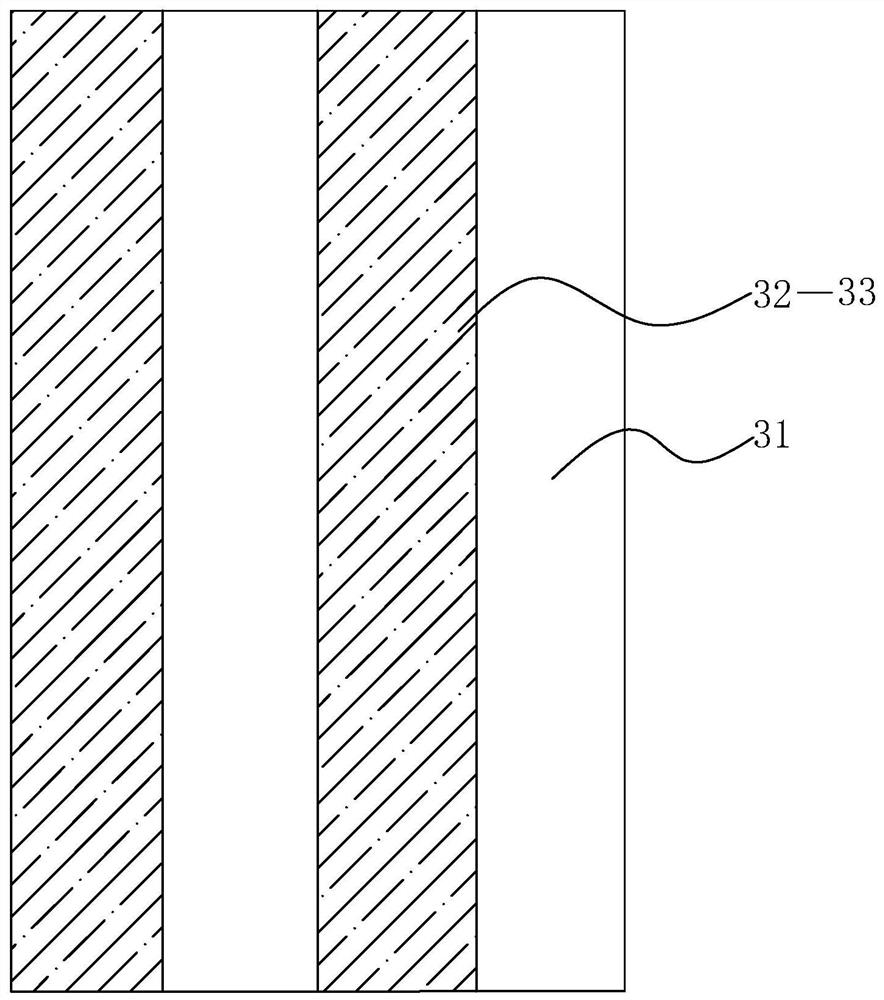

Preparation method of carbon fiber/carbon nanotube/organic silicone resin multidimensional hybrid composite material

The invention relates to a preparation method of a carbon fiber / carbon nanotube / organic silicone resin multidimensional hybrid composite material and belongs to the technical field of nanomaterials. The method comprises the following steps: 1) preparing carboxylated carbon nanotubes; 2) preparing aminated carbon nanotubes; 3) preparing functional carbon fiber; 4) preparing the carbon fiber / carbon nanotube / organic silicone resin multidimensional hybrid composite material. According to the method, the carbon nanotubes are endowed with the activity of participating in reaction, the dispersibility of the carbon nanotubes in silicone resin is improved, the organic silicone resin is strengthened by utilizing the excellent toughness and the strength of the carbon nanotubes, a nano-scale interface increases the mechanical meshing effect between the fiber and a resin matrix, the interface structure is improved and the mechanical properties of the carbon fiber / carbon nanotube / organic silicone resin multidimensional hybrid composite material are improved. The interlayer shear strength of the carbon fiber / carbon nanotube / organic silicone resin multidimensional hybrid composite material prepared by the invention can achieve 31.06Mpa, which is improved by 28.4% in comparison with that before treatment.

Owner:HARBIN INST OF TECH

Negative electrode current collector complex, preparation method thereof and lithium metal battery

ActiveCN113488659ALight in massLight weightElectrode carriers/collectorsSecondary cellsElectrical batteryLithium metal

The invention relates to the field of lithium batteries, in particular to a negative electrode current collector complex, a preparation method thereof and a lithium metal battery. The negative electrode current collector complex comprises a negative electrode and a current collector, the negative electrode is a lithium metal layer, the current collector comprises a polymer film, copper metal areas are arranged on the two side faces of the polymer film, copper metal layers are arranged on the copper metal areas, the lithium metal layer is attached to the side, away from the polymer film, of the copper metal layer, and the area of the copper metal layer is 20-70% of the area of the polymer film; the lithium metal layer and the polymer film coincide in size. The lithium metal battery provided by the invention adopts the current collector, so that the energy density of the lithium metal battery is improved, uneven lithium deposition on the surface of a negative electrode is also inhibited in the charging process of the battery, and the cycle life of the battery is further prolonged.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Copper-aluminium bilayer structure composite thin belt and preparation method thereof

ActiveCN111618093ASimple preparation processShort production cycleLamination ancillary operationsLaminationThermal insulationAluminium

The invention relates to a copper-aluminium bilayer structure composite thin belt and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: carrying out ordered superposition through enabling the polishing surface of to-be-rolled copper material to be upwards and enabling the polishing surface of to-be-rolled aluminium material to bedownwards, loading the ordered superposed bilayer structure copper-aluminium superposed material in a composite rolling guiding system, and adopting a double-roller rolling mill for composite rollingto obtain copper-aluminium bilayer structure composite strip; placing the copper-aluminium bilayer structure composite strip in a vacuum bell type annealing furnace, carrying out thermal insulation for 24-36 hours at the temperature of 565-675 DEG C, and adopting a 16-roller multi-roll rolling mill to carry out three-pass reversible rolling with front-back tension to manufacture the copper-aluminium bilayer structure composite thin belt. The preparation method has the characteristics of being simple in technology, short in production period and low in preparation cost, the prepared copper-aluminium bilayer structure composite thin belt is high in strength, excellent in toughness, large in strength of bonding interface, high in precision and excellent in strip shape, more than 70% of copper is saved, and the effect is obvious.

