Preparation method of carbon nanotube reinforced fiber metal laminate

A carbon nanotube and metal laminate technology, applied in coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of complex chemical vapor deposition operation, high equipment requirements, damage to the material body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Step 1: Take 25ml of nitric acid and 75ml of sulfuric acid respectively, pour them into a beaker and mix them evenly, add 2.0018g of carbon nanotubes, place them at 80°C for 2 hours, wash and filter with a large amount of deionized water and place them in a freeze dryer lyophilized, labeled as oxidized carbon nanotubes;

[0049] Step 2, measure 100 mL of absolute ethanol, and weigh 1.0002 g of carbon nanotubes to configure a 1 mg / mL carbon nanotube suspension. At the same time, in order to improve the conductivity of the solution, add 0.0025 g of Mg(NO 3 ) 2 ·6H 2 O, placed under ultrasonic dispersion for 30min;

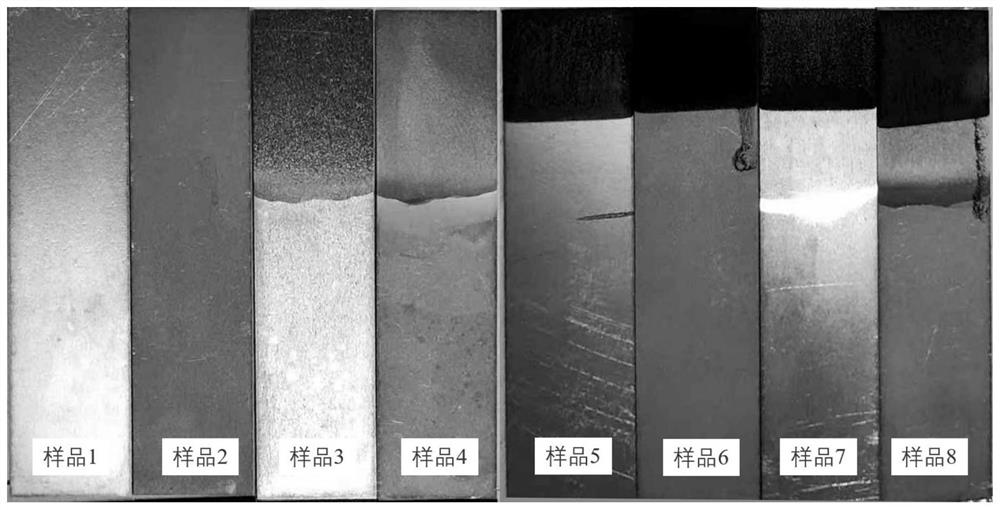

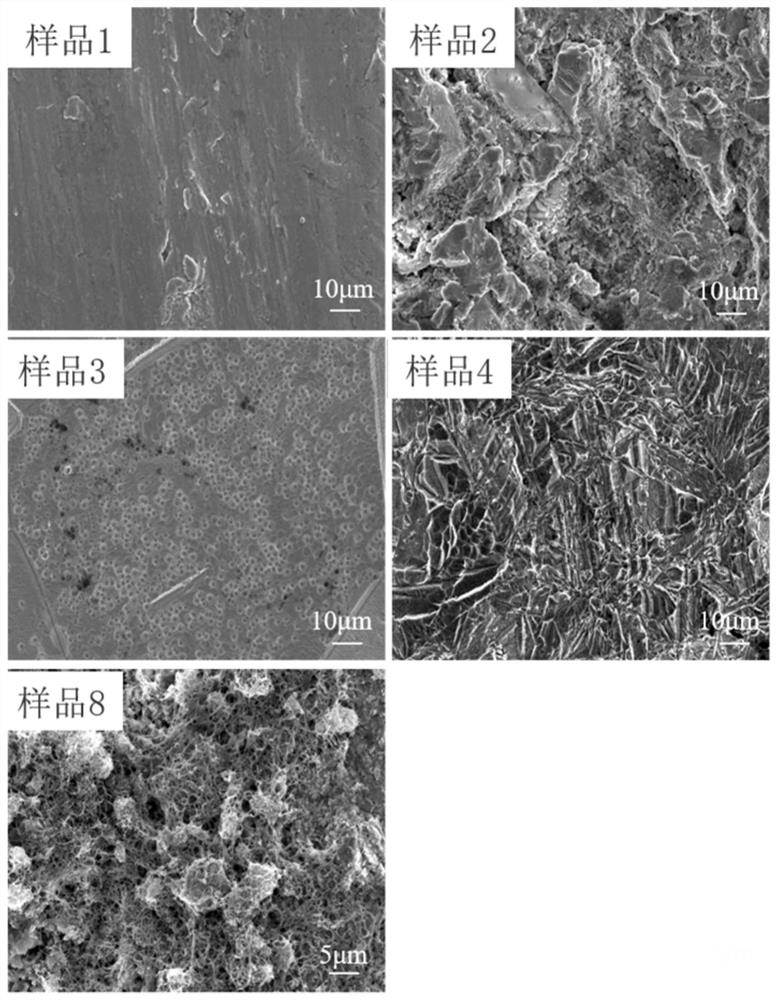

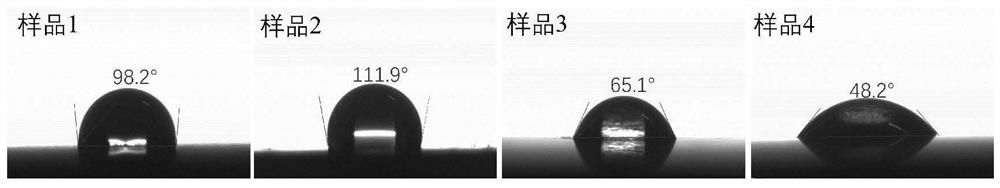

[0050] In step 3, TA2 that has been sandblasted and NaTESi anodized in turn is used as the cathode, and another TA2 of the same size is used as the anode. The parameters of the NaTESi anodization process are as follows: the pole spacing is 1.5 mm, the voltage is 10 V, and the time is For 10 minutes, the NaTESi electrolyte components are sodium hydroxide 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com