Surface control technology for PB cold-bonded board

A surface control and cold pasting technology, which is applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., can solve the problems of high process parameter requirements, low bonding strength, glue opening, etc., and achieve low process parameter requirements, enhanced viscosity, The effect of increasing the adhesive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

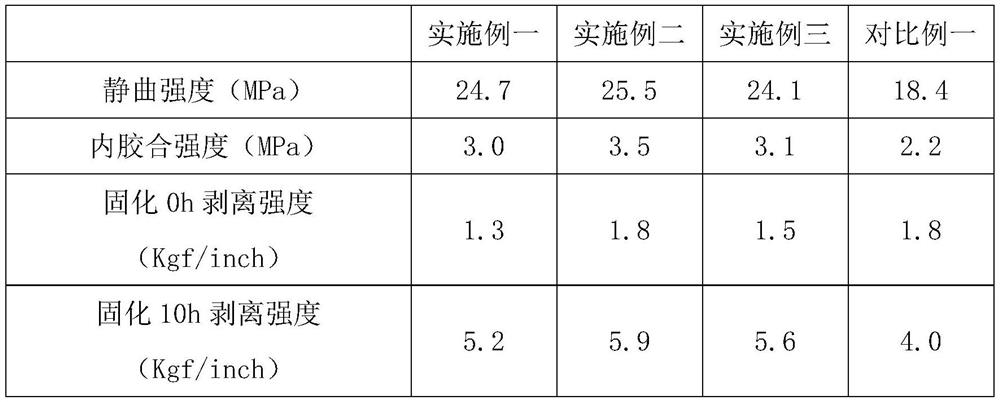

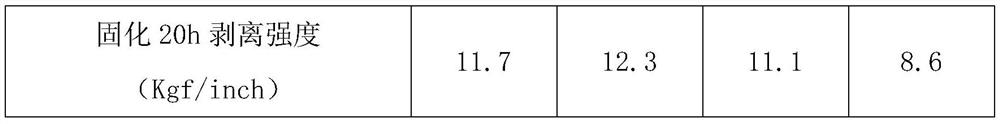

Embodiment 1

[0027] The present invention proposes a process for controlling the surface of PB cold laminated boards. The PB cold laminated boards are connected from composite veneer-plain board-composite veneer through adhesive I in the order from top to bottom, and finally cold-pressed and formed. The thickness of the adhesive I between the composite veneer and the plain plate is 0.1mm, and the bonding area is 100%; the adhesive I is composed of epichlorohydrin and polyvinyl alcohol with a mass ratio of 18:7:3:1. , methyl silicone oil and polyether amine mixed;

[0028] The surface control process of the PB cold paste board specifically includes the following steps:

[0029] S1, preparation of composite veneer:

[0030] S11. In parts by weight, weigh 20 parts of polyvinyl acetate, 25 parts of ethyl acetate, 1 part of magnesium oxide, 6 parts of 5mol / L ammonium chloride solution, and 3 parts of precipitated barium sulfate, and set aside;

[0031] S12. First blend polyvinyl acetate and e...

Embodiment 2

[0039] The present invention proposes a process for controlling the surface of PB cold laminated boards. The PB cold laminated boards are connected from composite veneer-plain board-composite veneer through adhesive I in the order from top to bottom, and finally cold-pressed and formed. The thickness of the adhesive I between the composite veneer and the plain plate is 0.4mm, and the bonding area is 100%; the adhesive I is composed of epichlorohydrin and polyvinyl alcohol in a mass ratio of 21:9:4:1. , methyl silicone oil and polyether amine mixed;

[0040] The surface control process of the PB cold paste board specifically includes the following steps:

[0041] S1, preparation of composite veneer:

[0042] S11, in parts by weight, weigh 30 parts of polyvinyl acetate, 35 parts of ethyl acetate, 2 parts of magnesium oxide, 8 parts of 5mol / L ammonium chloride solution, 4 parts of precipitated barium sulfate, and set aside;

[0043] S12. First blend polyvinyl acetate and ethyl ...

Embodiment 3

[0051] The present invention proposes a process for controlling the surface of PB cold laminated boards. The PB cold laminated boards are connected from composite veneer-plain board-composite veneer through adhesive I in the order from top to bottom, and finally cold-pressed and formed. The thickness of the adhesive I between the composite veneer and the plain plate is 0.7mm, and the bonding area is 100%; the adhesive I is composed of epichlorohydrin and polyvinyl alcohol with a mass ratio of 24:11:5:1. , methyl silicone oil and polyether amine mixed;

[0052] The surface control process of the PB cold paste board specifically includes the following steps:

[0053] S1, preparation of composite veneer:

[0054] S11. In parts by weight, weigh 40 parts of polyvinyl acetate, 45 parts of ethyl acetate, 3 parts of magnesium oxide, 10 parts of 5mol / L ammonium chloride solution, and 5 parts of precipitated barium sulfate, and set aside;

[0055] S12. First, blend polyvinyl acetate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com