Owner:WUHAN UNIV OF SCI & TECH

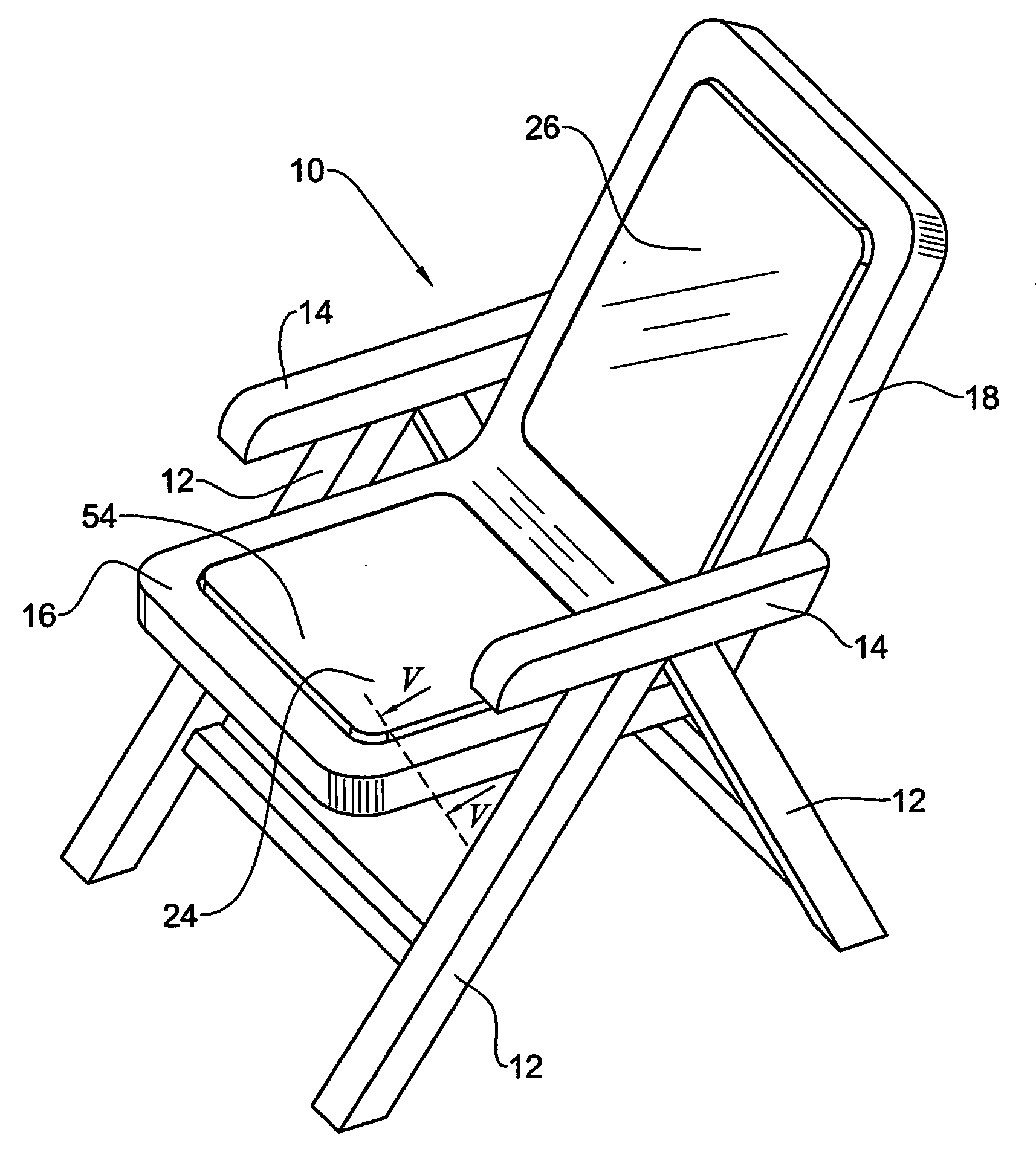

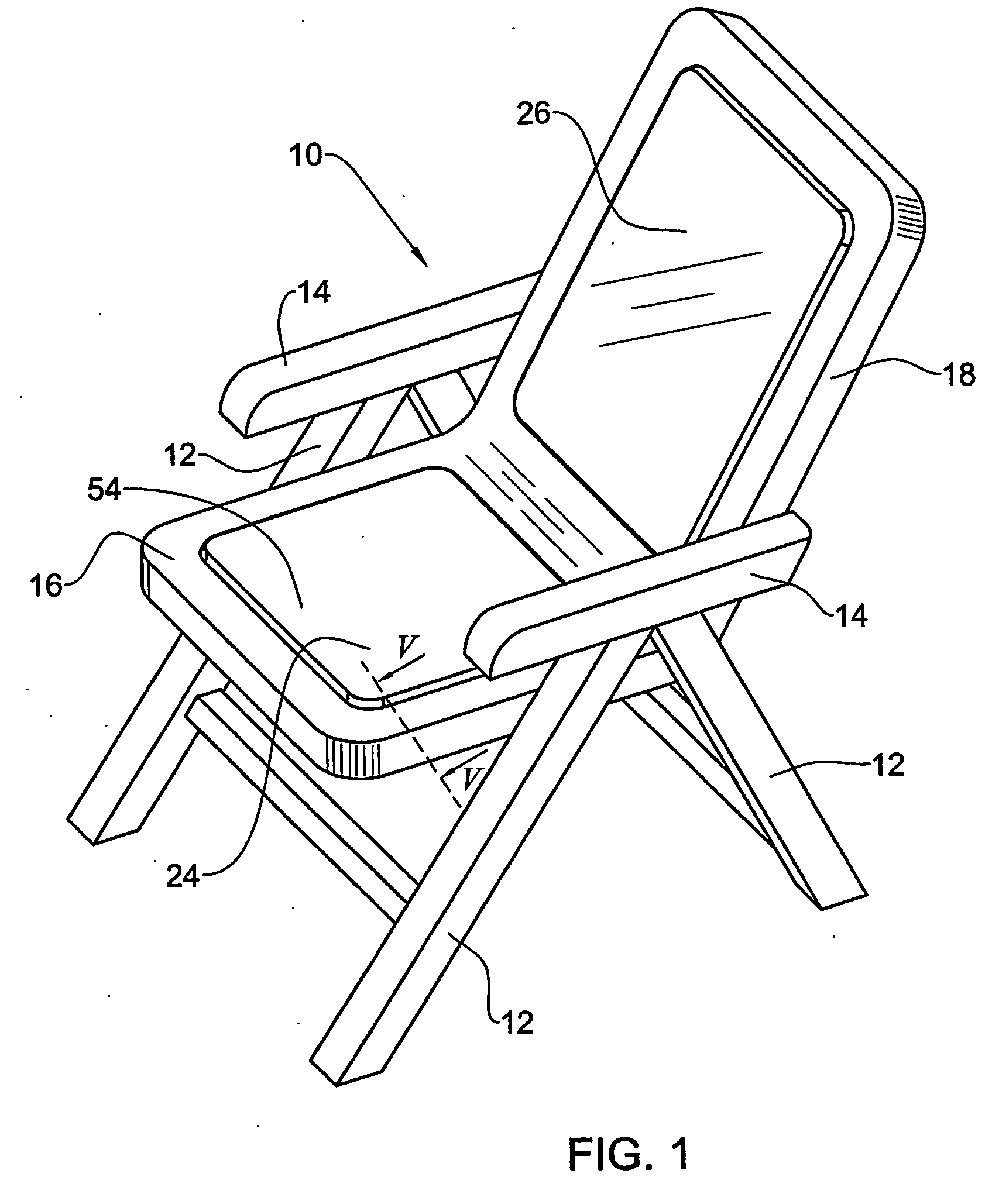

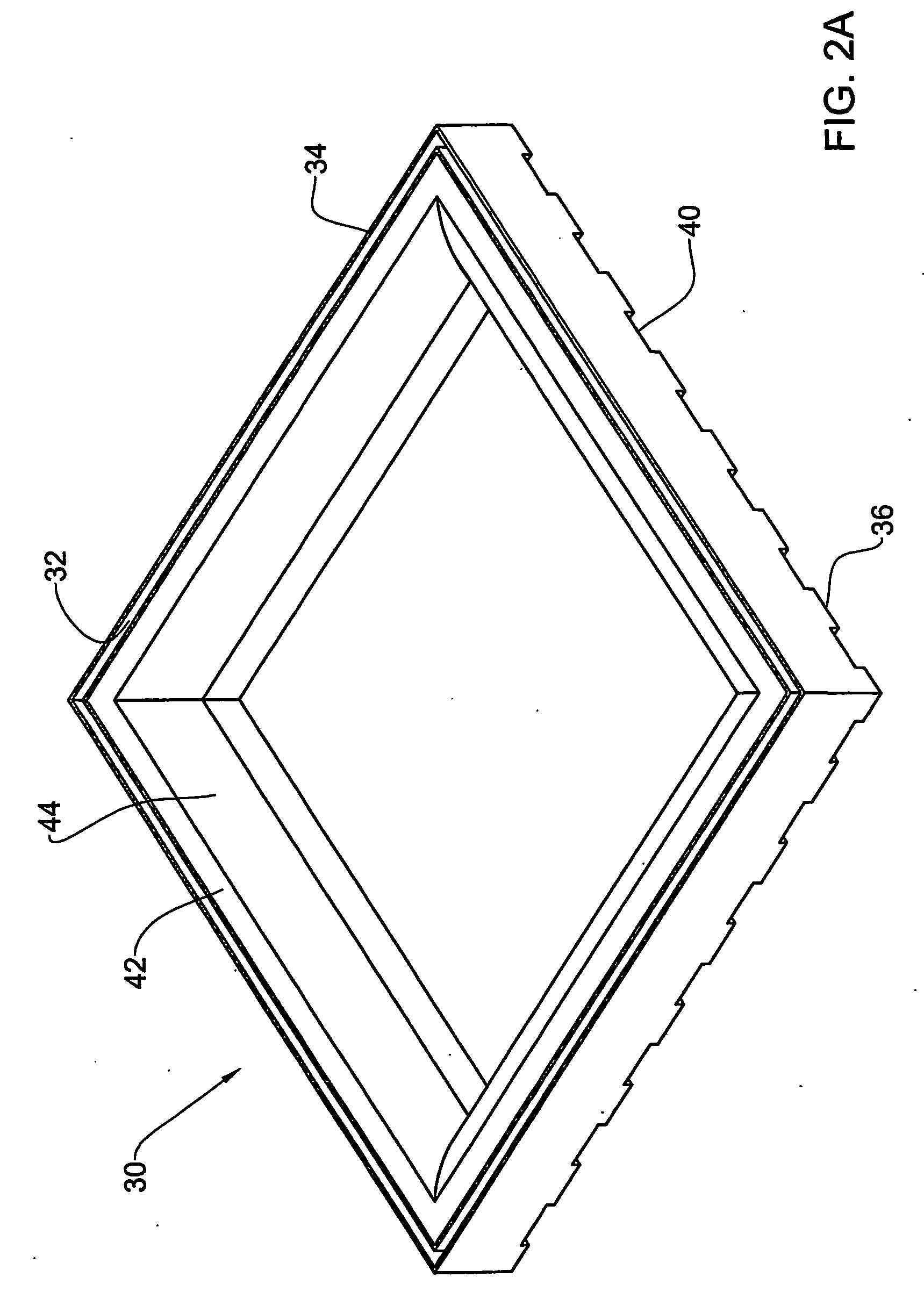

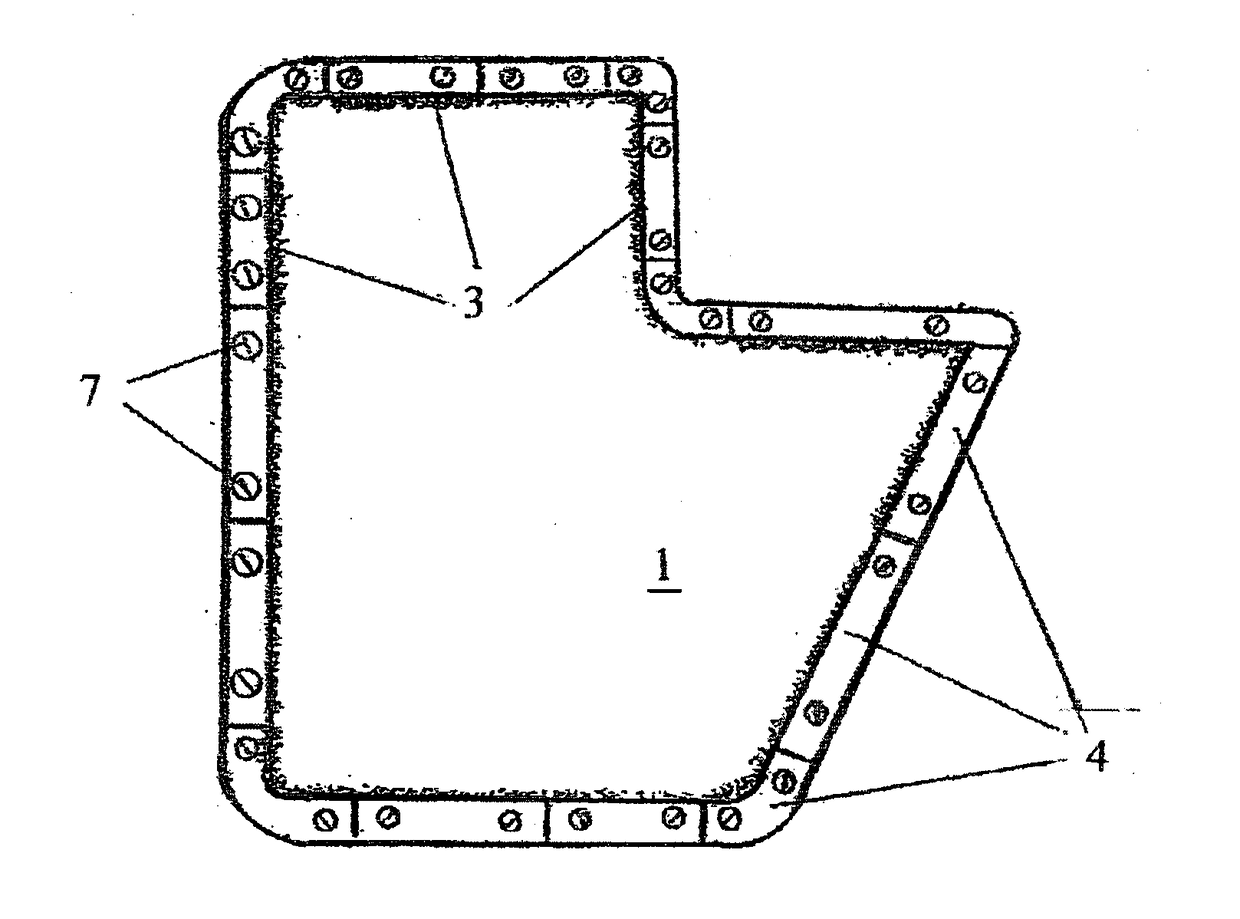

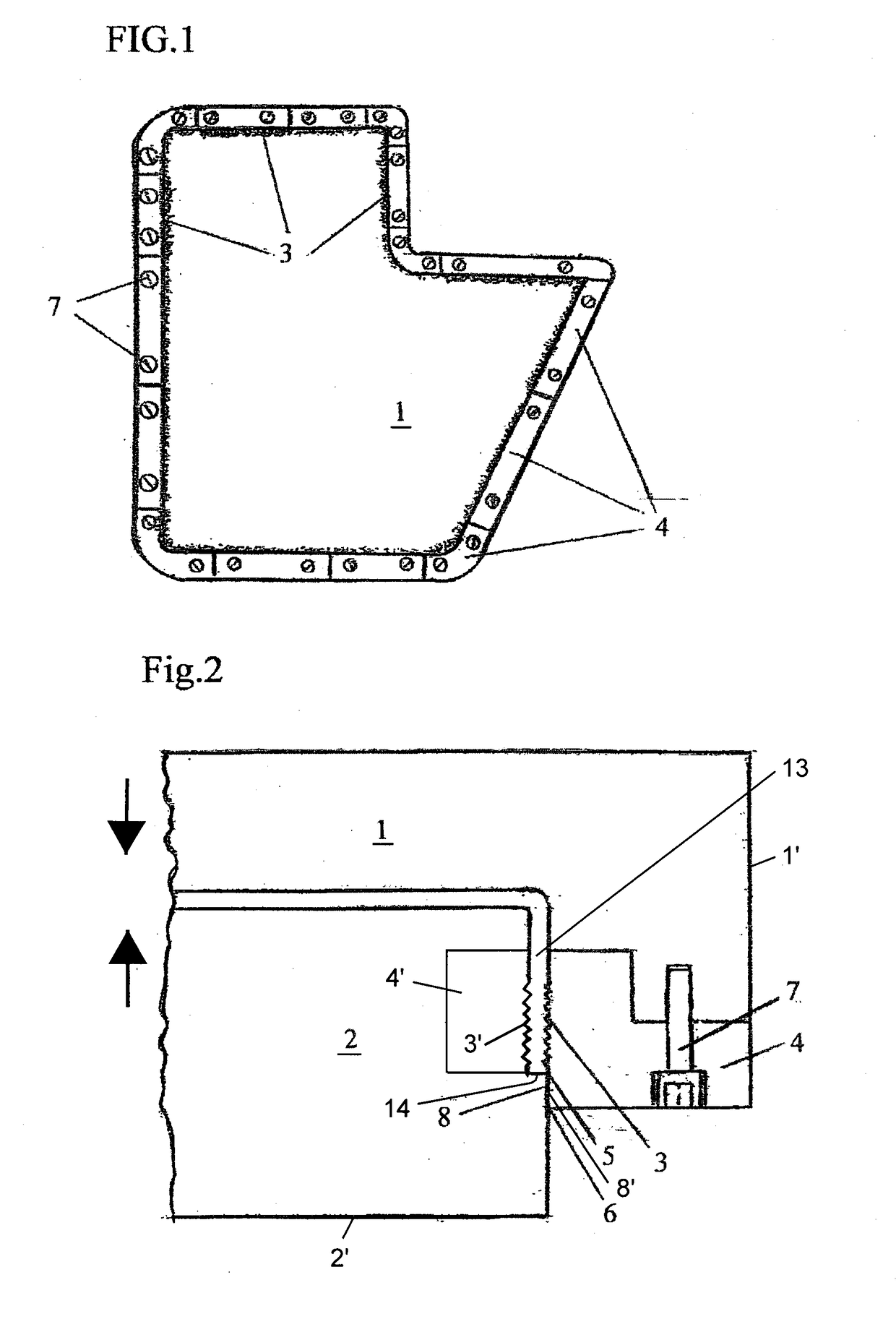

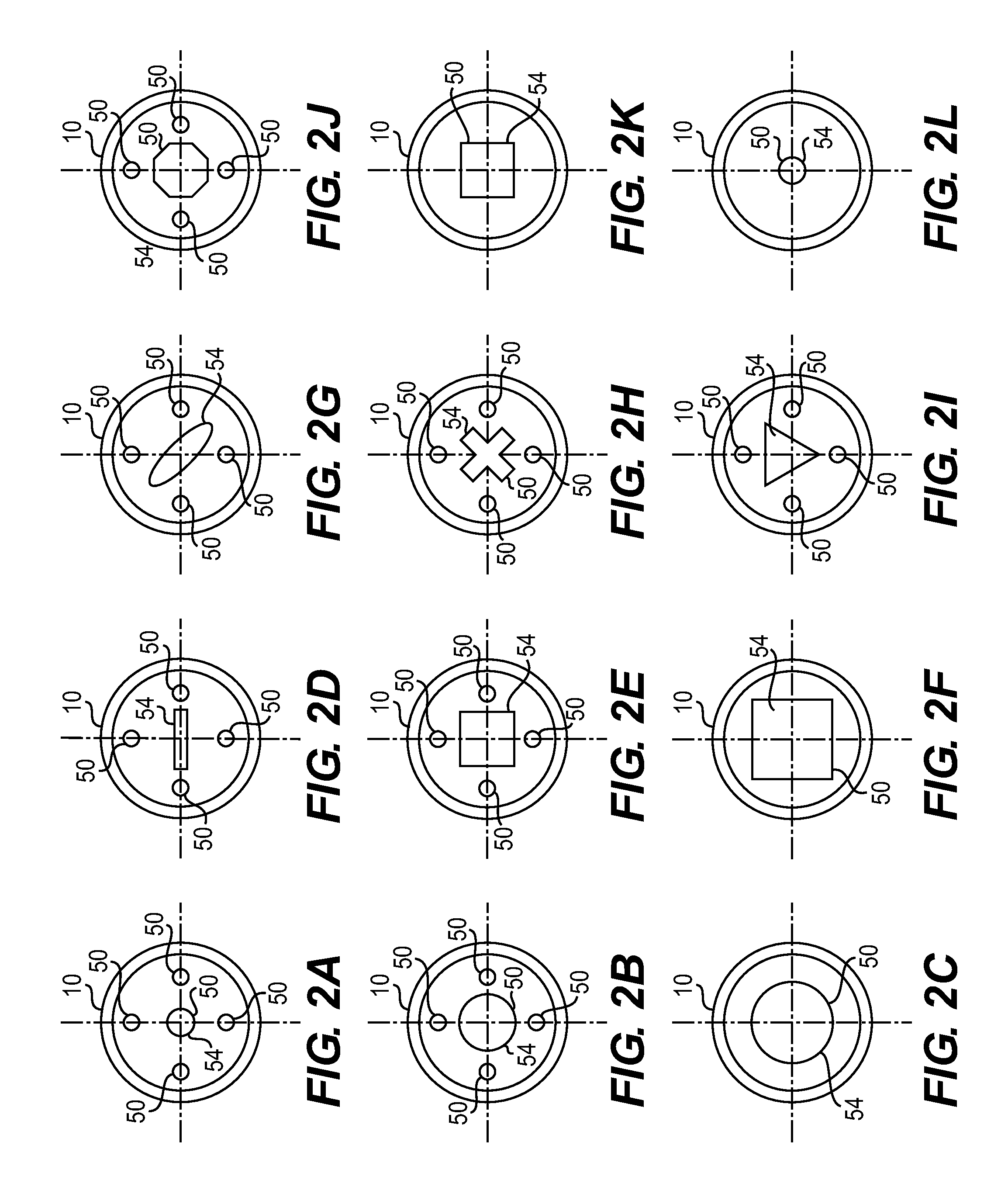

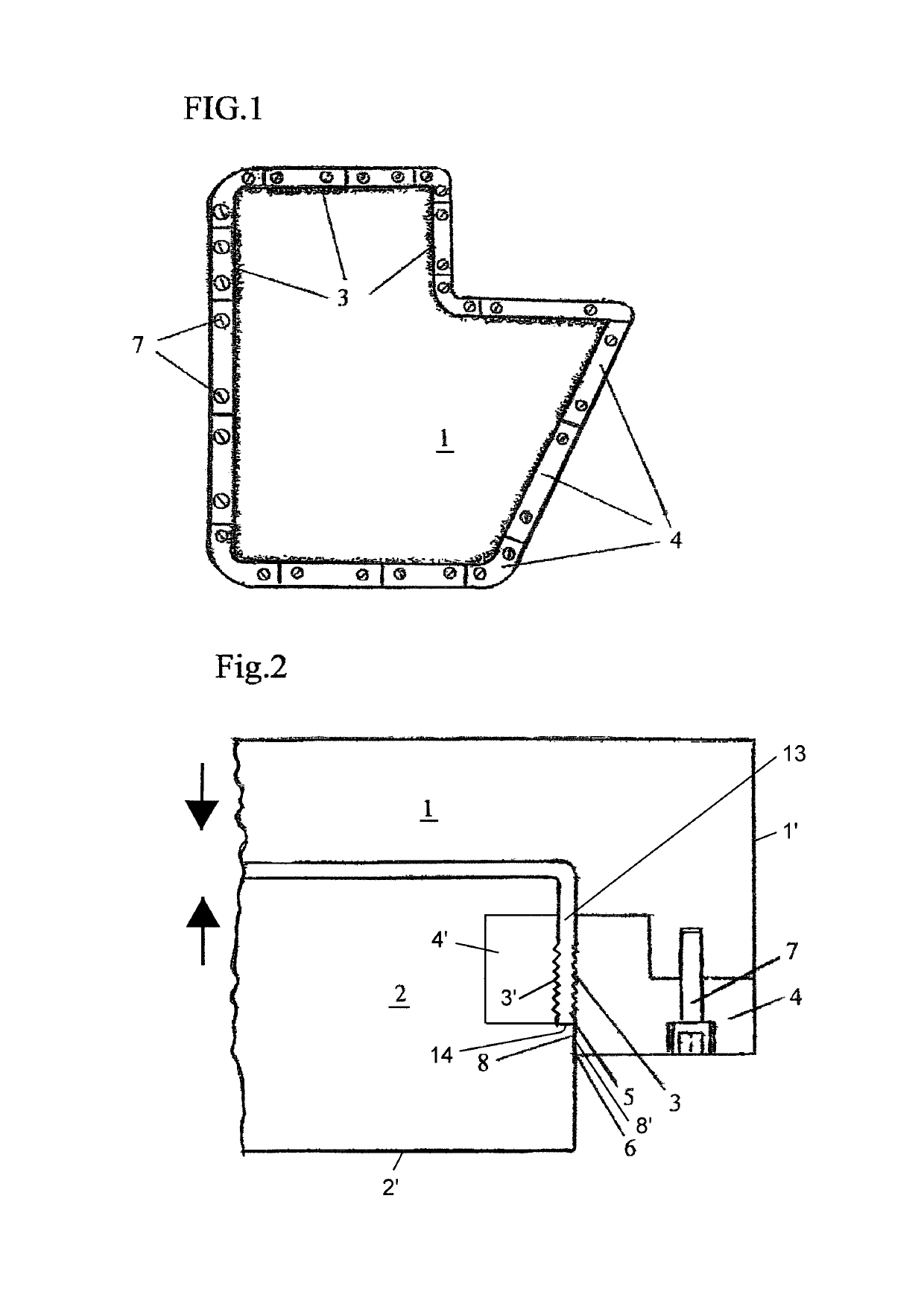

Furniture item and a method for attaching webbing thereto

InactiveUS20060192420A1Increased mechanical engagementEasy to attachWood working apparatusBedsEngineeringMechanical engineering

A furniture item and a method for its manufacture, the item comprising at least one support portion, said at least one support portion (24,26) comprising a receiving frame (30) and a support member (50) comprising a webbing (54) made of flexible material fitted at its edges with frame-engaging profiles (56) formed with first engaging members (66) for secure engagement with corresponding second engaging members (32) of the receiving frame (30); the invention characterized in that said frame-engaging profiles (56) are integrally molded with said webbing (54).

