Low carbon composite free-cutting steel product excellent in roughness of finished surface and method for production thereof

A technology for surface roughness and free-cutting steel, which is applied in the field of low-carbon resulfurized free-cutting steel products and its preparation, and can solve problems affecting machinability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Embodiments of the present invention are explained below. The effect of improving the machinability of steel wires by controlling the hardness of proeutectoid ferrite is first demonstrated in Examples 1 and 2.

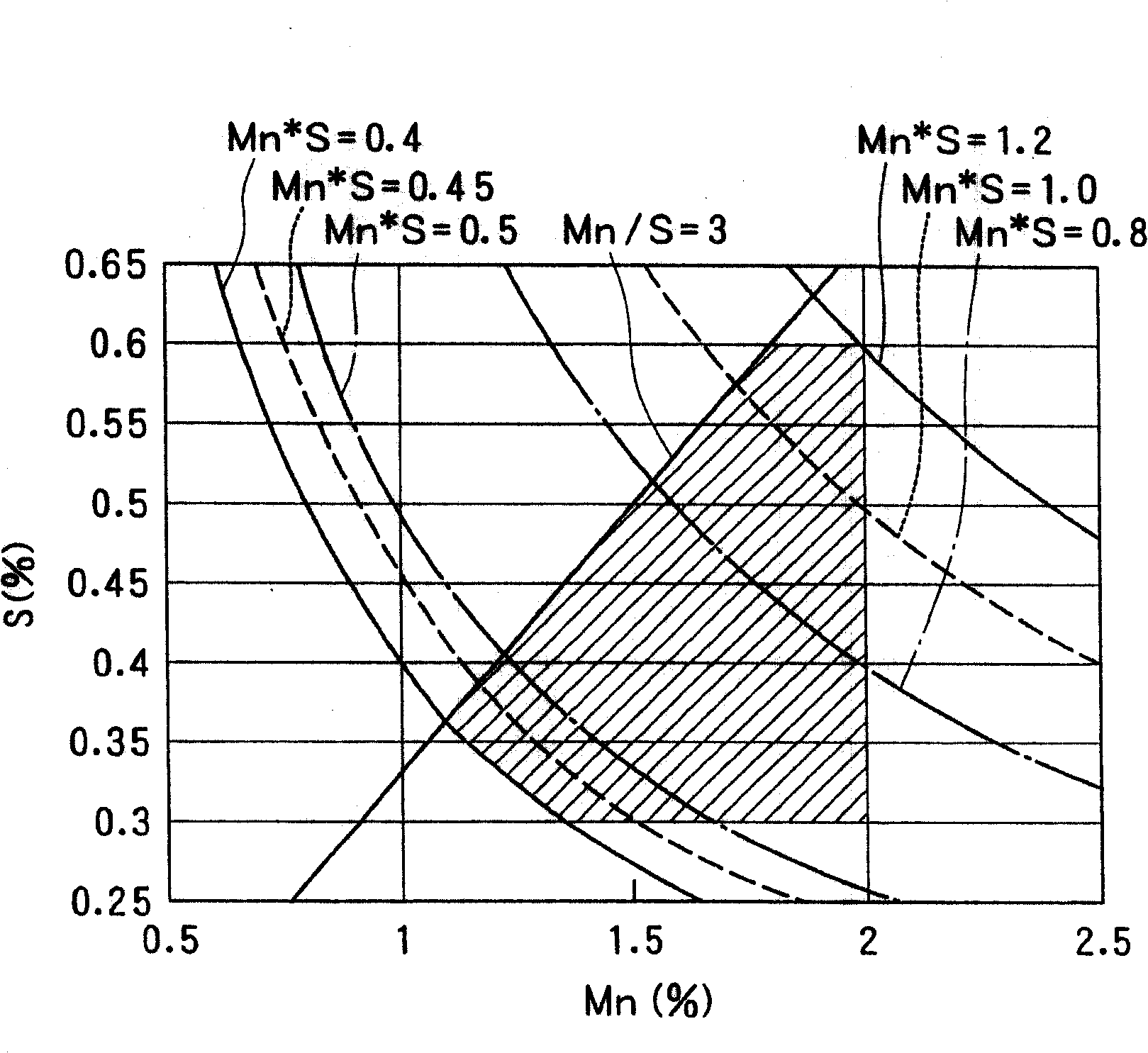

[0114] A series of steel wires with various compositions were prepared under various hot rolling conditions with actual equipment. The machinability and other properties of the steel bars were evaluated separately. Specifically, low carbon steel slabs having compositions 1 to 14 shown in Tables 1 and 2 below were prepared by melting and casting at a cooling rate of 20° C. / sec for casting solidification. Table 2 is a continuation of Table 1, and also shows the free oxygen content and Of / S in the molten steel before casting.

