A comprehensive electric loss curing method for carbon fiber reinforced resin matrix composites

A technology for reinforcing resin matrix and composite materials, which is applied in the field of carbon fiber reinforced resin matrix composite material manufacturing, can solve problems such as fiber etching, and achieve the effects of fast heating rate, low energy consumption, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

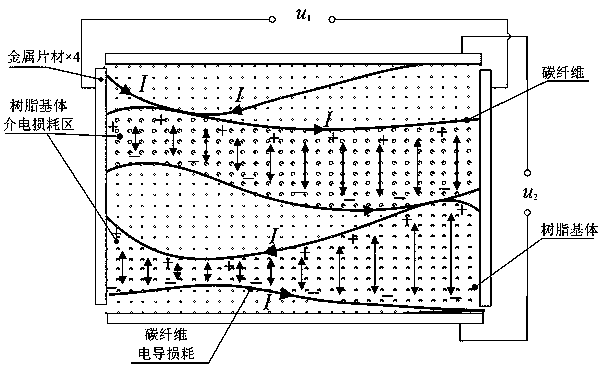

Method used

Image

Examples

Embodiment approach

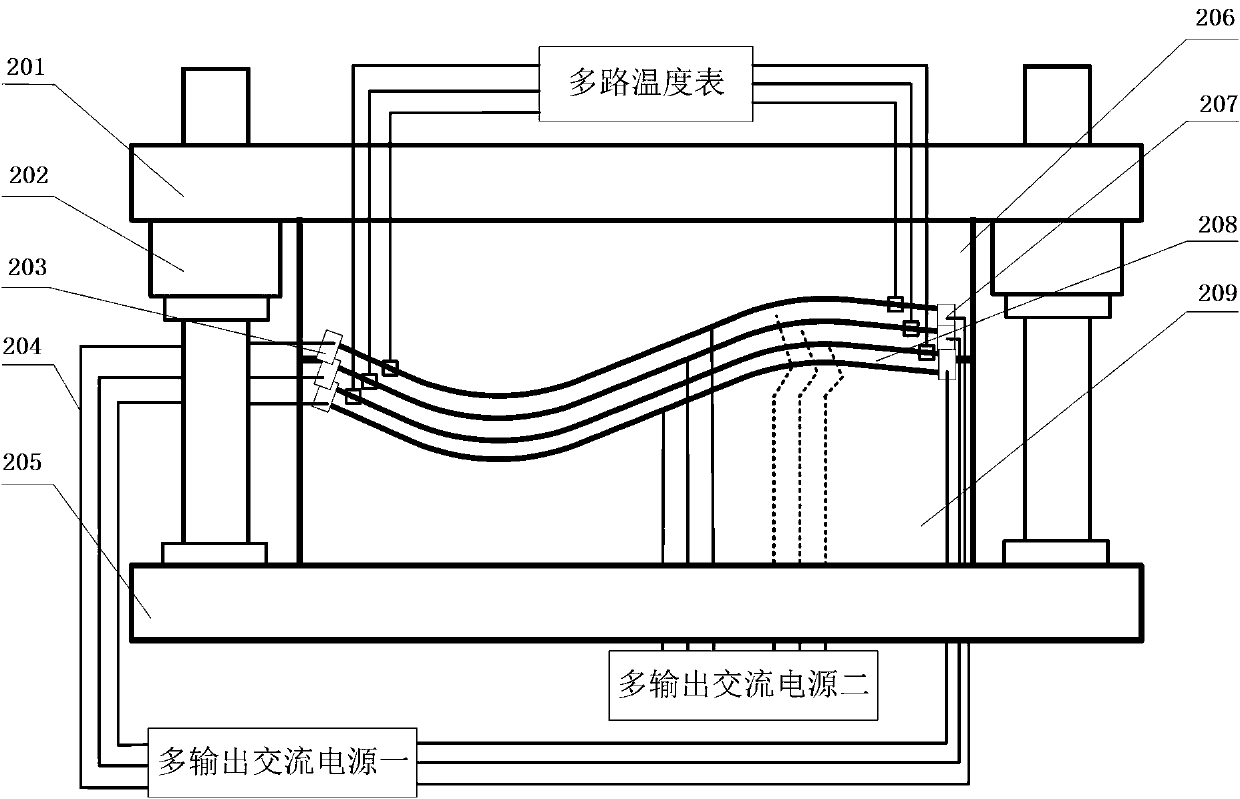

[0060] In this embodiment, the heat loss method of the present invention is used to solidify large-scale aerospace hyperboloid components in a high-pressure tank. The aviation hyperboloid large-scale component is made of unidirectional carbon fiber reinforced bismaleic polyimide resin-based composite material prepreg T700 / QY9611, and the laying method is as follows: There are 42 layers of symmetrical layup, the thickness of the single-layer prepreg is 0.25mm, and the projected size of the mold surface is 4500mm×2800mm. Apply a pair of metal sheet electrodes to the edge of the material, and lead out from the cable 3, the cable 3 is hermetically sealed through the flange 2 on the wall of the pressure tank, and lead out of the tank to connect to a multi-output AC power supply. The specific implementation method is as follows:

[0061] Step 1: Prepare for laying; call out the mold 8 from the mold library and place it in the designated layer area; use the method of mechanical rem...

Embodiment 2

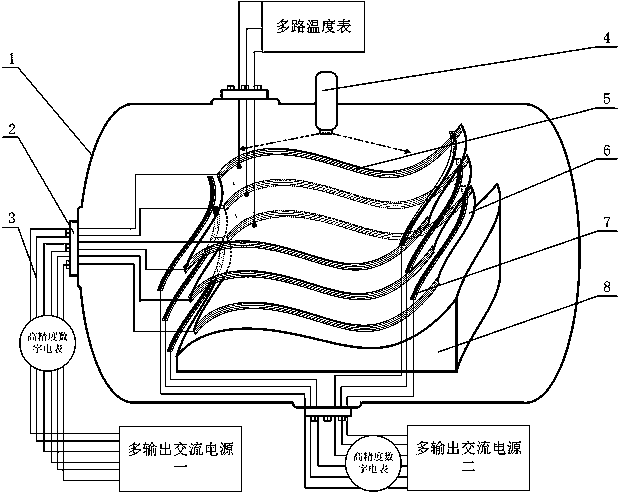

[0070] In this embodiment, with the assistance of a hydraulic press, the carbon fiber-reinforced resin-based composite material component is solidified by comprehensive electric loss. In order to reduce manufacturing costs, hydraulic presses can be used for some components with relatively simple shapes and structures. Traditional compression molding uses upper and lower molds as heat sources. For parts with large thickness, the heat transfer speed is slow and the temperature gradient in the thickness direction is large. Curing quality is lower. Such as Figure 5 As shown, the component is laid up by biaxial carbon fiber reinforced epoxy resin-based prepreg KWC-225-40, and the layup method is [0° / 90°] 8 , a total of 16 layers, the projection size of the mold surface is 1300mm×800mm. Similar to Embodiment 1, a pair of metal sheet electrodes are applied to the edge of each layer of prepreg, and the whole material is placed between the upper mold 206 and the lower mold 209 clamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com