A kind of low-carbon cr-ni series high-strength corrosion-resistant steel and its preparation method

A high-strength, corrosion-resistant steel technology, applied in the field of corrosion-resistant steel, can solve the problems that corrosion-resistant steel cannot meet various corrosion environments, and achieve the effects of avoiding localized corrosion, enhancing compactness, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

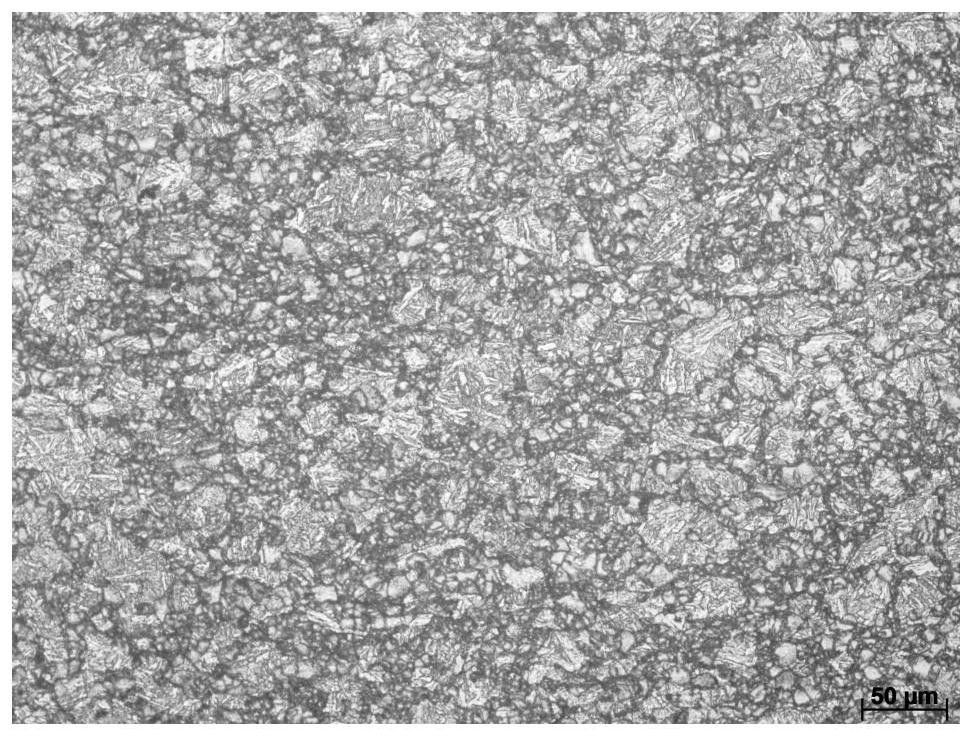

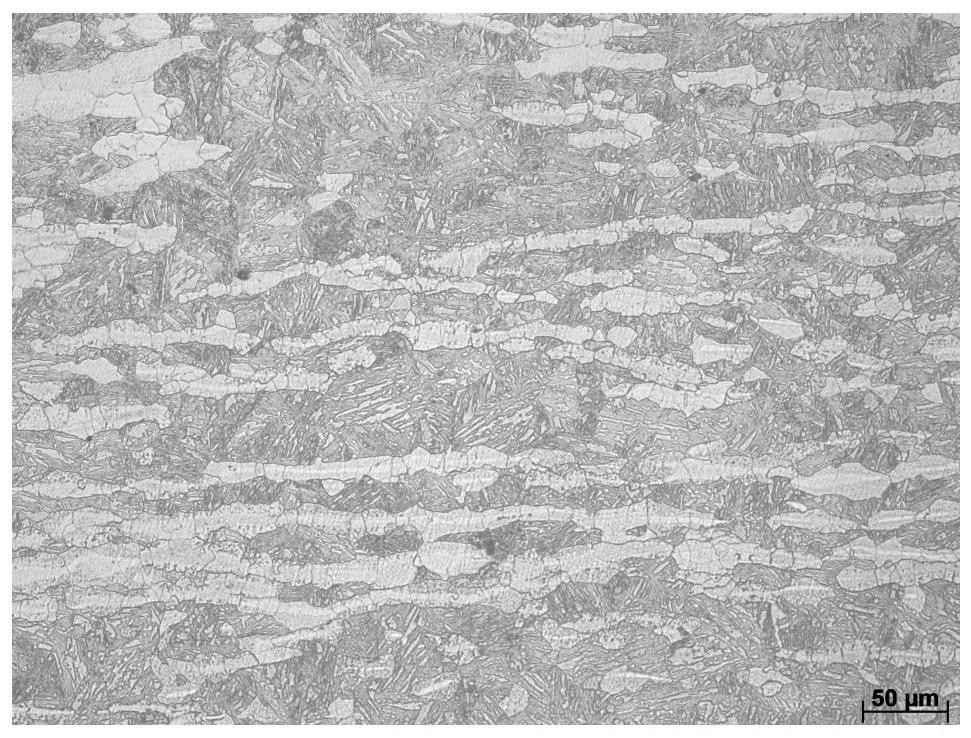

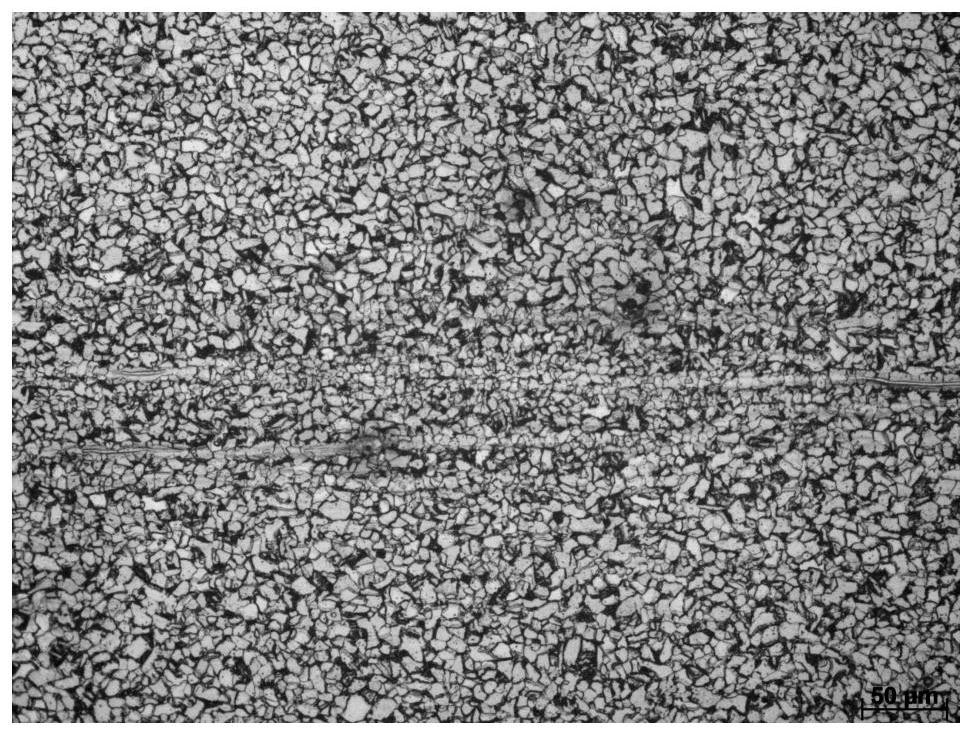

Image

Examples

preparation example Construction

[0045] A preparation method of low-carbon Cr-Ni series high-strength corrosion-resistant steel, comprising the following steps:

[0046] Step 1: smelting and casting to obtain a billet;

[0047] Step 2: Homogenize the slab, that is, heat to the austenite homogenization temperature and keep it warm;

[0048] Step 3: After heat preservation, the cast slab is removed from the furnace and then rolled directly, and the rolling process adopts two-stage rolling of recrystallized rough rolling and non-recrystallized finish rolling; wherein, the cumulative deformation of rough rolling is ≥ 65%;

[0049] Step 4: After rolling to the target thickness in step 3, laminar cooling to 550-750°C for coiling to obtain coils;

[0050] Step 5: Anneal the coil.

[0051] Specifically, in the above step 1, vacuum induction smelting is adopted according to the composition of the corrosion-resistant steel, and die casting is used to form an ingot.

[0052] Specifically, in the above step 1, convert...

Embodiment 1

[0066] Embodiment 1 and the remaining comparative examples 2-3 are vacuum smelted and continuously cast into blanks with a specification of 60mm (thick) × 70mm (wide), cut 1 block of 60mm (thick) × 70mm (wide) × 100mm, and heated to 1150 Insulate at -1250°C for 1 hour, remove the scale after coming out of the furnace, rough rolling according to 60mm-48mm-38mm-32mm-25mm-20mm (positive tolerance), finish rolling according to 16mm-13mm-11mm (positive tolerance), and the finished product is about 1m long , the final rolling temperature is not lower than 900°C, laminar cooling to 550-750°C for coiling, the hot-rolled coil is cooled to below 100°C and then reheated to 550-700°C, and kept for 0.5-5h. Since the steel of the present invention has high hardenability, a higher coiling temperature can also be used to obtain the same strength as that of a relatively low coiling temperature, and the coiling temperature window is wide. The purpose of cooling the hot-rolled coil to below 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com