A kind of emulsion type carbon fiber sizing agent containing nano material and its preparation method

An emulsion-type carbon fiber and nano-material technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems that organic solvents hinder the practical application of sizing agents, cannot give full play to the reinforcing effect of carbon fibers, and are prone to agglomeration and precipitation, etc., to achieve Excellent dispersibility and stability, improve surface free energy, and improve surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

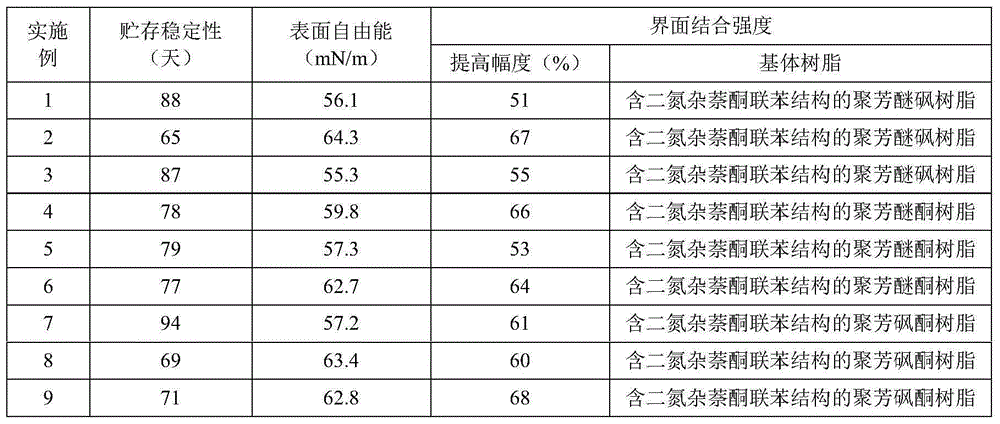

Examples

Embodiment 1

[0036] Weigh 0.1 g of polyarylethersulfone resin containing phthalazinone biphenyl structure in the main slurry, and nano-SiO with an average diameter of 50 nm. 2 0.01g, AEO-7 emulsifier 0.05g, NTX101 dispersant 0.05g, organic solvent dimethyl sulfoxide 0.15g and deionized water 99.64g. Add nanomaterials and dispersants into deionized water together, control the system temperature at 40°C, and ultrasonically disperse for 10 minutes to obtain a stable dispersion of nanomaterials in deionized water; then, dissolve the main slurry in an organic solvent, and then add Emulsifier, control the temperature of the main slurry solution to 50°C, and pass through the emulsifier at a speed of 12,000rpm, and stir at a high speed for 5 minutes; then, the stable dispersion of nanomaterials in deionized water is kept at a constant speed of the emulsifier Under conditions, add it into the main slurry solution, and continue to stir at a high speed for 60 minutes to obtain an emulsion-type carbon...

Embodiment 2

[0038] Weigh 2 g of polyarylethersulfone resin containing phthalazinone biphenyl structure in the main slurry, and nano-SiO with an average diameter of 10 nm. 2 1g, 2g of EL-40 emulsifier, 0.1g of NTX101 dispersant, 8g of organic solvent dimethyl sulfoxide and 86.9g of deionized water. Add nanomaterials and dispersants into deionized water together, control the system temperature at 50°C, and ultrasonically disperse for 15 minutes to prepare a stable dispersion of nanomaterials in deionized water; then, dissolve the main slurry in an organic solvent, and then add Emulsifier, control the temperature of the main slurry solution to 55°C, and pass through the emulsifier at a speed of 16000rpm, and stir at a high speed for 6 minutes; then, the stable dispersion of nanomaterials in deionized water is kept at a constant speed of the emulsifier Under certain conditions, add it to the main slurry solution, and continue to stir at a high speed for 70 minutes to obtain an emulsion-type c...

Embodiment 3

[0040] Weigh 2 g of polyaryl ether sulfone resin containing phthalazinone biphenyl structure in the main slurry, and nano-SiO with an average diameter of 30 nm. 2 0.01g, OP-10 emulsifier 1g, NTX105 dispersant 0.05g, organic solvent dimethyl sulfoxide 8g and deionized water 88.94g. Add nanomaterials and dispersants into deionized water together, control the system temperature at 60°C, and ultrasonically disperse for 20 minutes to prepare a stable dispersion of nanomaterials in deionized water; then, dissolve the main slurry in an organic solvent, and then add Emulsifier, control the temperature of the main slurry solution to 60°C, and pass through the emulsifier at a speed of 22,000rpm, and stir at a high speed for 7 minutes; then, the stable dispersion of nanomaterials in deionized water is kept at a constant speed of the emulsifier Under certain conditions, add it to the main slurry solution, and continue to stir at a high speed for 80 minutes to obtain an emulsion carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com