A high-conductivity dispersed copper-based high-temperature self-lubricating composite material and its preparation method

A high-temperature self-lubricating, composite material technology, used in aerospace, aviation, radar communication, high-speed railway fields, can solve the problem that copper-based composite materials are difficult to take into account high-temperature lubrication, wear resistance, electrical conductivity, limited application of friction components, and poor mechanical properties. High problems, to achieve the effect of improving lubricating performance and wear resistance, stabilizing friction characteristics, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

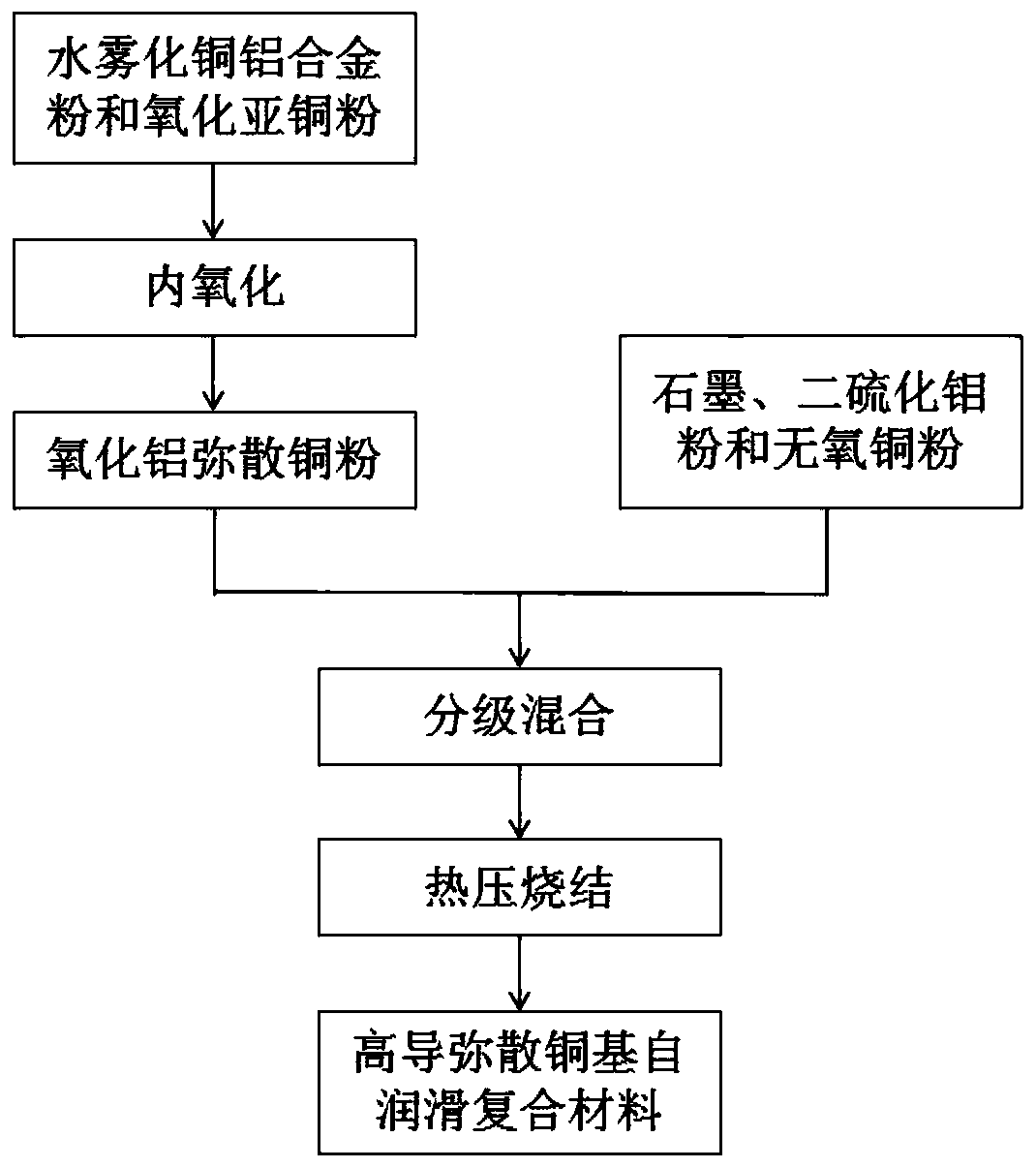

[0036] A high-conductivity dispersed copper-based high-temperature self-lubricating composite material of the present invention, its preparation method comprises the following steps (such as figure 1 shown):

[0037] (1) Internal oxidation: using water atomized CuAl alloy powder containing 0.13wt% Al as raw material, Cu 2 O is an oxidant, and Cu that is equivalent to 8.0 times the mass of Al is added to the CuAl alloy powder 2 O powder, placed in a V-type mixer and fully mixed for 4 hours, then oxidized in a vacuum tube furnace at 880°C for 2 hours to obtain alumina dispersed powder (Al 2 o 3 The mass fraction of is 0.25wt%);