Owner:KETER PLASTIC LTD

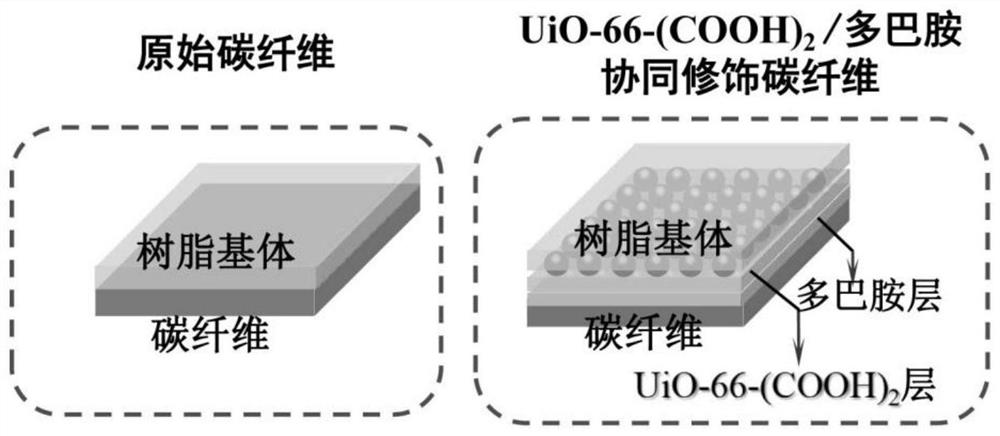

UiO-66-(COOH) 2/dopamine synergistically modified carbon fiber reinforced paper-based friction material and preparation method thereof

ActiveCN114016326AEnhanced interface bindingImprove friction and wear performanceNatural cellulose pulp/paperSpecial paperFiberCarbon fibers

The invention relates to a UiO-66-(COOH) 2 / dopamine synergistically modified carbon fiber reinforced paper-based friction material and a preparation method thereof. The preparation method comprises the steps that carbon fibers with clean surfaces are sequentially placed in trihydroxymethyl aminomethane (Tris buffer solution) and a dopamine solution, and a high-adhesion dopamine flexible film grows and wraps the surfaces of the carbon fibers; then, based on a hydrothermal reaction, a UiO-66-(COOH) 2 crystal layer grows on the surface of the carbon fiber in situ, and after the reaction is completed, the modified carbon fiber is fully washed and dried. An interface structure is constructed and reinforced by adopting the bi-component modified carbon fibers and a resin matrix, and the UiO-66-(COOH) 2 / dopamine synergistically modified carbon fiber reinforced paper-based friction material is prepared. The dynamic friction coefficient of the UiO-66-(COOH) 2 / dopamine synergistically modified carbon fiber reinforced paper-based friction material prepared by the preparation method disclosed by the invention is increased to 0.1353 from 0.1044, and the amplification is 29.60%. The wear rate is reduced from 3.35 * 10 <-8 > cm < 3 >. J <-1 > to 2.65 * 10 <-8 > cm < 3 >. J <-1 >, and the reduction amplitude is 20.89%. The result shows that the UiO-66-(COOH) 2 / dopamine synergistically modifies and reinforces the material interface structure, and the friction and wear performance of the paper-based friction material can be remarkably improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of emulsion type carbon fiber sizing agent containing nano material and its preparation method

The invention discloses an emulsion type carbon fiber sizing agent containing a nano material. The sizing agent comprises the following components in percentage by mass: 0.1-2% of a main sizing agent, 0.01-1% of a nano material, 0.05-2% of an emulsion agent, 0.05-0.1% of a dispersing agent, 0.15-8% of an organic solvent and 86.9-99.64% of deionized water. The sizing agent has the advantages the interface binding strength with carbon fibers is high and the surface free energy of the sized carbon fibers is no less than 55mN / m.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

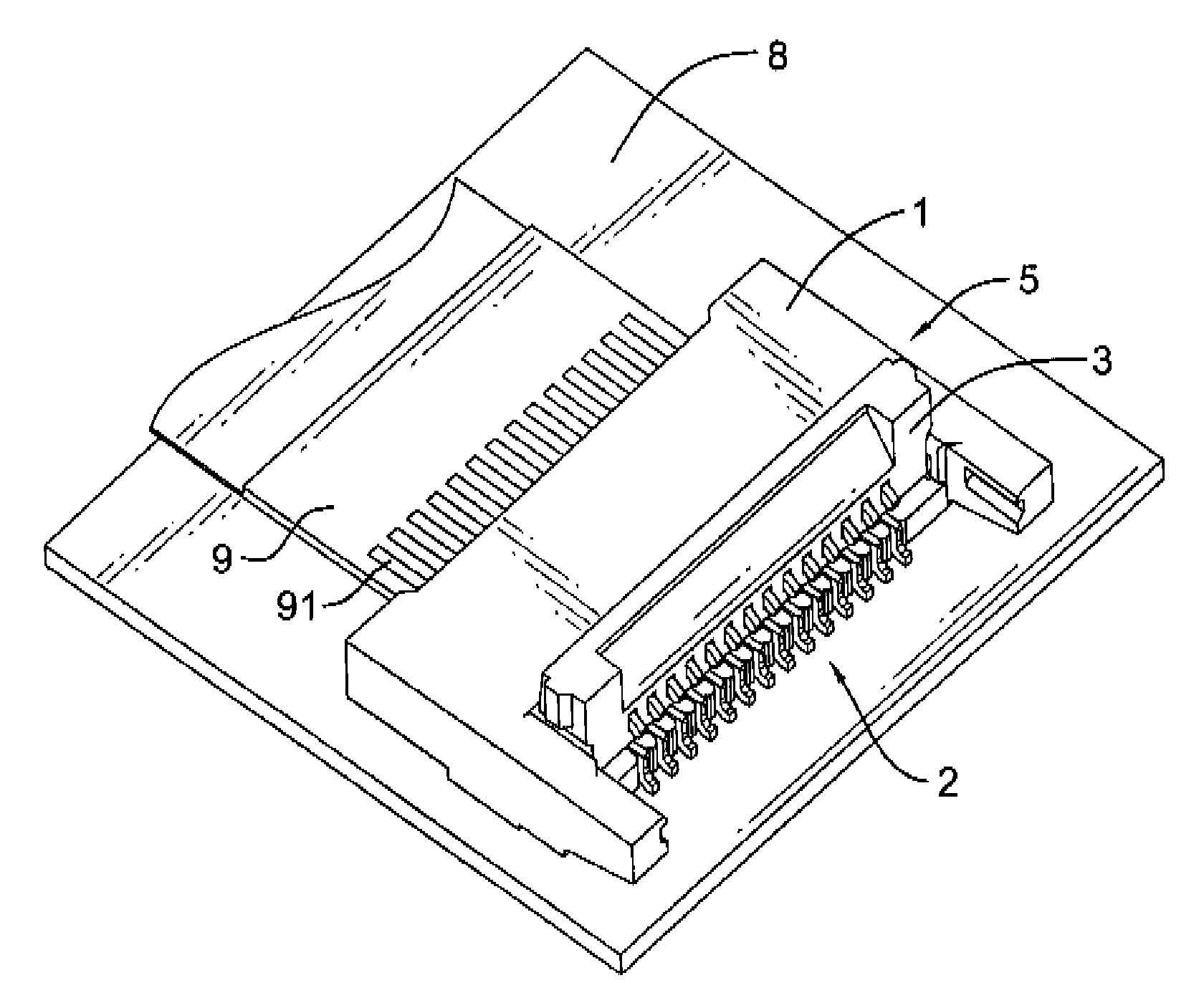

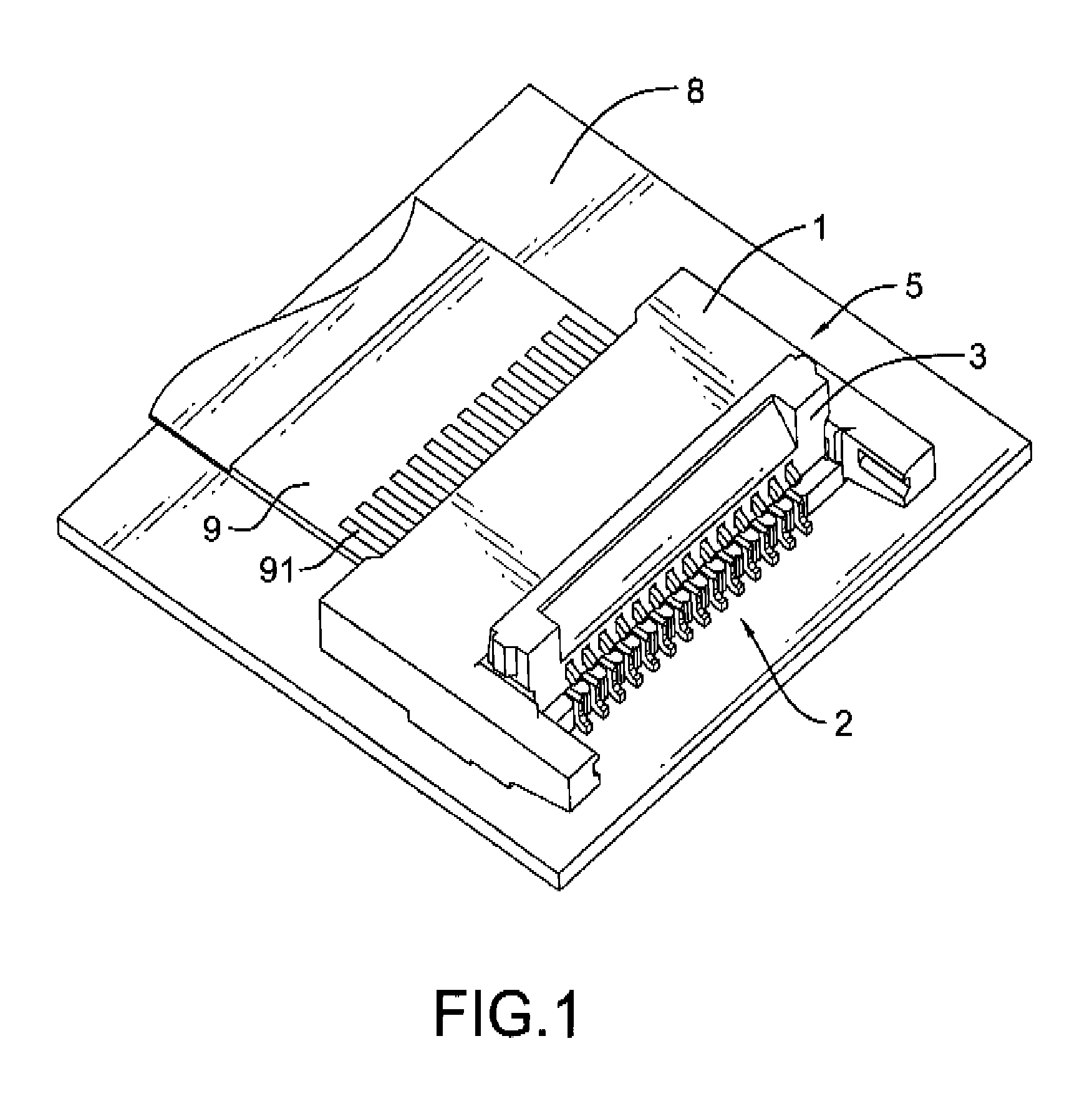

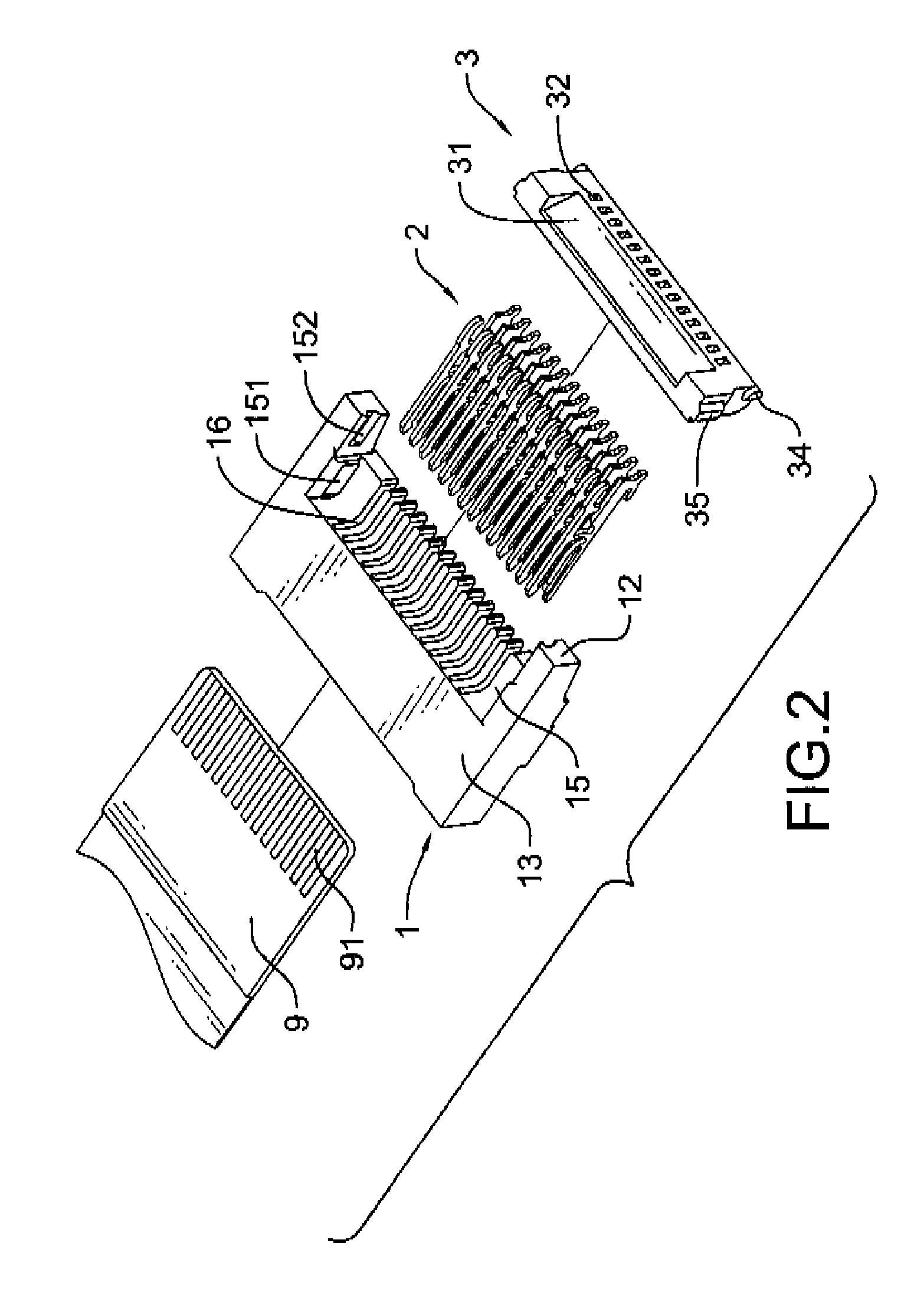

Electrical connector

ActiveUS20090061689A1Improve electricityIncreased mechanical engagementEngagement/disengagement of coupling partsCoupling contact membersElectrical connectorElectrical and Electronics engineering

An electrical connector for engaging with an electronic card has a insulative housing with a plurality of receiving spaces, a plurality of terminals respectively mounted in the receiving spaces of the insulative housing, and an operating member pivotally connected to the insulative housing. The operating member controls the terminals in the insulative housing to be moved for electrically and mechanically engagement with the electronic card. Each of the terminals has a base portion, an upper arm and a lower arm. The upper arm is connected to the base portion at a joint as a first fulcrum. The lower arm is connected to the base portion at another joint as a second fulcrum. As the operating member pivotally moves to a predetermined position, the upper arm and the lower arm respectively rotate about the first fulcrum and the second fulcrum to securely grasp the electronic card.

