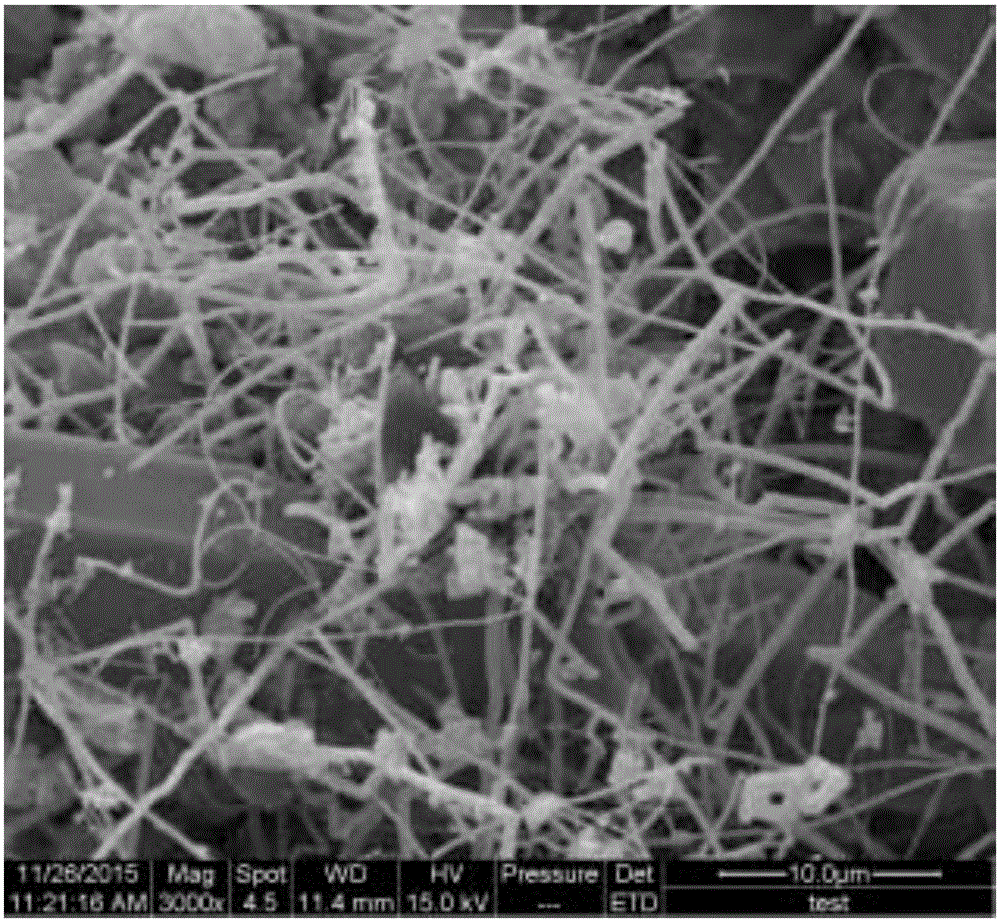

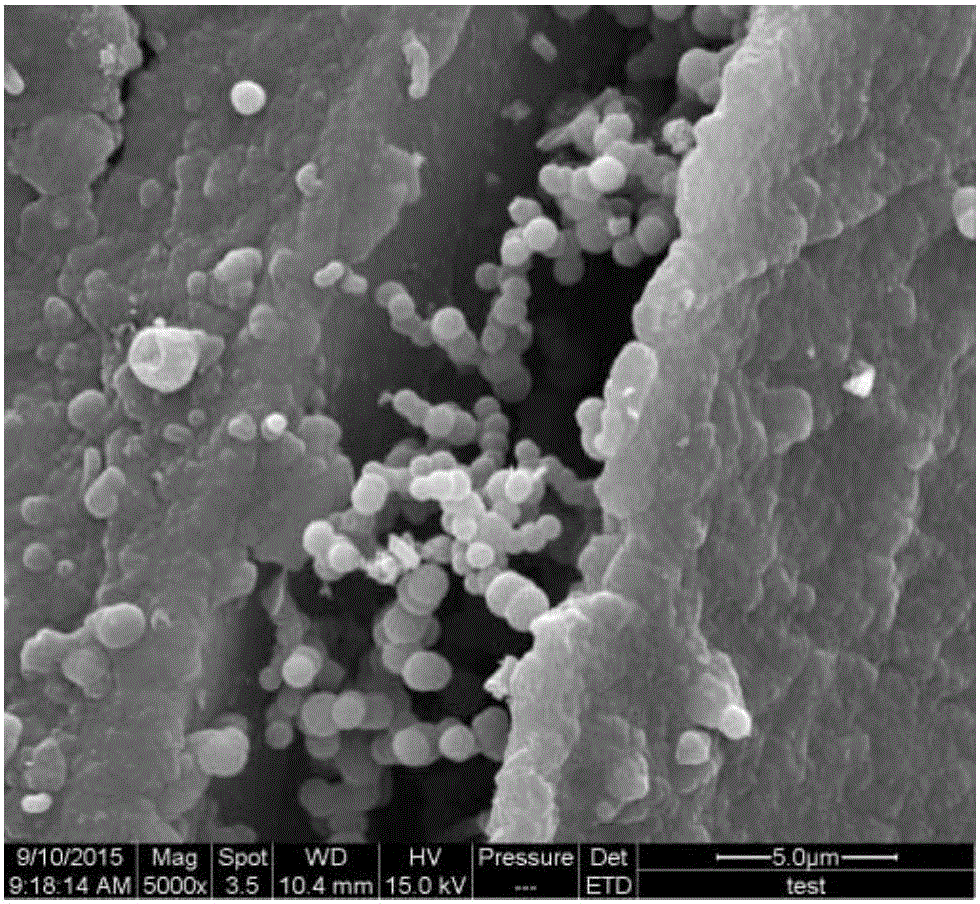

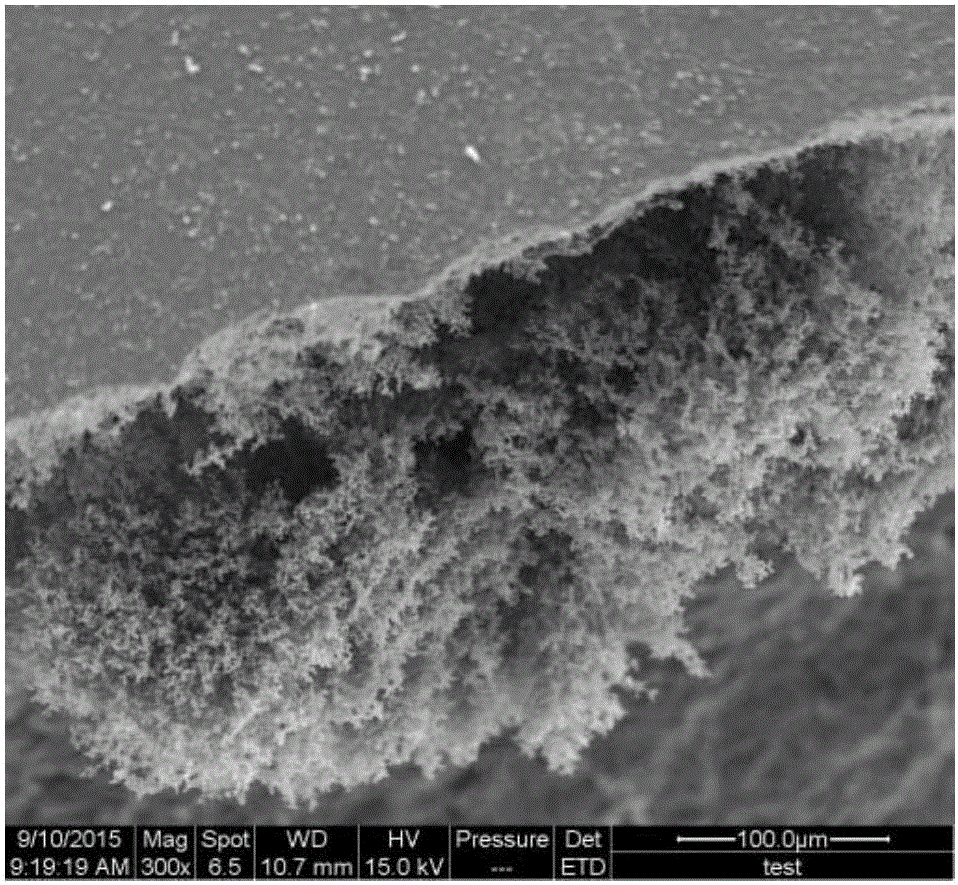

Preparation method of ceramic material capable of generating carbon nanowires in situ

A carbon nanowire and in-situ generation technology, which is applied in the field of ceramic material preparation, can solve the problems of cumbersome carbon nanowire preparation process and high condition requirements, and achieve the effect of simple and easy to obtain raw materials, simple principle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] Specific Embodiment 1: The preparation method of the ceramic material for in-situ generation of carbon nanowires in this embodiment is carried out according to the following steps:

[0038] 1. Resin curing: Heat polysilazane or silicon aluminum carbon nitrogen precursor resin in a tube furnace filled with nitrogen at a heating rate of 1°C-5°C to 140-160°C for 4 hours, and then heat at the same heating rate To 340 ~ 360 ℃ for 20 hours to cure cross-linking;

[0039] 2. Ball milling: place the resin cross-linked in step 1 in a ball milling tank for ball milling, then pass through a 60-mesh standard sieve to obtain a powder;

[0040] 3. Pre-press molding: Pre-press the powder into a block with a diameter of Ф12.5-20mm and a thickness of 4-7mm at room temperature, with a pressure of 10-18MPa and a pre-press time of 5-8min;

[0041] 4. Pyrolysis: heating and cracking in a tube furnace under the protection of nitrogen to obtain samples;

[0042] 5. Cooling: Cool the sample ...

specific Embodiment approach 2

[0044] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the preparation method of the silicon aluminum carbon nitrogen precursor resin described in step one is:

[0045] Dissolve polysilazane in xylene, weigh aluminum isopropoxide according to the mass ratio of polysilazane to aluminum isopropoxide 1: (0.05-0.20), dissolve in xylene, and ultrasonically vibrate for 15 minutes; The xylene solution of polysilazane and aluminum isopropoxide was placed in a glove box protected by an inert gas, and the temperature was raised to 120° C. to react for 24 hours to obtain a silicon aluminum carbon nitrogen precursor resin. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the ball milling in step 2 is placed in a high-energy ball mill for 30-40 minutes or placed in a planetary ball mill for 24-26 hours. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com