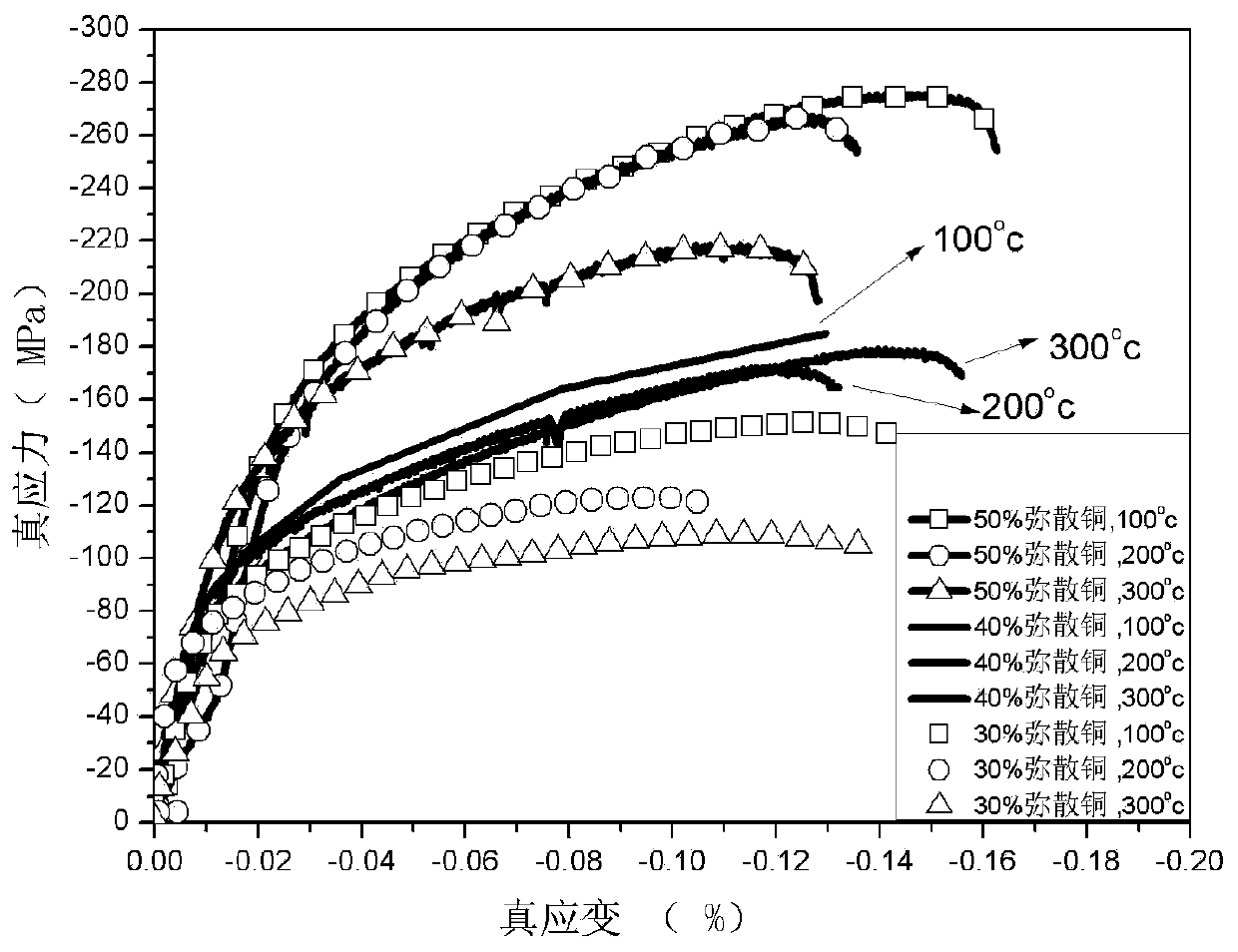

[0038] (2) Batching: take by weight 50wt% aluminum oxide dispersed copper powder (particle size-200 mesh), 2wt% molybdenum disulfide powder (particle size-300 mesh), 6wt% graphite (particle size-150 mesh) and 42wt% none Oxygen copper powder (particle size-200 mesh);

[0039] (3) Graded mixing: first put the oxygen-free copper powder and alumina dis...

Embodiment 2

[0047] A high-conductivity dispersed copper-based high-temperature self-lubricating composite material of the present invention, its preparation method comprises the following steps:

[0048] (1) Internal oxidation: using water atomized CuAl alloy powder containing 0.13wt% Al as raw material, Cu 2 O is an oxidant, and Cu that is equivalent to 8.0 times the mass of Al is added to the CuAl alloy powder 2 O powder, placed in a V-type mixer and fully mixed for 4 hours, then oxidized in a vacuum tube furnace at 880°C for 2 hours to obtain alumina dispersed powder (Al 2 o 3 The mass fraction of is 0.25wt%);

[0049] (2) Batching: take by weight 40wt% aluminum oxide dispersed copper powder (particle size-200 mesh), 2wt% molybdenum disulfide powder (particle size-300 mesh), 6wt% graphite (particle size-150 mesh) and 52wt% none Oxygen copper powder (particle size-200 mesh);

[0050] (3) Graded mixing: first put the oxygen-free copper powder and alumina dispersed copper powder into ...

Embodiment 3

[0053]A high-conductivity dispersed copper-based high-temperature self-lubricating composite material of the present invention, its preparation method comprises the following steps:

[0054] (1) Internal oxidation: using water atomized CuAl alloy powder containing 0.13wt% Al as raw material, Cu 2 O is an oxidant, and Cu that is equivalent to 8.0 times the mass of Al is added to the CuAl alloy powder 2 O powder, placed in a V-type mixer and fully mixed for 4 hours, then oxidized in a vacuum tube furnace at 880°C for 2 hours to obtain alumina dispersed powder (Al 2 o 3 The mass fraction of is 0.25wt%);

[0055] (2) Batching: take by weight 30wt% aluminum oxide dispersed copper powder (particle size-200 mesh), 2wt% molybdenum disulfide powder (particle size-300 mesh), 6wt% graphite (particle size-150 mesh) and 62wt% none Oxygen copper powder (particle size-200 mesh);

[0056] (3) Graded mixing: first put the oxygen-free copper powder and alumina dispersed copper powder into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com