Owner:ADVANCED CONNECTEK INC

A method for preparing an anticorrosion antioxidation material

A method for preparing an anticorrosion antioxidation material is disclosed. The method includes firstly adding bamboo powder into a NaOH solution containing cytosine; soaking and reacting the bamboopowder; then reacting the alkali-treated bamboo powder in an ethanol solution containing vinyltrimethoxysilane to obtain silane-modified bamboo powder; modifying and reacting alkali-treated bamboo powder in distilled water containing stearic acid and ammonium 3-bromocamphor-8-sulfonate to obtain bamboo powder modified with stearic acid; finally fully mixing the silane-modified bamboo powder, the bamboo powder modified with stearic acid, polypropylene powder and an antioxidant; and subjecting the mixture to melting and granulation to obtain the anticorrosion antioxidation material. Beneficial effects are that the method can effectively improve roughness of the surface and inside of bamboo powder, polarity of the bamboo powder is increased, the degree of crystallization of cellulose molecules is increased, mechanical meshing between the bamboo powder and a resin matrix is further improved, the density and uniformity of the composite material are improved, and mechanical strength and an antioxidation function of the material are improved.

Owner:陶玲

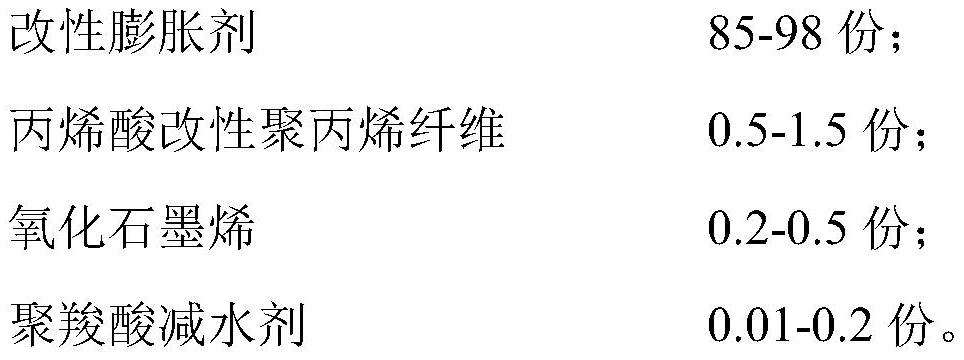

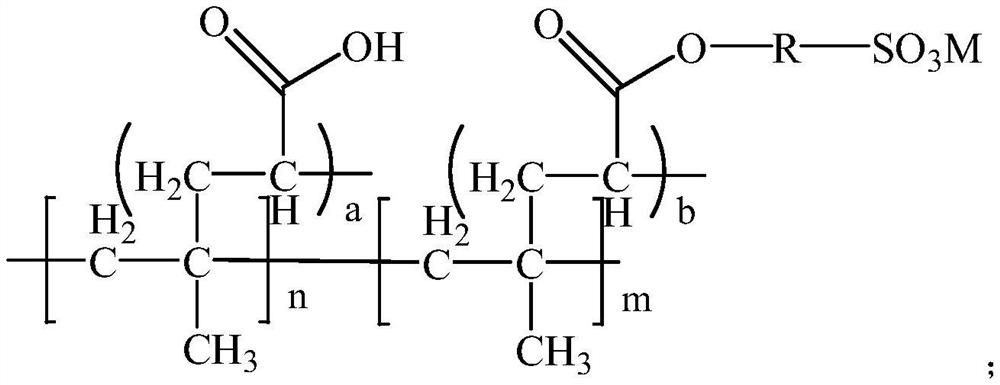

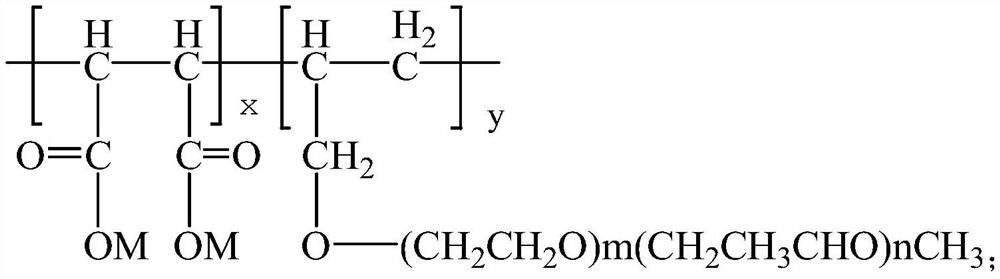

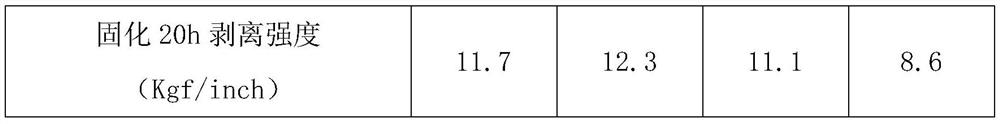

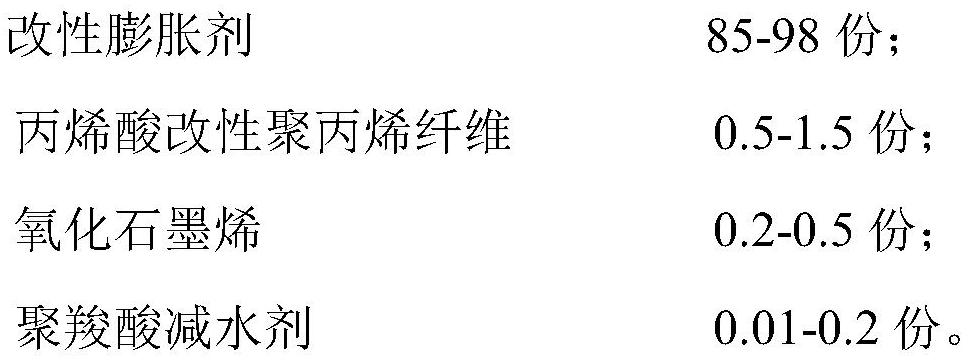

Composite internal-curing shrinkage-reducing anti-cracking agent for concrete and production method of composite internal-curing shrinkage-reducing anti-cracking agent

ActiveCN113003977ALarge amount of expansionInhibition of early plastic shrinkageHydration reactionCrack resistance

The invention discloses a composite internal-curing shrinkage-reducing anti-cracking agent for concrete and a production method of the composite internal-curing shrinkage-reducing anti-cracking agent, and belongs to concrete additives. The agent is prepared from the following components in parts by weight: a modified expanding agent, acrylic acid modified polypropylene fibers, graphene oxide and a polycarboxylic acid water reducing agent. The graphene oxide is used as an adsorption point to adsorb acrylic acid modified polypropylene fibers to form a three-dimensional network branch-tendril-shaped capillary structure, and countless uniformly-distributed micro water storage tanks are formed in the concrete, so that the hydration reaction of a cementing material is promoted to the greatest extent, and the deformation performance, the crack resistance and the durability of the concrete are obviously improved.

Owner:南京派尼尔科技实业有限公司

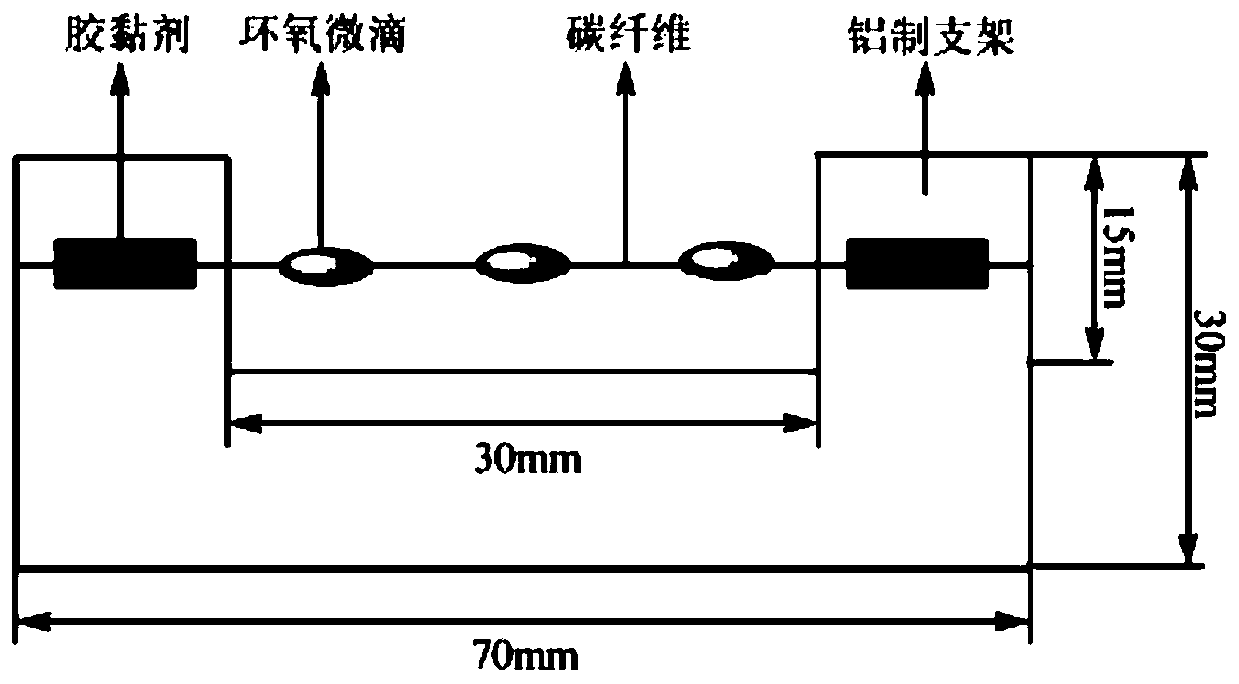

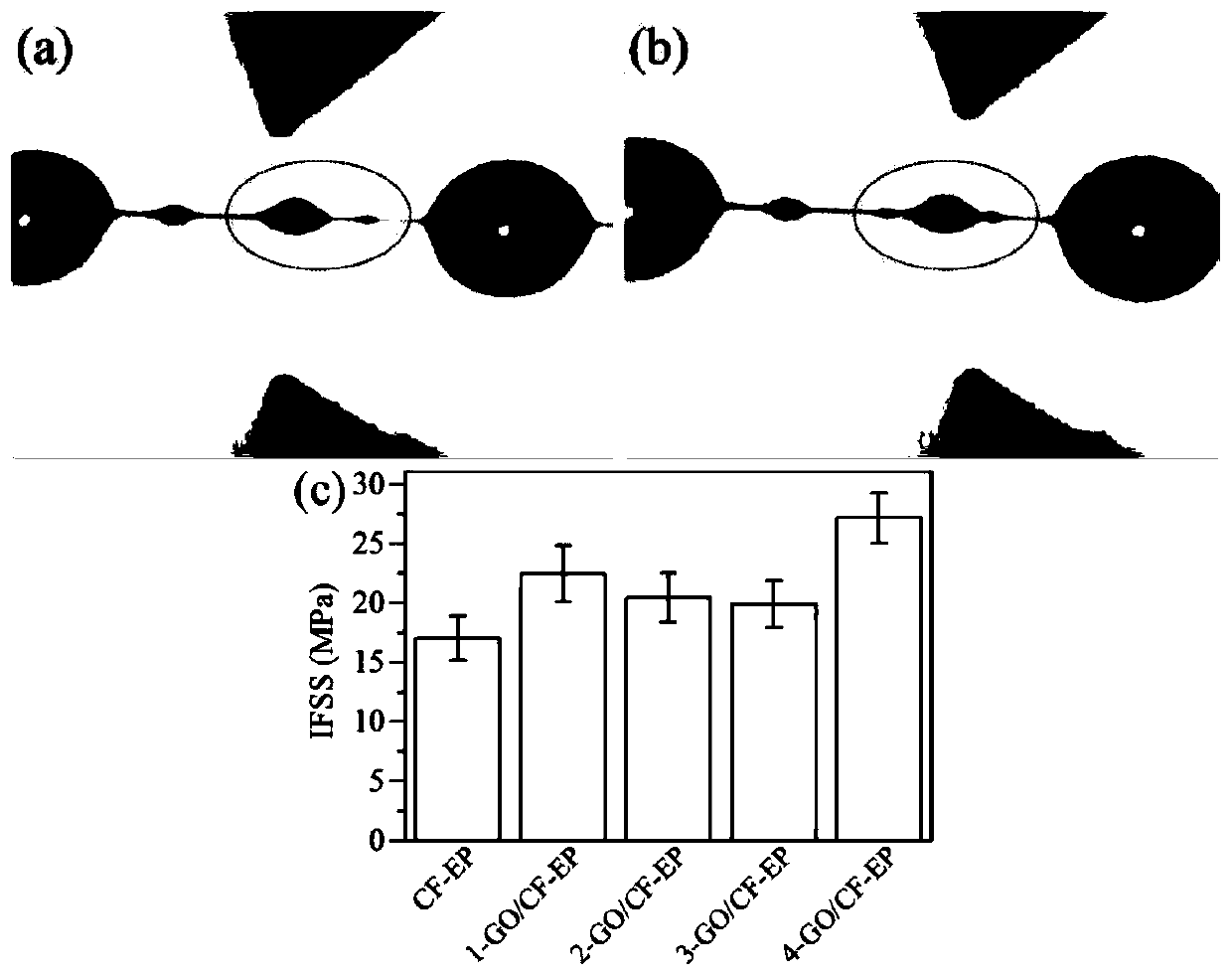

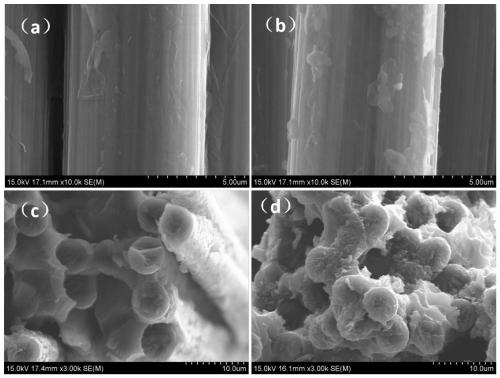

A preparation method of graphene oxide modified carbon fiber initiated by silane coupling agent-assisted electrophoretic deposition

ActiveCN108286187BRetain mechanical propertiesSolve reunionCarbon fibresCarbon fibersModified carbon

The invention discloses a preparation method of silane coupling agent assisted electrophoresis deposition initiated graphene oxide modified carbon fibers. The preparation method comprises the following steps: placing desized carbon fibers into an aqueous solution which contains amino propyl triethoxysilane (APTES) and ethanol for hydrolysis amination pretreatment to obtain carbon fibers treated bya silane coupling agent, connecting the carbon fibers treated by the silane coupling agent to a positive electrode of a power supply, connecting a copper sheet to a negative electrode of the power supply, and performing electrophoresis deposition by a graphene oxide aqueous solution used as an electrophoresis deposition solution to obtain the silane coupling agent assisted electrophoresis deposition initiated graphene oxide modified carbon fibers. The preparation method can effectively enhance the interfacial shear strength of a carbon fiber enhanced resin-based composite material, and can beapplied to a surface modification process of homemade carbon fiber.