[0115] These billets were heated and hot-rolled under the conditions shown in Table 3 below, thereby producing steel wire rods having wire diameters shown in Table 3. The cooling rate after rolling shown in Table 3 refers to the average c...

Embodiment 2

[0136]Next, in the same manner as in Example 1, a series of low-carbon billets having compositions 15-26 shown in Tables 4 and 5 were prepared by melting. Table 5 is a continuation of Table 4 and shows the free oxygen content and the Of / S ratio in the molten steel before casting. Hot rolling was performed according to the system B in Table 3 of Example 1. The machinability and other properties of steel wires produced using actual equipment were evaluated in the same manner as in Example 1.

[0137] Table 6 shows the wire diameter of the prepared steel wire rod and the average width of MnS, the relationship between the average width of MnS and the diameter (d) of the steel product [2.8 × (log d)] and the hardness of proeutectoid ferrite ( HV). Table 6 also shows the finished surface roughness of the prepared steel wire rods as determined in the machinability test. Observing the structure of the obtained steel wire rods, it is found that they are all ferrite-pearlite structur...

Embodiment 3

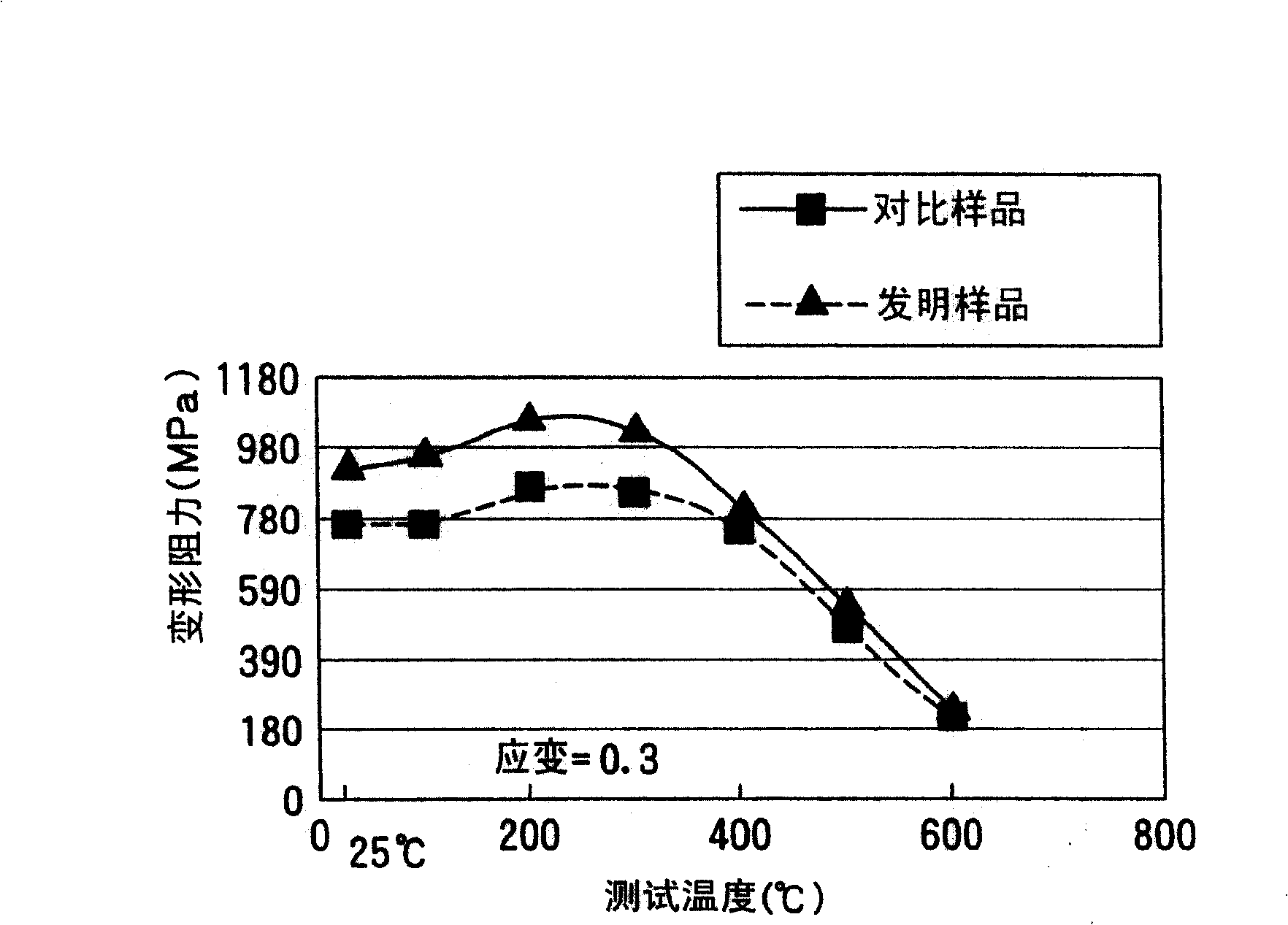

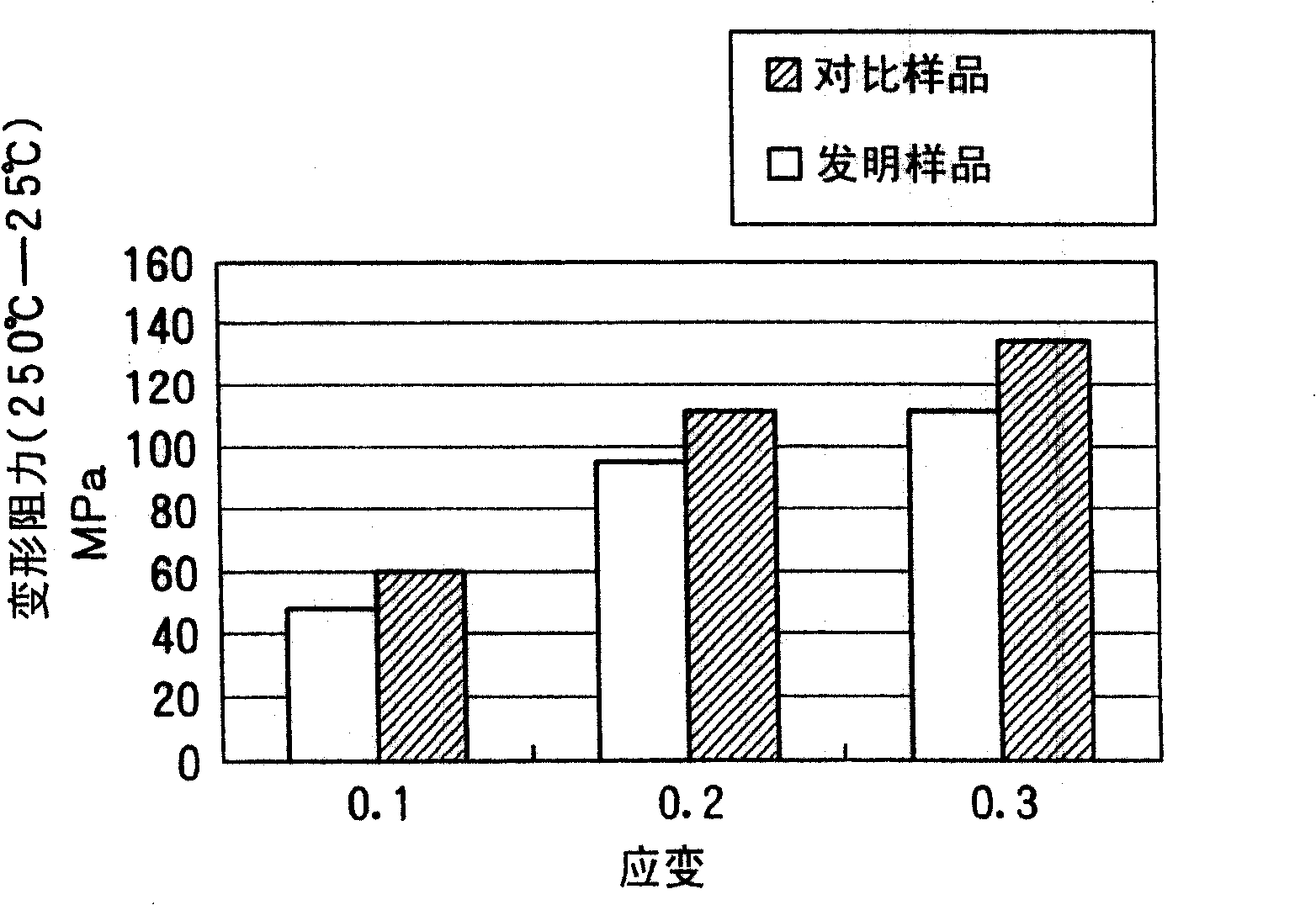

[0151] The effect of improving the machinability of steel wire by controlling the difference in deformation resistance between high temperature and room temperature in a compression test of steel products was demonstrated.

[0152] A series of low carbon billets having compositions 27-41 shown in Tables 7 and 8 were produced by melting in the same manner as in Example 1. Table 8 is a continuation of Table 7 and shows the free oxygen content and the Of / S ratio in the molten steel before casting. The low-carbon billets were hot-rolled using actual equipment at the heating temperature, finish rolling temperature, and cooling rate shown in Table 9, thereby obtaining steel wires each having a diameter of 8.0 mm. The machinability and other properties of the steel wires were evaluated separately.

[0153] The cooling rate after rolling shown in Table 9 refers to the average cooling rate in the case of placing the sample steel wire rod after finish rolling on the Stelmor conveyor, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com