A preparation method of cross-linked polyamino acid-based porous carbon material

A technology of porous carbon materials and polyamino acid salts, applied in carbon preparation/purification, nanotechnology, etc., can solve problems affecting performance, uneven doping of atoms, large pore size distribution of porous carbon materials, etc., and achieve controllable pore size And uniform, simple preparation process, the effect of environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the cross-linked polyamino acid-based porous carbon material provided by the present invention as provided in the first aspect of the present invention includes:

[0052] Step A, preparing cross-linked polyamino acid salt raw materials (including cross-linked polyamino acid salt and / or cross-linked polyamino acid salt coated with metal ions);

[0053] Step B, carbonizing the dried cross-linked polyamino acid salt raw material at high temperature, and cooling to obtain a crude activated carbon material;

[0054] Step C, cleaning and drying the crude activated carbon material to obtain a finished cross-linked polyamino acid-based activated carbon material;

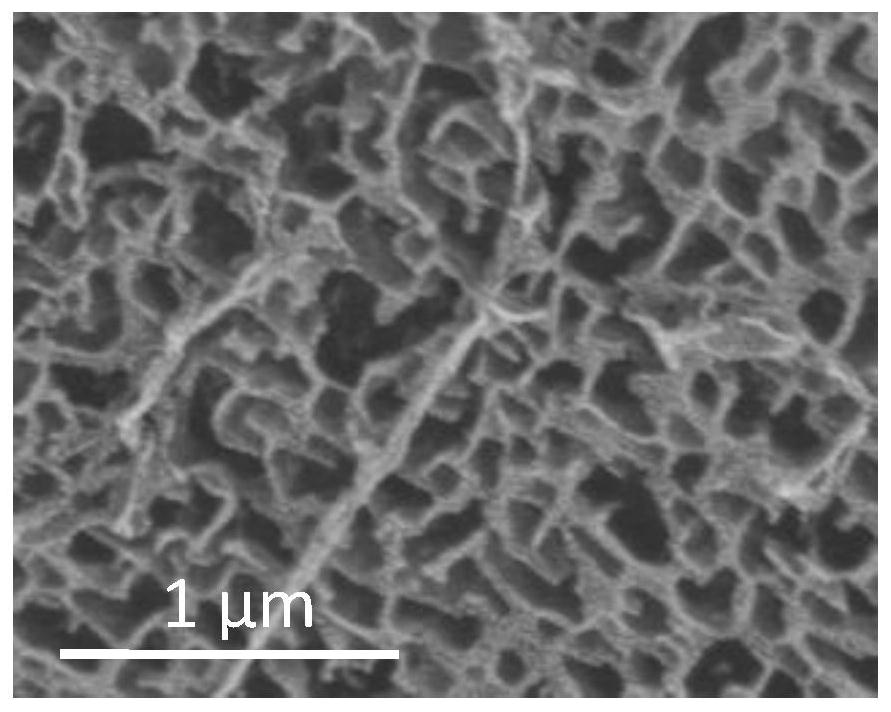

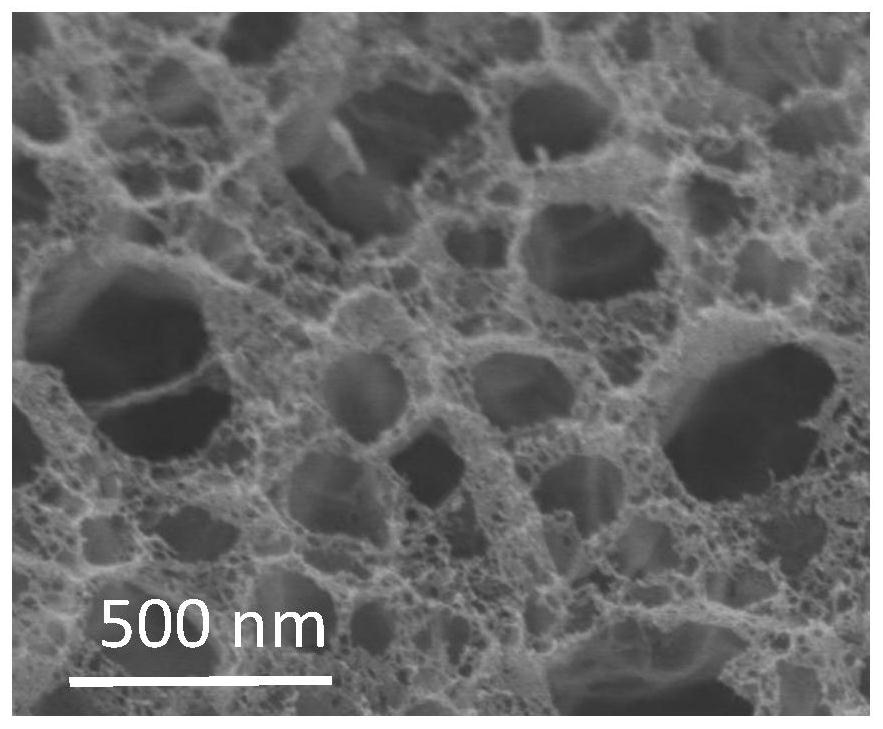

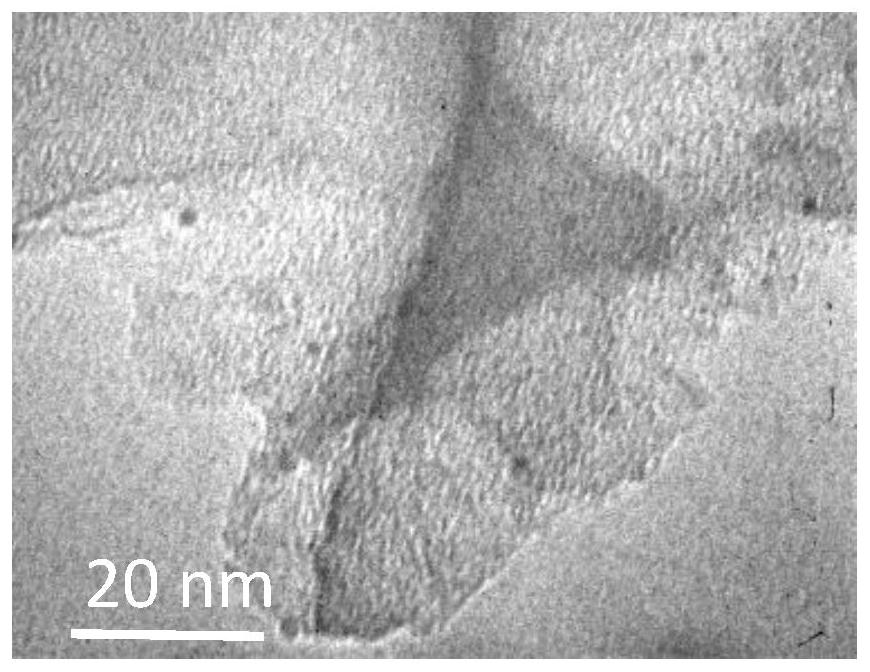

[0055] Wherein, the porous carbon material is a mesoporous / microporous carbon material, and the volume ratio of micropores to mesopores in the porous carbon material is 0.40-0.60, preferably 0.44-0.56, and more preferably 0.44-0.47.

[0056] In some embodiments of the present invention, in s...

Embodiment 1

[0096] (1) 8.7g of potassium polyaspartate and 15mL of water are configured into an aqueous solution of potassium polyaspartate, and 1g of NiCl is added to the aqueous solution of potassium polyaspartate 2 and mix evenly, then add 3 g of ethylene glycol diglycidyl ether into the above mixed solution, stir at 50° C. for 3 h, and obtain Ni-coated cross-linked potassium polyaspartate after the product is dried.