Owner:SHANDONG UNIV

Preparation method of titanium and titanium alloy surface black protective film for surgical implantation

ActiveCN101660190BThe preparation process steps are simpleEasy to operateSurface reaction electrolytic coatingProsthesisTectorial membranePlasma electrolytic oxidation

The invention discloses a preparation method of a titanium and titanium alloy surface black protective film for surgical implantation, comprising the following steps: step 1: carrying out micro-arc oxidation coloring processing on titanium and titanium alloy surface to be processed, in the process, firstly, preparing a micro-arc oxidation electrolysing solution, and then carrying out the micro-arc oxidation coloring processing; and step 2: carrying out subsequent processing on the micro-arc oxidation film, wherein the subsequent processing comprises the following steps: firstly, preparing a mixed solution for hydro-thermal processing, completely dipping the titanium and titanium alloy after micro-arc oxidation shading processing in the mixed solution, carrying out the hydro-thermal processing on the surface by adopting a hydro-thermal method, drying the titanium and titanium alloy under the condition of low temperature when the hydro-thermal processing is completed, and generating a layer of pure black micro-arc oxidation film with uniform and plump surface on the titanium and titanium alloy surface. The invention has simple and convenient operation, economy, high production efficiency, and high bonding strength between a generated ceramic film, i.e. the micro-arc oxidation film and a substrate, and the invention can effectively overcome various defects and deficiencies which exist in the prior coating processing techniques.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

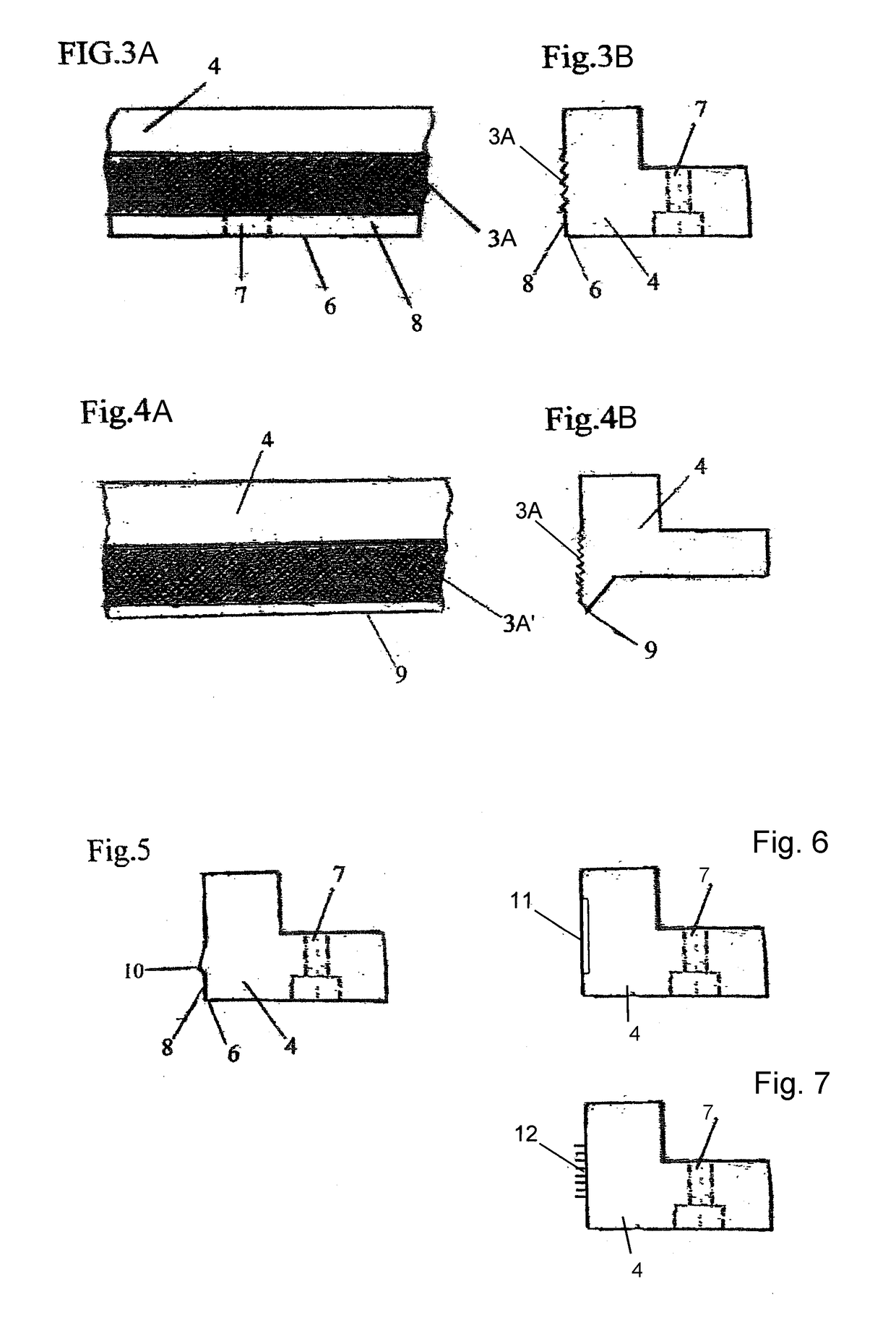

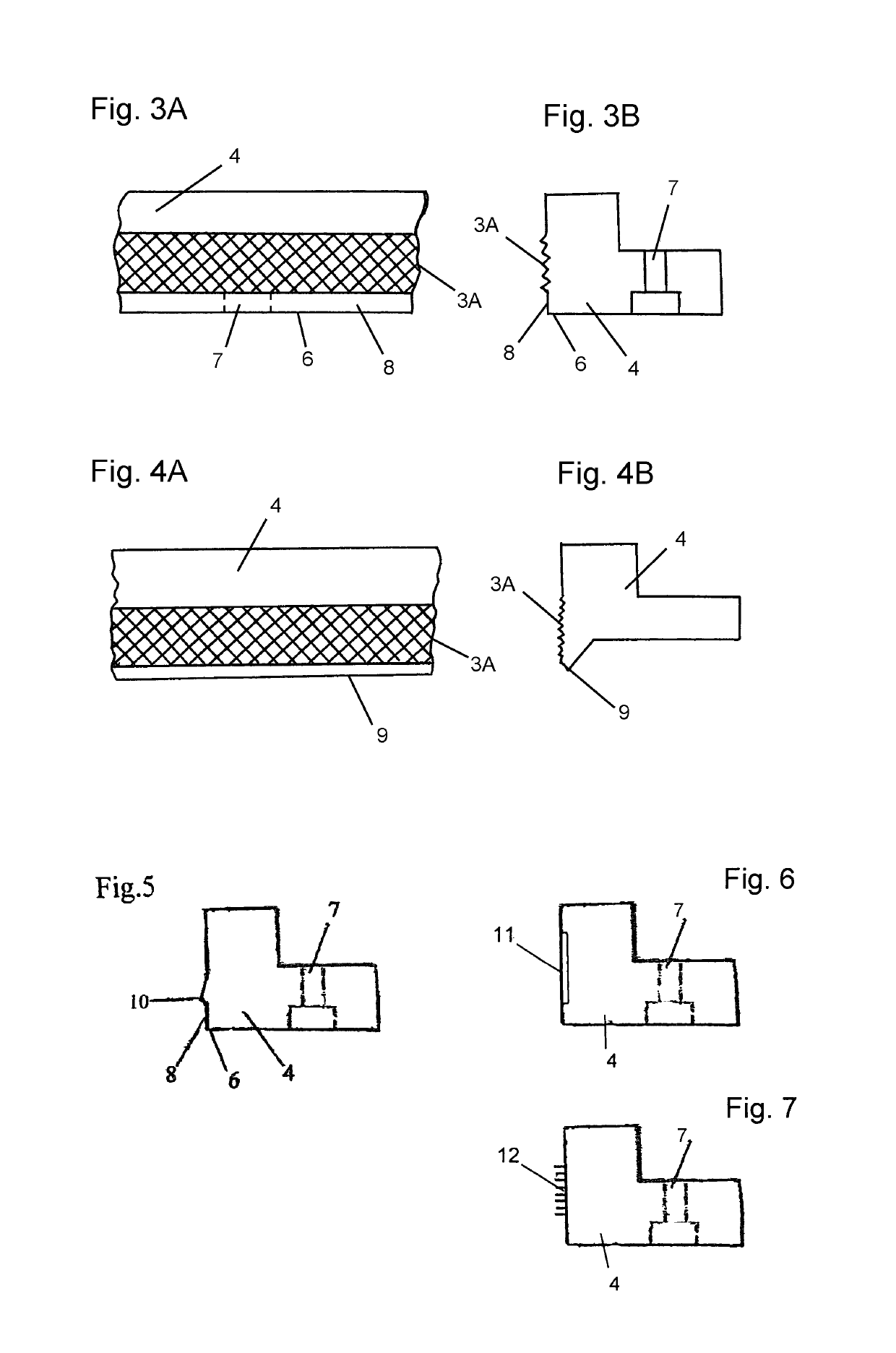

Molding Tools and Method With Grip-Enhancing Structure

ActiveUS20170190079A1Reducing and preventing pull-backReducing and preventing and retractionDomestic articlesPressesRough surfaceShell molding

A molding apparatus includes two mold tools that define and bound a mold cavity therebetween, for three-dimensionally press-molding a trim component. To minimize or avoid shrinkage or pull-back recession of the edge of the trim component during the molding process, at least one of the mold tools, on its molding surface bounding an end portion of the mold cavity, includes at least one grip-enhancing structure that provides increased grip on an edge portion of the trim component. The grip-enhancing structure may be or include a rough surface, a geometric configured surface, a geometric gripping edge, a surface coating, or mechanical engagement members. The grip-enhancing structure provides increased grip on the edge portion of the trim component by narrowing the mold cavity space, by increasing the surface friction or adhesion, and / or by mechanically engaging the material of the trim component. Thereby, the edge of the trim component is held in place while the three-dimensional molding proceeds and until the molded contour of the component is fixed.

Owner:SAM SUNGAN RALPH PAGENDARM GMBH

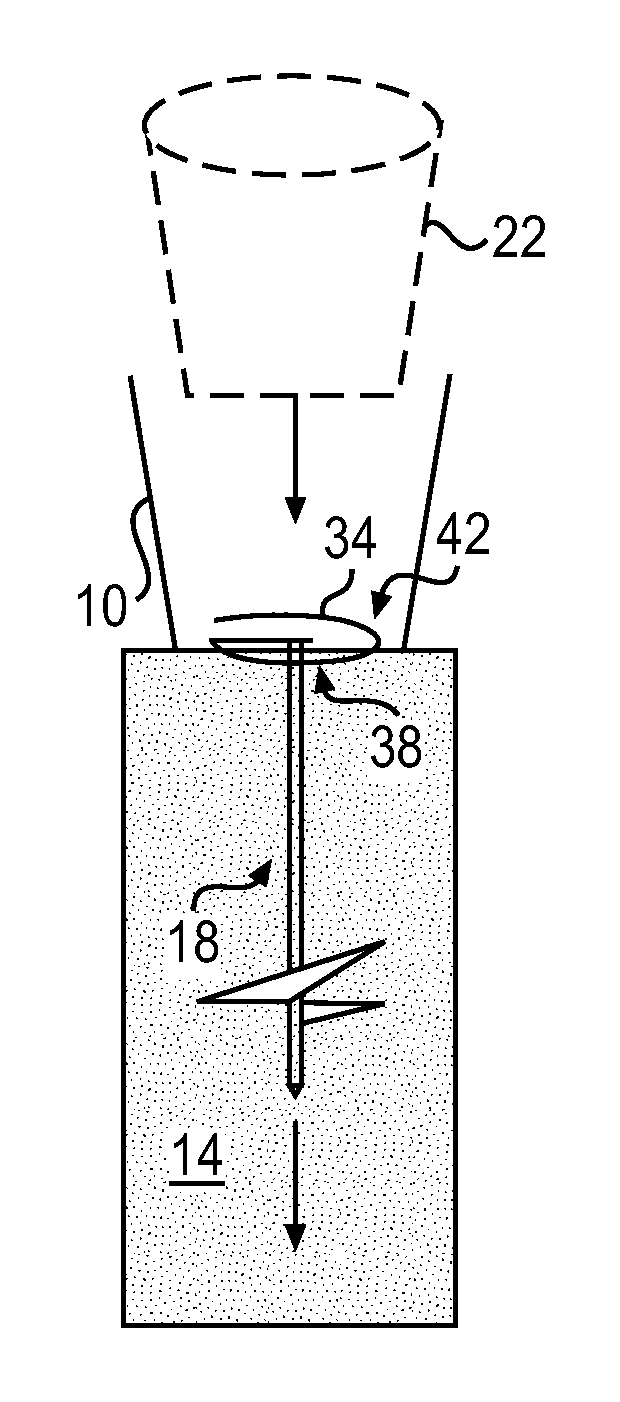

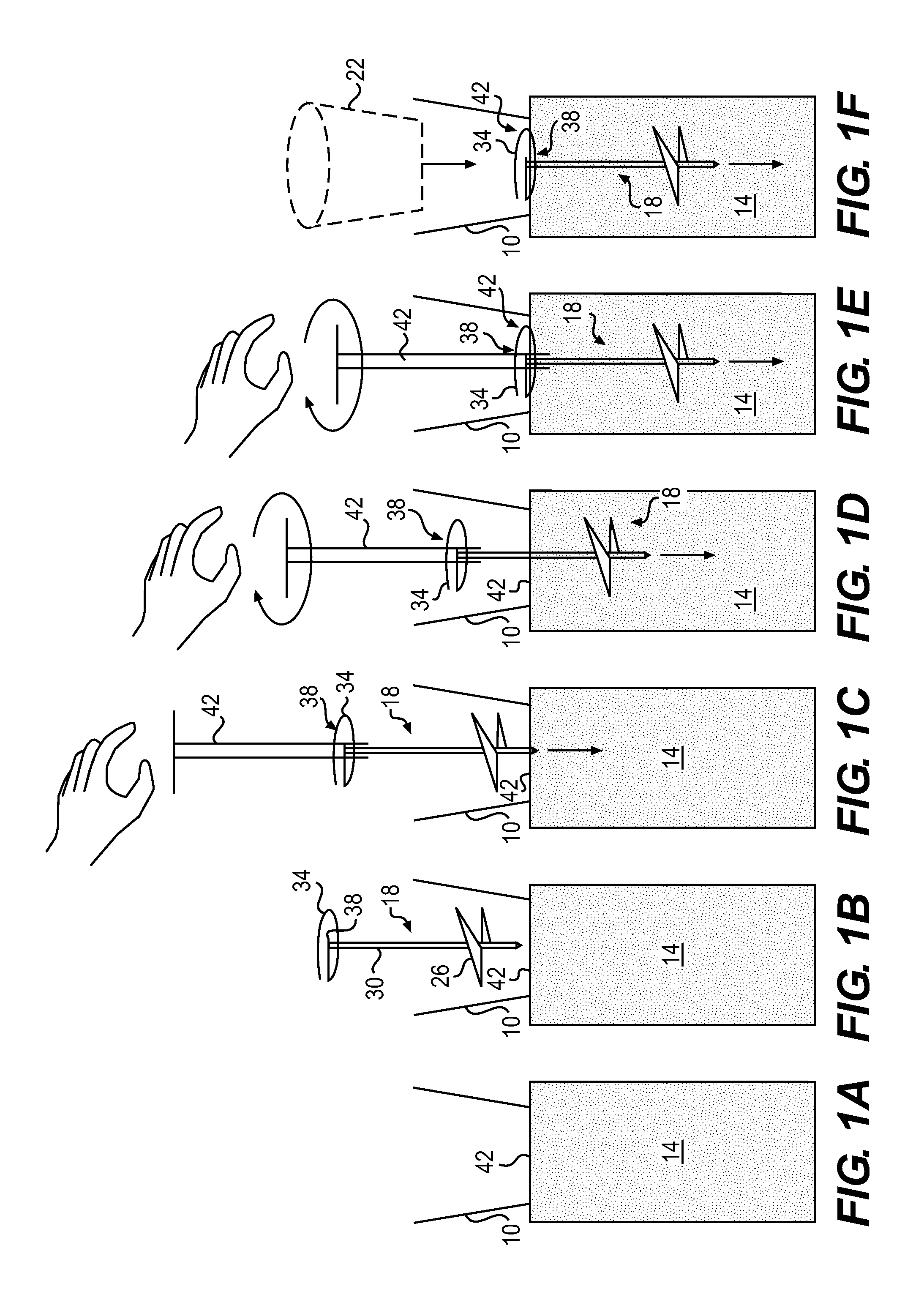

Pot-securing apparatus and method of use thereof

InactiveUS20140366436A1Increased mechanical engagementStrong holdFlower holdersEngineeringMechanical engineering

Owner:PEPINIERE DU JASEUR

Preparation method of ceramic material capable of generating carbon nanowires in situ

The invention relates to a preparation method of a ceramic material, particularly a preparation method of a ceramic material capable of generating carbon nanowires in situ. The method aims to solve the problems of high complexity and high condition requirements in the existing carbon nanowire preparation technique. The method 1 comprises the following steps: 1. carrying out resin solidification; 2. carrying out ball milling to obtain powder; 3. carrying out pre-press forming; 4. carrying out pyrolytic cracking; and 5. cooling to obtain the in-situ-generated carbon nanowire ceramic material. The method 2 comprises the following steps: 1. carrying out resin solidification; 2. carrying out ball milling to obtain powder; 3. carrying out hot-press forming; and 4. cooling to obtain the in-situ-generated carbon nanowire ceramic material. The method is simple and convenient, does not need complicated equipment or experimental steps, is low in cost, and can perform carbon nanowire in-situ generation inside the ceramic material. The method can promote the conductivity of the material. The method is applicable to the field of ceramic materials.

