Modified silicon carbide sizing agent for improving wave-absorbing property of carbon fiber and preparation method of modified silicon carbide sizing agent

A wave-absorbing performance, silicon carbide technology, applied in the direction of carbon fiber, fiber processing, textile/flexible product manufacturing, etc., can solve the problems of reducing the overall mechanical properties of carbon fiber composite materials, unfavorable interface bonding of resin composite materials, and high brittleness of carbon fiber, etc., to achieve Good interfacial compatibility, excellent wave-absorbing performance, and the effect of enhancing the resistance to heat and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

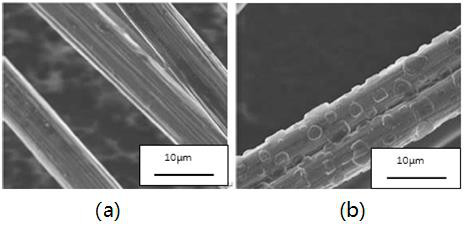

Image

Examples

Embodiment 1

[0025] A modified sizing agent for improving the wave-absorbing properties of carbon fibers, which is composed of the following components:

[0026] Modified silicon carbide, 3.6wt%;

[0027] Emulsifier, 12.05wt%;

[0028] Alcohol, 64.11wt%;

[0029] Thermosetting resin, 20.24 wt%.

[0030] The preparation method of the modified silicon carbide sizing agent comprises the following steps:

[0031] Step 1, preparing an emulsifier: mixing 40 wt% sorbitan monostearate, 40 wt% polyoxyethylene sorbitan monooleate, and 20 wt% sodium dodecylbenzenesulfonate;

[0032] Step 2, preparing silicon carbide modifier: adding 62.5wt% of silane coupling agent into a mixed solution consisting of 28.1wt% absolute ethanol and 9.4wt% hydrolysis agent to obtain silicon carbide modifier; the silane coupling agent The coupling agent is a commercially available product, and the specific model is silane coupling agent M611.

[0033] Step 3: Preparation of modified silicon carbide: The silicon carbi...

Embodiment 2

[0037] A modified sizing agent for improving the wave-absorbing properties of carbon fibers, which is composed of the following components:

[0038] Modified silicon carbide, 10wt%;

[0039] Emulsifier, 11.25wt%;

[0040] Alcohol, 59.85wt%;

[0041] Thermosetting resin, 18.9 wt%.

[0042] The preparation method of the modified silicon carbide sizing agent comprises the following steps:

[0043] Step 1, preparing an emulsifier: mixing 40 wt% sorbitan monostearate, 40 wt% polyoxyethylene sorbitan monooleate, and 20 wt% sodium dodecylbenzenesulfonate;

[0044] Step 2, preparing silicon carbide modifier: adding 62.5wt% of silane coupling agent into a mixed solution consisting of 28.1wt% absolute ethanol and 9.4wt% hydrolysis agent to obtain silicon carbide modifier; the silane coupling agent The coupling agent is a commercially available product, and the specific model is silane coupling agent M611.

[0045] Step 3: Preparation of modified silicon carbide: The silicon carbide...

Embodiment 3

[0049] A modified sizing agent for improving the wave-absorbing properties of carbon fibers, which is composed of the following components:

[0050] Modified silicon carbide, 3.6wt%;

[0051] Emulsifier, 12.05wt%;

[0052] Alcohol, 64.11wt%;

[0053] Thermosetting resin, 20.24 wt%.

[0054] The preparation method of the modified silicon carbide sizing agent comprises the following steps:

[0055] Step 1. Prepare emulsifier: mix 40 wt% sorbitan monostearate, 40 wt% polyoxyethylene sorbitan monooleate, and 20 wt% sodium dodecylbenzenesulfonate;

[0056] Step 2, preparing silicon carbide modifier: adding 20wt% silane coupling agent into a mixed solution consisting of 70wt% absolute ethanol and 10wt% hydrolyzing agent to obtain a silicon carbide modifier; the silane coupling agent It is a commercially available product, and the specific model is silane coupling agent M611.

[0057] Step 3: Preparation of modified silicon carbide: The silicon carbide and the silicon carbide mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com