[0097] (2) Using the above-mentioned Ni-coated cross-linked potassium polyaspartate as a precursor, in N 2 Under protection, carbonize at 800° C. for 180 min to obtain a crude mesoporous and microporous carbon material.

[0098] (3) After washing and drying the crude mesoporous and microporous carbon material above, a cross-linked polyamino acid-based mesoporous and microporous carbon material product is obtained.

[0099] The specific surface area of the above product is 2480m 2 / g, the average pore diameter is 0.74nm, and the volume ratio of micropores to mesopores...

Embodiment 2

[0101] (1) After 8.7g of potassium polyaspartate and 15mL of water were configured into an aqueous solution of potassium polyaspartate, 4g of ethylene glycol diglycidyl ether was added to the above mixed solution, and stirred at 50°C for 3h, the product Cross-linked polyaspartic acid was obtained after drying. Put the above product in 1g NiCl 2 In a solution prepared with 15 mL of water, after the adsorption of the cross-linked polyaspartic acid is saturated, it is dried to obtain the cross-linked potassium polyaspartate coated with Ni.

[0102] (2) Using the above-mentioned Ni-coated cross-linked potassium polyaspartate as a precursor, in N 2 Under protection, carbonize at 800° C. for 180 min to obtain a crude mesoporous and microporous carbon material.

[0103] (3) After washing and drying the crude mesoporous and microporous carbon material above, a cross-linked polyamino acid-based mesoporous and microporous carbon material product is obtained.

[0104]The obtained cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com