Owner:HARBIN INST OF TECH

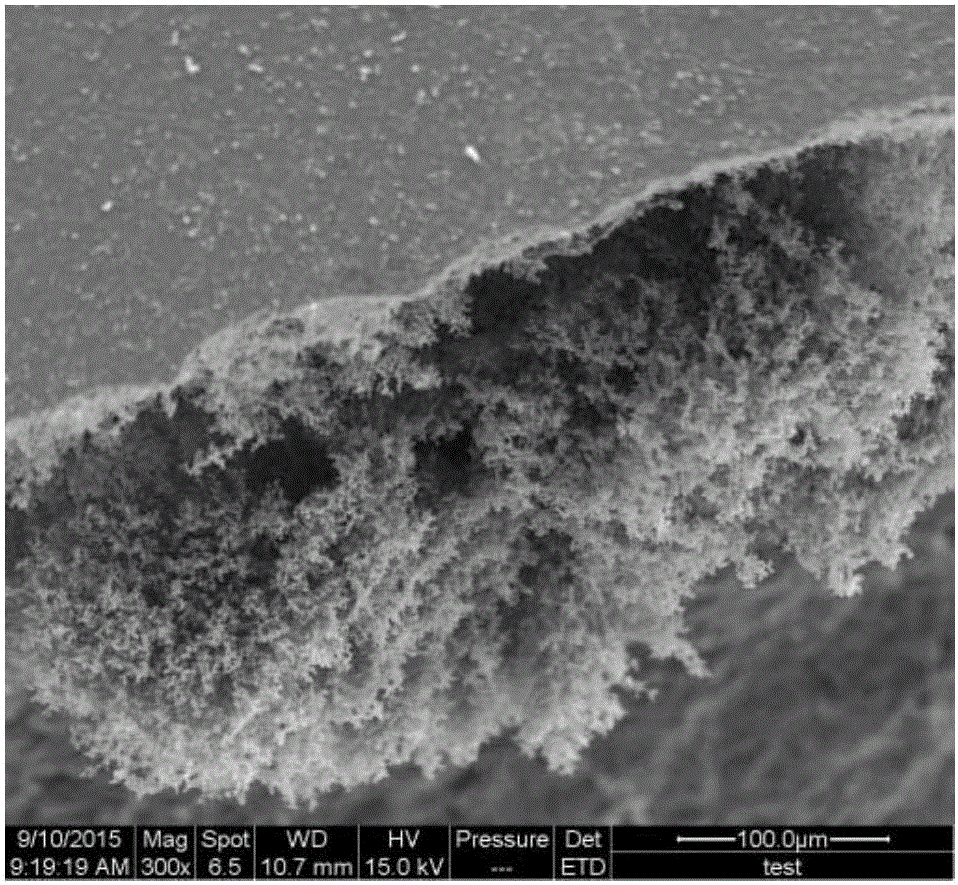

A kind of method for grafting hexamethylenetetramine on carbon fiber surface in supercritical methanol

InactiveCN104480707BImprove reaction efficiencyIncrease surface areaCarbon fibresCarbon fibersModified carbon

Owner:HARBIN INST OF TECH

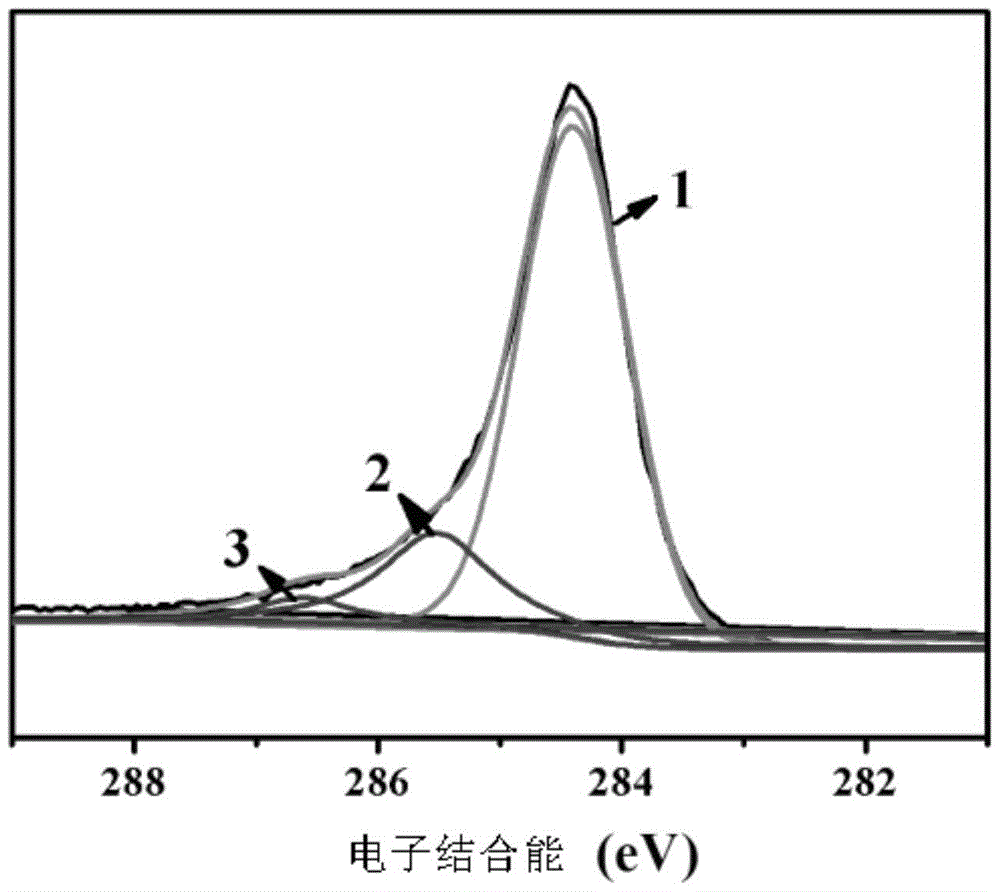

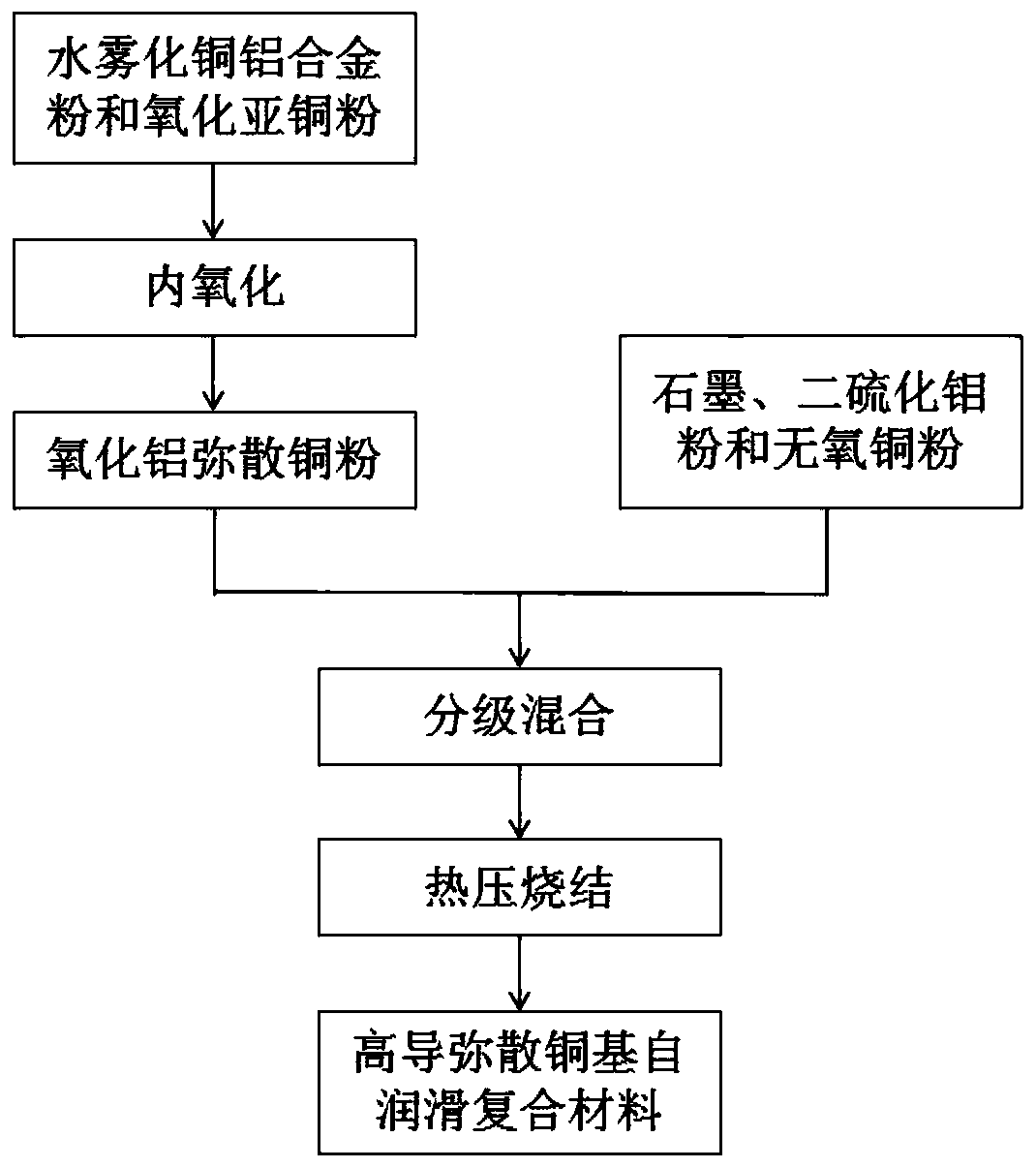

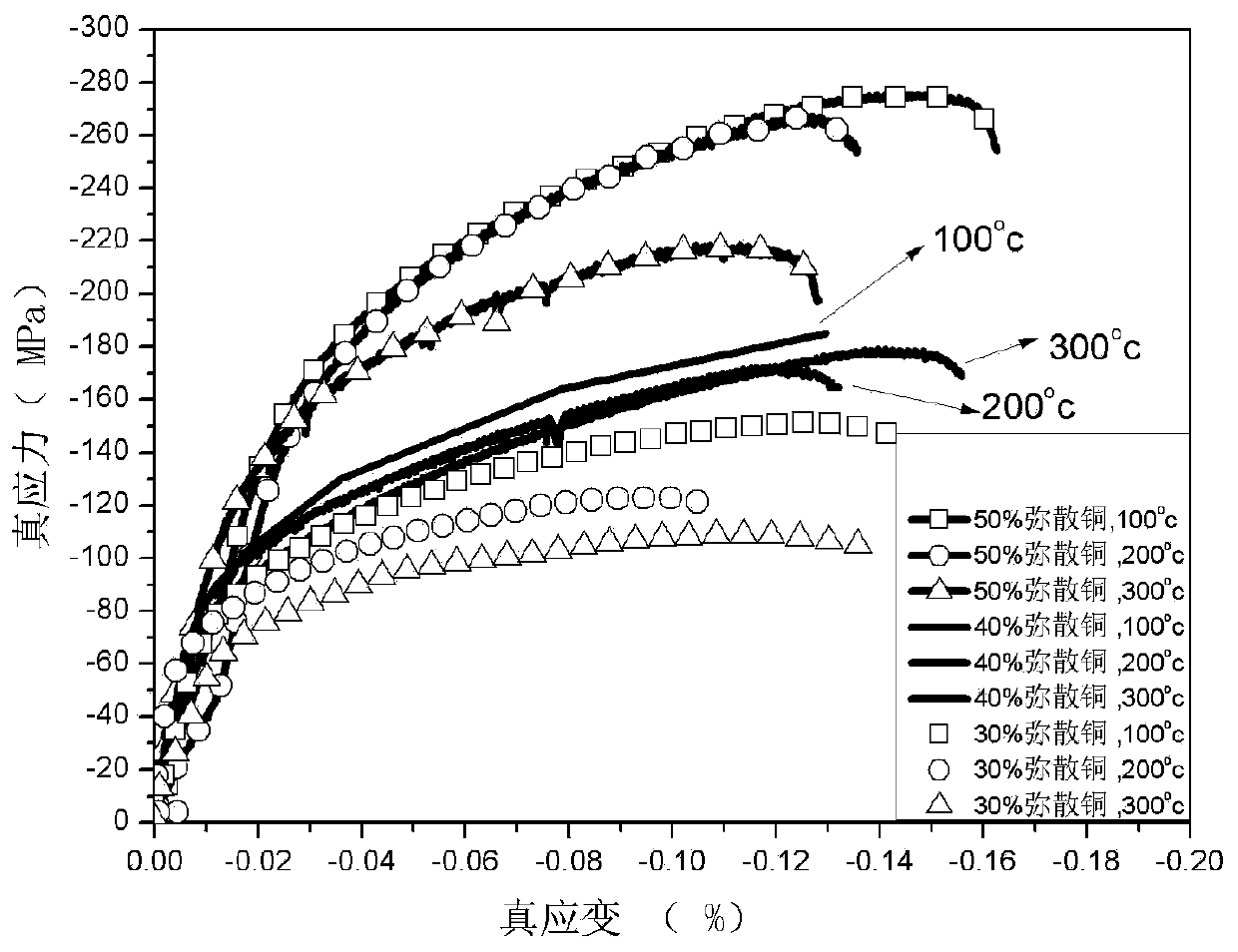

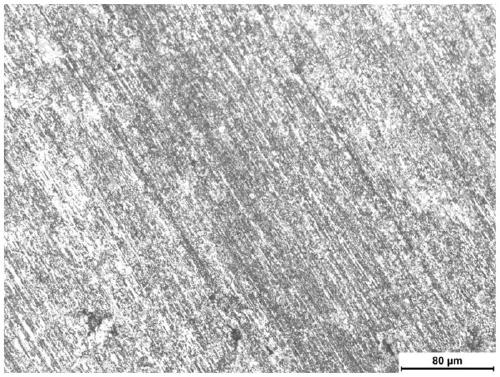

A high-conductivity dispersed copper-based high-temperature self-lubricating composite material and its preparation method

The invention discloses a high-conductivity dispersed copper-based high-temperature self-lubricating composite. The high-conductivity dispersed copper-based high-temperature self-lubricating composite comprises oxygen-free copper powder and the following components of, by mass, 30%-50% of aluminum oxide dispersion copper powder, 0-2% of molybdenum disulfide powder and 6%-8% of graphite. When the temperature of the friction surface increases, the friction coefficient cannot decrease obviously, the recovery capability of reusing after cooling is high, the friction coefficient in each temperature range is kept between 0.130 and 0.140, a stable frictional characteristic is achieved, the characteristics of a low expansion coefficient, a high conductivity and heat conducting rate, high strength and toughness and the like are achieved, the anti-declining property is high, high-temperature lubrication, wear resistance and electrical conductivity can be achieved simultaneously, and the low friction coefficient and the low wearing capacity under the working condition of high speed sliding can be ensured by the self-lubricating composite, the self-lubricating composite is suitable for the fields of aviation, spaceflight, high speed railways, radar communication and the like, and particularly suitable for the fields of high speed railway pantograph pans, radar electric brushes, high speed printing elements and the like.

