Composite internal-curing shrinkage-reducing anti-cracking agent for concrete and production method of composite internal-curing shrinkage-reducing anti-cracking agent

A production method and a composite technology, which are applied in the field of concrete additives, can solve the problems of not completely solving concrete cracks, difficulty, and inability to obtain additive effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

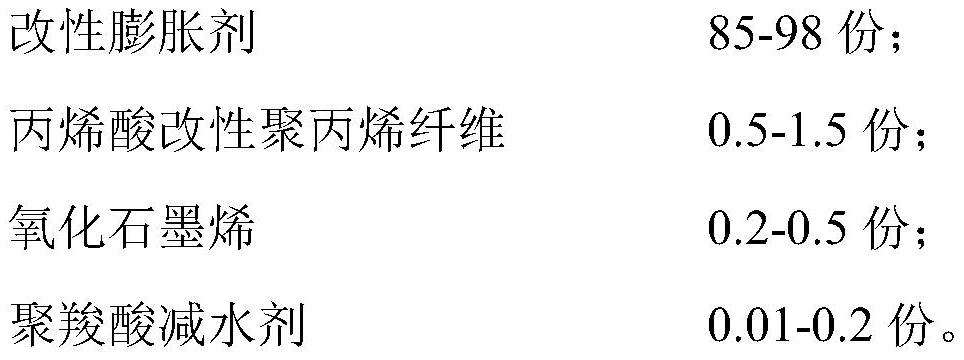

[0048] Example 1: 92 kg of modified expansion agent; 1.5 kg of acrylic acid-lignosulfonate modified polypropylene fiber; 0.4 kg of graphene oxide; 0.08 parts of polycarboxylate water reducer.

Embodiment 2

[0049] Example 2: 85 kg of modified expansion agent; 1.0 kg of acrylic acid-lignosulfonate modified polypropylene fiber; 0.2 kg of graphene oxide; 0.2 parts of polycarboxylate water reducer.

Embodiment 3

[0050] Example 3: 98 kg of modified expansion agent; 0.5 kg of acrylic acid-lignosulfonate modified polypropylene fiber; 0.5 kg of graphene oxide; 0.02 parts of polycarboxylate water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com