Owner:CENT SOUTH UNIV

A carbon fiber surface grafting method based on supercritical fluid technology

ActiveCN104987532BEffective wettingImprove the interface binding forceBulk chemical productionCross-linkFiber

Owner:HARBIN INST OF TECH

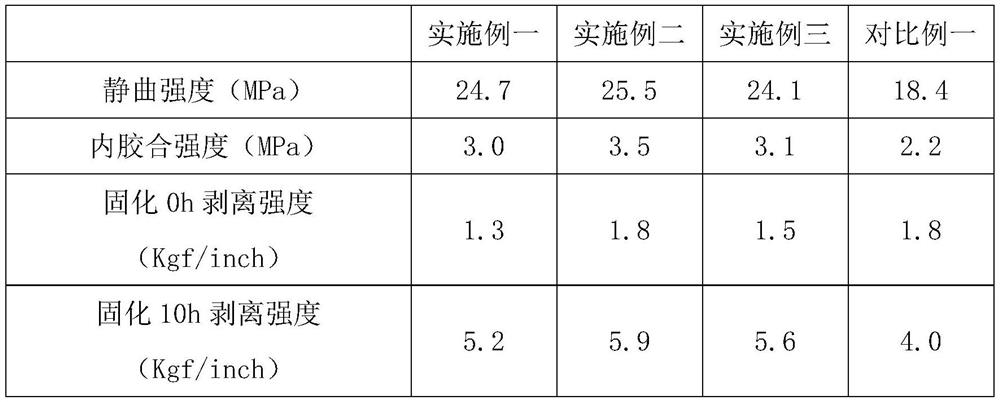

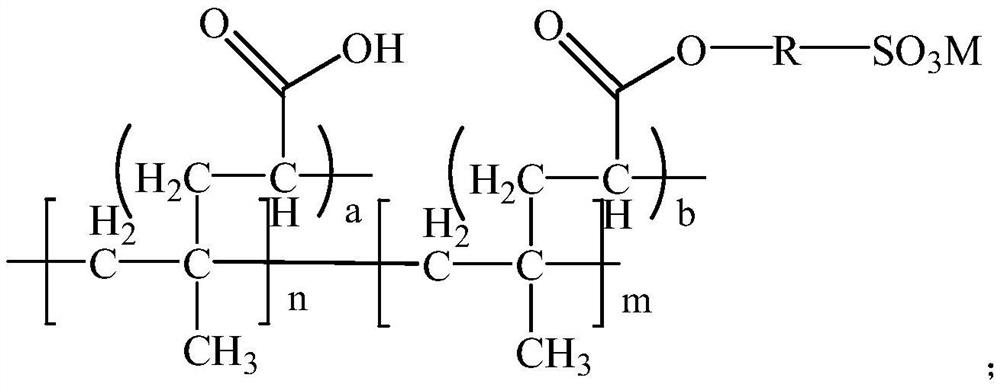

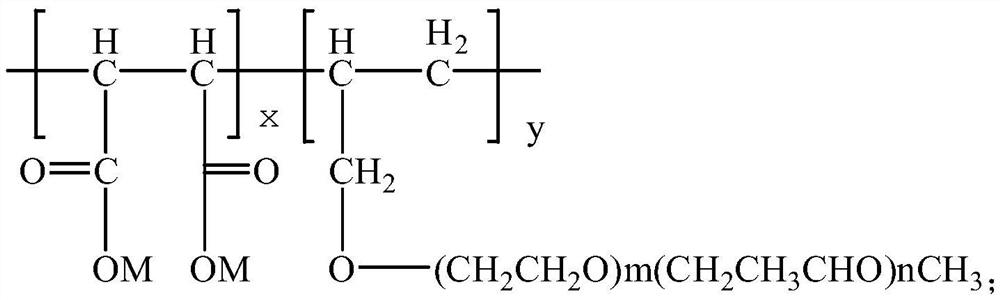

Surface control technology for PB cold-bonded board

ActiveCN113771152AIncreased adhesion areaIncreased mechanical engagementNon-macromolecular adhesive additivesWood veneer joiningAdhesive cementProcess engineering

The invention belongs to the technical field of artificial board manufacturing, particularly relates to a surface control technology for a PB cold-bonded board, and solves the problems that in the prior art, the requirements of PB board veneering treatment on technological parameters are relatively high, the produced veneered PB board is limited by the production technology level, glue failure, blistering, low bonding strength and the like are easy to occur. According to the technology, the PB cold-bonded board is formed by connecting a composite veneer, a plain board and a composite veneer through an adhesive I from top to bottom and performing cold press molding and post-treatment finally. According to the technology, the composite veneers, the plain board and the adhesive I are prepared, the composite veneer, the plain board and the composite veneer are connected through the adhesive I, and finally, cold press molding is performed to obtain the PB cold-bonded board. The preparation method is simple, cold press molding and cold press curing technologies are adopted, the technological parameter requirements are low, production operation is easy, the preparation cost is low, and the technology is suitable for industrial production.

Owner:佳诺威集团(河南)新材料有限公司

A kind of composite internal curing shrinkage reducing and anti-cracking agent for concrete and production method thereof

ActiveCN113003977BLarge amount of expansionInhibition of early plastic shrinkageHydration reactionPolymer science

Owner:南京派尼尔科技实业有限公司

Modified silicon carbide sizing agent for improving wave-absorbing property of carbon fiber and preparation method of modified silicon carbide sizing agent

PendingCN114541136ASmall granularityEasy reunionCarbon fibresTextile/flexible product manufactureFiberCarbide silicon

The invention discloses a modified silicon carbide sizing agent for improving the wave-absorbing performance of carbon fibers and a preparation method thereof.The sizing agent is composed of, by weight, 0.1-10% of modified silicon carbide, 10-20% of an emulsifier, 40-70% of alcohol and 10-40% of thermosetting resin, the sizing agent can be directly used for the carbon fibers, and the sizing agent can be applied to the carbon fibers. On the basis of improving the binding property of the carbon fibers, the carbon fibers have certain wave-absorbing property, so that the carbon fiber composite material product has wave-absorbing property.

Owner:江苏亨睿航空工业有限公司

A kind of pb cold laminate surface control technology

ActiveCN113771152BIncreased adhesion areaIncreased mechanical engagementNon-macromolecular adhesive additivesWood veneer joiningAdhesive cementUltimate tensile strength

The invention belongs to the technical field of wood-based panel manufacturing, in particular to a surface control process for PB cold-laminated panels, which solves the problem that in the prior art, the veneering treatment of PB panels has high requirements on process parameters, and the veneered PB panels produced are subject to the level of production technology. Restriction, problems such as glue opening, blistering, and low bonding strength are prone to occur. The surface control process of the PB cold veneer, the PB cold veneer, in the order from top to bottom, is composed of composite veneer-plain board-composite veneer The surfaces are connected by the adhesive I, and finally cold-pressed and formed after post-processing. In the present invention, the composite veneer, the plain board and the adhesive I are prepared, and the composite veneer-plain board-composite veneer is connected by the adhesive I, and finally the PB cold veneer is prepared by cold pressing; the preparation method of the invention is simple, and cold pressing is adopted. The molding and cold-pressing solidification process has low requirements on process parameters, simple production operation, low preparation cost, and is suitable for industrial production.

Owner:佳诺威集团(河南)新材料有限公司

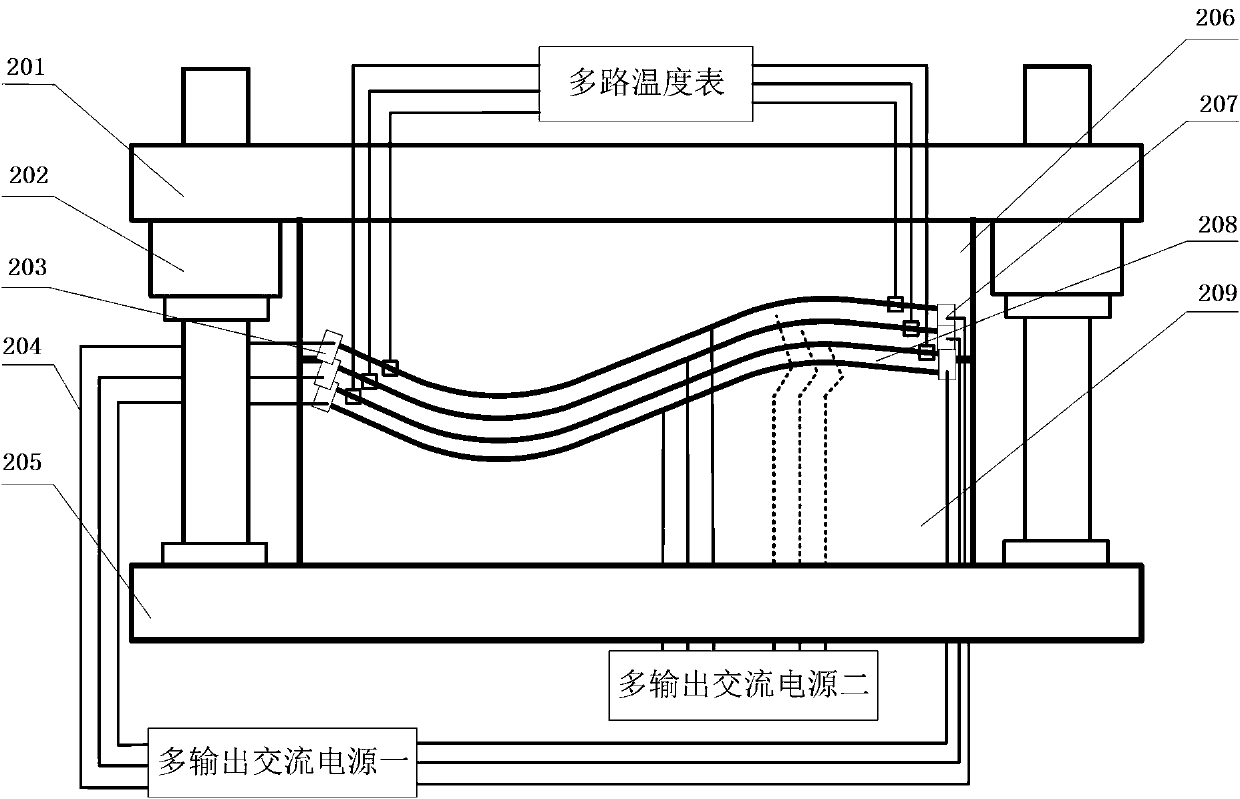

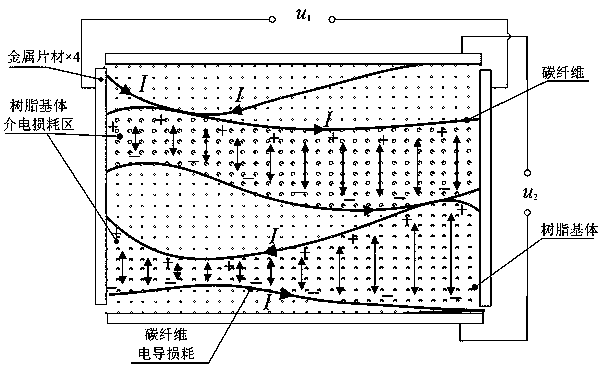

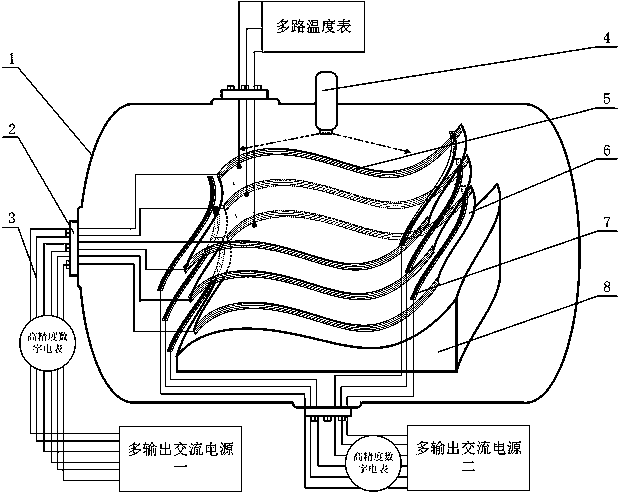

A comprehensive electric loss curing method for carbon fiber reinforced resin matrix composites

ActiveCN107662303BReduce distortionUniform curing reactionDomestic articlesPolymer scienceParallel plate

The invention discloses a comprehensive electrical loss curing method of a carbon fiber reinforced resin-based composite material. According to the method, paired metal sheets are respectively spreadalong the fiber direction and the direction vertical to fibers in each layer of the carbon fiber reinforced resin-based composite material; independently applying an alternating electric field havingcontinuous changing waveform, frequency and current density among each pair of sheets, and vertical to the fiber direction; vertical to the fiber direction, carbon fibers are the same as a plane-parallel capacitor, polarization loss, leakage conductance loss, free loss and other dielectric loss are generated from a fiber clearance matrix; along the fiber direction, conductance loss is generated bythe fibers under the current effect, and the material is integrally heated and finally cured into a composite material component under the comprehensive effect of lost heat with various modes. The method can realize high efficiency and low energy consumption curing of a large-sized large-thickness carbon fiber composite material component, improving the temperature uniformity of the component ineach direction in the curing process and improving the curing quality of large-sized components.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

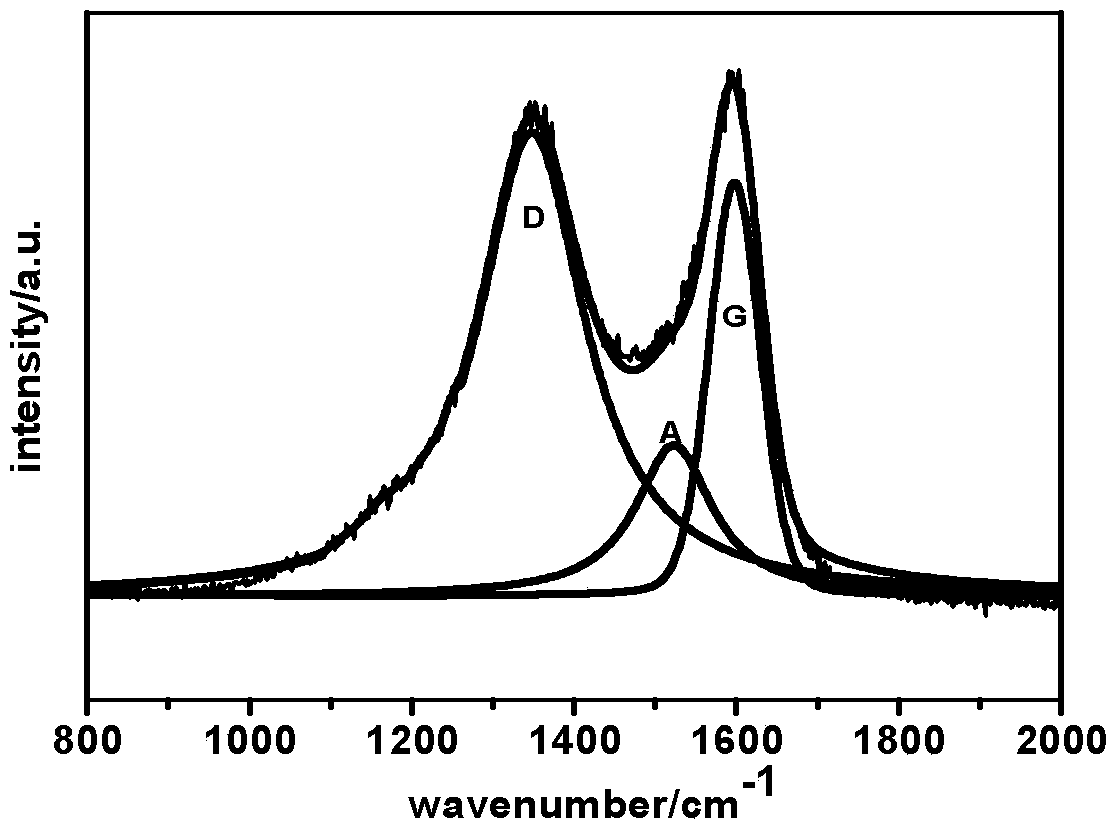

Method of grafting hexamine on carbon fiber surface in supercritical methanol

InactiveCN104480707AImprove reaction efficiencyIncrease surface areaCarbon fibresCarbon fibersModified carbon

The invention discloses a method of grafting hexamine on a carbon fiber surface in supercritical methanol and relates to a carbon fiber surface modification method. The method aims at solving the problems that few groups are grafted onto a carbon fiber and distributed on the carbon fiber nonuniformly, and the bonding strength of the modified carbon fiber with resin is low for the existing carbon fiber surface modification method. The method of grafting hexamine on the carbon fiber surface in supercritical methanol comprises the steps: I, cleaning, II, oxidizing, III, acylating chlorination, IV, alcoholysis, and V, grafting of hexamine in supercritical methanol to form the carbon fiber with hexamine grafted on the surface. Interfacial shear strength of the carbon fiber with hexamine grafted on the surface is improved to 106.1MPa from 64.9MPa of a precursor fiber by 63.5%.The method of grafting hexamine on the carbon fiber surface in supercritical methanol can be obtained.

Owner:HARBIN INST OF TECH

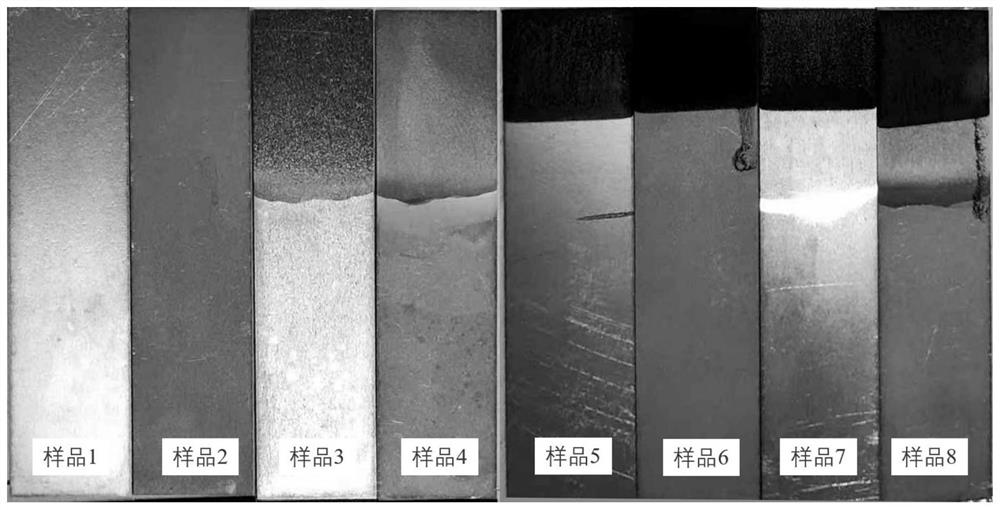

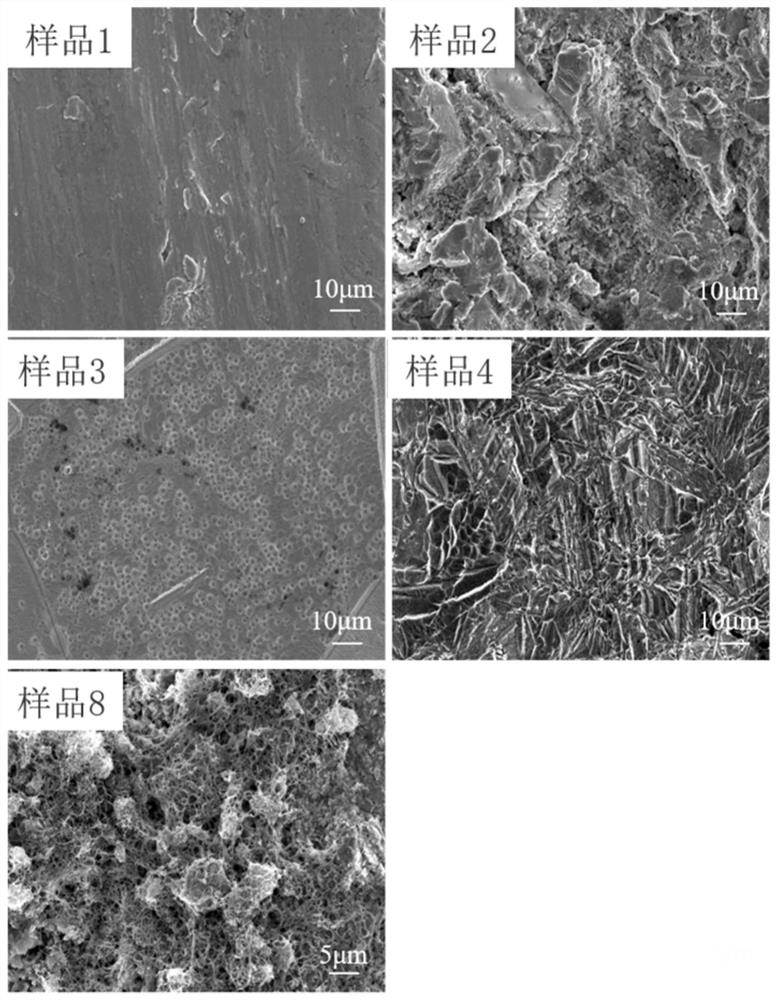

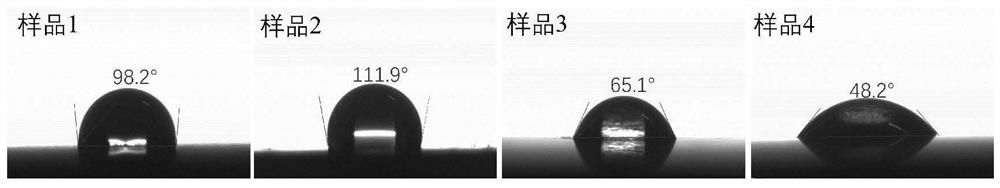

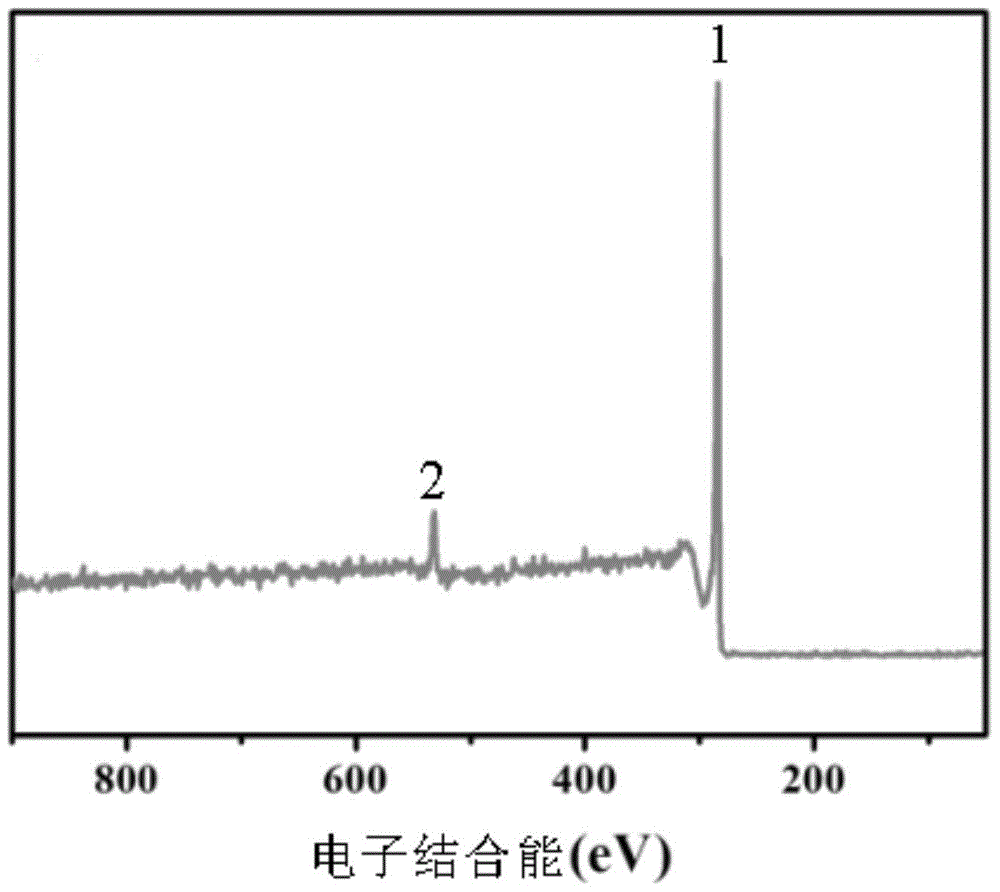

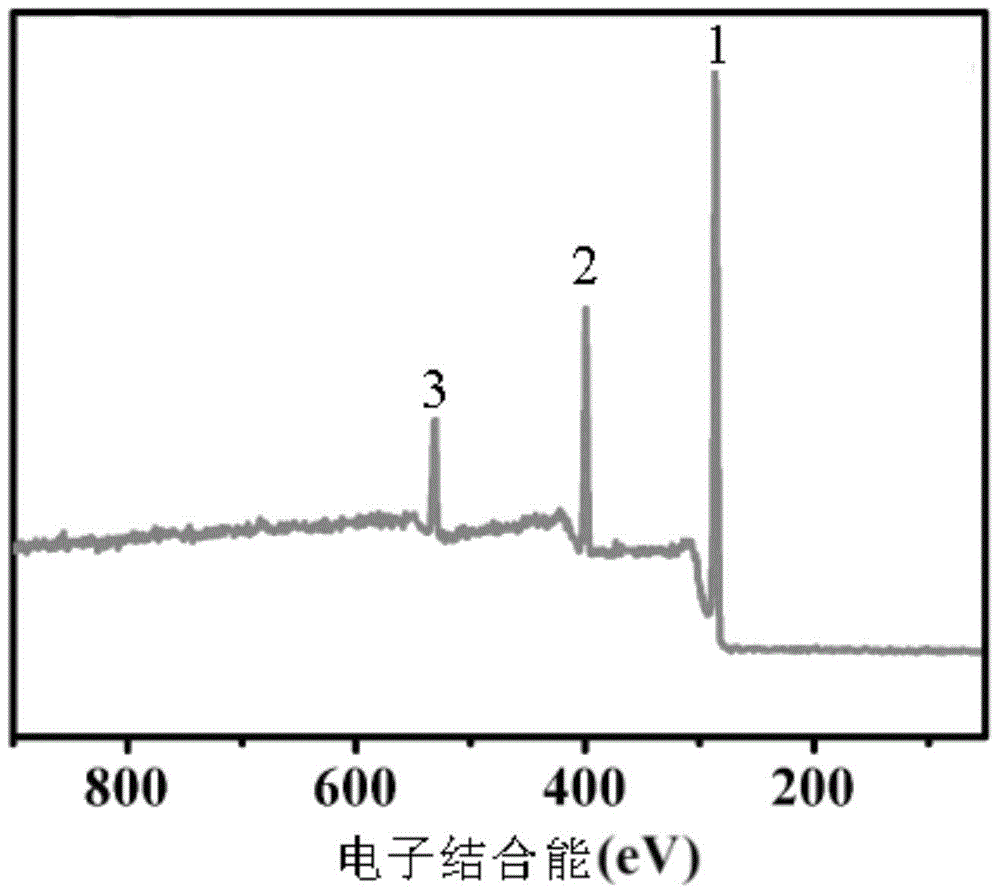

Preparation method of carbon nanotube reinforced fiber metal laminate

ActiveCN113373493AGood compatibilityImprove interface performanceElectrophoretic coatingsElectrophoresesAlcohol

The invention discloses a preparation method of a carbon nanotube reinforced fiber metal laminate, and belongs to the field of composite material preparation. According to the method, carbon nanotubes are deposited on titanium plates subjected to different surface treatment through electrophoretic deposition, absolute ethyl alcohol is adopted as a dispersion solution of the carbon nanotubes, and the stability of suspension liquid is improved by oxidizing the carbon nanotubes through mixed acid. According to the preparation method, the compatibility of the surfaces of the titanium plates and resin is improved, and the carbon nanotubes can be well embedded into the resin and the grooves in the surfaces of the titanium plates, so that the interface performance of the fiber metal laminate is improved, the preparation process is simple, and the time used in the deposition process is short. The method is not limited to stable titanium alloy surfaces, and can also be used for bonding metal with complex structures and resin.

Owner:NANJING UNIV OF SCI & TECH

A method for adsorbing polyethyleneimine on carbon fiber surface in supercritical methanol

InactiveCN104562707BIncrease N contentIncreased mechanical engagementCarbon fibresFiberCarbon fibers

The invention discloses a method for adsorbing polymine on a carbon fiber surface in supercritical methanol, relates to a carbon fiber surface adsorption method, and aims to solve problems that an existing carbon fiber modifying method causes severe strength loss to the carbon fiber, is complex to operate, not suitable for being performed, low in bonding strength with resin. The method comprises the following steps: I, cleaning; II, oxidizing; III, adsorbing polymine in supercritical methanol to obtain carbon fiber, surface of which is adsorbed with the polymine, thereby completing grafting hexamine on the carbon fiber surface in the supercritical methanol. According to the method, interface shearing strength of the carbon fiber, surface of which is adsorbed with the polymine, is increased to 101.8 MPa-103 MPa from unmodified 64.9 MPa, and increased by 56.9%-59.7%; impact strength is increased to 84.39 kJ / m<2>-86.7 kJ / m<2> from 55.77 kJ / m<2>. The invention discloses a method for grafting hexamine on the carbon fiber surface.

Owner:HARBIN INST OF TECH

Molding tools and method with grip-enhancing structure

ActiveUS10479002B2Reduce and prevent pull-backReduce and prevent and retractionDomestic articlesPressesRough surfaceMaterials science

A molding apparatus includes two mold tools that define and bound a mold cavity therebetween, for three-dimensionally press-molding a trim component. To minimize or avoid shrinkage or pull-back recession of the edge of the trim component during the molding process, at least one of the mold tools, on its molding surface bounding an end portion of the mold cavity, includes at least one grip-enhancing structure that provides increased grip on an edge portion of the trim component. The grip-enhancing structure may be or include a rough surface, a geometric configured surface, a geometric gripping edge, a surface coating, or mechanical engagement members. The grip-enhancing structure provides increased grip on the edge portion of the trim component by narrowing the mold cavity space, by increasing the surface friction or adhesion, and / or by mechanically engaging the material of the trim component. Thereby, the edge of the trim component is held in place while the three-dimensional molding proceeds and until the molded contour of the component is fixed.

Owner:SAM SUNGAN RALPH PAGENDARM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com